Rockwell Automation Returns to Chicago for Automation Fair®, Launches Products to Aid Smart Manufacturing

New products and innovations a main focus during manufacturing and technology event

Rockwell Automation, the world’s largest company dedicated to industrial automation and digital transformation, showcased and introduced a number of new products and solutions coming to market at its recently held annual event Automation Fair 2022.

One of the new solutions introduced this year will help machine builders simplify designs, reduce costs, and create the next generation of performance machines with the portfolio of on-machine products.

On-Machine™ solutions are a decentralized equipment design approach that helps reduce the challenges of cabinet-based solutions for OEMs and end users. Offering a simpler, more modular approach to machine design lowers total costs, saves floor space and minimizes time to deploy. This technology can speed design installation and maintenance and improve productivity and flexibility—important capabilities to address in today’s manufacturing environment.

“It’s always powerful to release new products and solutions to our partners and customers during Automation Fair,” said Tessa Myers, senior vice president, intelligent devices, Rockwell Automation. “We get instant feedback throughout the week as we delve deeper into our customer’s needs and how we can help bring their entire Connected Enterprise to life with new product offerings now and even into the future.”

Rockwell Automation offers drives and distributed I/O that are a scalable solution designed to help meet rigorous application needs:

Armor Kinetix® near-motor & integrated drive-motor servo solutions

The new ArmorKinetix distributed servo drives are equipping manufacturers with decentralized motion control solutions that helps them simplify designs and build smarter machines. These new servo drives provide the high-performance of the Kinetix® 5700 platform in a compact, On-Machine™ form factor to help create systems that are more efficient, flexible and cost-effective than ever before with options for a near-motor drive or an integrated drive-motor solution. ArmorKinetix will be available for customers early 2023.

ArmorBlock 5000™ I/O - Distributed I/O blocks with IO-Link technology

ArmorBlock 5000 I/O offers easy distributed monitoring and control through its IO-Link capabilities, enabling increased operational visibility and agility. The industrially-hardened blocks are optimized for On-Machine use to help meet demanding IP66, 67 and 69K application requirements in harsh environments.

ArmorBlock 5000 I/O will be available for customers the second quarter of calendar 2023.

Armor™ PowerFlex®—A drive for the most demanding applications

Armor PowerFlex drives are a new generation of On-Machine VFD motor control solutions that provide an integrated, near-motor solution where reducing installation time and cost are most critical. Armor PowerFlex drives combine an innovated design that reduce installation costs, installation time and unplanned downtime. They provide integrated gigabit dual-port EtherNet/IP™, a variety of motor control options, flexible mounting options and hardware and network safety features.

Rockwell Automation Speeds Time to Market for New Industrial Automation Design, Launches FactoryTalk Design Hub

New offering utilizes five core solutions as it merges improved collaboration and productivity for design teams.

Rockwell Automation announced the launch of FactoryTalk® Design Hub™. Industrial organizations can now transform their automation design capabilities with a more simplified, productive way to work powered by the cloud. Teams of all sizes, skillsets, and locations can work smarter through enhanced collaboration, improved lifecycle management, and on-demand access to cloud-based software. The result is increased design productivity, faster time to market, and systems that cost less to build and maintain.

“In this new age of ‘work from anywhere,’ having centralized, on-demand design tools is critical for businesses to scale production and easily adapt to evolving customer needs,” said Brian Shepherd, senior vice president, Software & Control at Rockwell. “FactoryTalk Design Hub gives manufacturing engineers access to the full breadth of Rockwell Automation tools and capabilities in a centralized nexus for successful design and collaboration across their team and the greater enterprise.”

FactoryTalk Design Hub improves development and deployment of automation projects for industrial organizations, while adhering to the latest security standards and information technology (IT) best practices. It enables teams to access designs on demand from any web browser with software that is always up to date and flexibly scales users and compute capacity to meet project workload demands.

“The digital transformation of automation design capabilities requires both the cloud to maximize control system developers’ productivity, and it also requires that all software tools are connected to each other by a digital thread to maximize collaboration, scalability, and productivity,” according to Craig Resnick, vice president, ARC Advisory Group. “Rockwell Automation’s FactoryTalk Design Hub enables seamless digital thread connectivity between its design, visualization, digital twin, storage, and remote access software tools that provide control system developers with immediate on-demand access to all automation designs as needed regardless of their location, helping these companies to accelerate their initiatives ranging from digital transformation to IT/OT convergence.”

Companies are looking for better ways to solve their most pressing problems. Traditional software design approaches limit collaboration, scalability, and productivity. FactoryTalk Design Hub addresses these three primary concerns for all automation workflow design needs.

“I’m really excited that Rockwell Automation is putting the resources behind this type of development on behalf of control system developers everywhere,” said Doug Hoffer, senior automation engineer at Samuel Engineering. “This could become a really significant way to tie cloud functionality and analytics to the control system development process.”

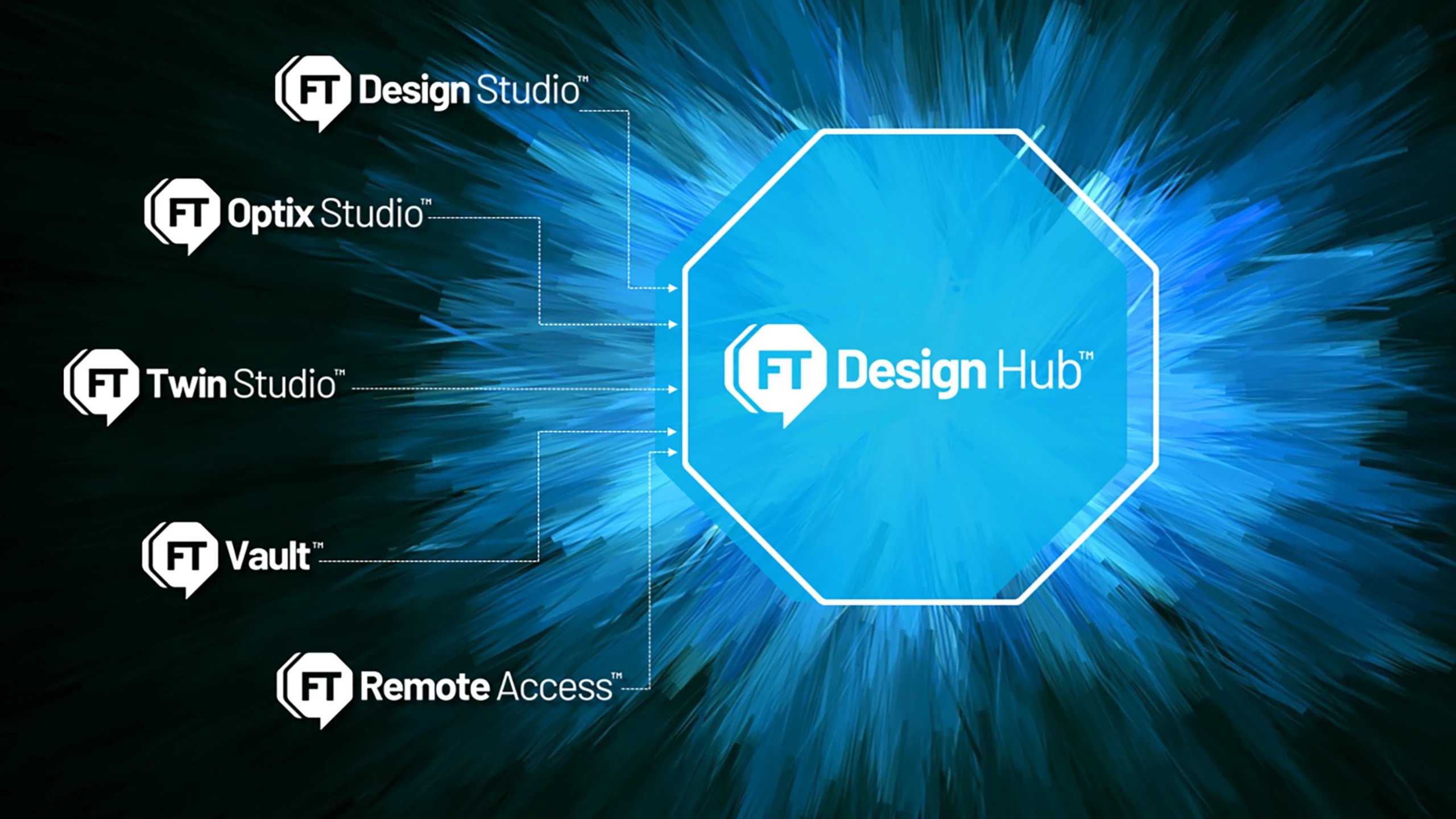

FactoryTalk Design Hub includes five core solutions:

FactoryTalk Design Studio

FactoryTalk® Design Studio™ is a new cloud-native software product built from the ground up to improve system design efficiency. Available anytime, anywhere using only a web browser, there are no downloads or installs required and no software maintenance responsibility. Beginning with controller design, FactoryTalk Design Studio reduces development time by leveraging modern software development practices and an integrated version control system. Teams can collaborate more easily than ever with automated tools to share and merge changes, and project sizes can scale dynamically with support for multiple controllers in a single project. FactoryTalk Design Studio is ready to change the way industrial automation systems are created.

FactoryTalk Optix Software

FactoryTalk® Optix™ is a new product addition to the Rockwell Automation visualization portfolio. Known as “visualization for visionaries,” FactoryTalk Optix is the first cloud-enabled HMI product to be launched within FactoryTalk Design Hub. With FactoryTalk Optix Studio, users can design, test and deploy applications directly from a web browser. Optional cloud-based connectivity enables new collaborative workflows that allow modifications to be made from anywhere, anytime. FactoryTalk Optix is designed to improve processes, efficiency, and deliverables using a scalable, modern platform.

FactoryTalk Twin Studio

FactoryTalk® Twin Studio™ is an end-to-end automation design solution where users can design, program, simulate, emulate, and virtually commission in one cloud environment. The cloud-hosted ecosystem employs Rockwell’s best-of-breed software products and is accessible from anywhere using a web browser. FactoryTalk Twin Studio allows users to develop their next project better and faster by moving seamlessly across Rockwell design solutions, collaborating with teammates in real time.

FactoryTalk Vault

FactoryTalk® Vault™ provides secure, cloud-native centralized storage for manufacturing design teams. With its modern version and access control, FactoryTalk Vault with advanced Design Tools allows for greater insights into designs through in-depth analysis of controller projects. Teams can now spend more time working on projects and less time searching for files or working from outdated versions.

FactoryTalk Remote Access Solution

FactoryTalk® Remote Access™ enables secure connections to equipment, allowing teams to respond to needs faster and rapidly resolve production issues from anywhere. FactoryTalk Remote Access quickly connects domain experts to critical issues, no matter the physical location of either, increasing support response time and reducing the costs associated with travel and asset downtime.

FactoryTalk Design Hub and its core components will all be generally available by the beginning of 2023. Click here to learn more about Rockwell Automation’s FactoryTalk Design Hub.

Since 1972, LeMatic has prided itself on delivering not only leading bakery solutions – but outstanding customer service throughout the lifecycle of their equipment.

“Our specific expertise is in slicing and primary packaging,” said Richard Kirkland, president, LeMatic. “While most of our customers today are large, wholesale bakers, we are developing equipment to help the mid-size baker get the job done.”

From headquarters in Jackson, Michigan, United States, the family-owned company supports an installed base extending across more than 40 countries. LeMatic is part of the Rockwell Automation PartnerNetwork™ program.