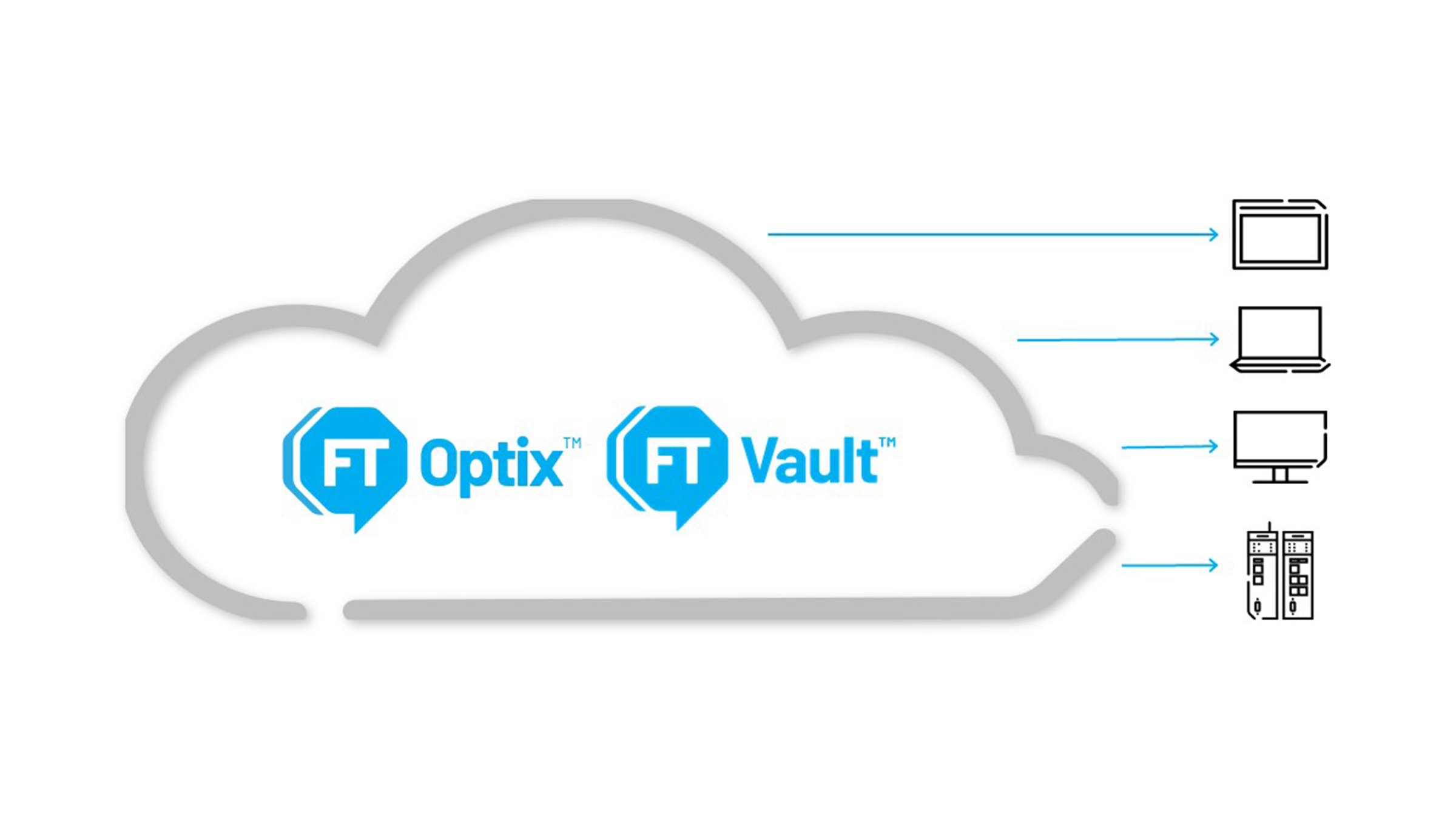

Welcome to FactoryTalk Optix, our new platform that enhances your HMI and data visualization experience and also augments your capabilities in Industrial Internet of Things (IIoT), edge computing, and data management. FactoryTalk Optix accelerates value delivery by leveraging modern technologies, innovative designs, and scalable deployment options.

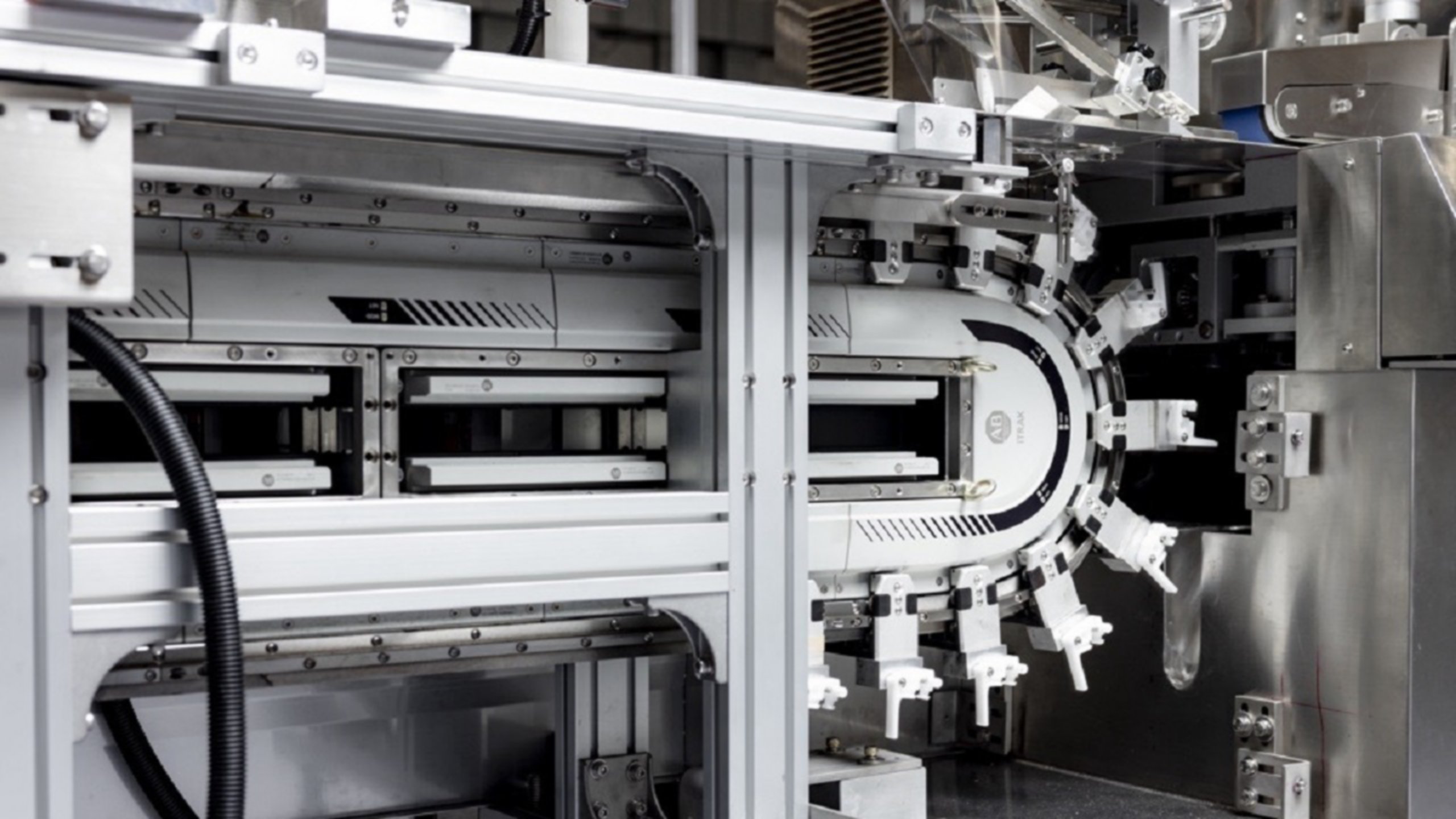

Improving Processes, Efficiency and Deliverables

FactoryTalk Optix can help improve your process, efficiency and deliverables – in one easy-to-access tool. Take advantage of new levels of collaboration, scalability, and interoperability to achieve your digital transformation vision.

New SaaS-enabled workflows will enable your team to collaborate any time, from anywhere, thanks to built-in change tracking and versioning that automatically keeps track of who did what and when.