Consumers continually seek the new and different — prioritizing taste, nutritional value, variety, and sustainability. For manufacturers, this dynamic creates the pressure to meet evolving consumer demand while navigating high material costs, workforce challenges, and increased operational risks. We help manufacturers develop a connected, agile response to consumer and market variability. From upgrading legacy systems to enabling autonomous operations, we support your transformation journey to become more flexible, data-driven, and growth oriented.

A key pillar of our approach is strategic partnerships that enable us to expand value by leveraging best-in-class complementary technologies. By understanding your production needs and unique positioning, we help you reach key business goals:

- Reduce operational complexity

- Improve yield and throughput

- Mitigate security risks

- Drive production efficiency

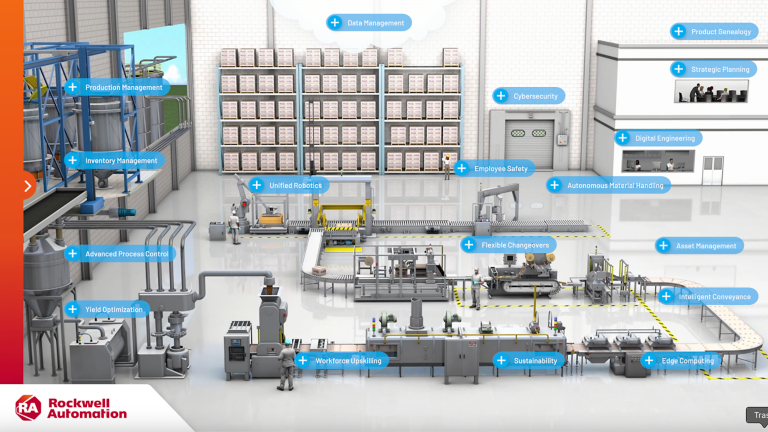

Accelerate your digital transformation journey by taking the steps to become a more agile, integrated enterprise today. To see our full suite of smart manufacturing solutions, explore our Food and Beverage Interactive.

The Food and Beverage Industry is Continuously Transforming

Drive Agility in a Changing Market

In the food and beverage industry, digital transformation is central to operational agility. Aging equipment can severely limit your productivity and competitiveness, and using disparate systems can amplify risk. From rising maintenance costs to component obsolescence and increased cyber threats, the cost of delaying modernization is high.

Realize the benefits of modernization:

- Mitigate obsolescence risk by strategically prioritizing modernization efforts

- Simplify workforce demands with integrated, multi-discipline control

- Strengthen cybersecurity by modernizing your architecture

- Lower total cost of ownership by integrating process and power control into a single platform

Optimize Production to Improve Yield

Disparate systems hinder visibility across networks and production lines, making it difficult to form pathways to optimization. When companies connect their systems, they gain the visibility and real-time information necessary to make data-informed decisions. This capability enables true optimization at every step of the production lifecycle.

Explore data-enabled pathways toward optimization:

- Enable scalable automation with smart machines built for connectivity, Internet of Things, and seamless data integration

- Make data actionable with Industrial DataOps as the foundation for IT/OT integration, analytics, and AI

- Improve quality and accuracy with vision and soft sensing technologies

- Reduce variability and increase throughput with model predictive control

Rockwell Automation works with 100% of global Fortune 500 CPG companies

Rockwell Automation is a trusted partner in digital transformation. We solve next-generation challenges and drive accelerated time-to-value through the breadth of our portfolio and ecosystem, industry-specific domain expertise, and premier integration. See how we’ve helped businesses like yours.

Learn from the experts - explore the latest food and beverage insights

Industry Challenges

Deliver Value With Industry-Specific Expertise

How Automation Works in the Food and Beverage Industry

Others also viewed

Based on your activity