啟動綠色氫氣工廠的複雜性可能令人感到壓力重重,但您不必獨自面對。我們了解設計、建造及優化綠色氫氣生產設施所面臨的挑戰。透過數據驅動的方法及廣泛的PartnerNetwork™,我們能協助您實現長期成長,擴展並維護您的綠色氫氣生產設施。我們的關鍵解決方案,包括網路安全、互操作性、連接性及生命週期服務,可加快產品上市速度。我們將協助您建立基礎,支持長期綠色氫氣生產並降低維護成本。

世界氫能領袖情報報告

隨著每日有眾多項目宣布,清潔氫能時代已經來臨。閱讀由Rockwell Automation帶來的世界氫能領袖情報報告,了解氫能生產商如何克服行業障礙。

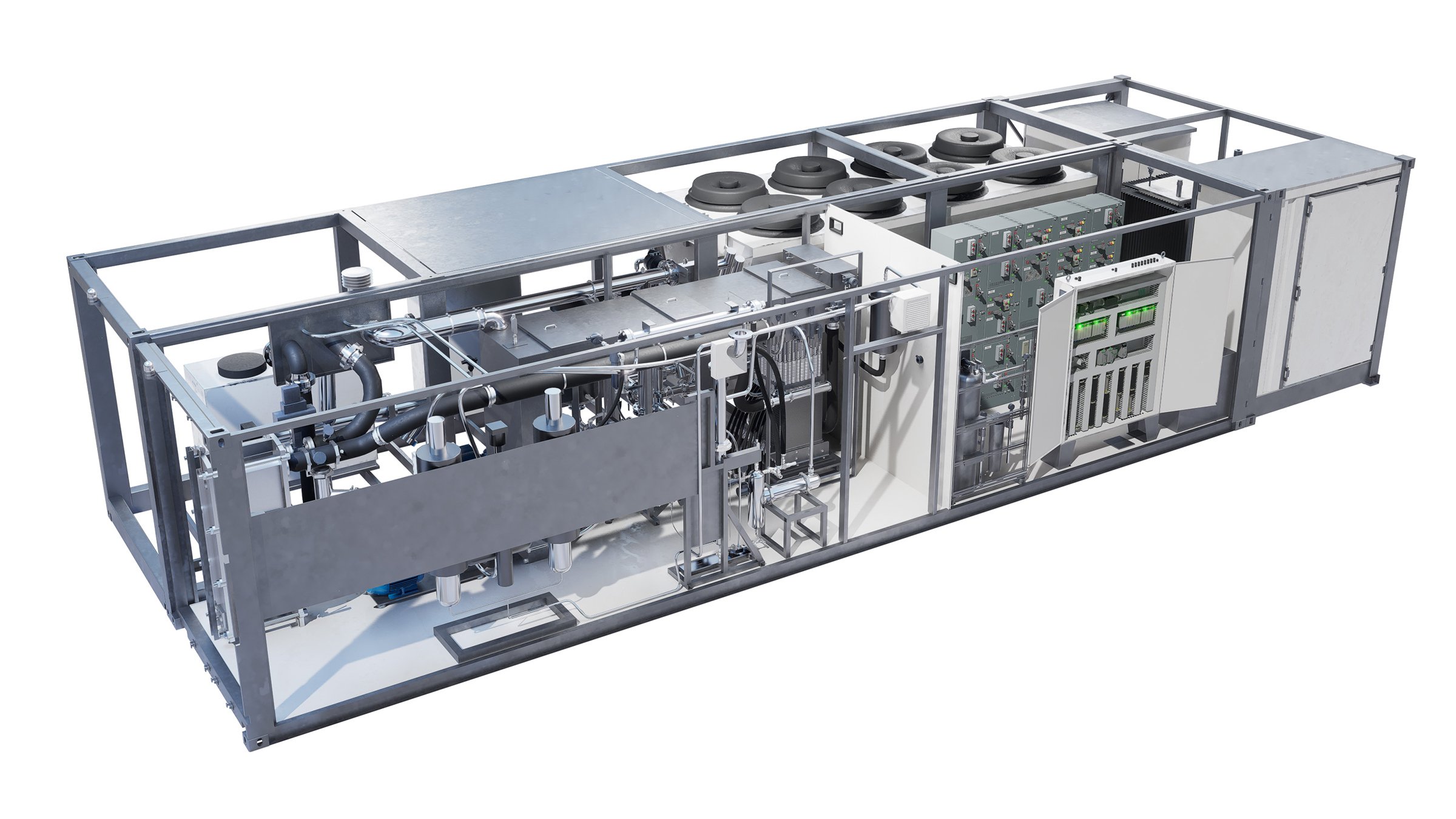

探索我們的綠色氫氣生產解決方案

了解Rockwell Automation如何透過提供量身定制的解決方案與專業諮詢服務,協助您優化綠色氫氣營運。我們深知綠色氫氣生產商所面臨的應用挑戰,而我們全面的數位解決方案正是為了有效解決這些挑戰而設計。此外,我們的專家團隊將與您密切合作,設計並優化您的生產流程,協助您在市場中取得競爭優勢。

您的綠色氫氣生產設備值得擁有專屬的合作夥伴

確保安全營運

安全地建設及擴展氫氣產生的生產規模。

實現無縫整合

體驗強大的數位基礎與全球全生命週期支援。

實現高效重複性

設計和優化具成本效益的氫氣產生系統。

提升綠色氫氣生產的方法

無論您是從零開始,還是改造棕地設施,都需要堅實的基礎來建構一個有利可圖的綠色氫氣設施。然而,一旦您完成基礎建設,就有一些關鍵方式可以優化您的氫氣營運。數據與數位優先策略發揮著重要作用。

綠色氫氣生產業務挑戰

成功快速擴大生產規模

具成本效益的解決方案

全生命週期支援(建構、擴展、維護及擴充)

支援安全標準與要求

面向未來

數位工程

從一開始就做對,找出哪種系統配置能為您的藍氫或綠氫專案優化最佳報酬。

製程與電力管理

製程與電力是任何H₂生產的核心。它們確保最佳、可靠且更安全的運作。

智能儀器設備

精確的儀器設備確保所有H₂生產過程都能持續且一致地受到監控。

智慧分析

可視性以確保高效生產。

能源智慧

將氫氣生產與再生能源發電結合的能源管理系統(EMS)。

聯網工作者

對於從事氫能相關活動的工作者所需技能與知識的識別需求日益增加。

探索我們的 LifecycleIQ 服務能為您的氫氣生產廠帶來哪些效益

加速業務成長

創新協助您在每個生命周期階段以更快、更聰明及更具敏捷性的方式工作

實現卓越勞動力

安全地連接人員、流程與技術

提升生產力

透過數據驅動的決策持續提升績效與產能

管理風險

在保護人員與流程的同時,達到法規合規與品質標準

推動永續發展

關於綠色氫氣生產您需要了解的事項

氫氣是地球上最豐富的化學元素。儘管存在於約75%的物質中,但它從不單獨存在,而是與其他化學元素(如氧)結合。

氫氣長期以來被廣泛用於各種用途,包括作為燃料來源,以及在化學製造和冶金等多個行業中使用。然而,由於氫氣無法直接從自然界中以最純淨的形式分離出來,因此必須人工進行。

從歷史上看,這個過程產生了所謂的灰色氫氣,即從化石燃料中分離氫氣。雖然這種方法能夠生產成本低廉的氫氣,但分離過程會向大氣中排放大量CO₂。為了解決這個問題,許多氫氣生產商正在轉向一種稱為綠色氫氣的可再生氫氣生產來源。

什麼是綠色氫氣生產?

綠色氫氣生產是指通過水的電解過程分離氫原子的工藝。綠色氫氣生產同時利用可再生能源來驅動該過程。因此,綠色氫氣生產可消除向大氣中排放污染物。

如何實現綠色氫能?

綠色氫能是通過對水分子進行電解產生的。這表示水分子在通電下被分解為氫氣和氧氣。綠色氫能的生產會利用可再生能源,如風能或太陽能,來產生電解過程所需的電力。

分離出的氫氣隨後儲存在專用儲槽中,直到需要時再使用。為了將氫氣轉化為能源,會將其輸送至燃料電池,與空氣中的氧氣結合,產生電力,唯一的副產品是水。

綠色氫氣生產的好處

由於綠色氫氣生產在整個過程中減少了排放到大氣中的污染物,因此帶來了多方面的環境效益。綠色氫氣生產的主要好處包括:

- 它是一種清潔的可再生能源 – 綠色氫氣在燃燒或生產過程中不會排放污染氣體。

- 它可儲存 – 氫氣易於儲存,因此能夠用於多種用途。

- 它用途多元 – 綠色氫氣可轉化為電力或合成氣體,應用於商業及工業領域。