Rockwell Automation and Microsoft Deliver on a Shared Vision to Accelerate Industrial Transformation

Collaboration to deliver advanced cloud and AI solutions, empowering manufacturers with enhanced data insights and operational efficiency

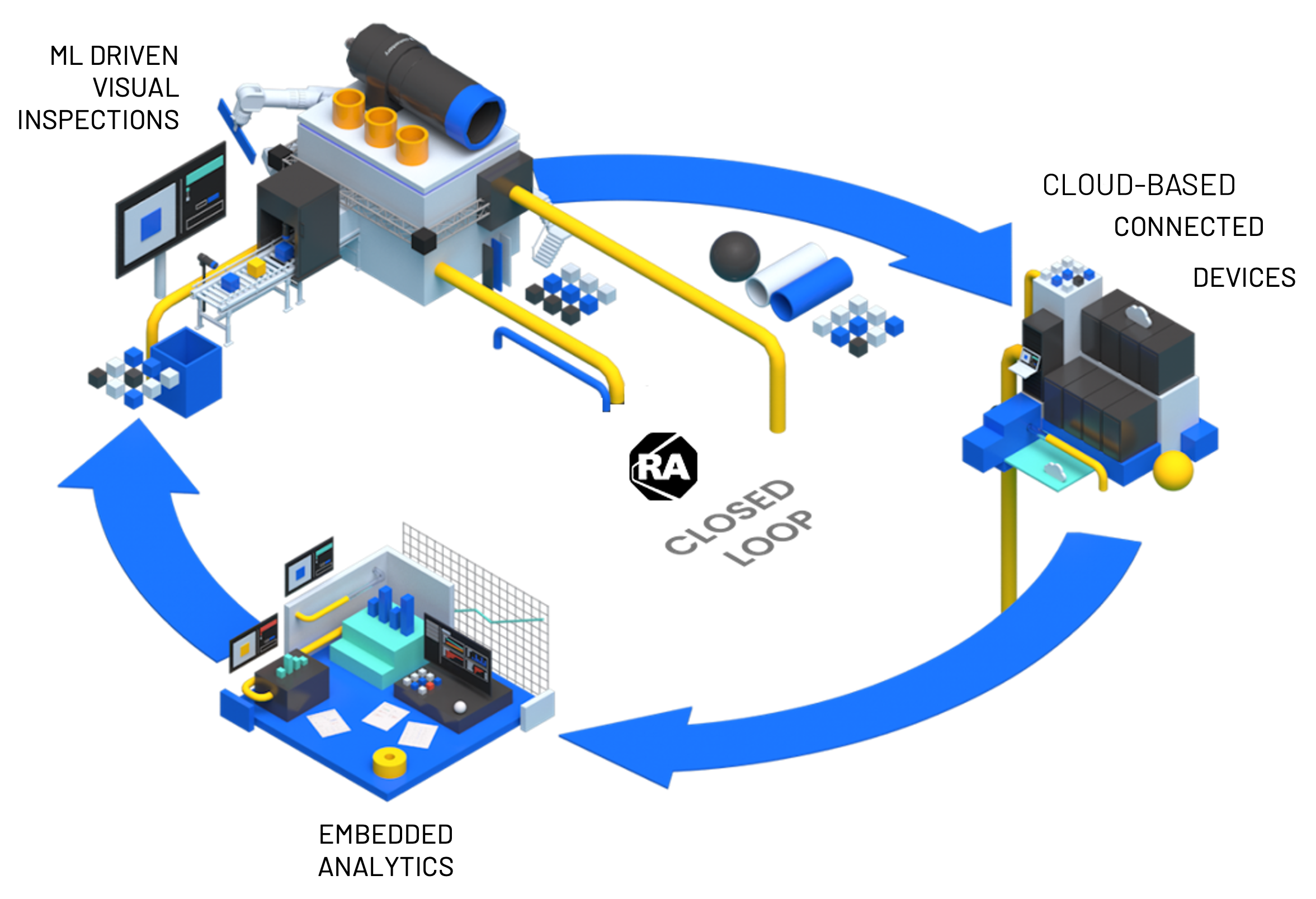

Rockwell Automation and Microsoft Corp., a leading global technology company, are proud to announce an expanded strategic collaboration aimed at revolutionizing industrial transformation. Together, the companies will provide manufacturing customers with advanced cloud and AI solutions that deliver powerful data insights, streamline operations and enhance scalability – driving operational efficiency and sustainable growth across the industry.

This shared vision is supported by several new releases that were previewed at Automation Fair®. This relationship uniquely combines Rockwell’s deep industrial automation expertise with Microsoft’s cutting-edge cloud and AI capabilities. Together, the companies will bridge the gap between traditional industrial practices and modern digital applications, creating integrated solutions designed to unlock the full potential of industrial data.

More info here.