Rising costs, relentless demand and labor shortages are adding pressure to meat, seafood, poultry, and plant-based protein processors. We’re helping customers embrace the demands of tomorrow with world-class automated meat processing technology and digital transformation strategies to provide:

- Workforce productivity and safety

- Consistent, high-quality product

- Yield savings and scrap reduction

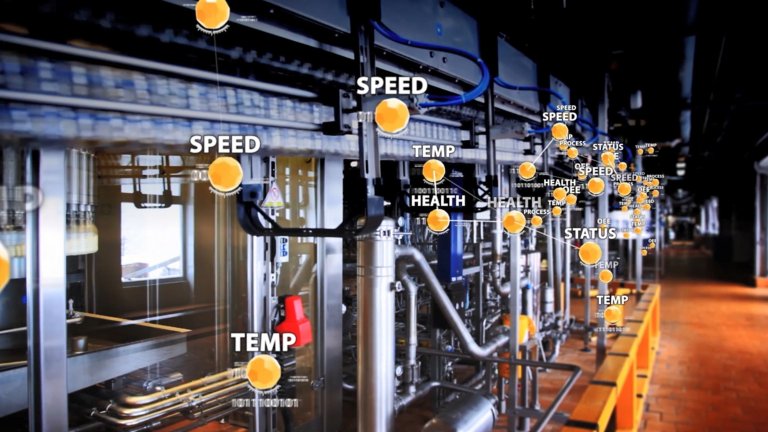

- Production and quality monitoring with data

- Real time operations visibility

- Protection against security threats

Unsure where to start? Connect with a Rockwell Automation consultant today.

4000

Product configurations at 100 cases/min with smart, agile production

80%

Or more OEE with digitalization and AR-trained workers

40%

Energy reduction through improved machine design and accuracy

Explore industry solutions in protein food processing for:

Improving Workforce Effectiveness

Accelerating new hire time-to-value and worker retention

Price pressure and competition for skilled workers is fierce in the protein industry. To be successful, meat, seafood and poultry processing facilities must find better ways to capture more value from the equipment on their plant floors – and attract, train and retain workers.

One approach is to attack productivity from several angles, like focusing on fewer, shorter downtime events, increased first pass quality, and faster Mean Time to Repair (MTTR). We partner with global meat processors to empower their limited workforce with:

- Simplified, integrated robotics

- Precision, advanced motion

- Productivity-improving machine safety

Manufacturers are also using creative solutions to help train and retain staff, like Augmented Reality (AR) and Virtual Reality (VR). Using this type of learning experience can help increase knowledge retention, reduce training time and upskill the workforce.

Leveraging Technology to Optimize Yield and Throughput

Deploying next-generation software to overcome challenges and satisfy requirements

Let’s face it, the manufacturing environment is changing and becoming more complex every day. Consumers want increased visibility about your products, regulators want increased information about your meat processing methods, and stakeholders are demanding more sustainable operations. The common underlying theme…information.

Cloud-based technologies such as Plex® manufacturing execution system (MES) or Fiix® computerized maintenance management system (CMMS™) provide your team with the information they need at their fingertips, with the flexibility to quickly scale with your business needs.

The result is increased visibility to machine performance, inventory levels, maintenance requests, quality control, energy usage and more. Use this information to your advantage to build a more robust, sustainable operation.

Boost food safety, quality and security

Meeting the needs of consumers has introduced greater complexity across your production and supply chain. This complexity requires you to manage food safety, quality and security across a broader product spectrum.

A comprehensive strategy to help protect product safety and quality is critical to mitigating risk.

Learn more about our solutions:

Industrial Safety Solutions | Rockwell Automation

Food Safety and Quality Control Systems | Rockwell Automation

Food & Beverage Cybersecurity Solutions | Rockwell Automation

Drive next-level machine productivity

From enhanced robotic capabilities without additional complexity to digitally enabled machines revolutionizing data insights, explore how machine builders are leveraging technologies to create smart and flexible protein food processing machinery to deliver value through added precision, minimized bottlenecks and efficiency gains.

Moving to Alternative Protein Production

Producing sustainable protein, while driving down costs.

Changing consumer preference for healthy and eco-friendly options are driving unprecedented growth for alternative meat production. However, operators face unique challenges to deliver high-quality proteins that look, smell, and taste as expected.

Leverage the power of IT and OT integration to achieve consistent batch control, integration with suppliers, and operational control that drives down cost and increase consumer adoption.

What is Automated Meat Processing?

Automated meat processing refers to the use of advanced technology, such as robotics and artificial intelligence, to handle various stages of meat production with minimal human intervention. This technology streamlines tasks such as cutting, deboning, trimming, grinding, and packaging, helping to improve efficiency, hygiene, and consistency in meat products.

Meat processing automation reduces labor costs and enhances worker safety by minimizing direct contact with sharp tools and repetitive tasks. It often incorporates computer vision and AI to optimize yield and maintain quality standards.

Benefits of Meat Processing Automation

Meat processing automation offers a wide range of benefits, from enhancing efficiency to improving worker safety. The primary benefits of meat processing automation include:

- Increased efficiency: Automated systems work faster and more consistently than manual labor, significantly speeding up processing and reducing production time.

- Improved product consistency: Automation ensures uniform cutting, portioning, and packaging, leading to higher product quality and standardized output.

- Enhanced food safety and hygiene: Minimizing human contact with meat reduces the risk of contamination, meeting strict food safety regulations.

- Cost reduction: Automation decreases the need for manual labor, lowing operational costs and addressing labor shortages in the industry.

- Greater yield optimization: Advanced systems use sensors and AI to maximize meat yield, reducing waste and improving profitability.

- Improved worker safety: Machines handle hazardous tasks like cutting and deboning, reducing workplace injuries and enhancing overall safety.

Types of Automated Meat Processing Equipment

Automation in meat processing makes use of a variety of specialized equipment and protein food processing machinery. These can include:

- Automatic cutting machines

- Deboning machines

- Meat grinders and mixers

- Slicing and dicing equipment

- Packaging machines

- Vision and X-ray inspection systems

- Robotic arms and conveyors

These machines are often integrated into smart production lines that use sensors, AI, and software to monitor and optimize performance in real time.

Others also viewed

Based on your activity