Challenge

Integrated historian software solutions are designed to collect and save process data. However, it is only when this data can be aggregated into meaningful reports that its true value becomes evident. It is only then that companies are in a position to compare production data and batch records, in order to improve not only the quality of their production, but also reduce reaction times in terms in response to changing market demands.

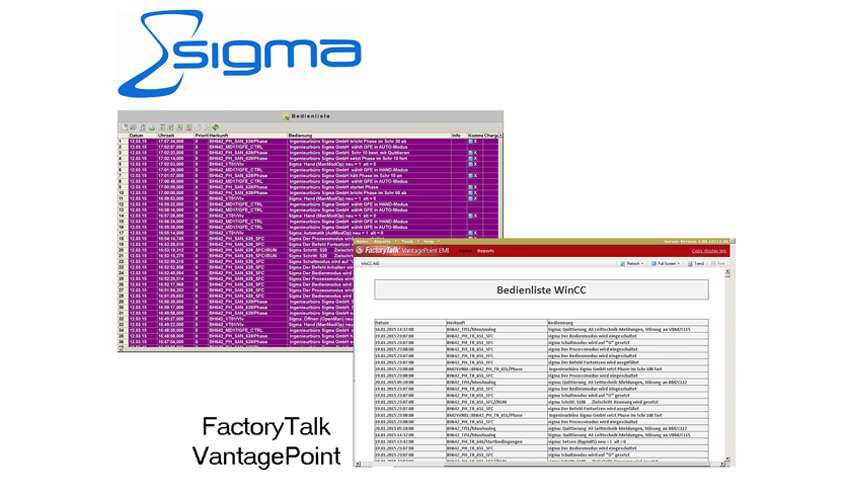

SIGMA has addressed these needs and has deployed just such a solution for the German biotechnology centre. The transition from basic process data capture to a configured data analysis solution now helps provide optimal data collection and collation.

“With process data capture being based on information from 3rd party PLCs and control systems, the challenge was getting effective access to alarms and events data from the existing fragmented database,” says Jochen Hasselbach Site Manager at SIGMA. “If this company could combine the process information with trending, alarms and events, it would improve productivity by eliminating friction points.”