Advanced chemical process automation integrates automation with digital technology, enhancing operational efficiency and profitability for chemical manufacturers. By combining digital solutions, like chemical plant software, with traditional automation and implementing asset lifecycle management, manufacturers can significantly improve throughput and reduce unplanned downtime. This approach minimizes manual interventions, boosting productivity and yield.

Real-time equipment monitoring and predictive maintenance capabilities enable proactive management of equipment health, helping to prevent unexpected failures and deliver continuous production. Integrating additional data analytics provides deeper insights into production processes, facilitating continuous improvement and better asset lifecycle management. This comprehensive approach not only boosts throughput but also improves safety and reduces waste, giving manufacturers a competitive edge in the market.

How to Achieve Efficiency and Flexibility in Industrial Chemical Production

Efficiency in industrial chemical manufacturing is crucial for delivering the right products at the right time and cost. Our chemical manufacturing software and process solutions are designed to significantly enhance plant efficiency, meet product quality targets, and maximize asset utilization by minimizing cycle times and improving personnel situational awareness.

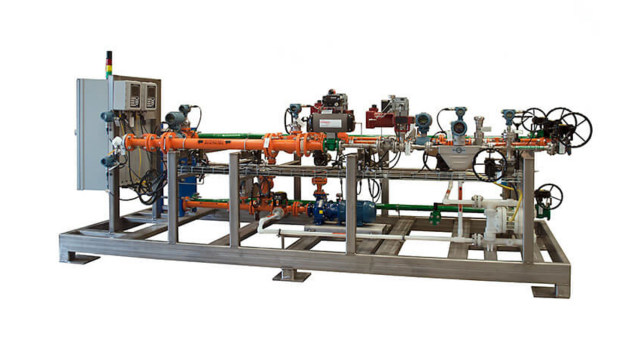

Scale and modernize plant control and automation with PlantPAx®, a modern and scalable distributed control system for chemical producers. It integrates control, process safety, field instrumentation, power, motor management, and analytics.

Enjoy flexible design, operations, changes, and upgrades with the power of universal I/O. FLEXHA 5000™ I/O is a reliable and flexible distributed I/O solution that allows users to choose I/O to meet operational needs.

Achieve batch consistency with FactoryTalk® Batch, a modern batch control solution adhering to the S88 batch system design standard. It offers:

- Controller-based solutions for organizing routines for batch processing

- Basic sequence execution on the controller

- Complex unit coordination, resource arbitration, and optimization of routes

- Recipe Management, including formulations, scaling, secure approvals, and versioning

- Web-based and integrated visualization

Improve process stability with FactoryTalk® Analytics™ PavilionX™, featuring model predictive control (MPC) that improves complex, multivariable processes. MPC can simultaneously track and optimize multiple applications, handle restrictions and constraints, and manage variability. It consistently delivers better process stability, lower energy usage and costs, and better throughput.

Benefits of Chemical Process Automation: How Digital Transformation is Changing Chemical Manufacturing

Digital transformation is revolutionizing the chemical manufacturing industry by driving increased efficiency and innovation. Rockwell Automation is at the forefront of this transformation, offering software and services that optimize operations through advanced data analytics.

Predict equipment failures and reduce unplanned downtime: FactoryTalk® Analytics™ GuardianAI™ leverages artificial intelligence (AI) for predictive maintenance. It provides advanced notice of upcoming asset failures, allowing you to take proactive action and minimizing unplanned downtime.

Digitize your maintenance activities: Fiix® is a cloud-based Computerized Maintenance Management System™ (CMMS) software that allows users to plan, monitor, and optimize maintenance. Schedule work orders, track asset health, generate reports, and utilize integrated AI features to make decisions.

Boost workforce effectiveness with mixed reality solutions for immersive training, knowledge capture systems for preserving expertise, and operator rounds that can help chemical companies reduce safety incidents and improve operational performance.

Support your digital transformation journey and avoid pitfalls: Our digital transformation consulting team at Kalypso can work with you on a strategic plan that addresses priority use cases, business justification, change management.

Build Resiliency in the Chemical Industry

Aging structures, systems, and components of chemical plants are becoming a major process safety concern. Modernization of aging equipment and processes minimizes the risk of failures and allows operators to leverage advanced technology to enhance overall productivity.

Modernize with confidence: Rockwell Automation modernization services can fundamentally transform your business. By upgrading to the latest control and information systems, you can future-proof your plant. More than that, modernization can address the most persistent problems you face today, from equipment obsolescence to safety challenges to workforce transitions.

Enhanced process safety: Logix SIS (Safety Instrumented System) provides a modern and integrated safety solution, offering both SIL 2 and SIL 3 certifications to meet your plant’s safety needs. The system is engineered to provide high availability and integrates well with existing Rockwell Automation control platforms.

Help protect your plant and business against cyberthreats: Implementing robust cybersecurity measures is essential to protect sensitive data and control systems from cyber threats, helping prevent potential disruptions and harm to employees, the environment, and a producer’s brand.

Sustainability - Empowering Chemical Operators for Future Market Challenges

Sustainability in chemical manufacturing aims to create products through processes that help to minimize environmental impact by reducing energy consumption, water use, waste emissions, and increasing the adoption of renewable resources – and consequently observing to the principles of green chemistry.

Emissions monitoring: Software CEM® is a patented, model-based Predictive Emissions Monitoring System (PEMS) that provides a certifiable, software-based and lower-cost solution as an alternative to hardware-based Continuous Emissions Monitoring Systems (CEMS).

FactoryTalk® Energy Manager™, energy monitoring platform that provides energy and production information based on an energy plant model of the underlying process at a plant, process area, line and equipment level. Chemical Manufacturers can understand where, when and how their facilities use energy to establish the necessary scope of their energy savings efforts and define key metrics.

Others also viewed

Based on your activity