Keeping military aircraft in mission-ready shape is a major operation all its own. During maintenance, a plane must be completely disassembled so its individual parts can go through inspections and upkeep before the plane is reassembled. It’s a laborious but necessary process for maintaining performance and safety.

The Warner Robins Air Logistics Complex (WR-ALC) provides this and other critical support to the U.S. Air Force at Robins Air Force Base in central Georgia. With about 7,000 employees, the complex provides aircraft maintenance, depot maintenance support, engineering support and software development for major air weapons systems.

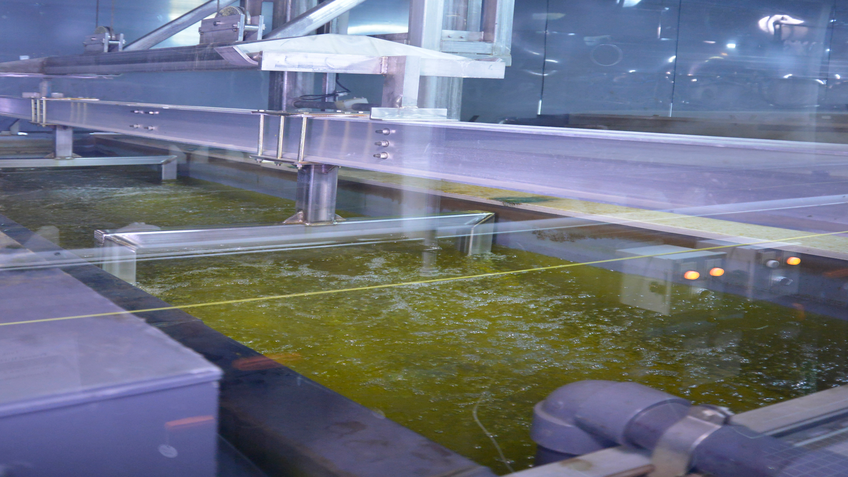

In recent years, the WR-ALC completed construction of its advanced metal finish facility (AMFF) for the upkeep of aircraft parts. The 98,000-square-foot facility has nine automated lines that chemically treat and clean aircraft parts. And while this new automated facility has provided major benefits – including reducing worker exposure to chemicals – issues with one of the facility’s control systems created problems, including damaged parts and extended downtime.

Challenge

- An aircraft maintenance depot had an unreliable, proprietary system that caused costly damage to critical parts.

Solutions

- FactoryTalk Batch provides recipe management and reliability

- FactoryTalk VantagePoint offers a centralized data source that provides reporting based on user needs

- FactoryTalk View lets operators see the process up-close and quickly detect any possible issues

- FactoryTalk Historian provides historical data for trending analysis

- Thin clients with ThinManager software can be centrally configured and managed, mitigating downtime

Results

- Improved Throughput - Increased throughput by 80 percent and no parts have been dropped since the new system implementation

- Increased Reliability - Operators are confident when selecting a recipe and that the system will operate efficiently Converged Plantwide Ethernet (CPwE)-based network is fault tolerant and more robust

- Efficient Data Management - Improved management of data reports and analytics can now be run during operation

Published February 11, 2020

The proprietary control system used on the AMFF’s 24-tank, two-hoist plating line presented multiple challenges. It would run the wrong timing sequence for handling of jet parts. This could result in a hoist being in the wrong position, picking up parts at the incorrect time and dropping them, causing irreparable damage. The system could also damage parts by leaving them in the stripping or plating solutions for too long.

Because of these issues, the original system did not allow for scheduling and required constant supervision to ensure it was performing tasks at the right time.

Additionally, the control system was unable to pull important reports to help analyze a part’s journey through the process in real time. Instead, reports had to be run during an off shift, when the line was not performing another task, which inconvenienced operations.

“We utilized our system for around two years and continuously had issues that caused major inconveniences for our operations,” said James Prince, mechanical engineering technician, WR-ALC. “We needed our system to be more reliable, overall. We needed it to more easily run reports and efficiently handle parts to reduce costs and damage. We also really needed the information from the reports to be more useful and provide greater operational insights.”

When looking at solutions for a new control system, the WR-ALC team already had experience with Rockwell Automation products and solutions.

“There really was no other option that came to our minds when picking a solution to our problem,” Prince said. “We have used Rockwell Automation products, so we knew their solutions would be scalable and easy to update, allowing for the longest life cycle possible.”

PREMIER System Integrators, a Solution Partner in the Rockwell Automation PartnerNetwork program, helped design and implement the line’s new control system. With expertise in network architecture design and manufacturing execution systems, the integrators helped minimize downtime to just one week for implementation of the new system.

Many network changes were made to build a new and more reliable system. The network was upgraded to a collapsed-core design, where the network’s core and distribution layer functions are implemented with a single device. This design was based on Converged Plantwide Ethernet (CPwE) guidelines, which Rockwell Automation developed with Cisco, a Strategic Alliance partner in the PartnerNetwork program. CPwE guidelines help industrial companies deploy scalable, secure, safe and future-ready industrial network architectures.

All device control was transitioned to PLC logic. Additionally, the unmanaged switches in PLC cabinets and industrial data center were upgraded to Stratix 5400 industrial managed switches and Cisco Catalyst 3850 Series switches. This allowed traffic to be segregated, and it provided more visibility into the network’s health.

Beyond network upgrades, the team installed the FactoryTalk software suite from Rockwell Automation, including batch, production intelligence, HMI and historian systems.

The modern batch software helps the company with recipe management, creating a consistent recipe for all the different jet parts and their corresponding cleaning and maintenance processes. This has put an end to the dropping of parts. Material manager software was also used to help track parts during their inspections. Operators can now rely on the system and expect it to perform as ordered.

Overall, the batch solution provides efficient time management and improved operational reliability for operators.

“The FactoryTalk Batch software is flexible and was easy to adapt from its traditional use to control the plating line,” said Larry Grate, director of technology, PREMIER System Integrators. “Integrating process data into the Batch reporting framework was also a straightforward process and gave WR-ALC operators the information they needed to improve product quality and operating efficiency.”

The production intelligence software helped create a one-batch quality report. This report includes important operational information such as product details, temperature, timing data, alarm information and more during operation. If a problem arises down the line, this allows operators to troubleshoot at the source, saving the WR-ALC valuable time and money. New HMIs also provide direct visualization for operators while the parts are going through the inspection process to help make sure everything is performing correctly.

Throughout the process, the historian records all the information gathered and acts as an extra hard drive for the network. Lastly, old HMI PCs have been replaced with thin clients equipped with ThinManager software. Unlike PCs, the thin clients can be centrally configured and managed, and don’t need to be individually patched. And if a terminal goes down, it can be replaced in fewer than two minutes with no loss of data.

These solutions put the WR-ALC on solid ground when it came to the maintenance of critical aircraft parts.

No parts have been damaged or dropped since the startup of the converted system in February 2018. Operators now know that the system will run the correct recipe. The robust batch-control system no longer experiences errors when scheduling or running a batch. And system throughput has increased to 80 percent.

The production intelligence software is providing reports that are concise but convey more useful information for operators with historical data available for analysis trending. An integrated alarm system is timely and effective, helping operators and engineers diagnose potential issues quickly, before they occur and cause damages. And the CPwE-aligned network is fault tolerant and more robust.

“With these new solutions, operators feel confident using the system and have a sense of ownership when working with the different components. There is no reason to worry that the system will not perform as it is told, and overall, damages have been completely eliminated – saving us millions of dollars,” Prince said.

The results mentioned above are specific to Warner Robins Air Logistics Complex’s use of Rockwell Automation products and services in conjunction with other products. Specific results may vary for other customers.

Trademark Information:

FactoryTalk, PartnerNetwork, Stratix and ThinManager are trademarks of Rockwell Automation Inc.

Recommended For You