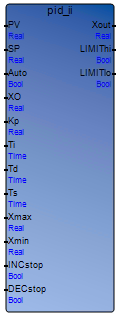

PID_II

Process regulator that uses the feedback concept to regulate the

process variable according to the difference between its current value and the value of the

set point. PID achieves calculation by a method of sampling.

Parameter values for the PID_II function block:

Parameter | Data Type | Description | ||

|---|---|---|---|---|

PV | REAL | Process variable. Must be a REAL value. Infinity

or Not a Number (NaN) values are not supported by this input. | ||

SP | REAL | Set point. Must be a REAL value. Infinity or Not a

Number (NaN) values are not supported by this input. | ||

Auto | BOOL | Determines whether PID_II operates in AUTO or MANUAL mode. TRUE for AUTO mode FALSE for MANUAL mode | ||

XO | REAL | Adjustment value. Must be a REAL value. Infinity or Not a Number (NaN) values are

not supported by this input. In MANUAL mode, Xout = XO | ||

Kp | REAL | Proportionality constant. Must be a REAL value.

Infinity or Not a Number (NaN) values are not supported by this input. | ||

Ti | TIME | Integral time constant. Possible values range from 0ms to 23hr59m59s999ms. | ||

Td | TIME | Derivative time constant. Possible values range from 0ms to 23hr59m59s999ms. | ||

Ts | TIME | Minimum sample period. If Ts is less than the application scan time, uses the application scan time as

the effective sample interval. The maximum effective sample period is Ts plus the application scan time. Possible values range from 0ms to 23hr59m59s999ms. | ||

Xmax | REAL | Maximum value of Xout. Must be a REAL value.

Infinity or Not a Number (NaN) values are not supported by this input. | ||

Xmin | REAL | Minimum value of Xout. Must be a REAL value.

Infinity or Not a Number (NaN) values are not supported by this input. | ||

INCstop | BOOL | Increment stop. | ||

DECstop | BOOL | Decrement stop. | ||

Xout | REAL | PID_II function block output. Action required on the system to keep the regulation. Xout recalculates each time

a sample is taken. | ||

LIMIThi | BOOL | TRUE if Xout is clamped at its maximum value

(Xmax). | ||

LIMITlo | BOOL | TRUE if Xout is clamped at its minimum value

(Xmin). | ||

TIP:

Loss of precision and underflow may

occur.

When Xmax < Xmin, the function assumes that the values are reversed and

swaps the values. The Reversed error counter increments each time the function has to swap

the parameters.

When overflow occurs during execution, the stored integral and error

terms set to zero.

In AUTO mode:

- Xout sets to zero

- LIMIThi sets to FALSE

- LIMITlo sets to FALSE

In MANUAL mode:

- Xout sets to XO clamped to the range Xmin to Xmax

- LIMIThi sets to XO > Xmax

- LIMITlo sets to XO < Xmin

AUTO Mode Operation

When a new sample is made and Auto

= TRUE, calculates the output Xout:

Xout = Kp * ( E[t] + I[t]/Ti + D[t] *

Td)

where

E[t] = SP - PV (error) I[t] = I[t-1] + ( E[t] * T ) (integral term) D[t] = ( E[t] - E[t-1] ) / T (derivative term)

E[t-1] is the stored error

value, that is the value during the last sample.

I[t-1] is the stored integral term,

that is the value during the last sample.

T is the elapsed time in milliseconds since

the last sample.

On initialization, the stored integral term sets to zero, and the

action is calculated using proportional action only:

Xout = Kp * E[t]

When Ti =

0, the stored integral term sets to zero and Xout is calculated using proportional and

derivative naction only:

Xout = Kp * (E[t] + D[t] * Td)

Once Xout is calculated,

the increment stop (INCstop), decrement stop (DECstop) and the clamp (Xmax and Xmin) are

applied. When INCstop = TRUE and Xout has increased since the last sample or if DECstop =

TRUE and Xout has decreased since the last sample, Xout sets to its previous value. When

Xout > Xmax or Xout < Xmin, Xout is clamped to the range Xmin to Xmax, LIMIThi sets to

Xout > Xmax, and LIMITlo sets to Xout < Xmin.

When INCstop, DECstop, or the

clamp are active, the previous integral term is retained, that is the stored integral term

is not set to the current integral term. On initialisation, INCstop, and DECstop have no

effect.

MANUAL Mode Operation

If a new sample is made

and Auto = FALSE, the output Xout immediately follows the adjustment value (XO) clamped to

the range Xmin to Xmax. LIMIThi sets to XO > Xmax and LIMITlo sets to XO < Xmin. The

stored error term sets to (SP - PV) and the stored integral term sets to zero. The increment

and decrement stop (INCstop and DECstop) have no effect.

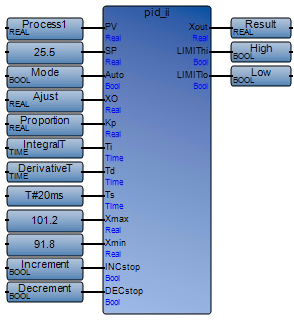

Example

(*FBD example with PID_II function block*)

(*ST

example*)

PID_II(Process1, 25.5, Mode, Adjust, Proportion, IntegralT, DerivativeT, T#20ms, 101.2, 91.8, Increment, Decrement); Result:= PID_II.Xout; High := PID_II.LIMIThi; Low := PID_II.LIMITlo;

Provide Feedback