What can AI/ML do for you?

Using artificial intelligence (AI) or the ability of a computer or computer-controlled robot to perform tasks commonly associated with people, ML or the capability of a machine to imitate intelligent human behavior, manufacturers can boost performance with:

Up to 10% Reduced Downtime – Anticipate equipment faults using predictive rather than reactive maintenance and receive warnings when equipment is operating out of normal ranges.

Up to 12% Better Quality – Earlier detection of process or material faults

Up to 30% More Productivity – Reduced rework and scrap, efficient maintenance planning and greater awareness of process issues

According to Randy Thompson, Senior Business and Solution Architect for TT PSC, ML algorithms build a mathematical model based on available data to make predictions or decisions without being explicitly programmed to do so. During the model building process, historical data is used as an input to train the model – typically 70% for training and 30% held back for evaluation and confirmation of the model.

What makes a good ML use case?

A good ML use case consists of a measurable prediction goal, many variables and available historical data. Companies usually have a lot of data, but often not the data they need to predict the goal they’d like to achieve. This may require additional sensor inputs or modifying the prediction goals. This is an area where having an experienced partner can help.

A good ML use case example is a wood drying process with the goal of getting the wood to a certain moisture content. With ML you can input all the measurable variables from the process to predict what speed to operate the dryer to achieve the correct drying level. What’s great about machine learning, says Thompson, is that after you add the needed data, the model will do the work for you. Other questions to determine include:

- Is this a problem worth addressing? What’s the expected business benefit?

- How often does the issue occur? Best case scenario is that it occurs regularly enough to give you sufficient data to create a model and see results.

- What is the cost in downtime?

- What will you do differently if you have this prediction?

Finally, do you have the data needed to build the model? It begins with a hypothesis. Choose what you think is important rather than feeding in all the data. Next, ask what data is available and is there enough data to make an accurate prediction.

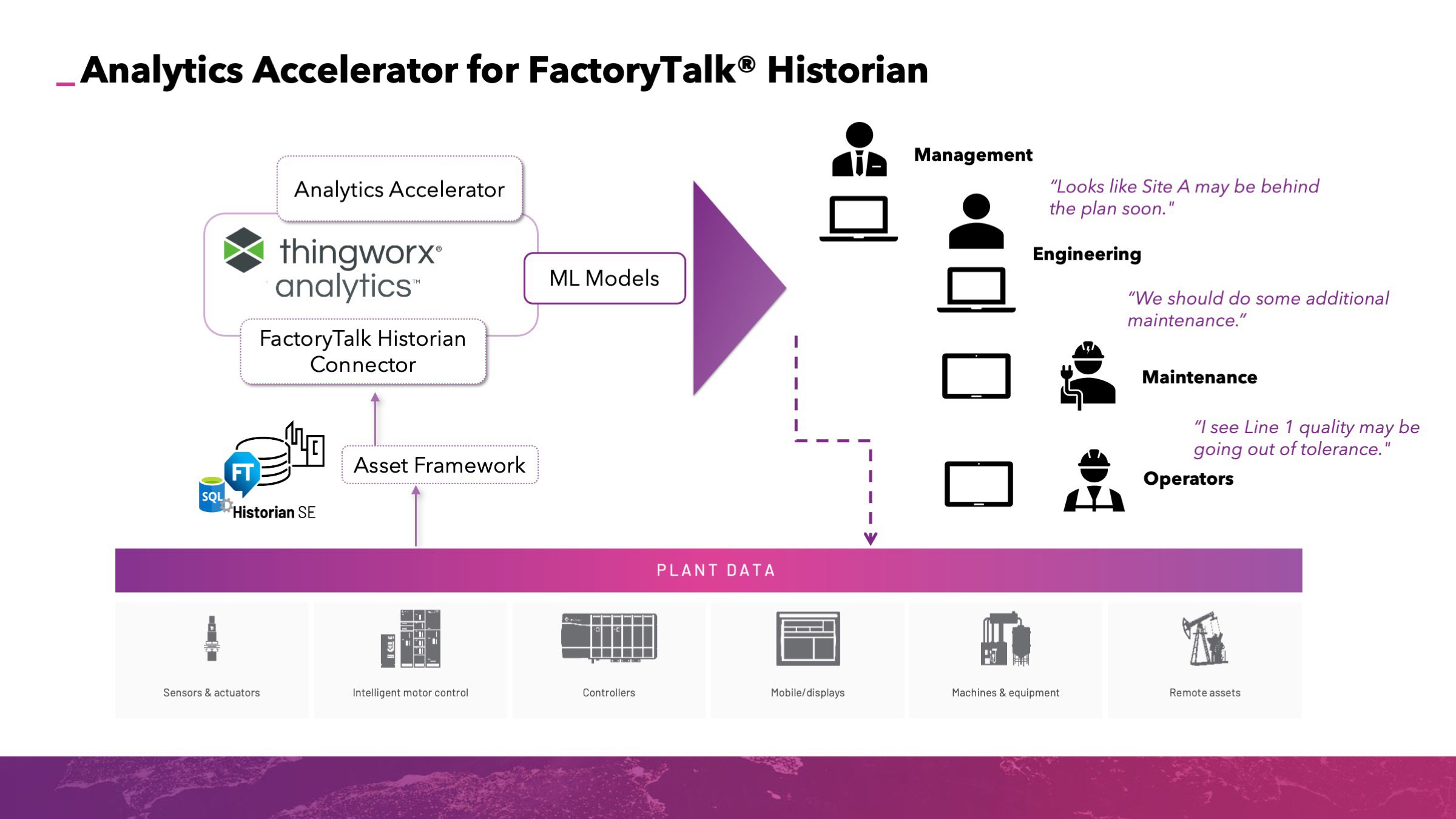

Using the Analytics Accelerator for FactoryTalk Historian

Analytics Accelerator for FactoryTalk Historian is a combination of tools that Rockwell Automation has developed to assist manufacturers in doing their own modeling.

It’s an Integrated Portfolio Solution built using ThingWorx® to make it easier to apply ML to data stored in FactoryTalk Historian data archives. The solution consists of several services and ThingWorx mashups which make up the user interface.