Industrial Smart Devices

Allen-Bradley Smart Devices are an integrated, scalable solution, offering new efficiencies and reduced total cost of ownership.

Smart Devices improve product quality, reduce downtime, and future-proof your investment in smarter machines to allow smarter manufacturing.

Efficient motors drive industrial performance

Across multiple applications, the electric motor keeps industry running, from motion systems, ventilators and conveyors to pumps and compressors. Central as they are to manufacturing and industrial performance, the impact of motor failure can be significant, costing thousands or even hundreds of thousands per hour of lost production. The most expensive motor isn’t necessarily the most critical: a failure on a small, single mixer motor can be enough to cause a major disruption to plant productivity.

How much do unforeseen motor failures cost you?

Motor costs

- Motors are the largest consumers of energy in industry

- Responsible for over 50% of the total energy used by industry

- Running a motor can cost 10 times its initial purchase price each year

- Reducing the speed of a motor by 20% can save up to 50% energy

Why motors fail

The most common causes of motor failure are:

- Thermal overloads

- Single phasing

- Bearing failure

- Rotor failure

- Stator failure

- Contaminants

Cost of downtime

- Loss of production

- Manufacturing scrappage

- Establishing cause of failure (mechanical/electrical)

- Motor and system repair costs

- Safety issues

- Impact on other equipment

Maintenance options

- Advanced diagnostic information

- Preventative not reactive maintenance

- Planned downtime possible

- Be in control of your plant

- Reduced maintenance costs

Increased productivity

- Reducing unplanned downtime improves productivity

- Be in control of your production process

- Reduce energy costs

- Make fact-based decisions with advanced diagnostic information

Smart Motor Control at work

Motors are used in many industrial applications and these are critical to the productivity of the enterprise.

With Smart Motor Control solutions it is possible to monitor the health and performance of each motor to help identify, in advance, potential issues that could lead to unwanted downtime or reduced productivity levels.

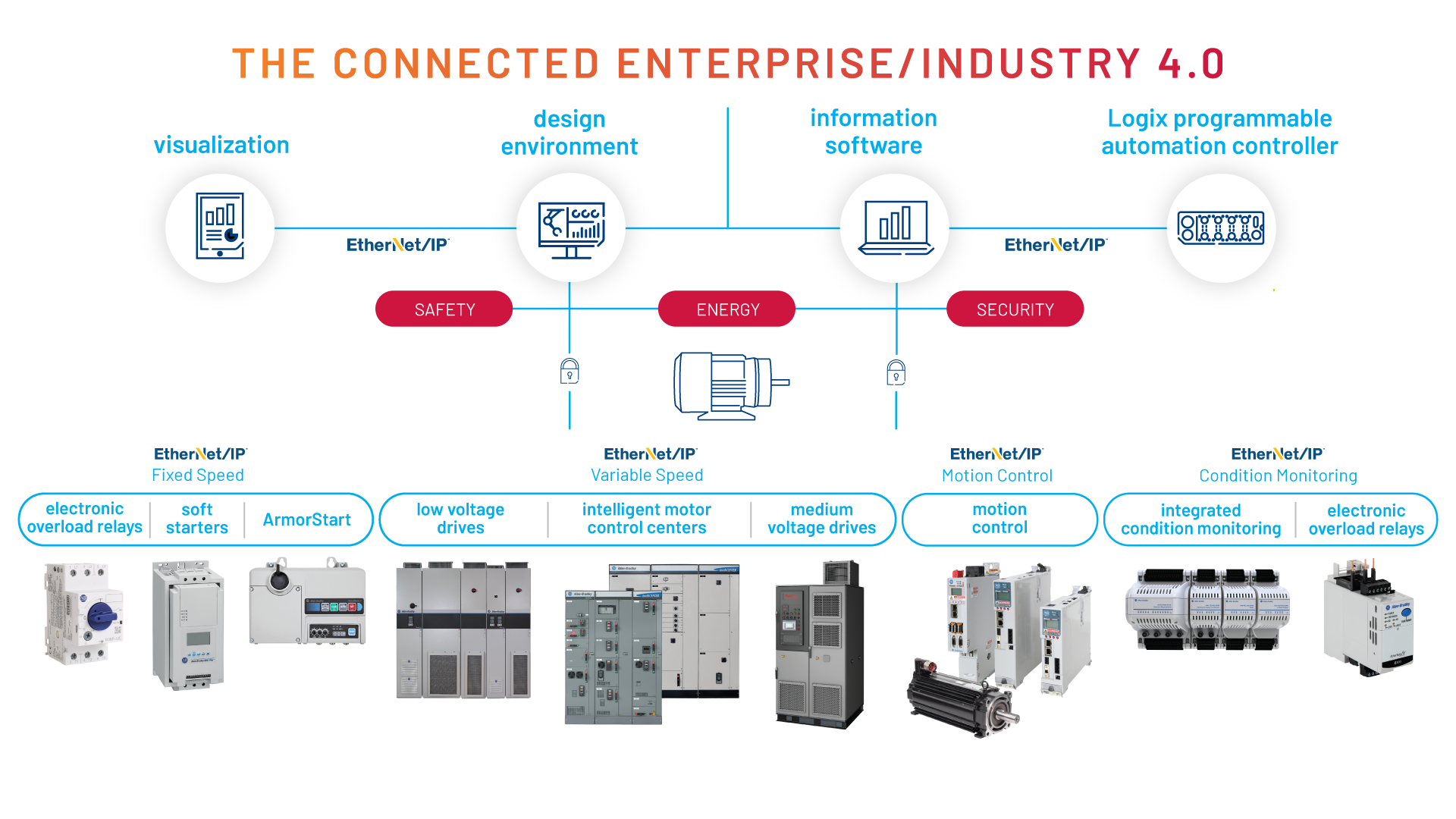

Smart Motor Control devices

Smart Motor Control provides a continuous flow of valuable process and diagnostic data to your design environment, visualization system, information software and Logix Programmable Automation Controller – facilitating smart manufacturing and helping to increase productivity and minimize downtime while reducing total cost of ownership.

Smart Motor Control enables Smart Machines for Smart Manufacturing

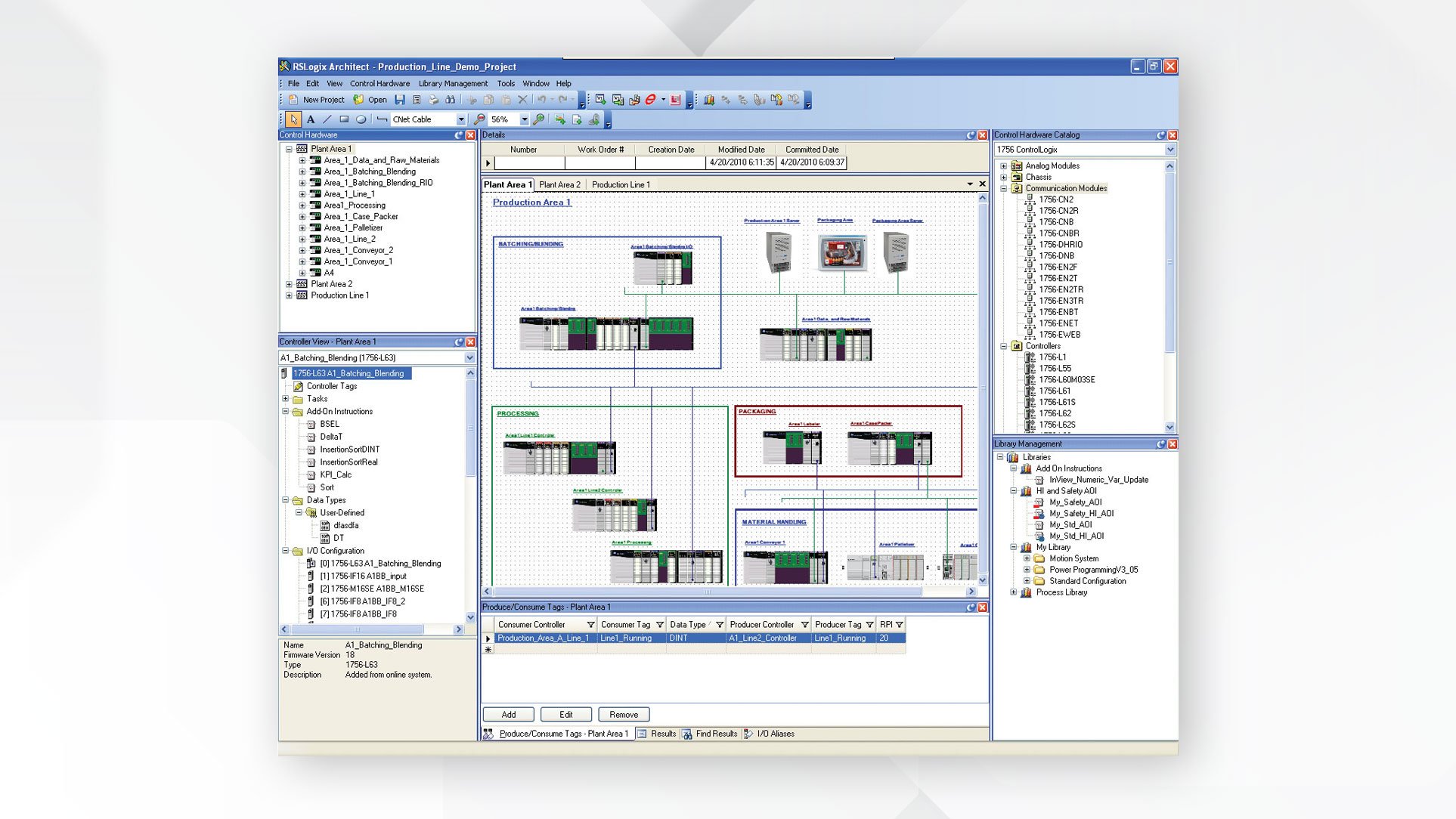

The integration of Allen-Bradley Smart Motor Control solutions help reduce programming time, ease startup and commissioning, and streamline diagnostics. By providing consolidated programming, device and system configuration, operation and maintenance within the Studio 5000 engineering environment, complexity and potential errors are minimized.

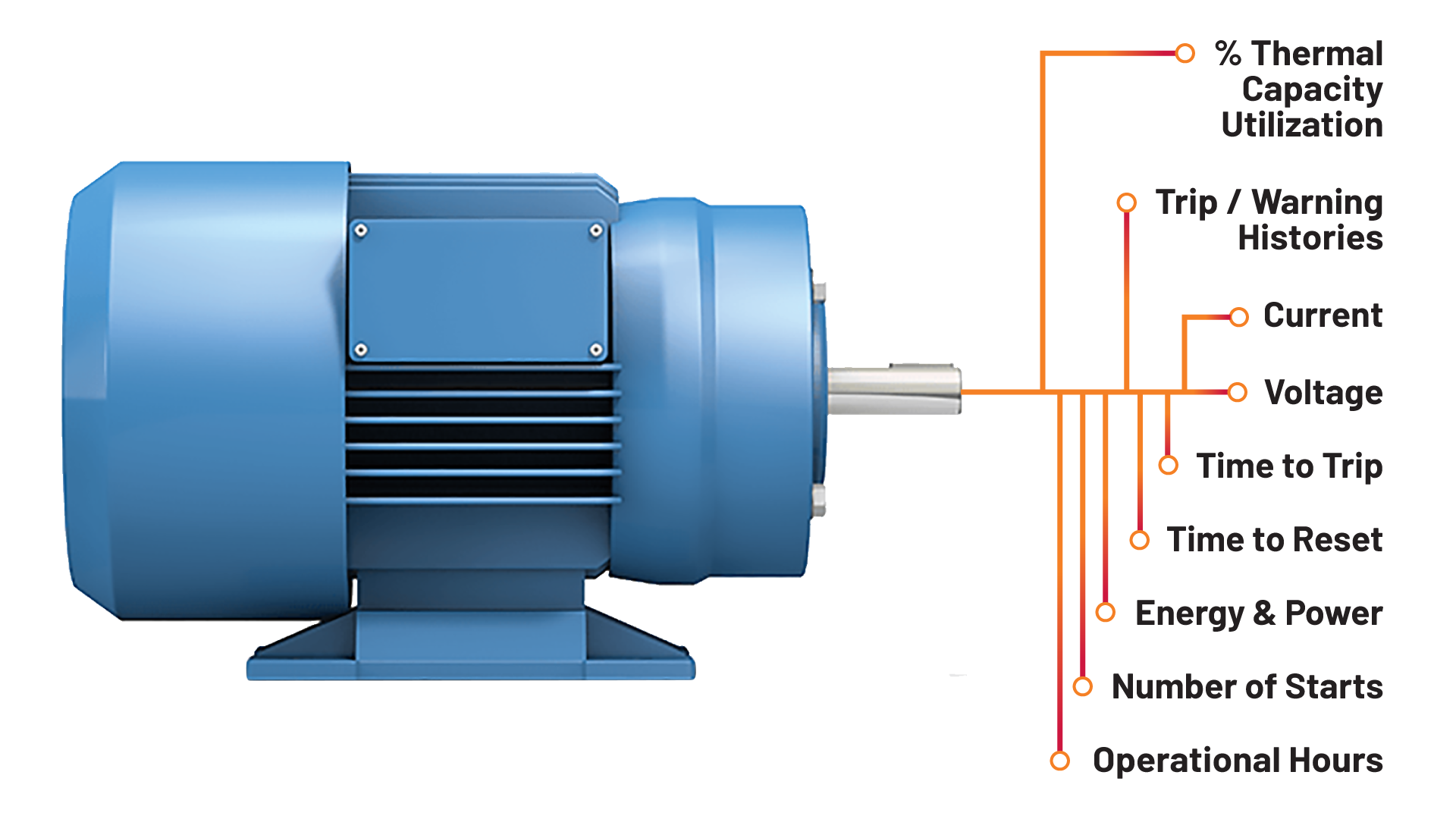

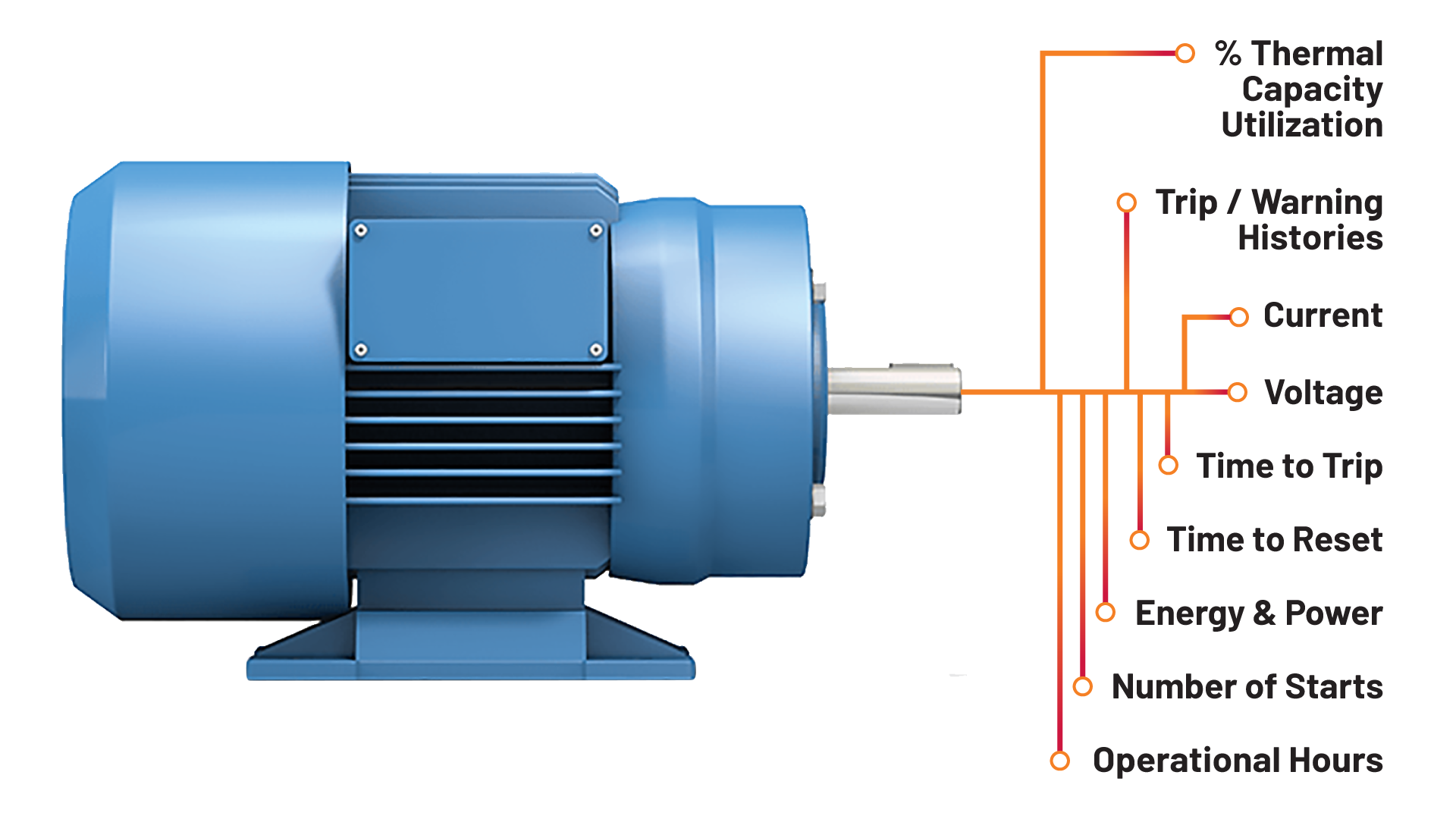

Smart Motor Control provides key diagnostic information that enables you to optimize performance with real-time access to operation and performance trends.

Today's smart approach

• Seamless communication and system visibility for increased performance and flexibility

• Control & maintain motor performance through smart equipment and networks

• Reduce unplanned downtime with alarms and advanced diagnostic information

• Monitor energy consumption

• Simplify troubleshooting and reduce startup times

Smart Motor Control solutions are programmed using Studio 5000® software

Just one development environment for configuring and programming

Add-On Profiles for simplified machine development, operation and maintenance

Application Scenario 1 of 14

Motor underload

Helps detect and inform of mechanical failures

Reduces costs associated with production loss

Can help minimize repair costs due to controlled shutdown

Time to repair and restart process reduced

Allows maximum efficiency to be benchmarked and monitoredApplication Scenario 2 of 14

Process optimization

Can help increase production throughput

Reduces unnecessary wait times

Helps increase product quality

Optimizes efficient use of energy

Application Scenario 3 of 14

Motor overload

Early warning and diagnostic functions provided

Minimizes production downtime

Helps protect your critical assets from costly failure

Fact-based decision making using real time diagnostic information

Opportunity for predictive, rather than reactive maintenance

Application Scenario 4 of 14

Ground fault current detection

Predictive monitoring of motor health

Proactive maintenance can be achieved

Reduced downtime of critical equipment

Application Scenario 5 of 14

Network issue

Local management of process in event of network communication issue

DeviceLogix™ allows for decentralized intelligence and reduces unnecessary network traffic

Critical asset health can be maintained

Batch production can be completed reducing clearing and cleaning issues

Application Scenario 6 of 14

Energy waste detection

Automatically identifies possible issue

Helps reduce the cost of energy consumption

Minimizes stress on motor and mechanical equipment

Reduces maintenance time and cost

Application Scenario 7 of 14

Device health and diagnostics

Aggregate, analyze and present data from your devices, no matter where you are

Automatic discovery of EtherNet/IP connected devices

Automatically generated dashboards monitor the control system and perform analytics

Action cards delivered when a situation occurs that needs attention

Voice activated function to request and interact with networked devices

No cloud connection and no dashboard development required

Application Scenario 8 of 14

Automatic device configuration

Set-up automatically downloaded from controller

Minimizes downtime and simplifies maintenance

Minimal specialist knowledge needed, allowing quick device replacement

Reduces risk of incorrect configuration

Device configuration stored locally in controller

Application Scenario 9 of 14

Single programming environment

Single programming environment helps minimize programming errors

Easy to access and edit information

Diagnostic, fault, alarm and event information are integral to Studio 5000®

Helps reduce development time by up to 70%

Application Scenario 10 of 14

Predictive maintenance

Predictive maintenance features predict when to replace critical drive components

Prediction based on real time operating conditions

A variety of functions are available to monitor

Can configure and retrieve data via HIM, software tools and Studio 5000® engineering environment

Application Scenario 11 of 14

Energy management

Use network access to configure and troubleshoot devices without opening MCC enclosure doors

Smart motor control technology within the MCC can warn of failures before they occur

Network devices are pre-configured with node addresses so you can configure device parameters via the network

IntelliCENTER Software includes electronic versions of manuals, wiring diagrams and spare parts

Application Scenario 12 of 14

Application Code Manager

Leverage Rockwell Automation provided libraries

Flexible library authoring, structuring reusable content the way you want

Easily generate your standardized application code in bulk to configure projects

Users don’t need to understand the library object dependency structure; the tool manages the dependencies per the librarian’s rules

Out of the box integration enables simple and fast bulk deployment of the Library of Process Objects and Machine Builder Library

Facilitates continuous reuse of IP and aids to enforce standards

Application Scenario 13 of 14

Automotive - Adaptive Tuning

Load Observer - Helps reduce startup time by reducing the effort needed for tuning

Automatically monitors and compensates for changes in inertia and for motor‑to‑load compliance by anticipating need for torque

Compensates for normal machine wear

Provides consistent dynamic behavior

Adaptive Tuning - Helps increase machine reliability and performance

Monitors drive performance characteristics and adapts if necessary

Tracking notch filters automatically suppress potentially harmful resonance and vibration conditions. With four tracking notch filters, the PowerFlex 755T drives can identify up to four resonances

Can be used to indicate machine wear out over time

Application Scenario 14 of 14

Automotive - Predictive Maintenance

Predictive Maintenance parameters are customizable enough to fit a multitude of machine applications

Track maintenance items such as motor bearings, motor lubrication, machine bearings and machine lubrication

Configure system components and determine when periodic maintenance may be required

A variety of functions are available to monitor

Can configure and retrieve data via Human Interface Module (HIM), software tools and Studio 5000 engineering environment

Efficient motors drive industrial performance

From fixed and variable speed control to precise torque and position control, Rockwell Automation supports you with application knowledge,

industry experience and a complete portfolio of Smart Motor Control solutions, helping you achieve the control you need.Adopt a Smart Motor Control solution today

Efficient motors drive performance and the impact of motor failure can be significant. With smart motor control devices, you can improve productivity and help avoid motor failures with an integrated, data-driven approach.

Our smart products include:

• Fixed Speed Control

• Variable Speed Control

• Motion Control

• Condition Monitoring

Others also viewed

Based on your activity