Water, waste and worry

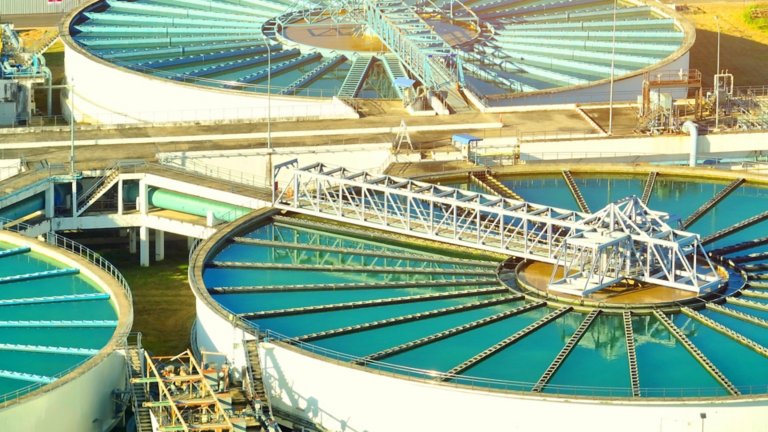

As a wastewater treatment operator, you face a complex balancing act every day. On the one hand, your plant must manage power- and process-intensive operations across multiple systems while meeting strict regulatory standards for effluent quality. Then there’s the treated water you return to the environment. It must be consistently safe and, in many cases, potable, regardless of fluctuations in influent conditions or system load.

At the same time, you’re under pressure to reduce energy consumption and improve overall efficiency. Maintaining consistent water quality throughout the treatment process is critical, but it’s becoming harder as contaminants evolve and expectations rise. And to add to your balancing act, a shrinking pool of skilled labor and an aging workforce makes staffing your operations with experienced personnel more difficult than ever.

All of this unfolds under the watchful eye of ever-tightening environmental and public health regulations. The stakes are high, and so is the need for smarter, more connected solutions.