Downloads

What is this for?

The SQL motor startup sequence introduces the use of FactoryTalk Transaction Manager (FTTM) to link communication between an SQL database and Studio 5000. FTTM reads values from different recipes for flexible and reconfigurable manufacturing and applies these values to tags in sequence programs to start the corresponding process once the current routine is completed. This way, an information exchange is implemented between production floor control and commercial databases.

The current model performs bidirectional information transactions between FTTM and Studio 5000. These are carried out once the control system indicates it and proceeds to take information from the database for application in the system. All transactions made are stored for the necessary traceability of production operations. With applications in consumption, automotive, packaging, and other industries, this project serves as a template for commissioning motors with parameters in databases.

General characteristics

The motor startup sequence with an SQL database offers the following features:

- Information exchange between plant floor and commercial databases

- Connectivity between backed-up information for processes

- Remote commissioning of motors

- Parameterization of processes controllable in the database prior to implementation.

- Structured organization of productive process information

Advantages

- Organized production parameter changes

- Secure and backed-up procedural information

- Centralized or distributed architecture according to scalability requirements

- Traceability of historical operations with transaction records

- Process quality traceability

- Download of recipes and configuration information to the control system

- Collection of information and automated storage

- Production performance monitoring

Is it useful for me?

The demand for multiple SKUs (Stock Keeping Unit) on production lines requires quick transitions between manufacturing setups. This project serves as a fundamental basis for connecting a Studio 5000 program and an SQL database with all necessary production parameters. Through flexible technology, manufacturers will be able to improve equipment performance and overall efficiency (OEE), while digitizing operations to provide real-time process control and production support.

Customer demand will continue to increase and present different scenarios on production lines. Manufacturers will need to implement flexible and reconfigurable manufacturing to address these challenges. Through this project, a Studio 5000 program commissions motors according to the selected recipe number and provides an integrated database solution for production companies.

Implementations of this project can vary from serving as a demonstration for companies facing these challenges to being used as a template for configuring production parameters from an SQL instruction database.

How can I make it work?

Hardware:

- Motor stations (Motor, VFD’s Power Flex,PAC).

Software:

- Studio 5000 (v33-35)

- FactoryTalk Transaction Manager v13

- FactoryTalk Live Data source (Logix Echo, Logix Emulate, or Logix controller)

- FactoryTalk Administration Console

- Microsoft SQL Server 2016 w/SQL Server Management Studio

Knowledge:

Familiarity with the use of SQL databases, motor commissioning through frequency inverters and PAC controllers, knowledge of network configuration for motor stations.

Links of interest:

Please note: You will need to agree to the Terms & Conditions for each download.

Need Help?

If you need help with an application or have feedback from the Innovation Center, please contact us.

Installation Guide

Step 1

Identify the applications used for this implementation: Studio 5000, SQL Server Management Studio, FactoryTalk Transaction Manager, and FactoryTalk Administration Console.

Step 2

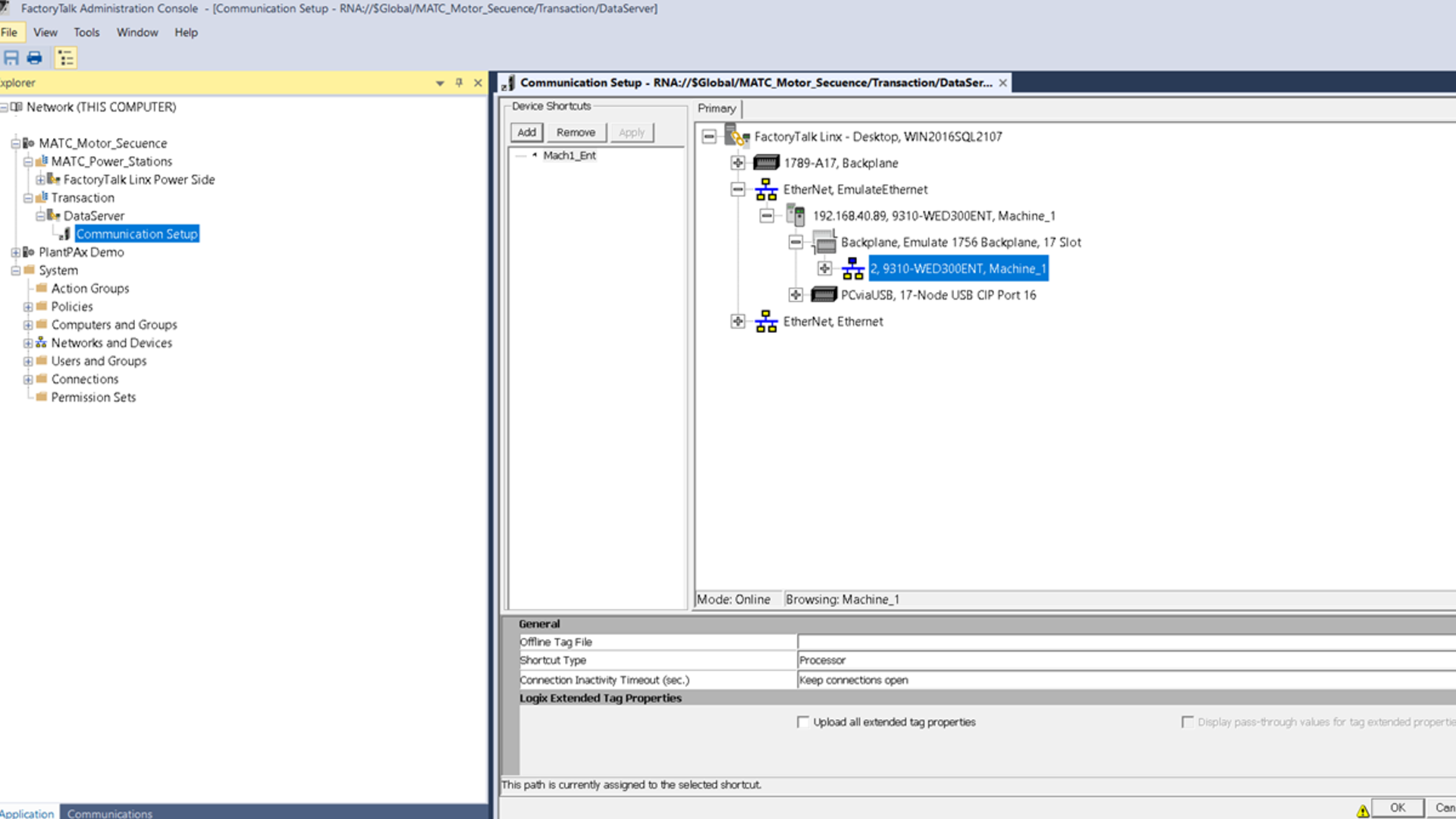

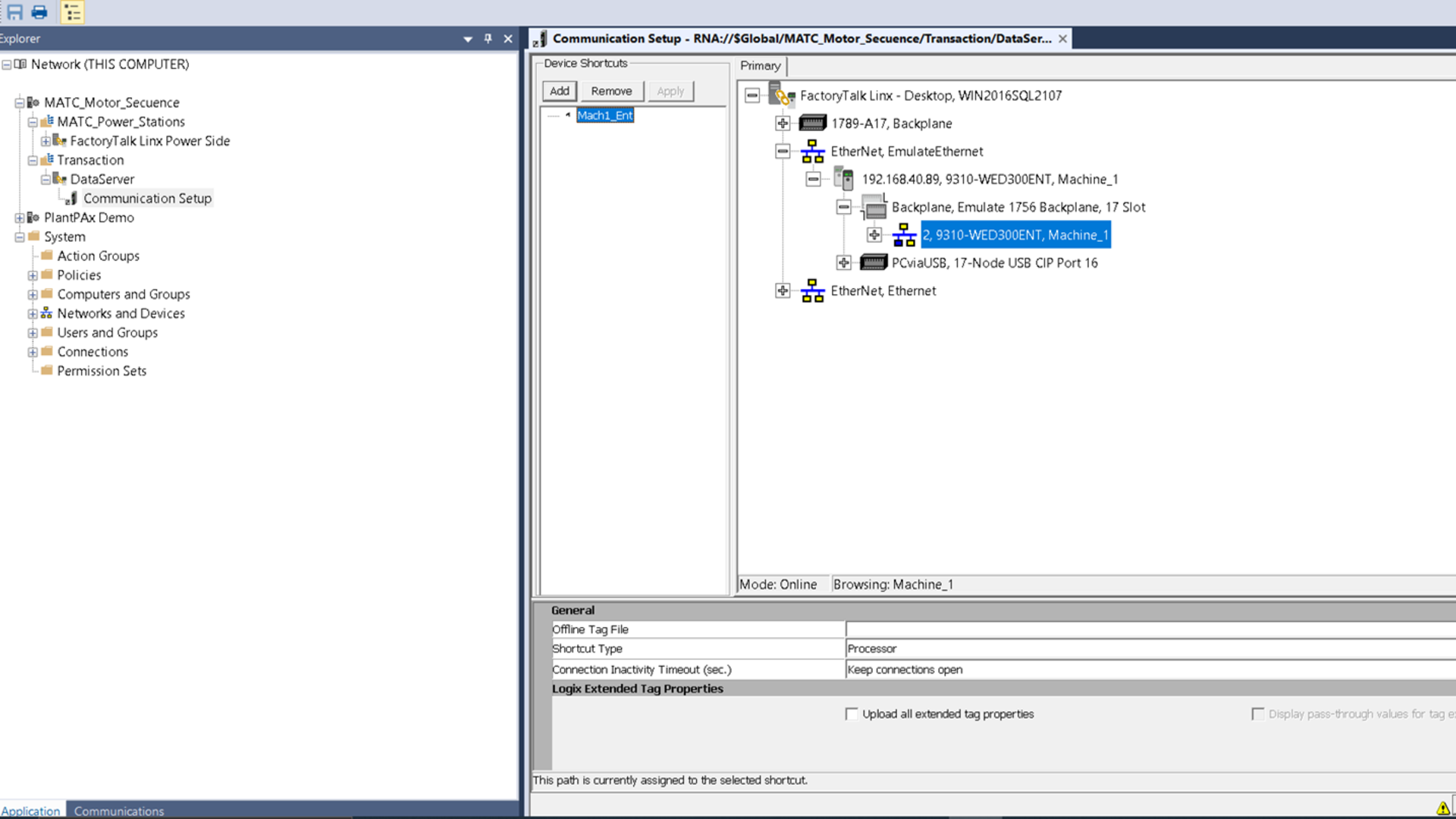

In the FactoryTalk Administration Console application, create a shortcut to the motor system controller named "Mach1_Ent".

Step 2 - Image 1

Step 3

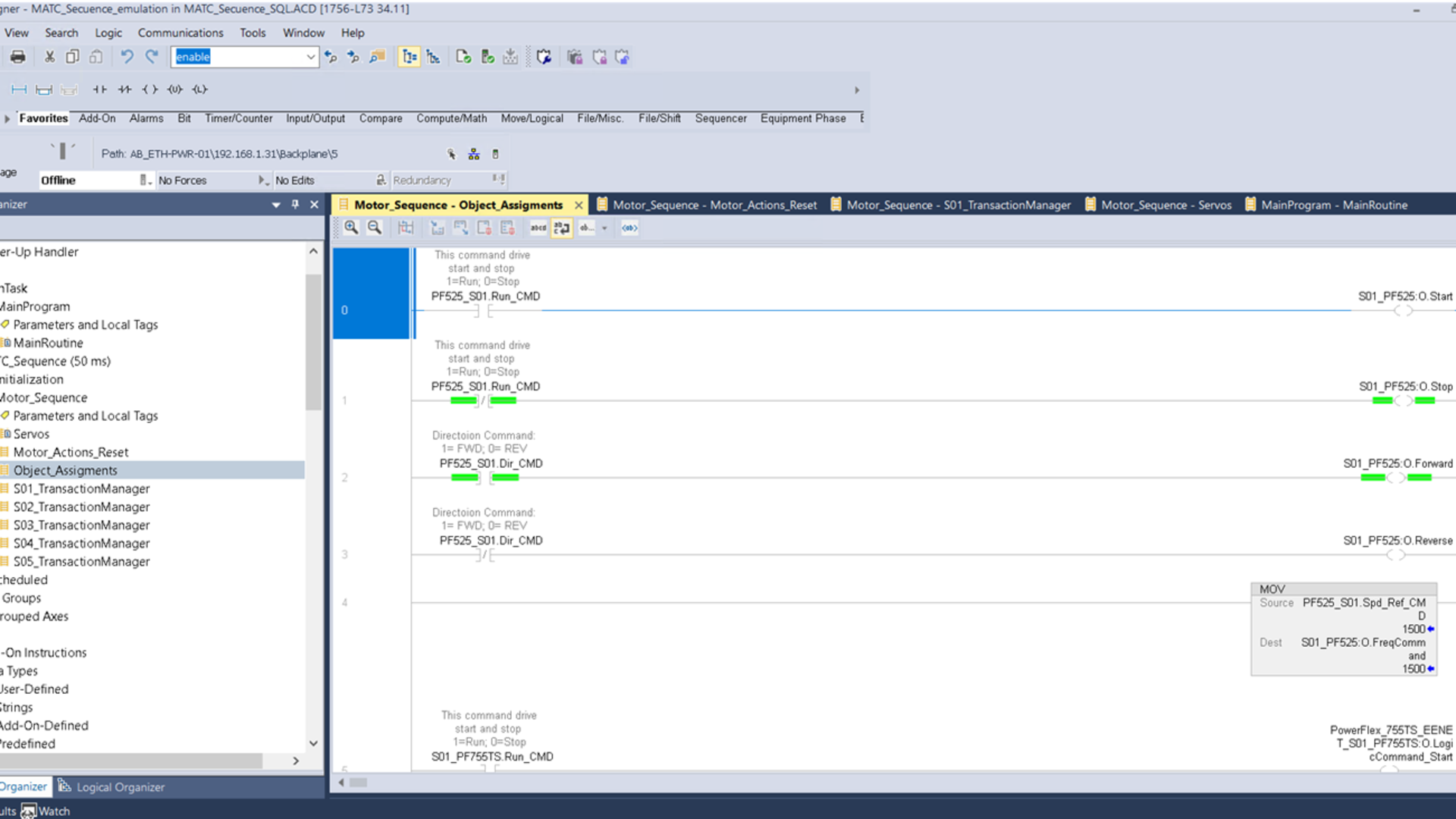

3.1 Enter the Studio 5000 program attached with the motor startup sequence. Go to the Object_Assignments routine. Adjust the variables of the motor commands towards the used PowerFlex VFDs.

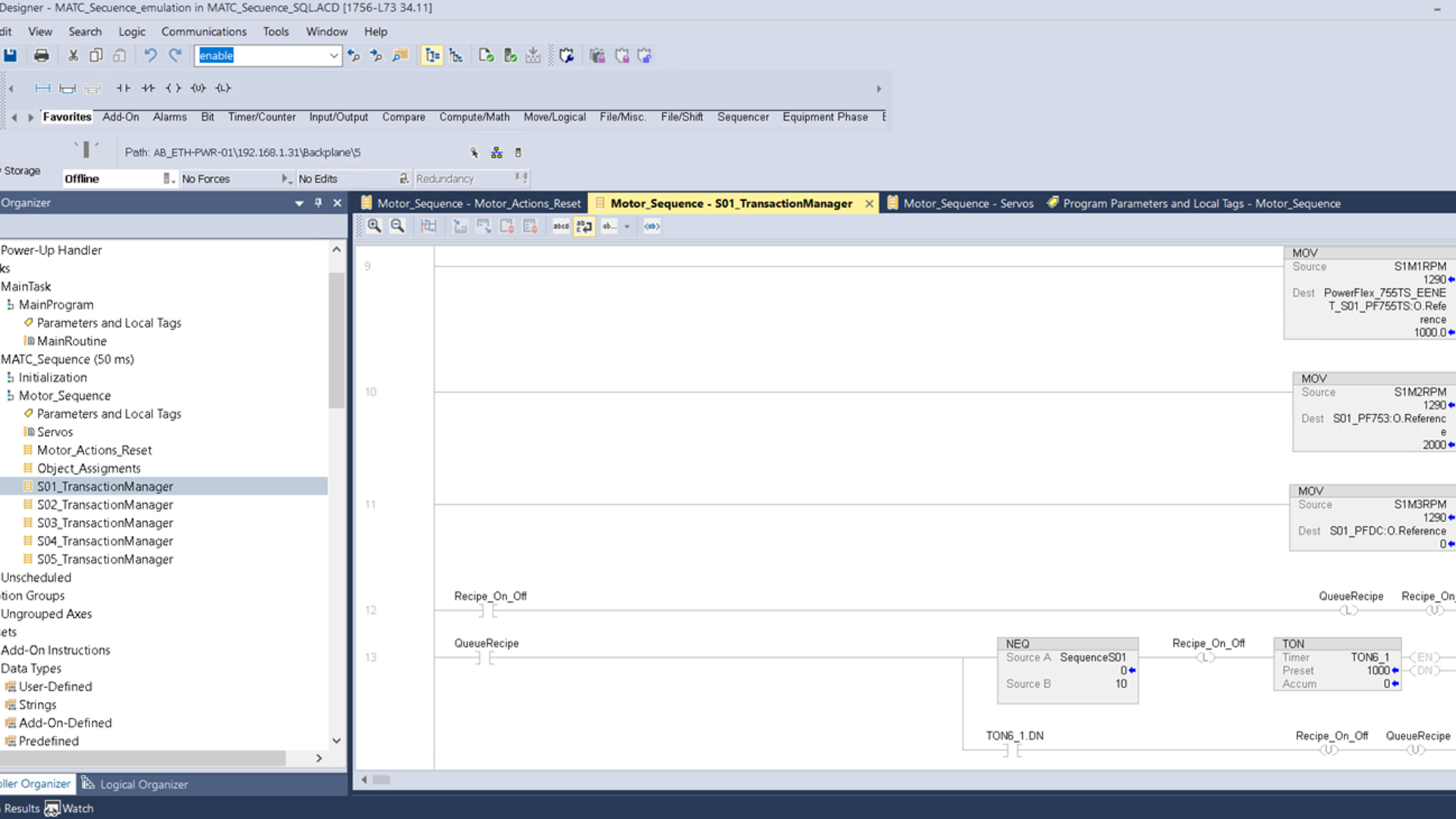

Step 3 - Image 1

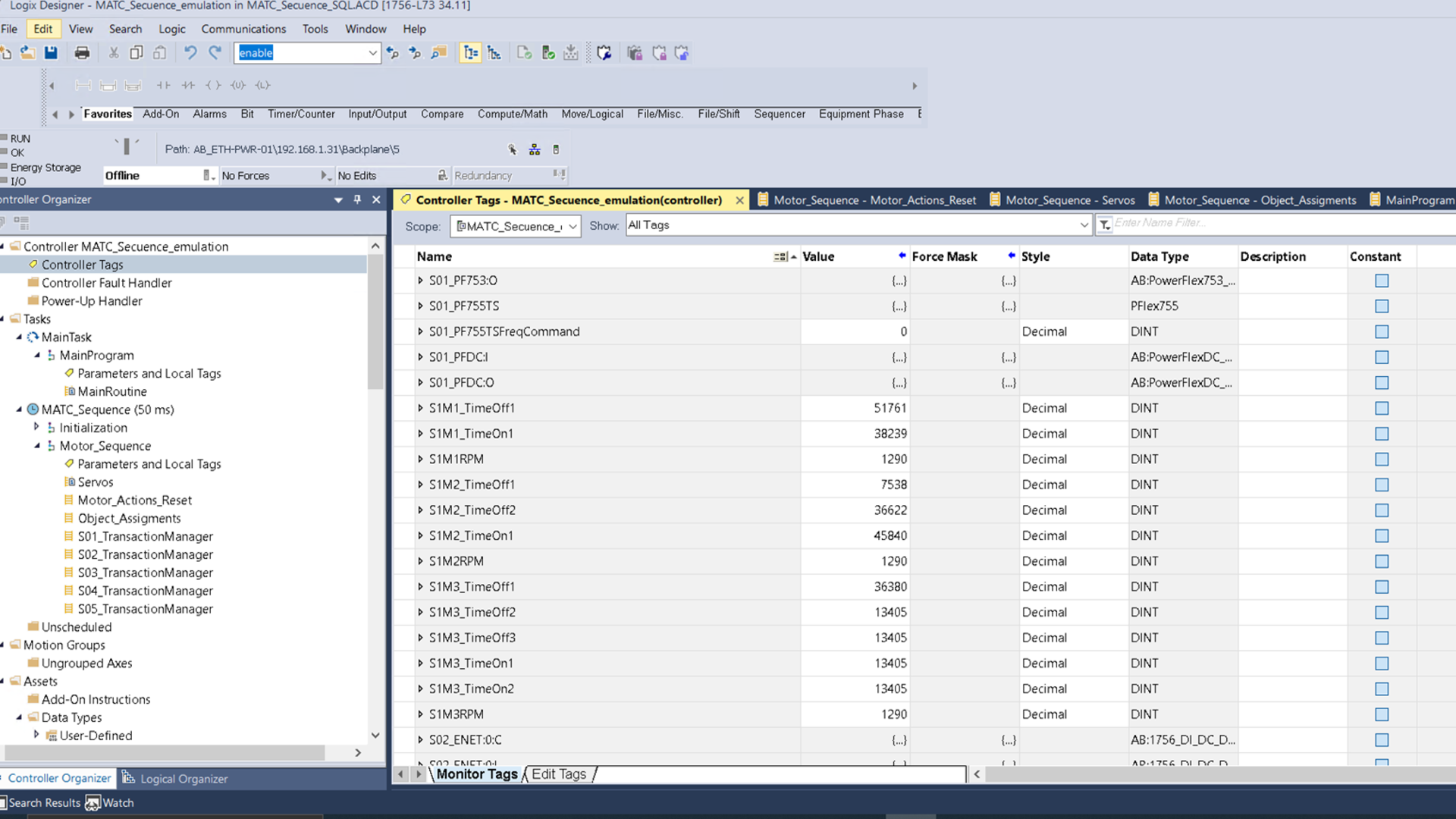

3.2. If you wish to create different variables for your VFDs, do so in Controller Tags.

Step 3 - Image 2

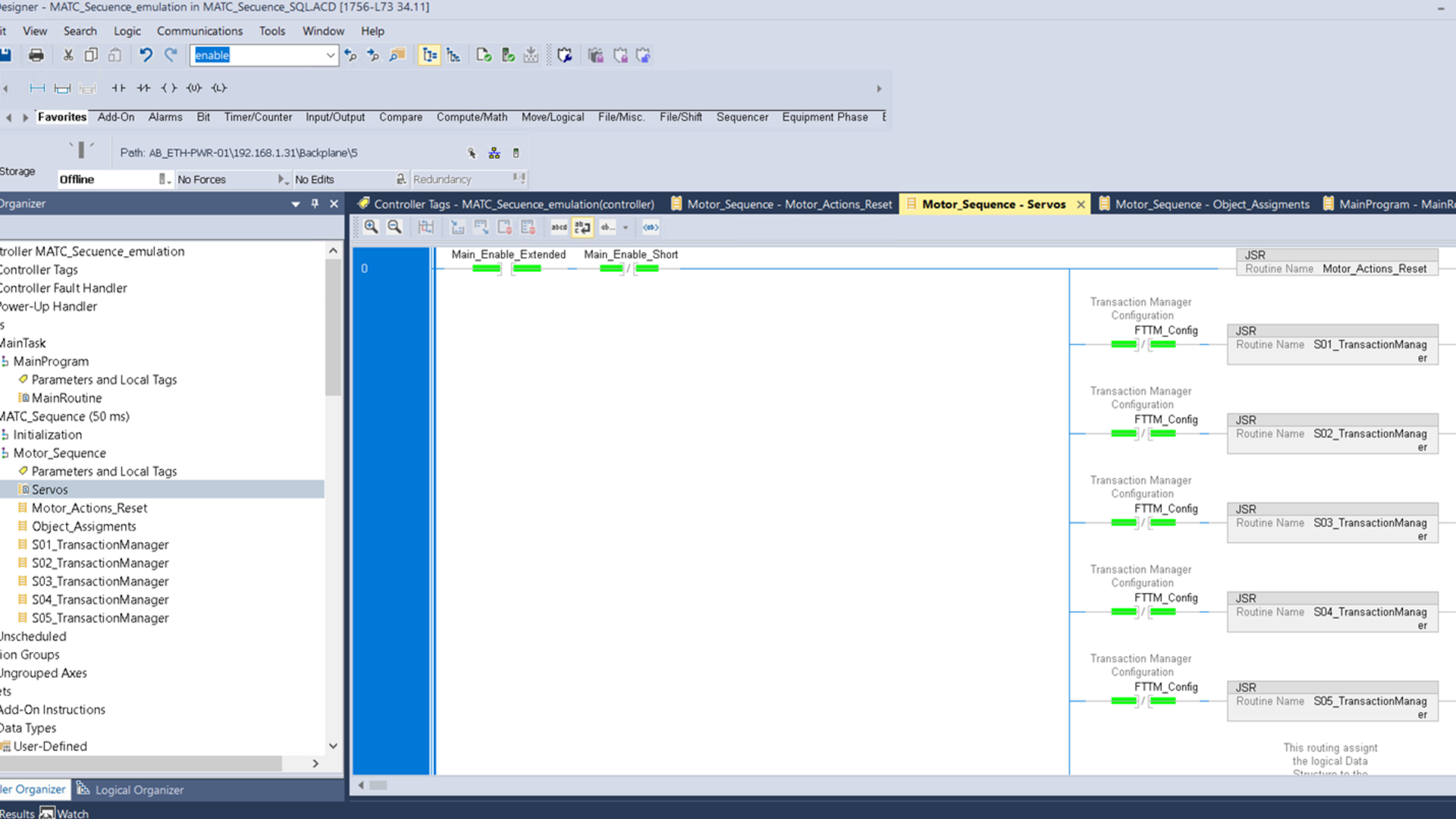

3.3. If you need to change or improve the routine, you can activate or deactivate them with the Jump to Sub Routine (JSR) instruction found in the Servos routine.

Step 3 - Image 3

Step 4

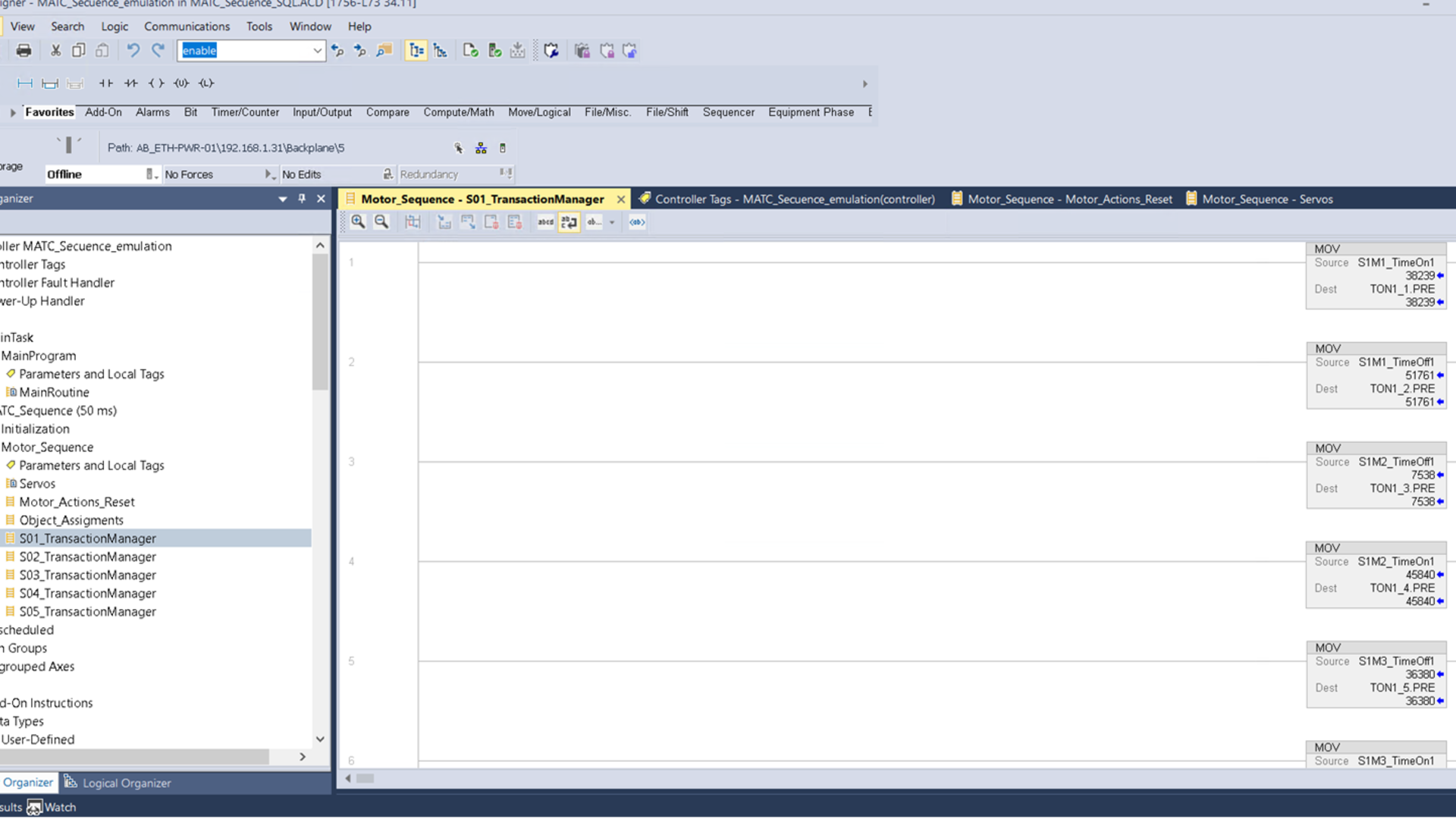

Access the routines of each station (in this case there are five stations) and assign values to the variables using the MOV command. For example, if you want to change the "PRESET" time of a timer, in our case the S1M1_TimeOn1, or if you want to change the RPM value of the motor, you can also do it with this instruction. In the attached program, there are examples for assigning time intervals and changing speeds.

Step 4 - Image 1

Step 5

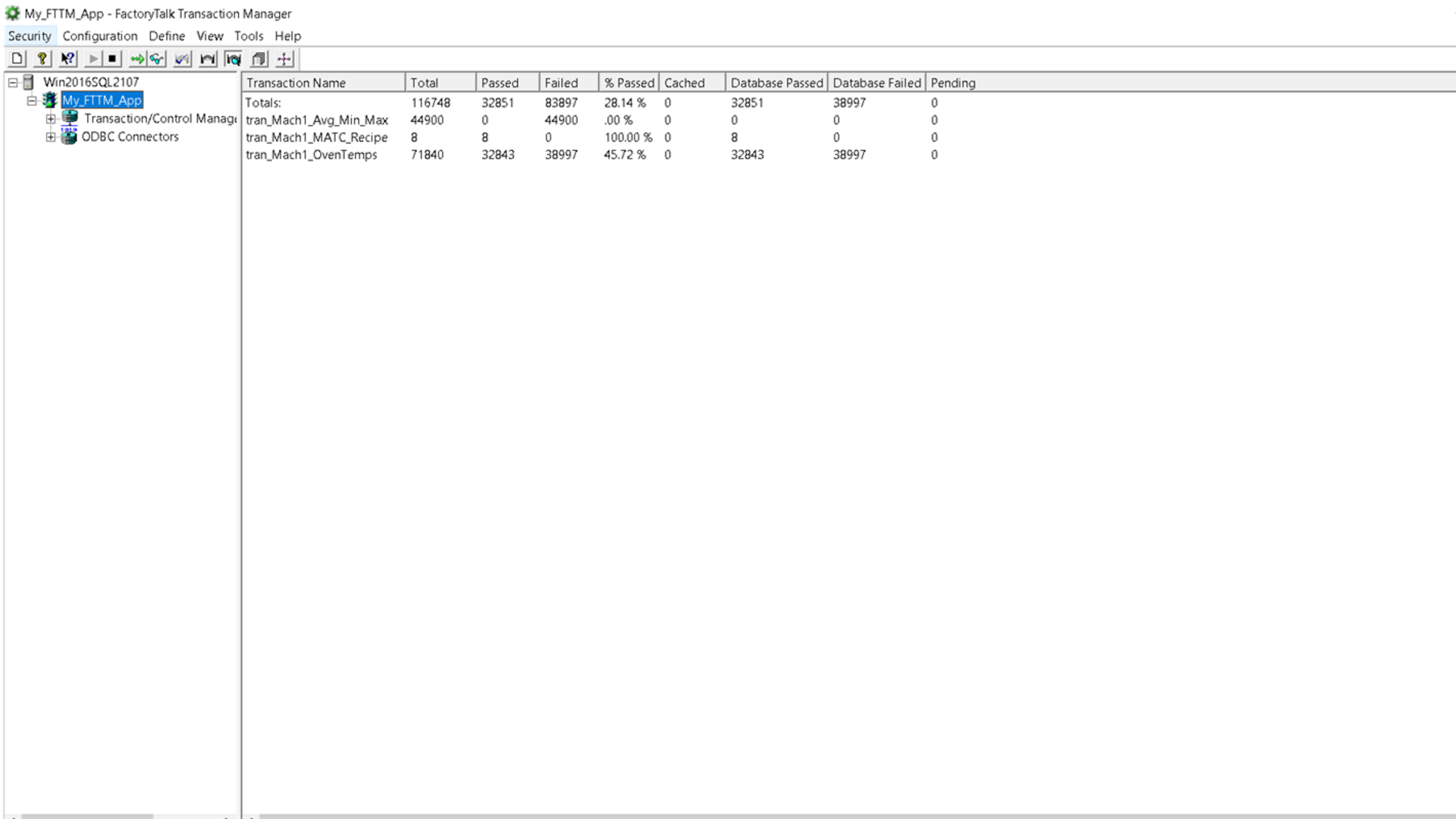

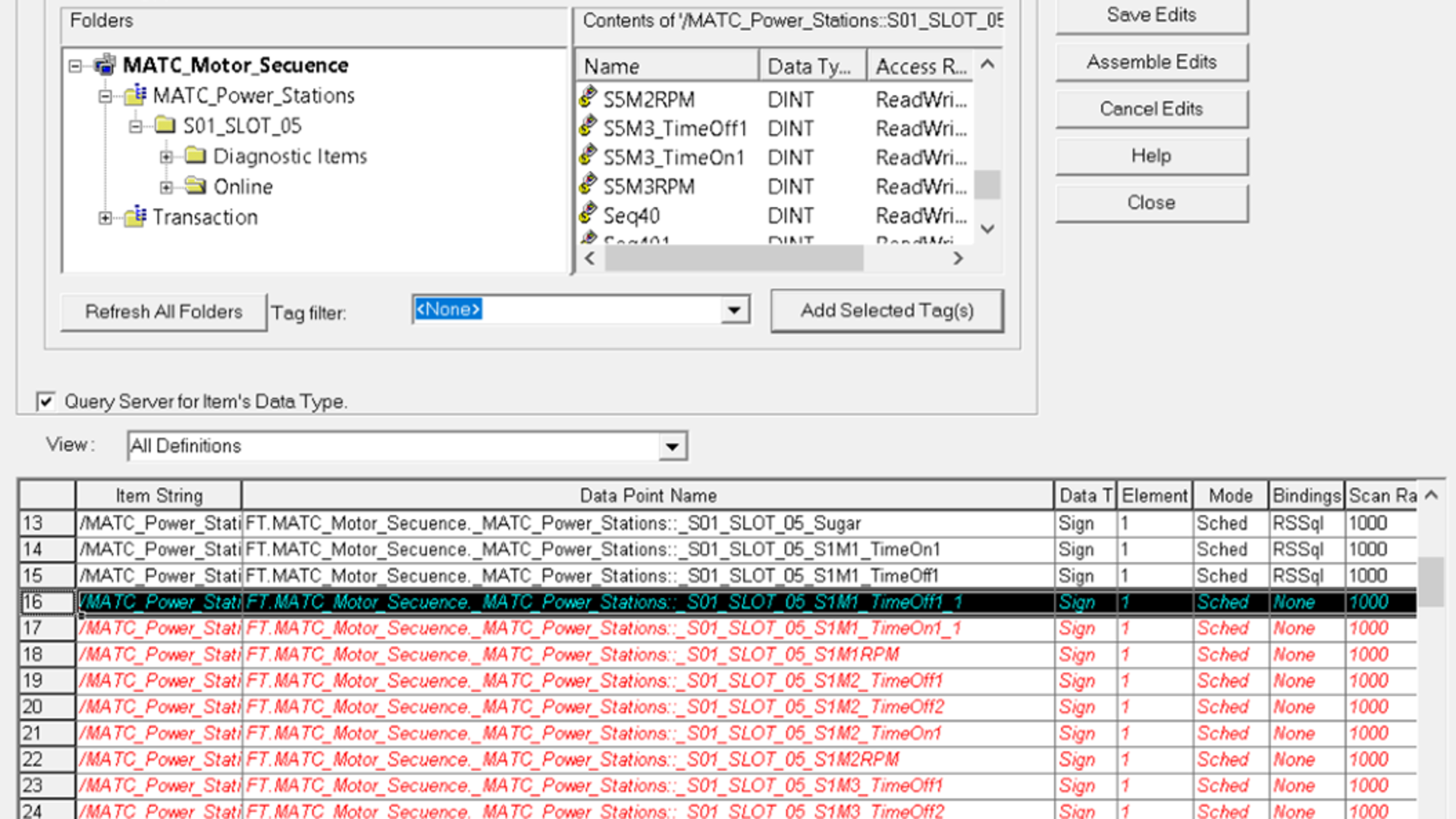

Access FTTM and add the created variables as Data Points in the Checklist. Then click on Save Edits and subsequently Assemble Edits.

Step 5 - Image 1

Step 6

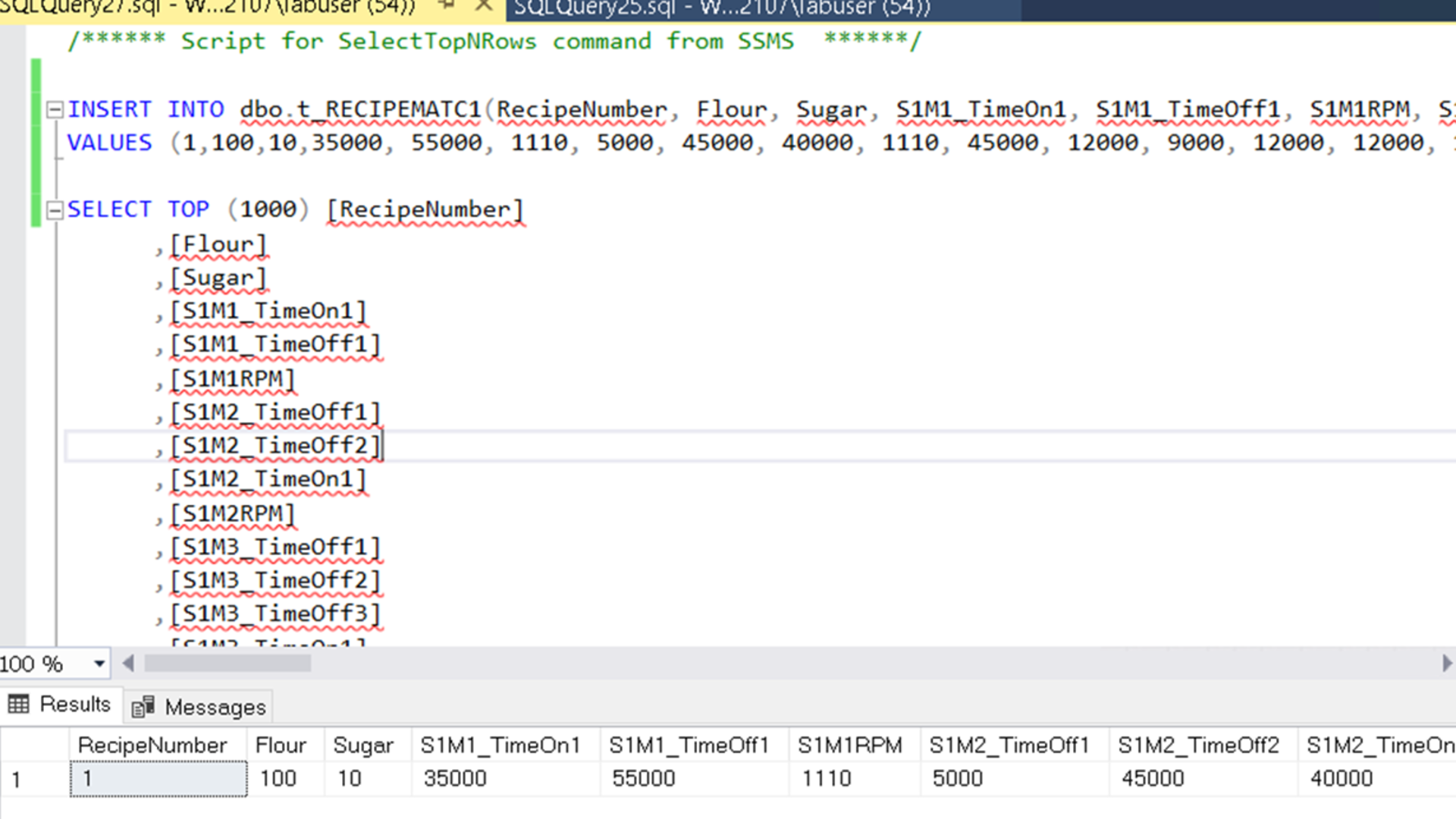

Access the SQL queries in the MotorStationCommands Excel file and modify the database using the columns as the variables used in Studio5000 to commission the motors. Add as many recipes as desired.

Step 6 - Image 1

Step 7

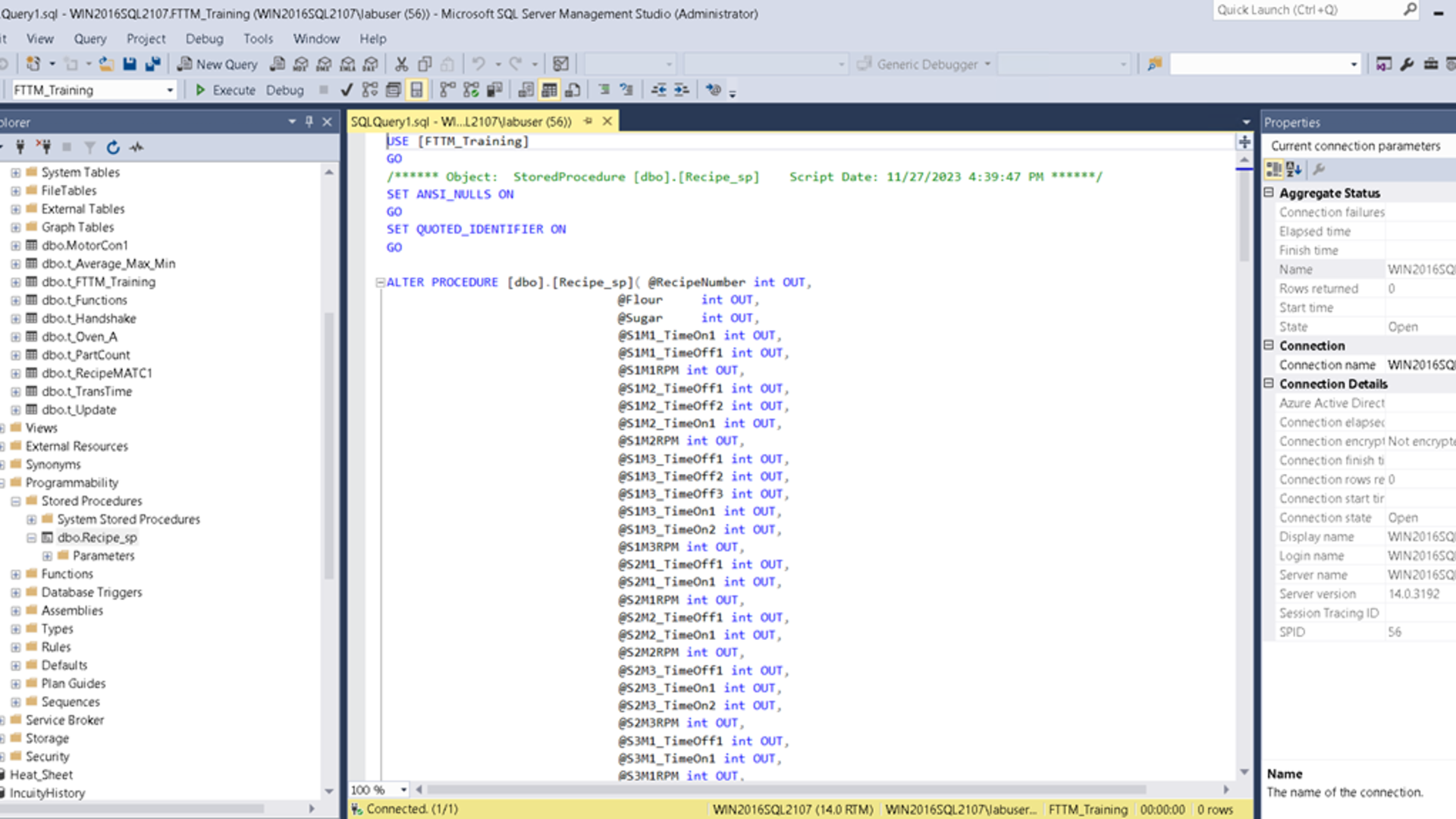

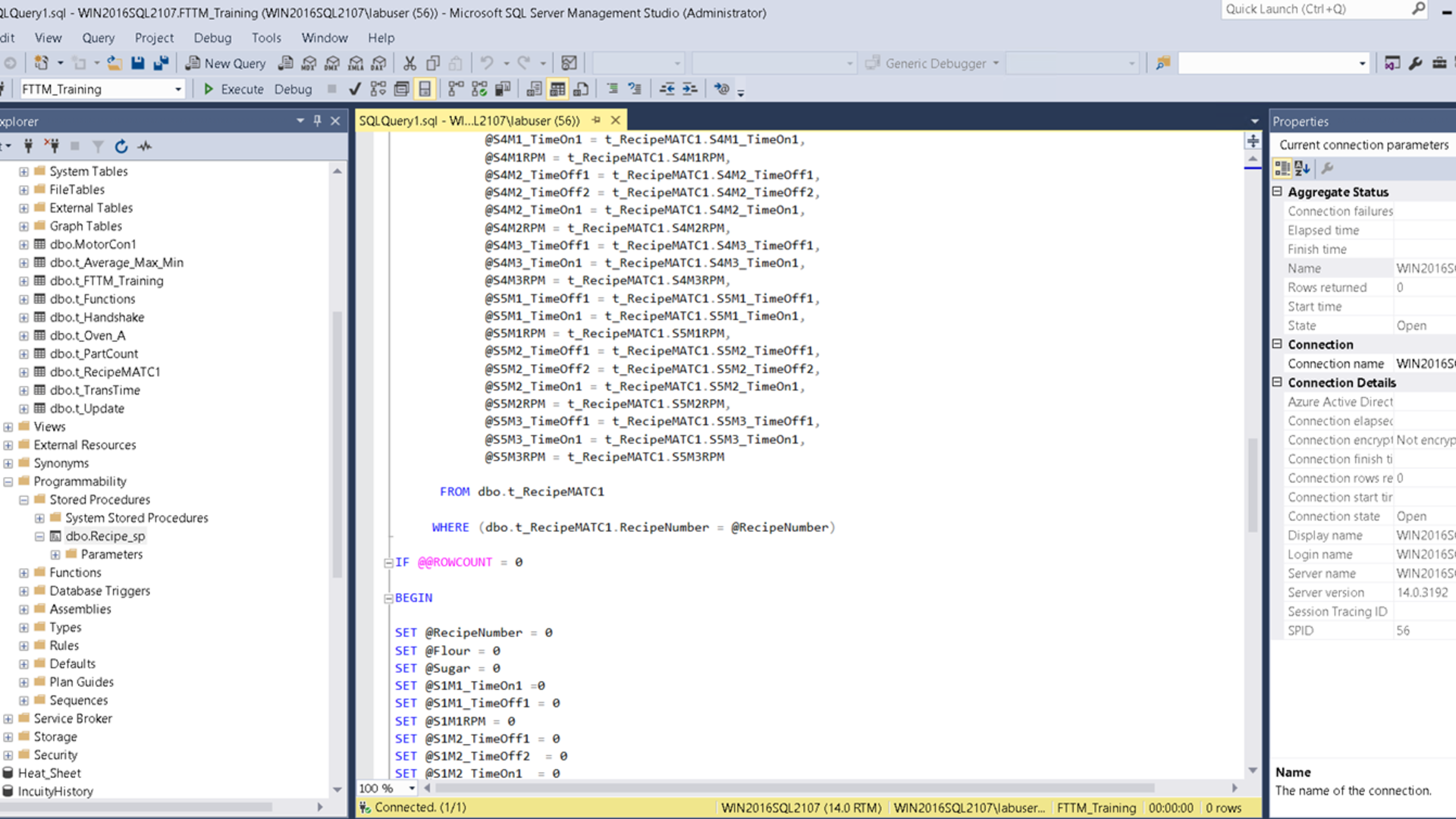

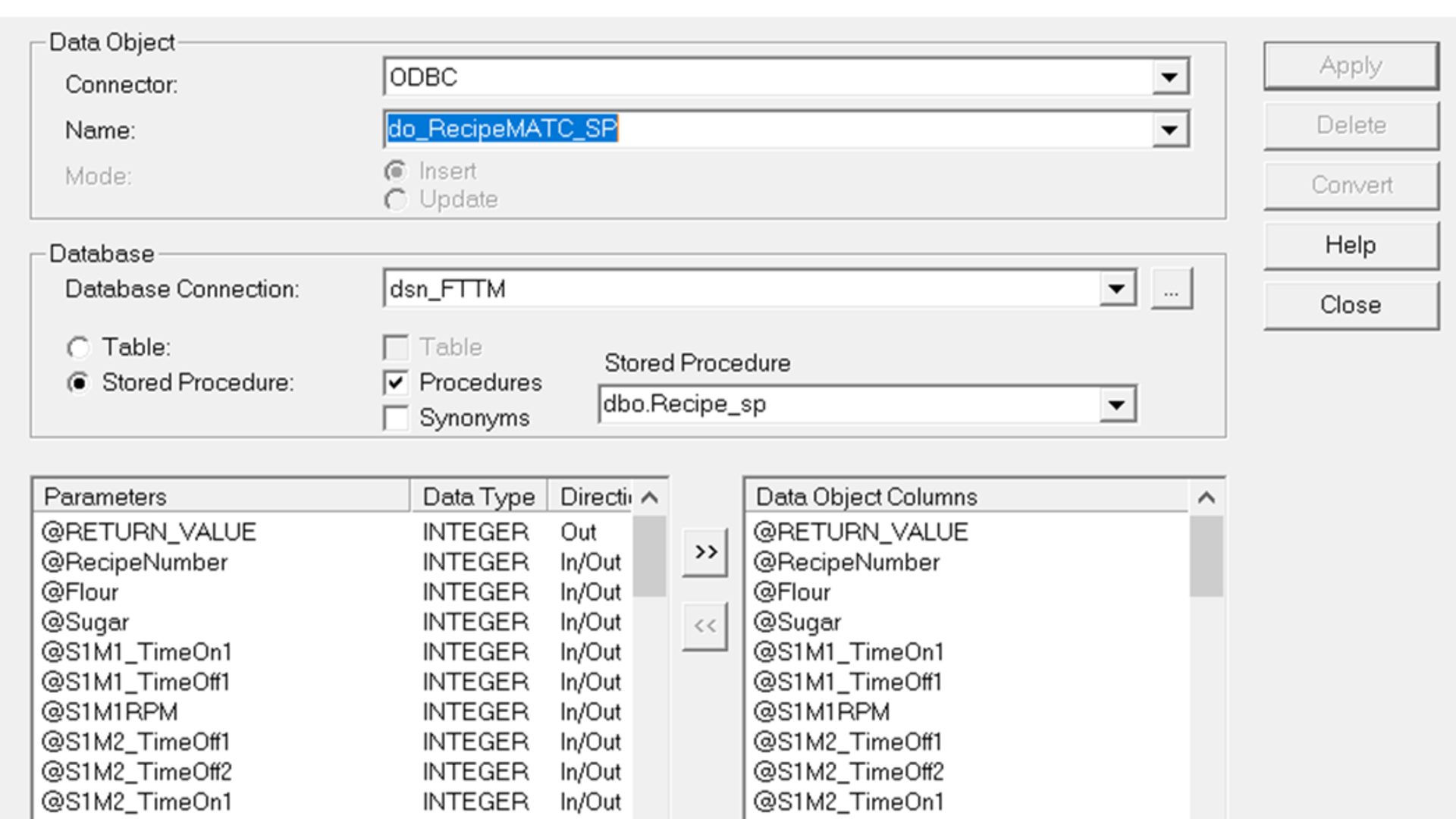

Access Programmability: Stored Procedures: dbo.Recipe_sp. Modify the SQL query procedure to get the values of the columns and assign them as data points in FTTM.

Step 7 - Image 1

Step 8

In step 4 of the FTTM checklist, add the parameters of the revised procedure in the previous step of the SQL database.

Step 8 - Image 1

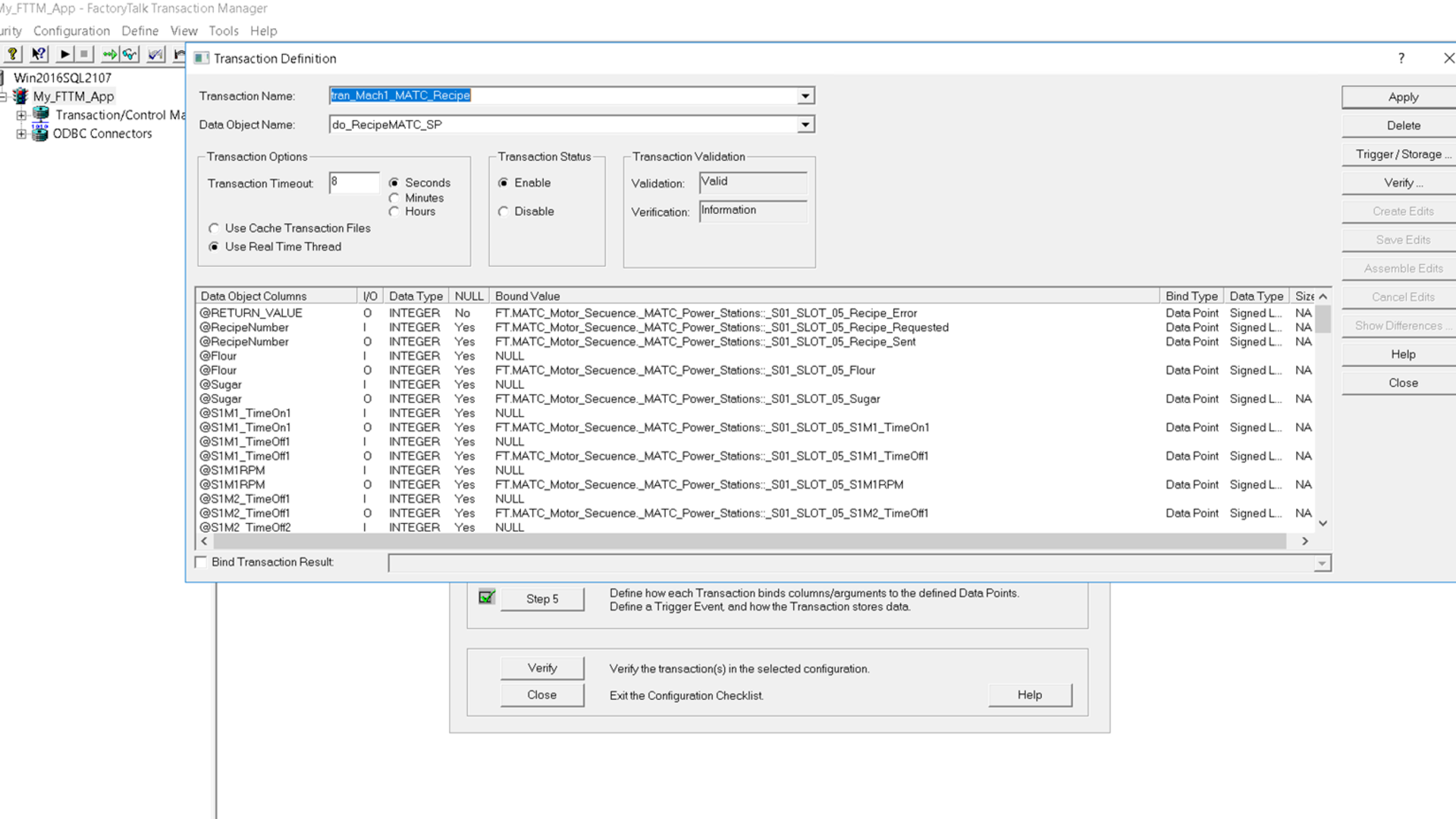

Step 9

Separate the input and output parameters of the variables in step 5 of the FTTM configuration. Assign null values to all input variables for motor control. Apply and save all changes and start the FTTM configuration.

Step 9 - Image 1

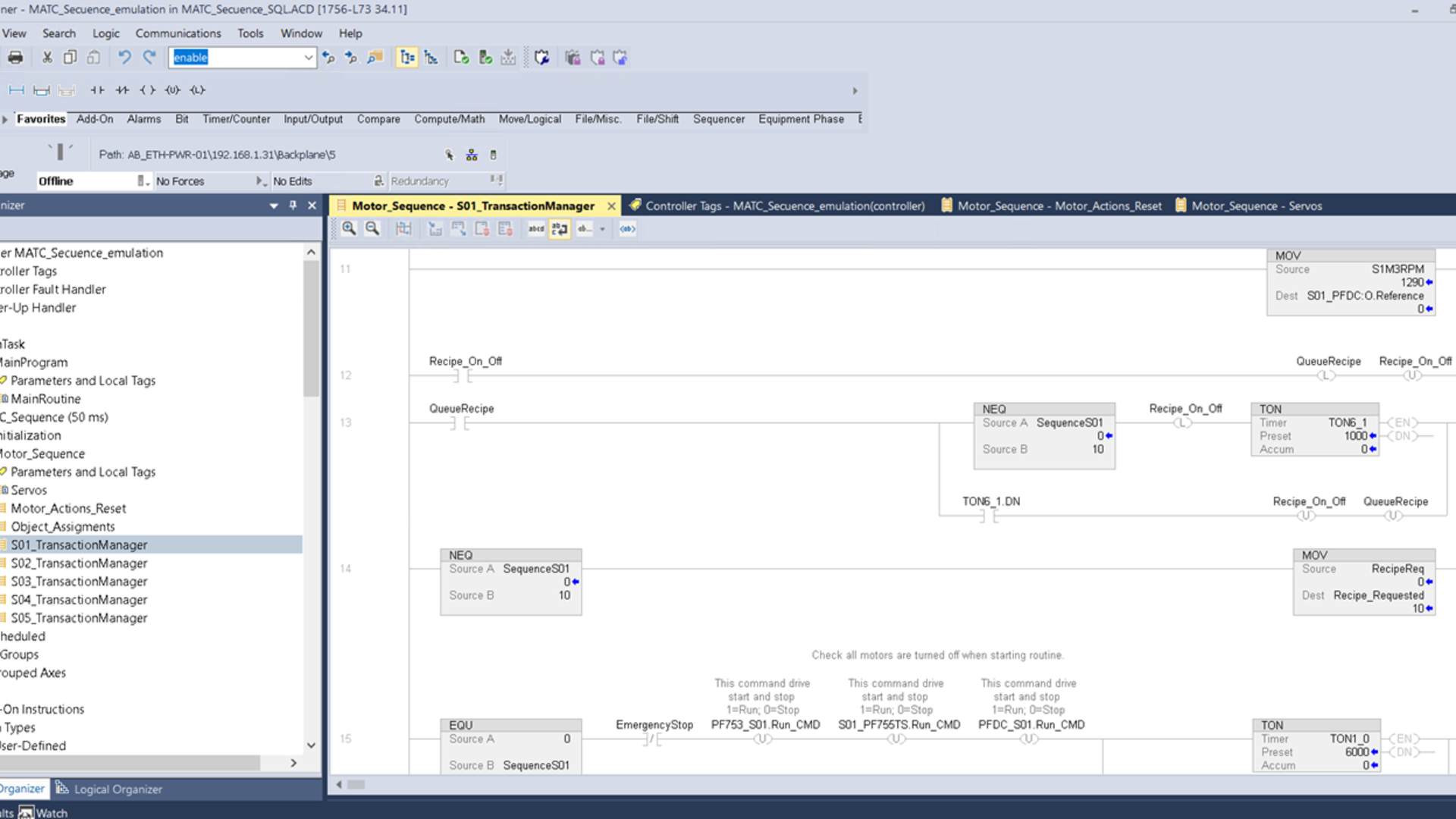

Step 10

Enter the Studio5000 program and test all changes by selecting different recipes. To do this, enter the recipe number in the RecipeReq tag in the S01_TransactionManager program. Then toggle the Recipe_On_Off bit. Validate the process operation by checking the recipe values once the current cycle is completed.

Step 10 - Image 1