Downloads

What is this for?

A winder and unwinder machine are essential in various industries, particularly in the manufacturing and processing of web materials such as paper, film, textiles, rubber, wire, tape, etc.

These machines are used to wind and unwind continuous rolls of material, facilitating efficient production, storage, and transportation.

Winder is designed to wind the web material onto a core or a spool, creating a tightly wound roll.

Unwinder on the other hand, is used to unroll or unwind the material from a roll, feeding it into the downstream processes or applications.

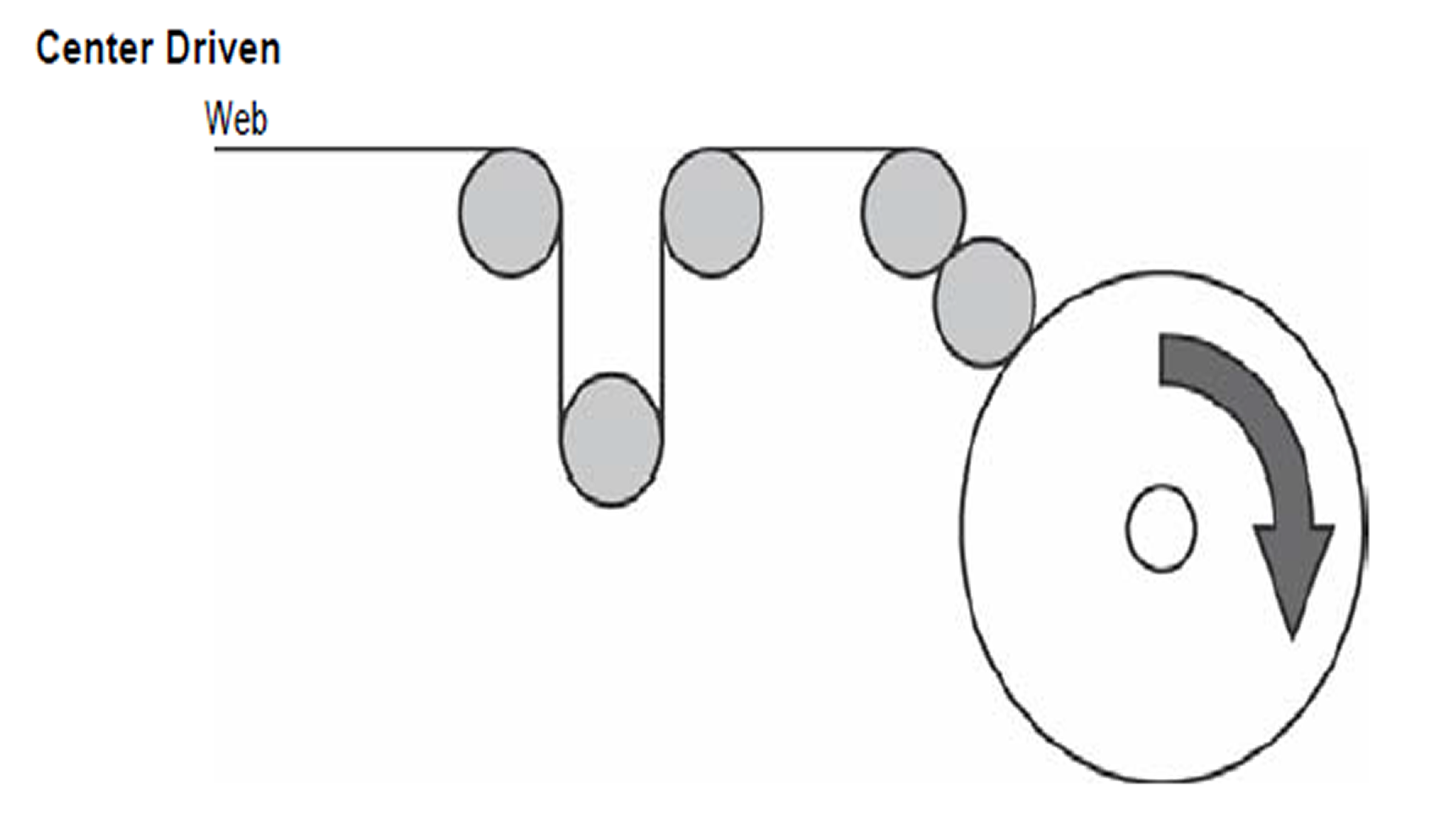

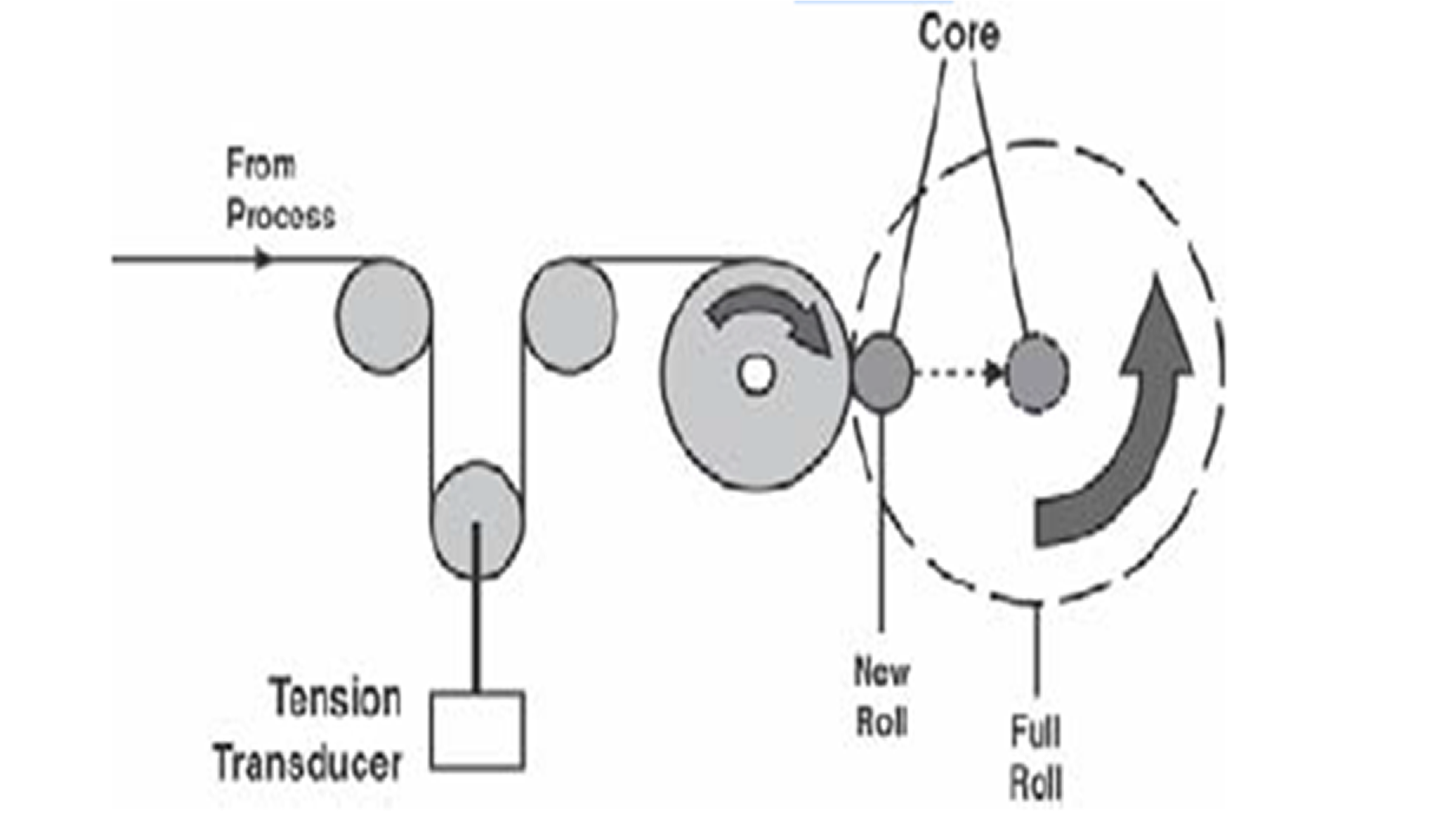

This sample code shows us how to use it in applications with variable diameter spindle based on tension feedback from a load cell, uses Torque Regulator to control web tension of material in center driven.

General Features:

- Center Driven application.

- Torque control for Winder, Unwinder drives.

- Speed Limited Adjustable Torque

- Speed control for the puller drive.

- Speed follows a virtual axis.

- Tension control at line speed.

- Full tension control when accelerate and decelerate.

- Flexible parameters

- Reference speed of machine.

- Acceleration time.

- Deceleration time.

- Roll Unwind tension control.

- Roll Wind tension control.

- Roll length control.

- Roll diameter control.

- Drive status, Alarms and Faults.

Advantages:

The Winders controlling web tension in a center driven has excellent accuracy of torque control for web material.

- Flexible, Predictive Diagnostics, Integrated Safety.• Automatic Device Configuration.

- Integrated Architecture.

- Speed Limited Adjustable Torque.

Limitations / Disadvantages

- Drive for Unwinder and Winder must have torque control.

- Controller must at least 1769-L19 or above.

- Must adapt the application if use Surface Driven.

Is this useful for me?

In general, systems can be recommended to customers, OEM manufacturers,

Use when:

- Controlling web tension in a center driven (un)winder.

- Torque Control to control web tension.

- Tension feedback device is a load cell or a dancer.

Do NOT use when:

- Speed Trim Regulator to control web tension is preferable is over Torque control.

- Drive has no torque control feature.

- Surface driven for Winder or Unwinder. Must adapt the application to calculate it.

Application areas

Web Material, CPW, Converter, Printer, Metals, Plastics

Benefits of application:

- Center driven winders have the benefit of controlling tension via directly controlling the torque of the wound product.

- Tension taper can be applied as the diameter increases.

- Flexible control and production gain and speed.

- Increased dynamism in production.

- Full tension control when accelerate and decelerate machine.

- Automatic Device Configuration, if have any problem with devices. This feature reduces downtime of process.

- Control length of product by tracking material.

- Control Diameter of product if include sensor diameter.

How can I make it work?

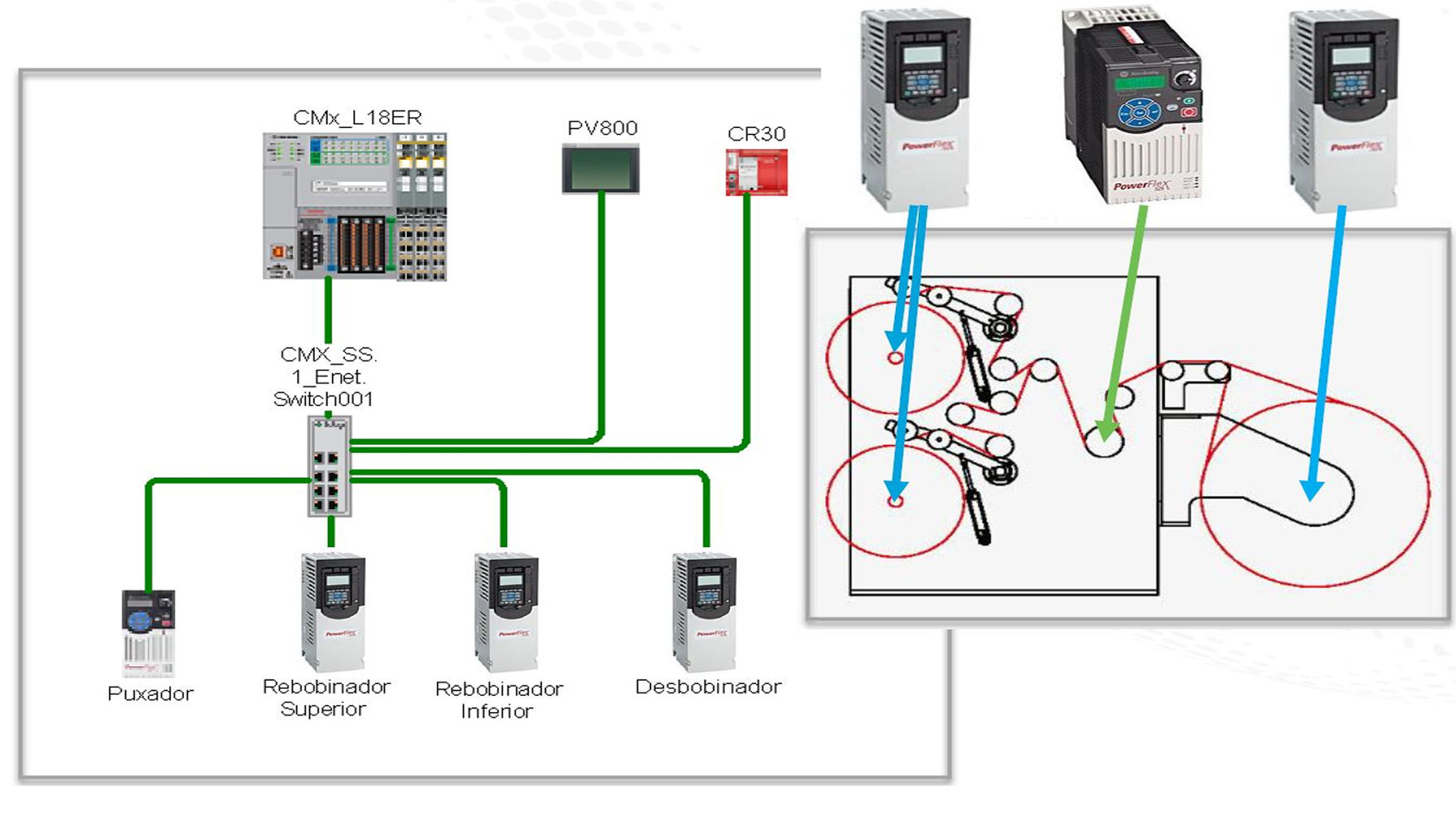

Hardware:

- CompactLogix 1769-L19ER, 5069-L310ER or high

- PowerFlex 753 or PowerFlex 755.

- PowerFlex 525.

- PanelView 800.

- CR30.• Firmware revision 30 or high

Software:

- Logix Design Studio 5000 version 30 or higher.

- Connected Component Workbench, version 21 or higher.

- Winder_Unwinder.ACD.

- WinderUnwinder.ccwarc.

Previous Knowledge

Basic knowledge of programming and configuration in Logix Design Studio 5000 software:

Basic knowledge of programing and configuration in Connected Component Workbench software:

- PowerFlex 525 configuration.

- PowerFlex 753 and PowerFlex755 configuration.

- PanelView 800 configuration.

- CR30 configuration.

- Ladder language (LD), Function Block Diagram (FBD)

Knowledge about Drive System, Speed, Torque, Position Control.

Please note: You will need to agree to the Terms & Conditions for each download.

Need help?

If you need help with an application or have feedback from the Innovation Center, please contact us.

Installation Guide

Step 1

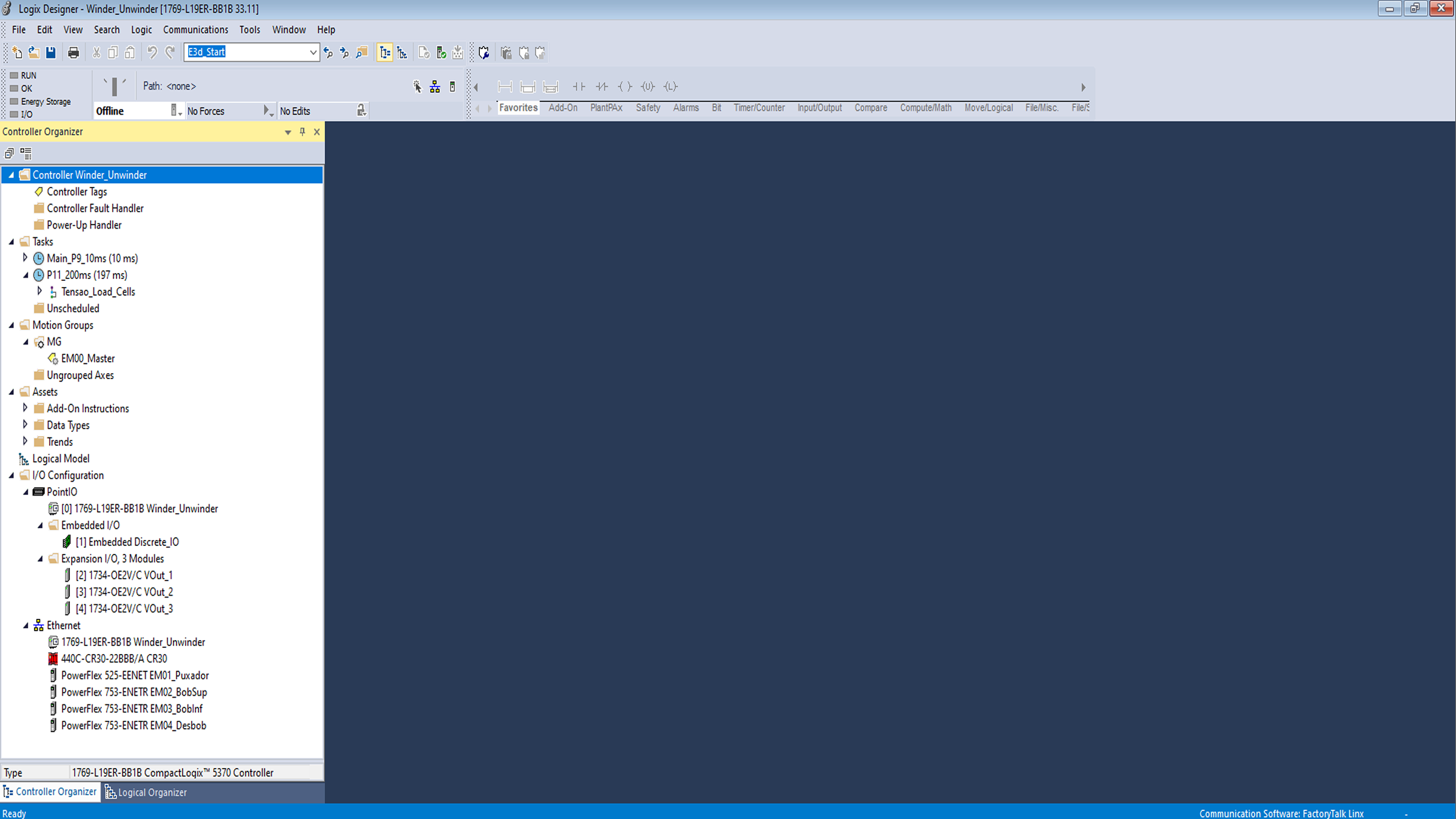

1. Open program Winder_Unwinder.ACD – This file is located on Generalfiles.

Step 1 - Image 1

Step 2

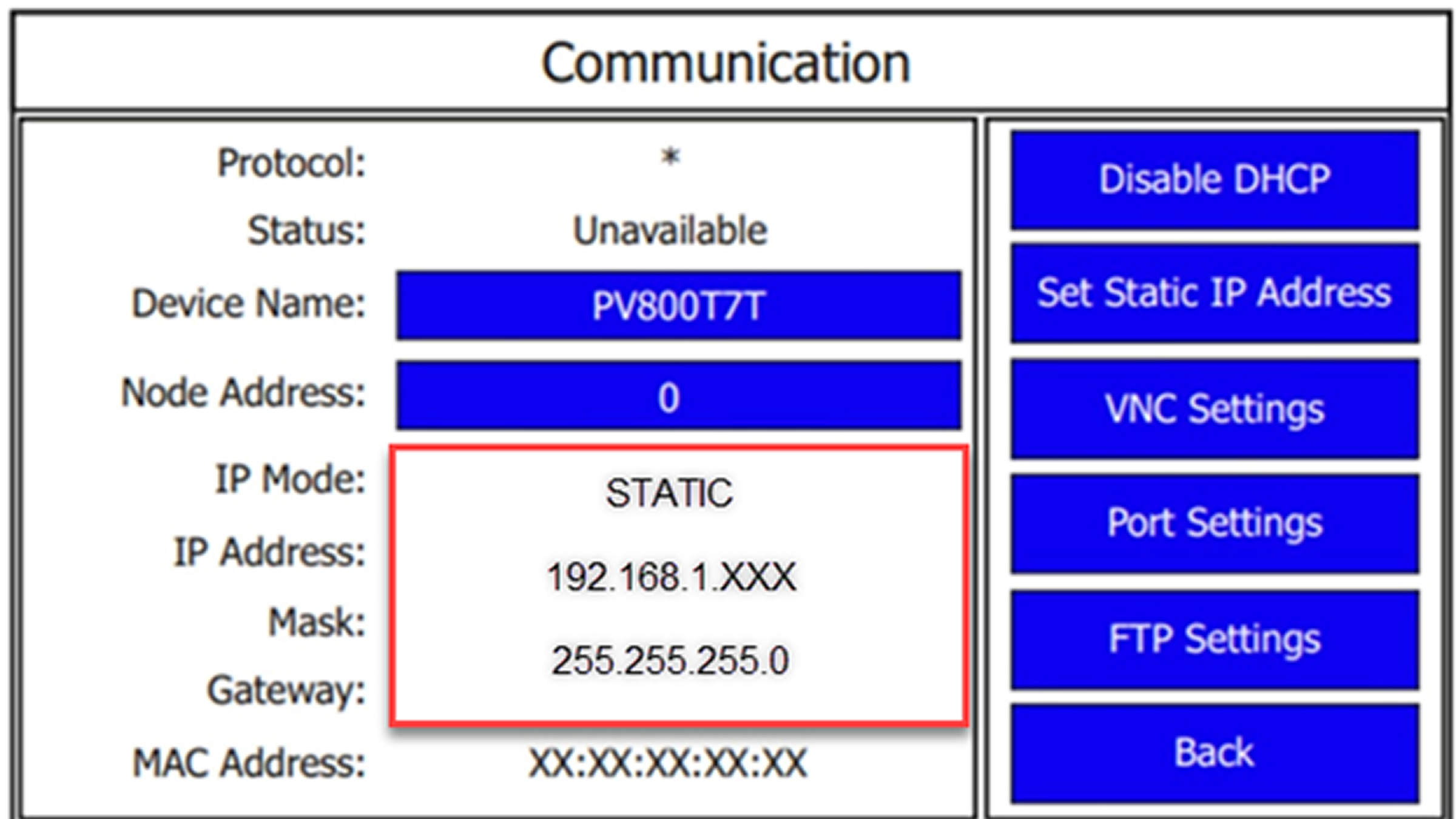

Assign static IP address and last firmware version for all components of the architecture.

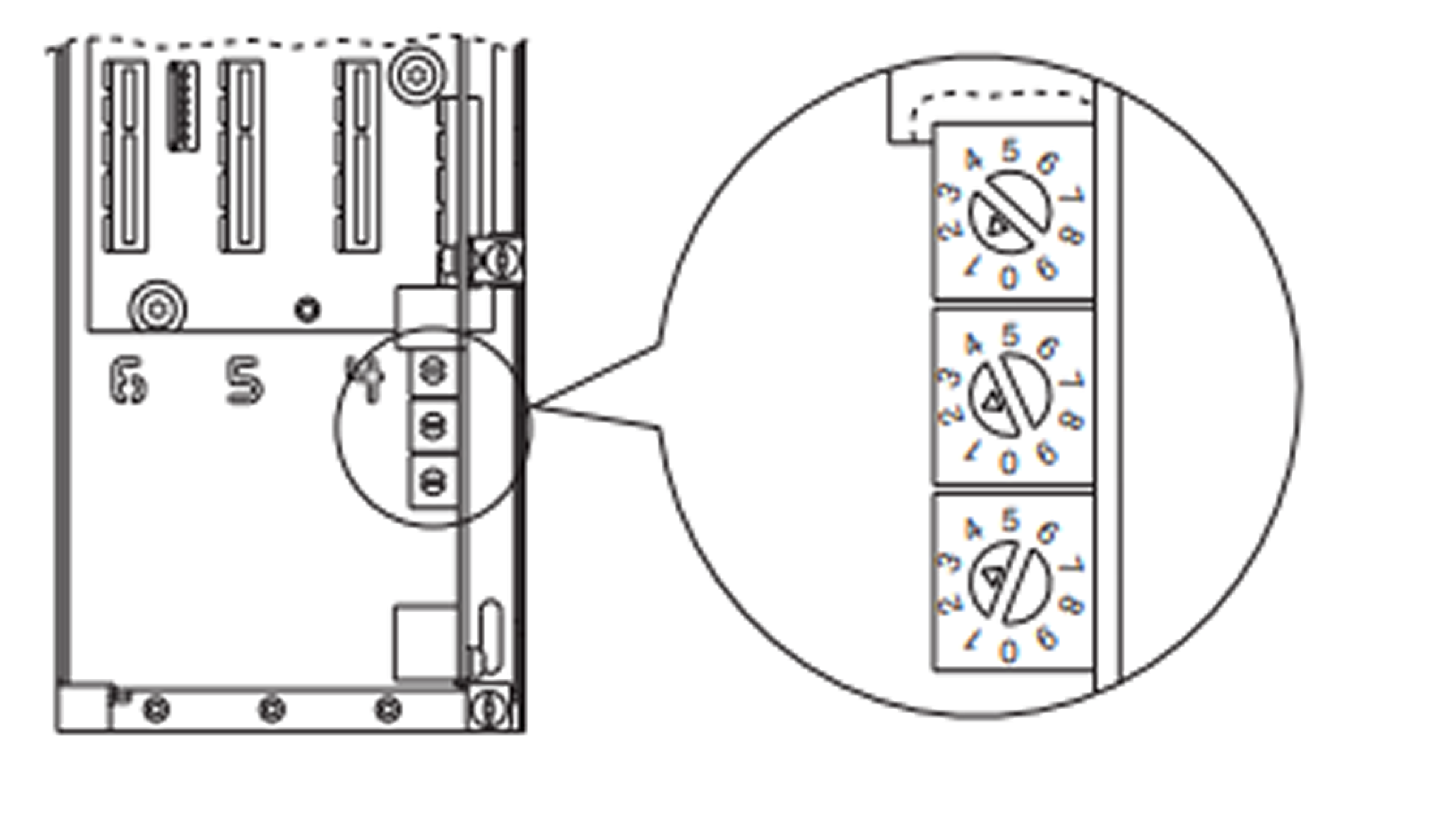

CR30

https://rockwellautomation.custhelp.com/app/answers/answer_view/a_id/702836/loc/en_US

https://literature.rockwellautomation.com/idc/groups/literature/documents/um/440c-um001_-en-p.pdf#page=106

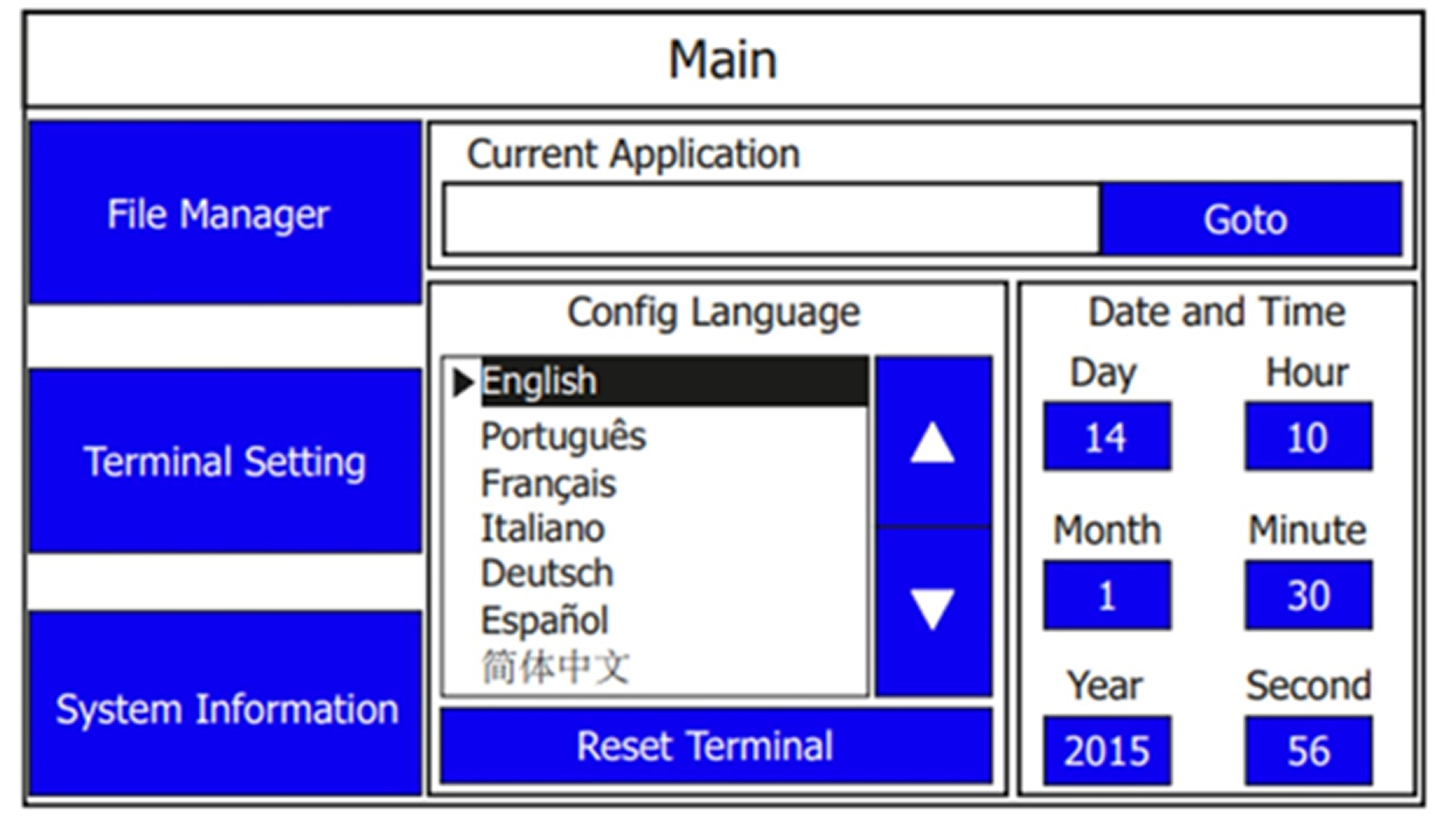

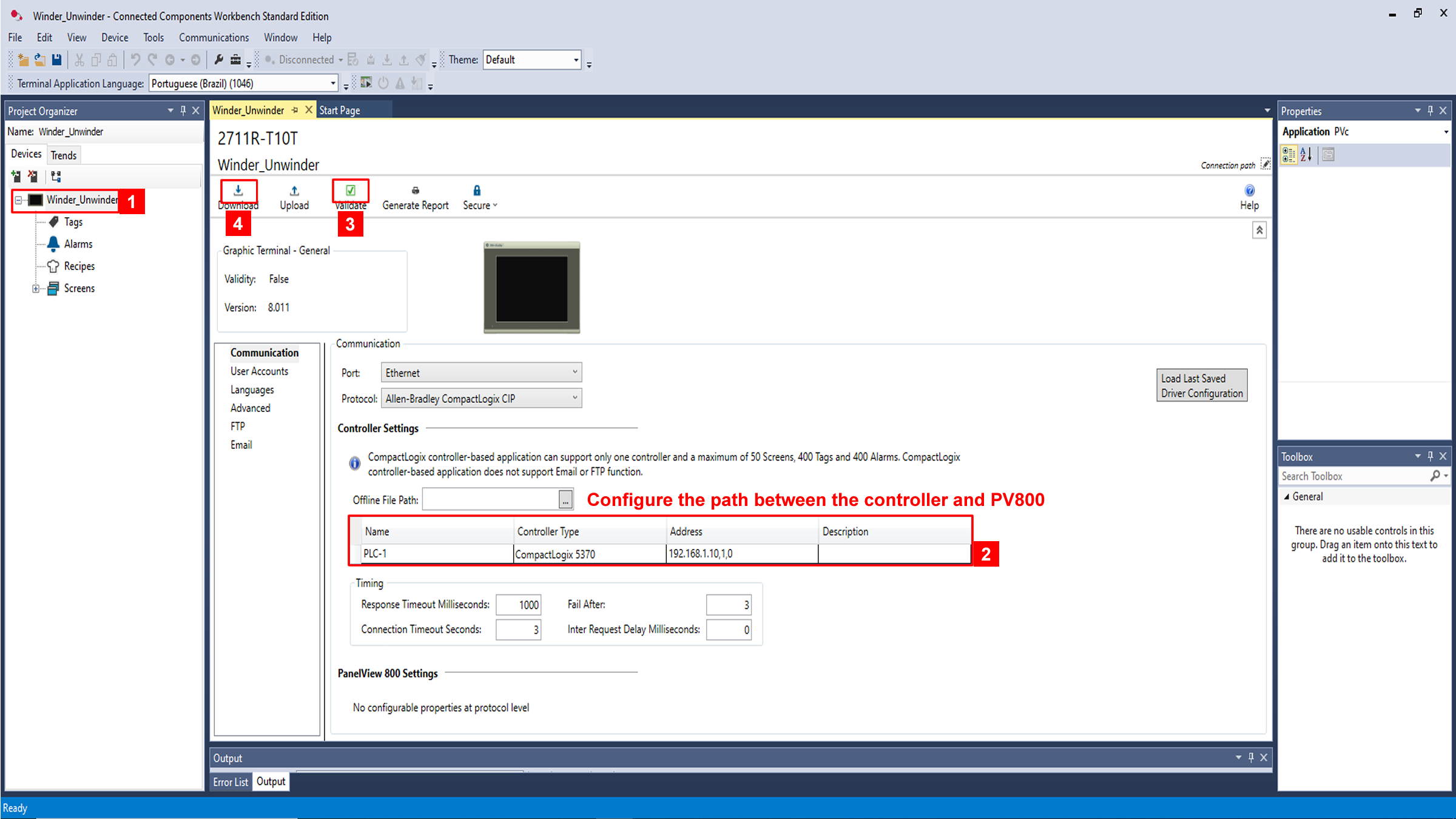

PanelView 800

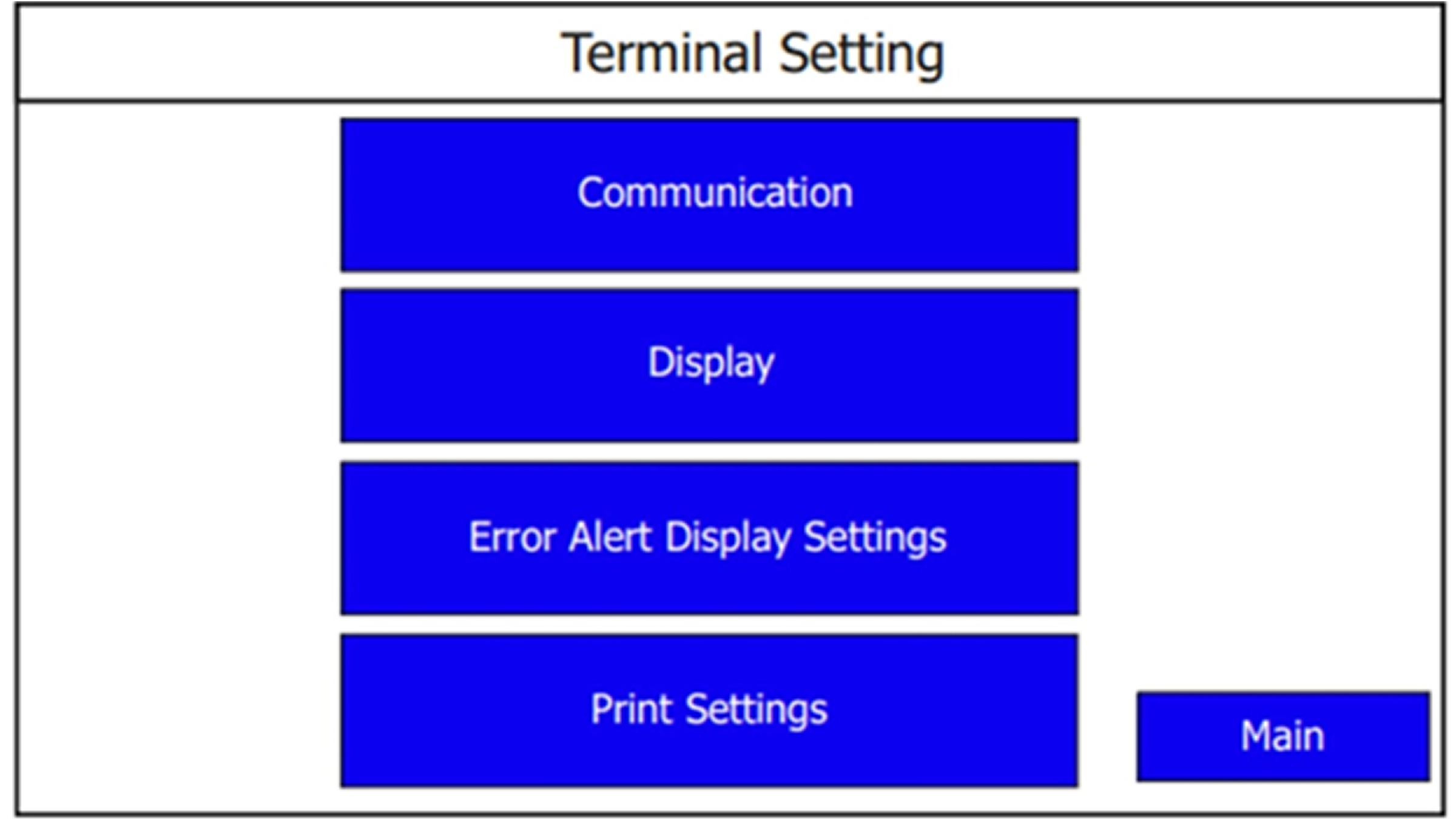

1.1 Communication Settings, Configure PanelView 800: Go to the main configuration screen.

1.2 Press terminal settings.

1.3 Press Communication.

Step 3

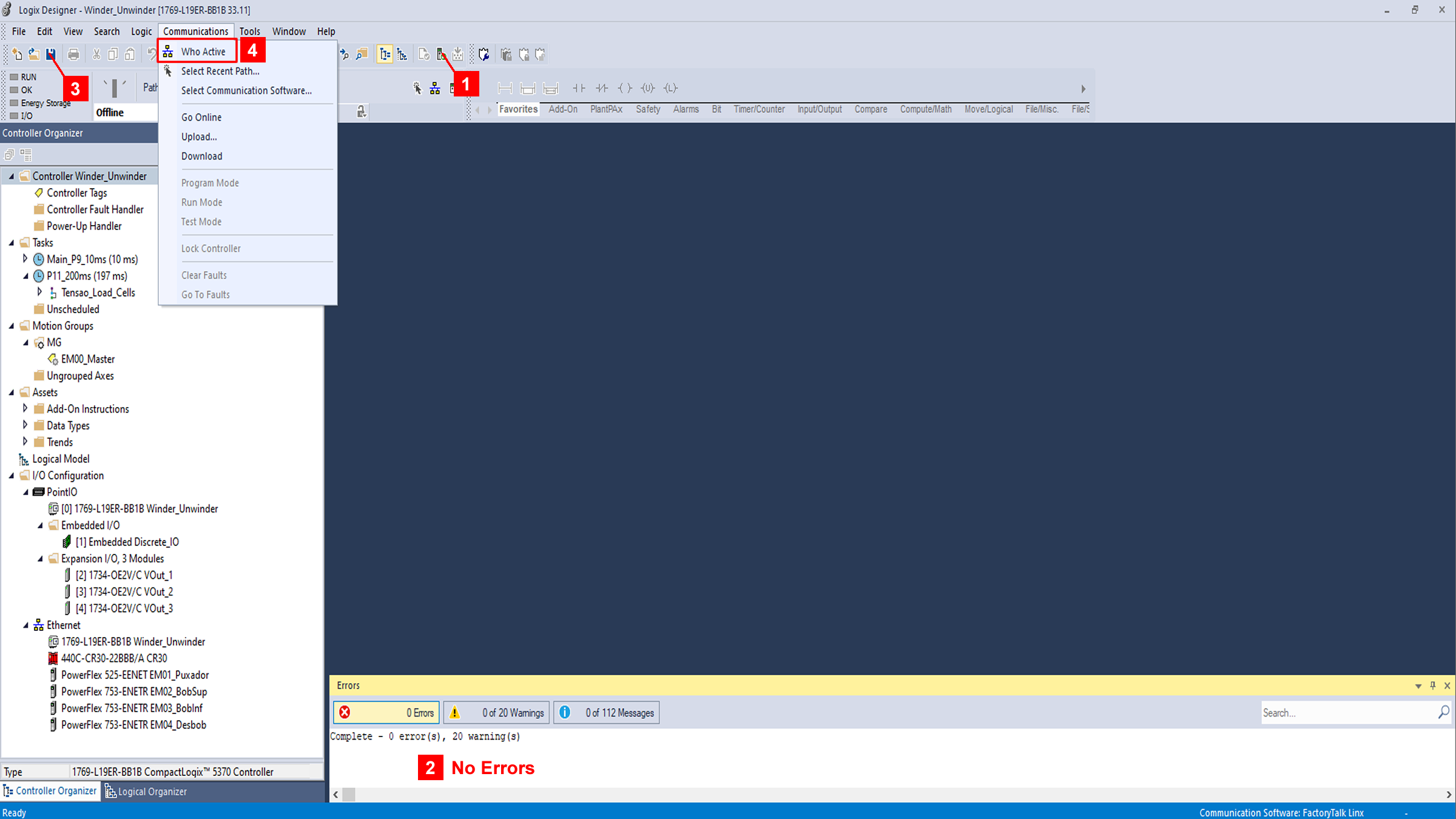

Download application for controller.

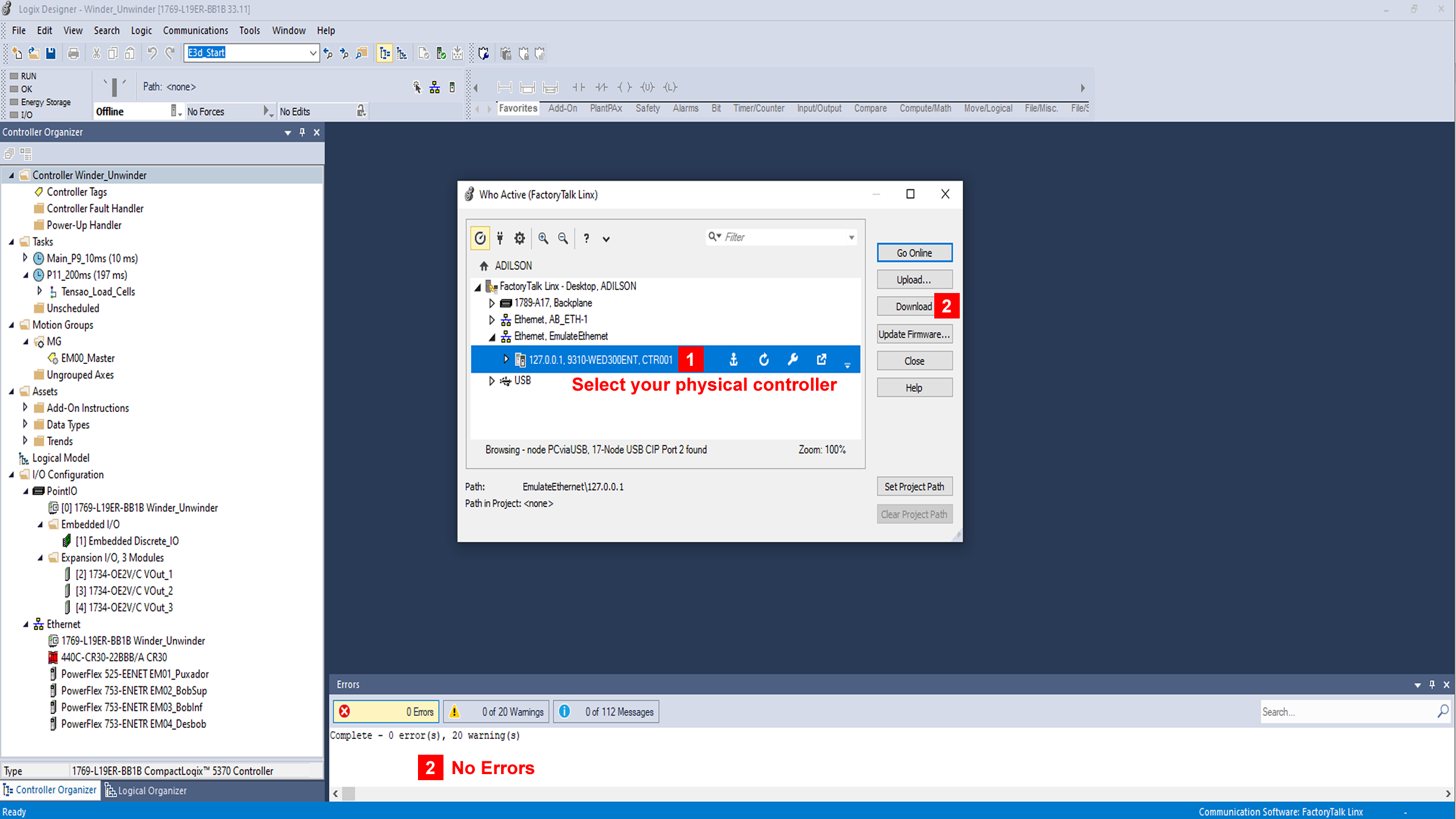

- From the Communications menu, choose Who Active to open the Who Active dialog box.

- From the navigation pane, find the path between your Workstation and the target Logix controller for this project.

- Click Download to open the Download dialog box.

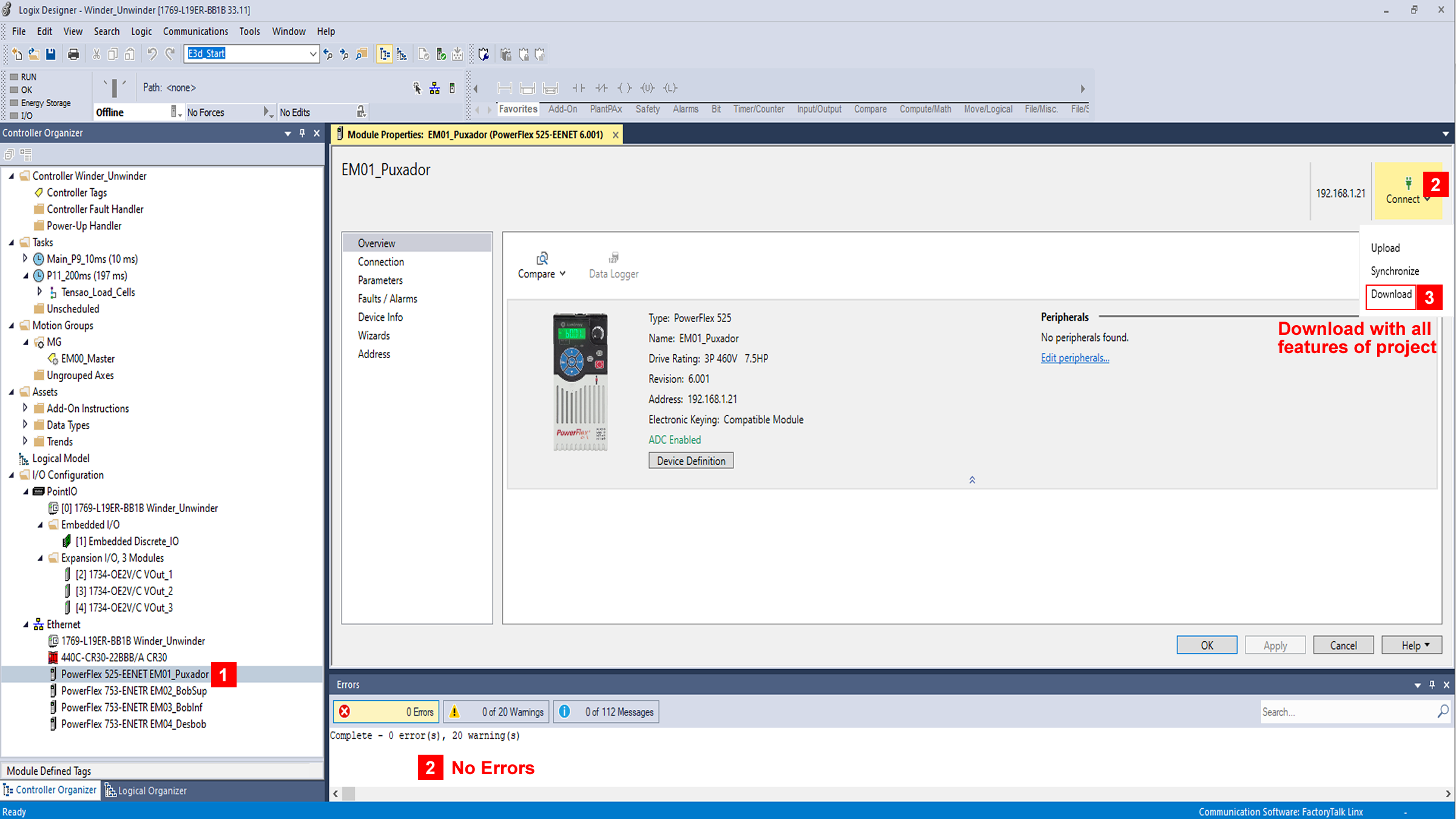

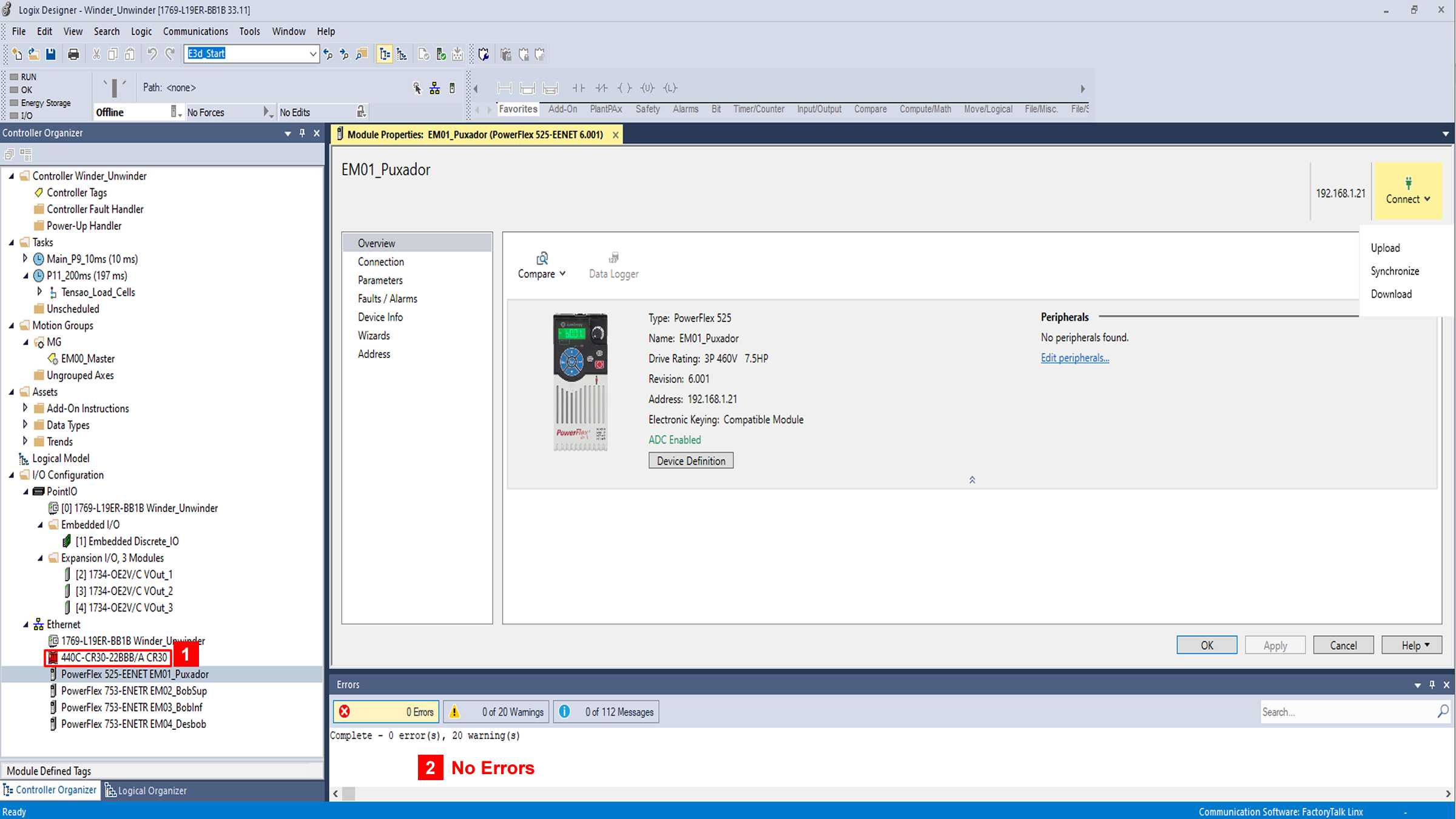

Step 4

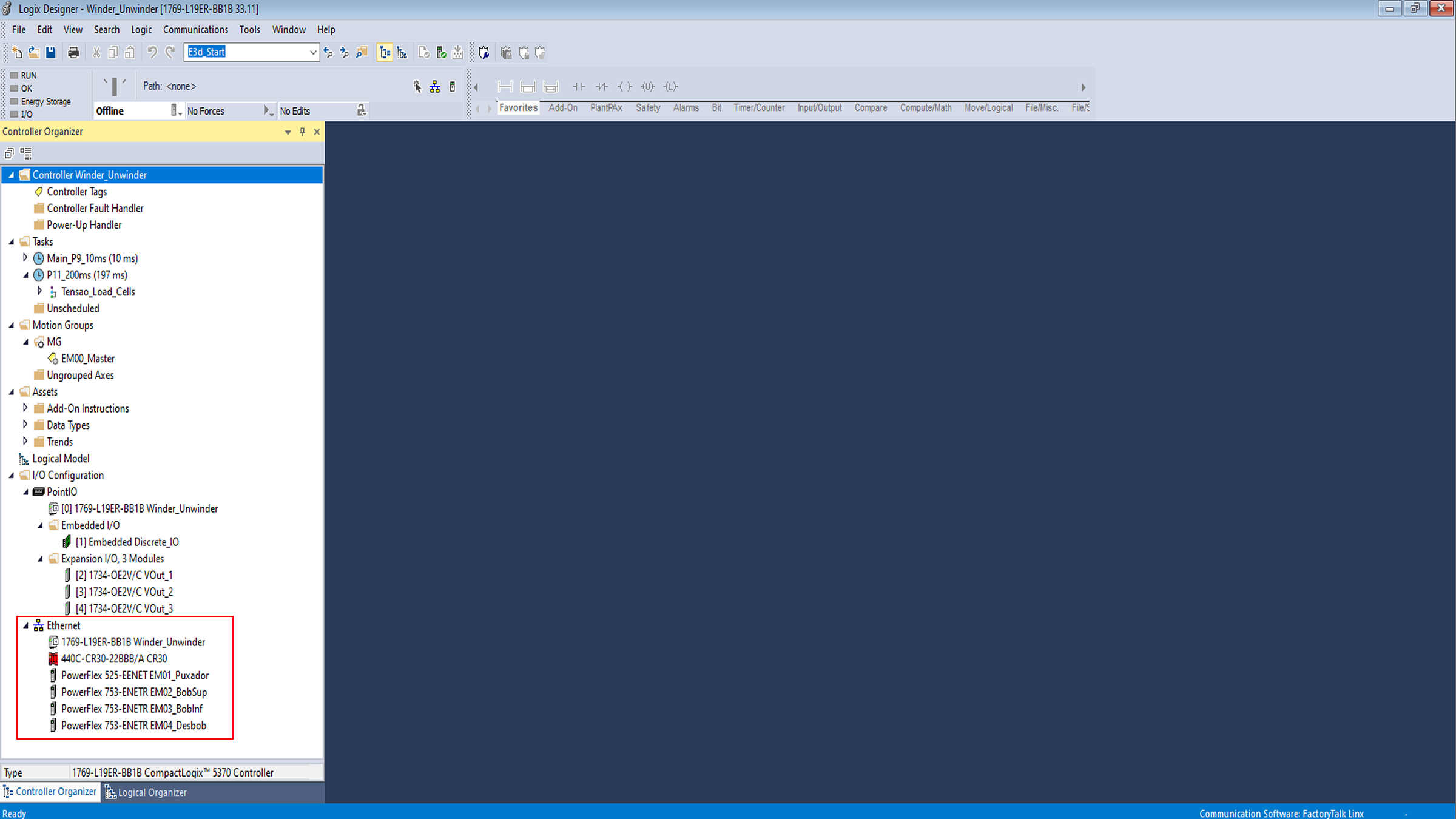

Repeat this step, for another PowerFlex 75x drives.

Step 4 - Image 1

Step 5

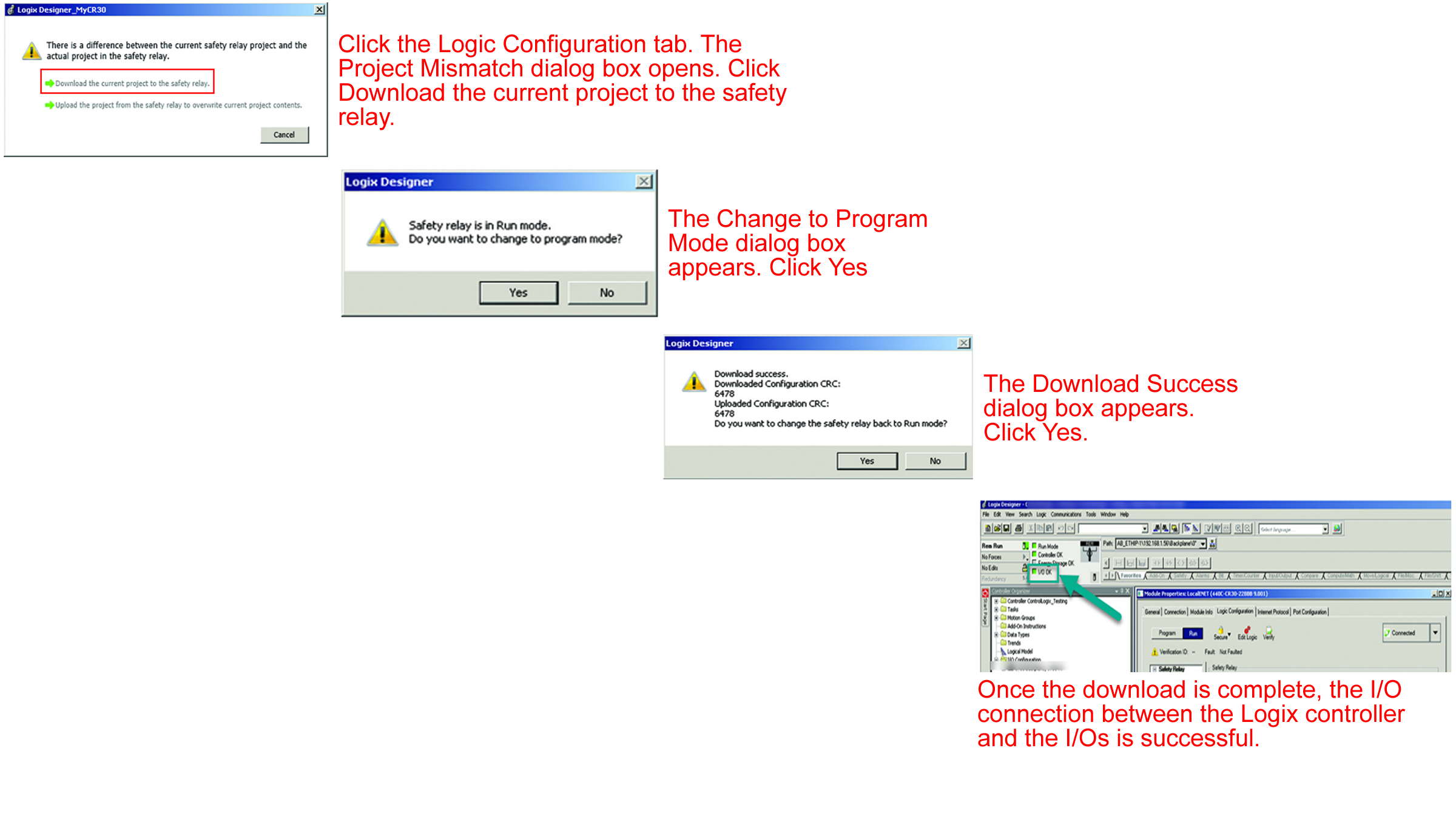

Download application for CR30

After the download is complete, the I/O Not Responding indicator flashes.

A warning icon appears on the CR30 safety relay in the I/O Configuration tree.

The module fault is Code 16#0106 as the configuration in the Logix controller for the safety relay CR30 does not match what is in the physical device.

- Double-click the safety relay profile.

- Click the Logic Configuration tab. The Project Mismatch dialog box opens. Click Download the current project to the safety relay.

- The Change to Program Mode dialog box appears. Click Yes

- The Download Success dialog box appears. Click Yes.

- Once the download is complete, the I/O connection between the Logix controller and the I/Os is successful.

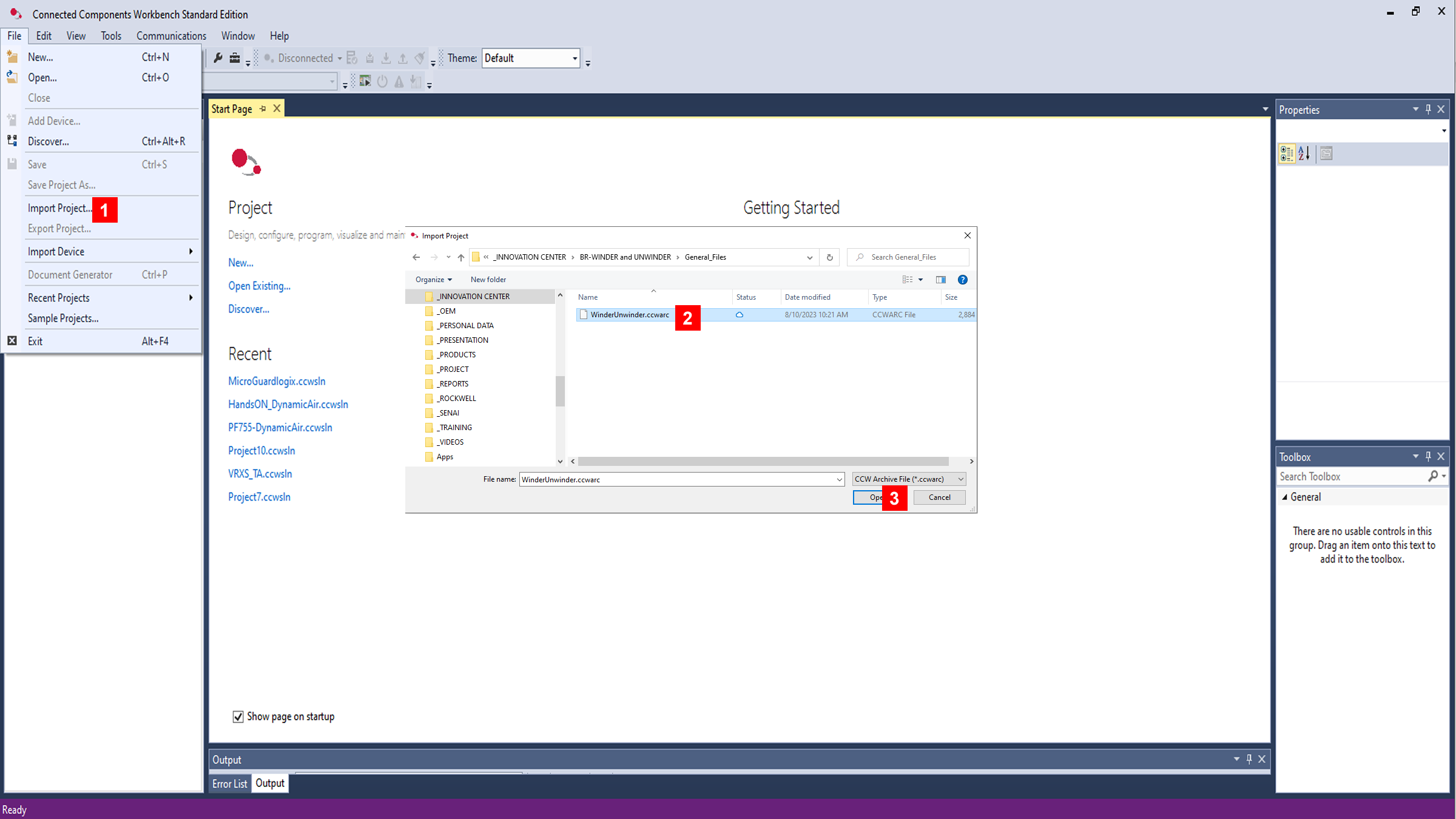

Step 6

Open and Download for PanelView 800 the HMI application.

- Open program Connect Components Workbench - CCW

- Open program WinderUnwinder.ccwarc – This file is located on Generalfiles.zip.

- Download the application to the PanelView 800 and execute it.

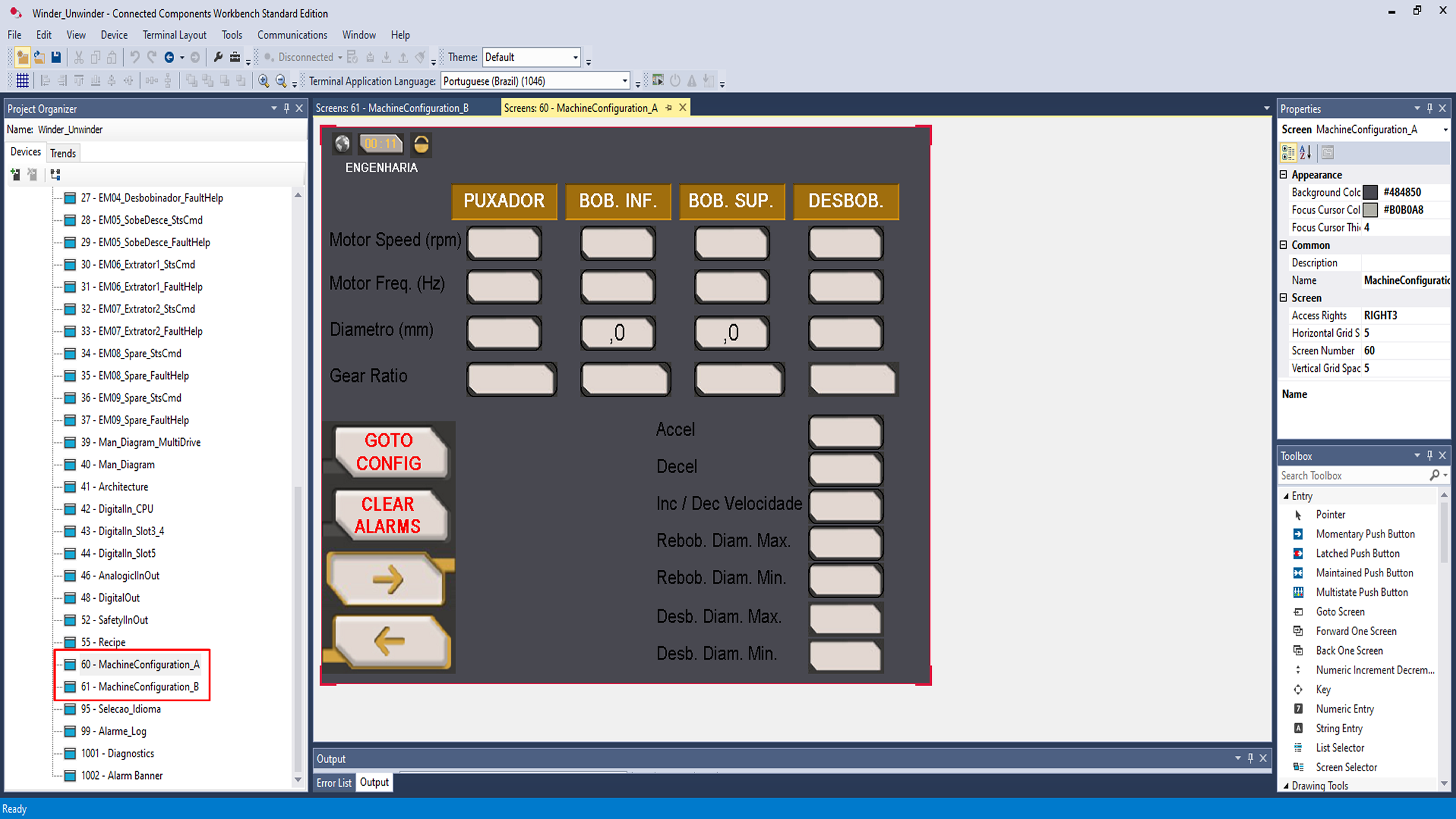

Step 7

Configure the application according to your respective project.

For all drives, you must configure:

- Motor Speed (rpm).

- Motor Frequency (Hz).

- Roll Diameter (mm).

- Gear ratio

When the PanelView 800 is running you have this screen to configure all these parameters: