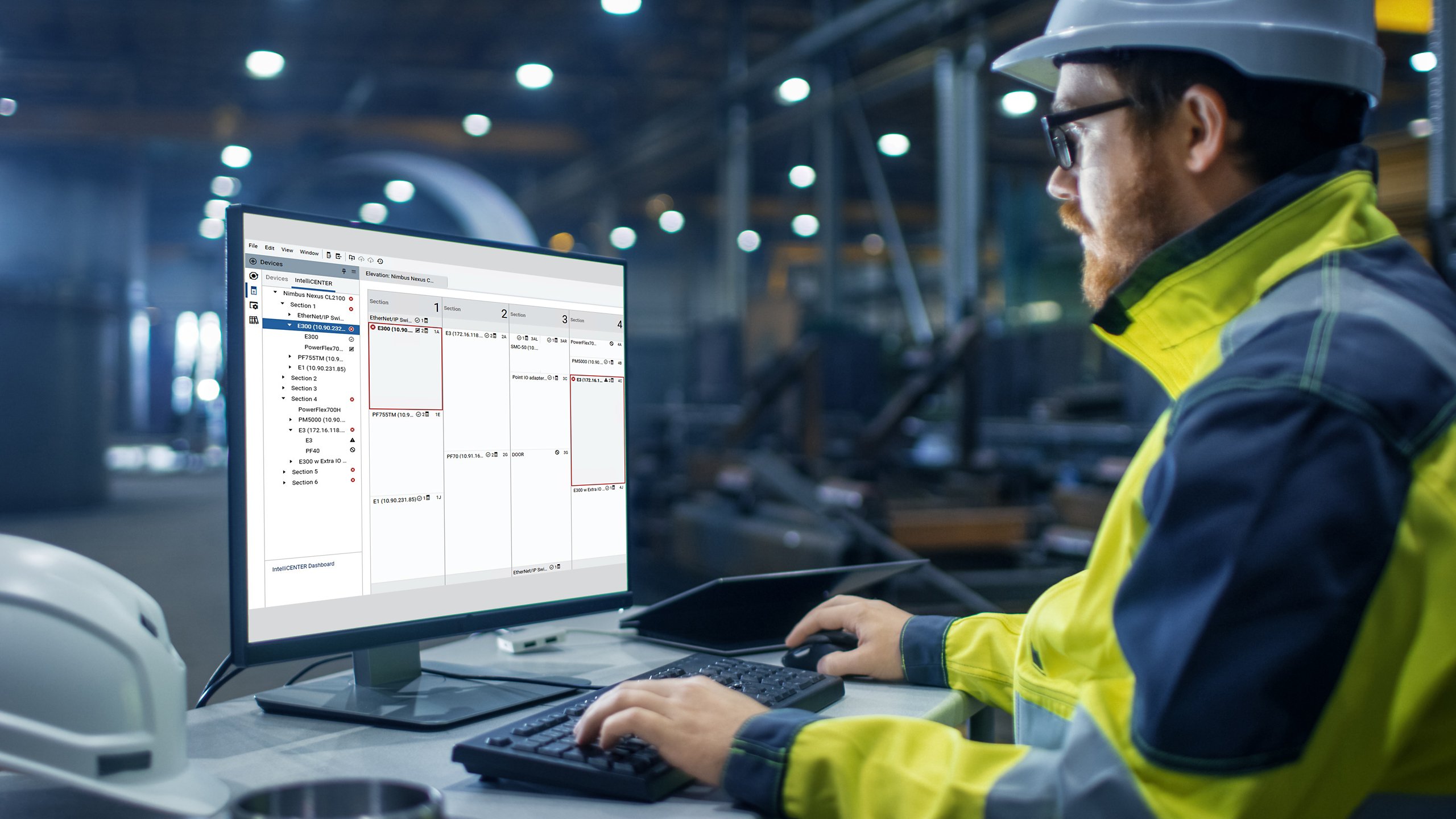

Industries turn to smart motor control technology

Dynamic market conditions, technology limitations and margin pressures are driving organizations to look for smarter equipment and connected operations.

Industrial automation technology from Rockwell Automation is leading the way. Twenty percent of manufacturers are using smart manufacturing at scale, over 55% are piloting smart manufacturing and 20% are planning investments. See how pivoting to a smart motor control center delivers the return on investment your plant needs…