Rockwell Automation Opens Registration for Automation Fair 2025

34th annual event attracts industrial operations professionals from around the globe to connect, collaborate and create

Rockwell Automation Opens Registration for Automation Fair 2025

34th annual event attracts industrial operations professionals from around the globe to connect, collaborate and create

Registration is now open for Automation Fair® 2025, returning to McCormick Place in Chicago from November 17-20. More than 10,000 professionals from across the world will come together for four immersive days packed with insight, innovation and hands-on discovery.

This global event sets the stage for what's next in industrial operations. It's where groundbreaking technologies make their debut, where never-before-seen innovations are unveiled and where fresh thinking emerges - sometimes even before they're on the roadmap. Major product reveals and meaningful connections all come together to drive real breakthroughs.

Step onto the expo floor and explore more than 140 exhibits featuring live demos and working applications. Take a guided tour and catch a session at the Discovery Theater. Hear big ideas and fresh perspectives in the half-day summits built around today’s most relevant topics. Attend the daily keynotes to hear what’s next from leaders shaping the future of industrial operations.

More on the event here.

94% of APAC Manufacturers Investing in AI to Navigate Uncertainty and Drive Smart Manufacturing

10th annual global report reveals how the convergence of people and technology is transforming operations and strengthening industrial resilience.

Rockwell Automation announced the results of the 10th annual “State of Smart Manufacturing Report”. The global study, fielded in March 2025, surveyed more than 1,500 manufacturers across 17 of the leading manufacturing countries, including China, Japan, India, South Korea, Australia and New Zealand.

As manufacturers continue to face uncertainty driven by economic shifts, the report highlights how companies are turning to smart manufacturing technologies to manage risks, improve performance, and support their workforce. It also examines adoption of emerging technology, including artificial intelligence (AI), machine learning (ML), and cloud-based systems.

“We’re seeing strong momentum across Asia Pacific in adopting AI and smart manufacturing technologies, not just as buzzwords but as mission-critical capabilities to drive quality, agility and growth,” said Scott Wooldridge, Regional President, Asia Pacific, Rockwell Automation. “What stands out this year is the region’s tech-first mindset, with nearly half of the manufacturers already scaling AI to address workforce gaps, cybersecurity risks, and evolving sustainability targets. The focus has clearly shifted from experimentation to execution.”

More results here.

AI Adoption Surges in Life Sciences Manufacturing as Talent, Risk, and Quality Pressures Intensify

Global survey reveals how manufacturers are adopting advanced technologies to stay competitive and meet rising patient demands amid economic uncertainty.

Rockwell Automation announced the results of the 10th annual “State of Smart Manufacturing Report: Life Sciences Edition.” The global study encompasses the responses of 143 leaders from life sciences manufacturers across 15 of the leading manufacturing countries.

Life sciences manufacturers are working to keep up with growing demand, rising costs, growing cybersecurity threats, and complex compliance requirements, all while navigating economic uncertainty and ongoing workforce challenges. Many are turning to advanced technologies to help them become more agile and adapt to constant change.

Smart manufacturing is a clear area of focus with 95% of life sciences manufacturers saying they are using or evaluating smart technology. Specifically, companies are using artificial intelligence (AI) to help improve product quality, protect systems and support employees where skilled labor is hard to find. Leaders are also thinking beyond quick wins and investing in technologies that will help them expand capacity and build more secure operations over time.

More results here.

Automotive Industry Shifts Gears as Talent and Technology Take Center Stage

Report shows manufacturers are leaning into AI, upskilling and innovation to overcome workforce and operational challenges.

Rockwell Automation announced the results of the 10th annual “State of Smart Manufacturing Report: Automotive Edition.” The global study encompasses the responses of 130 leaders across automotive and tire manufacturers, original equipment manufacturers, engineering procurement companies and systems integrators across 15 countries, revealing a sector rapidly embracing change to stay competitive.

Rockwell Automation report shows manufacturers are leaning into AI, upskilling and innovation to overcome workforce and operational challenges.

Workforce pressures have emerged as the most urgent challenge for automotive companies, signaling a significant shift from last year’s findings. At the same time, concerns around cybersecurity have declined, suggesting many manufacturers have made progress in securing their digital environments.

More results here.

Nukon Adds Plex Cloud-Based Smart Manufacturing Platform to its Digital Solutions

Plex is a cloud-based smart manufacturing platform that empowers manufacturers to boost efficiency, streamline operations, and scale with confidence.

Nukon, a SAGE Group company, is now an Australian reseller and implementer of the Plex cloud-based smart manufacturing platform. Previously the Plex platform was only sold and implemented in Australia directly by Rockwell Automation.

The Plex smart manufacturing platform aligns specific industry needs, eliminating information silos, digitizing the supply chain, automating processes, enabling tracking from almost anywhere over any device, and producing actionable data.

Plex ERP adds a deeper layer of connected enterprise visibility for monitoring assets and plant-level performance. Included is a fully integrated, flexible, configurable MES, which standardizes operations and ensures that every change from the top floor is effortlessly dispatched to the shop floor, with no disruption to workflow.

Learn more here.

Rockwell Automation Advances Sustainability Through Smart Manufacturing

As part of its global mission to achieve carbon neutrality by 2023 (scope 1 and scope 2 emissions), Rockwell Automation recognizes the need for a structured and data-driven approach to energy optimization. The company’s Asia Pacific Business Center (APBC), a manufacturing facility based in Singapore, partnered with Kalypso, Rockwell’s digital consulting services team, to implement a structured transformation roadmap to meet its sustainability goals and align with local government climate targets.

“Manufacturers today face increasing pressure to balance production efficiency with sustainability goals,” said Ferdi Aksoy, senior director, Asia Pacific operations. “However, many industrial facilities lack the necessary digital tools to analyze energy consumption, predict inefficiencies, and implement corrective measures. Our facility in Singapore aimed to bridge this gap by developing a scalable strategy that could drive tangible energy savings while supporting long-term decarbonization efforts.”

Learn more here.

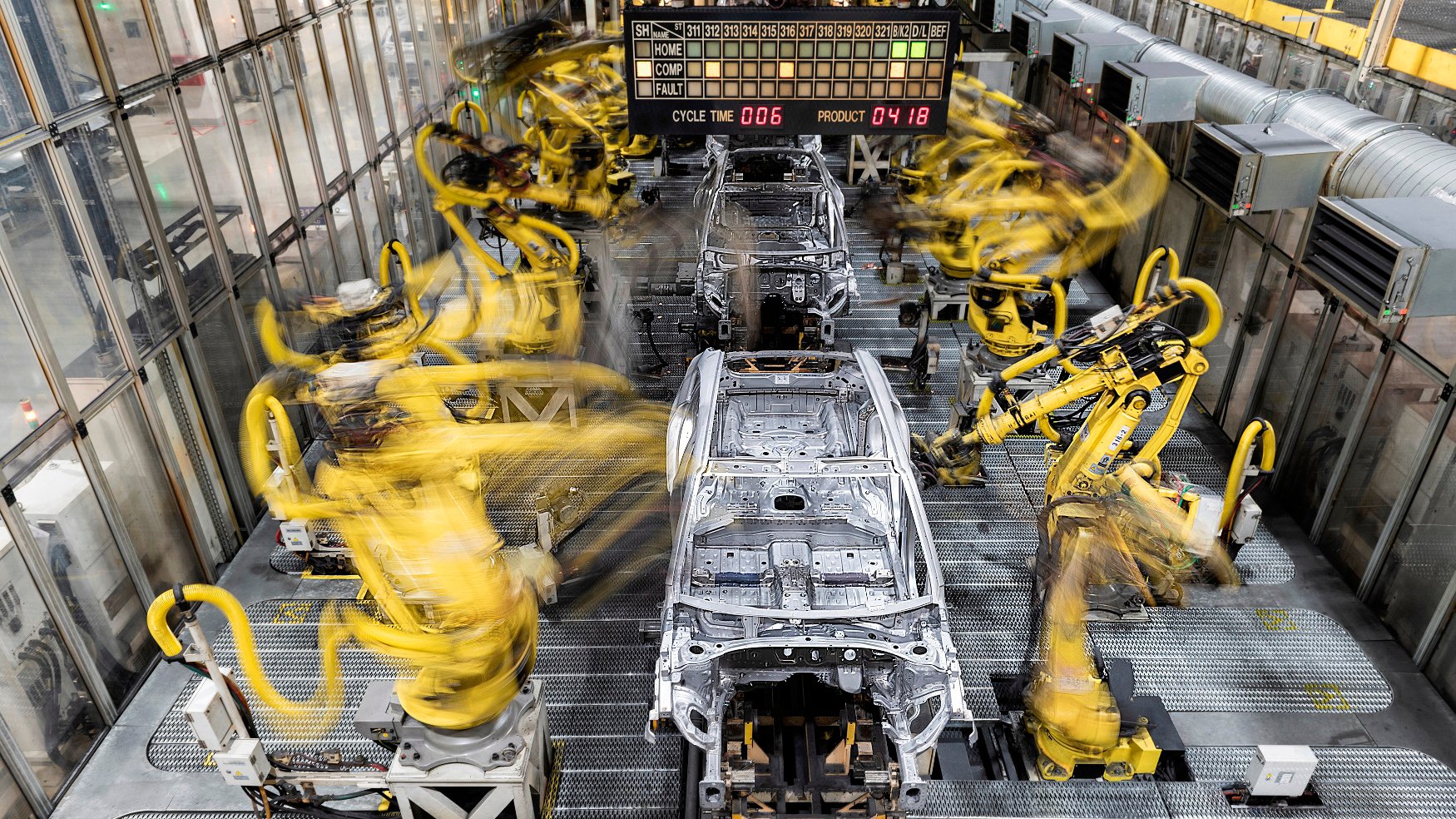

Kia Slovakia boosts production line resilience, uptime, and digital capabilities through motion solution modernization

Important equipment upgrade streamlines programing, component changeovers, software migration, and version management using the latest Kinetix servo technology from Rockwell Automation

Rockwell Automation announced that Kia Slovakia is to upgrade elements of its body shop through the deployment of the latest servo technologies from Rockwell Automation.

The body shop lifters use servo motors and drives to elevate and orient primary car body components during the manufacture of Kia’s Ceed and Sportage models. The lifter’s existing servo solution was identified by Kia engineers as approaching end-of-life, so the system will undergo replacement over the summer shutdown. Through this modernization program, the body shop not only benefits from greater uptime-related resilience, but also the added capabilities delivered by modern digitalized hardware running contemporary communication networks.

“End-of-life and obsolete components elevate risk levels and the possibility of downtime in any manufacturing operation,” said Mark Bottomley, regional vice president, strategic accounts and sales specialists, EMEA at Rockwell Automation. “But in lean, just-in-time environments, such as automotive, this downtime can have a significant and costly impact on the critical path. Users of legacy equipment also miss out on the many benefits delivered by digitally capable hardware. For this reason, we offer a comprehensive modernization program that helps companies leverage the benefits of digital transformation.”

Learn more here.

Rockwell Automation Appoints Innovation-Focused Leader Adrian Giecco as Regional Director, South Pacific

Rockwell Automation has announced the appointment of Adrian Giecco as regional director, South Pacific, effective July 1, 2025.

Adrian will take over the role from Anthony Wong, who was recently promoted to vice president – enterprise software sales and consulting services – Asia Pacific, for Rockwell Automation.

“I’m thrilled to be returning to the region at such a pivotal moment for manufacturers and producers,” said Giecco. “Rockwell is well positioned to unlock new value through our innovations, deep domain expertise, and strong partner ecosystem. I’m excited to lead this incredible team, strengthen existing relationships, and explore new partnerships as we help shape the future of industrial operations,” he said.

Learn more here.

Rockwell Automation Increases Network Performance with Simple-to-Use Industrial Ethernet Switch

The Allen‑Bradley Stratix 2100 Unmanaged Industrial Ethernet Switch provides a compact solution for network reliability, stability, and security.

The Allen‑Bradley® Stratix® 2100 Unmanaged Industrial Ethernet Switch reduces the complexity of network deployments and delivery with its simple dip-switch settings and easy-to-install functionality.

This small form-factor device improves network reliability that best meets overall network system design and application requirements. End users will also benefit from reduced training needs, improved first time fix rates, and lower maintenance costs from the Stratix® 2100.

Offering gigabit speeds, Quality of Service, Energy-Efficient Ethernet, industrial-grade enclosure, and an extended temperature rating as a standard offering, the Stratix® 2100 helps protect against unwanted network traffic, prioritizing data as needed, while providing increased reliability and network security.

Rockwell Automation Introduces PointMax I/O to Empower Flexible Industrial System Design and Reduce Operational Complexity

New I/O solution gives manufacturers greater design freedom to build smarter, more adaptable machines.

Rockwell Automation announced the release of PointMax™ I/O, a flexible remote input/output (I/O) system designed to help manufacturers tackle the growing complexity of modern industrial operations.

As manufacturing environments become increasingly dynamic and interconnected, the ability to quickly adapt system architectures is more important than ever. Traditional I/O systems, which rely on extensive wiring and large control cabinets, are becoming harder to scale and maintain as production demands grow and equipment footprints shrink. To keep pace, manufacturers need flexible and efficient solutions that allow for design flexibility without adding unnecessary complexity.

PointMax I/O was built to address the real-world constraints manufacturers face on the plant floor. Its modular design supports scalable and easily reconfigurable I/O deployments—freeing engineers from the constraints of rigid, centralized control systems. For both new machine builds and existing equipment, PointMax I/O delivers the flexibility today’s fast-paced manufacturing operations demand.

Learn more here.

Rockwell Automation Helps Customers Unlock Potential of Their Data with Launch of OptixEdge

Advanced edge gateway solution transforms the way data is processed, enabling time and cost savings.

Rockwell Automation announced the global launch of OptixEdge, an innovative edge gateway solution that revolutionizes data processing for industrial customers.

Today’s smart machines are generating more data than ever, but according to Rockwell’s latest State of Smart Manufacturing Report, only 44% of data is being used effectively. Many companies face challenges that prevent them from utilizing a vast amount of their data, such as network limitations, security concerns, or storage costs. Traditionally, data is sent to distant cloud servers to be processed, but this can be expensive and inefficient.

OptixEdge can directly address these issues by processing information where it’s created – at the machine, in real time. It connects to the user’s control system through Rockwell’s FactoryTalk® Optix™ software to collect, analyze, and send data to the cloud, enabling users to monitor and analyze machine or system data from multiple locations. This means faster insights, lower costs, and smarter decision-making.

Read more here.

Rockwell Automation Simplifies Smart Machine Development with Latest Enhancements in Micro800 Controllers and Design Software

The expanded controller and software capabilities enable easier and faster transition from the legacy MicroLogix controllers to the newer Micro800 controllers, reducing migration time and effort.

Industrial manufacturers can design smarter machines faster and more efficiently with Allen‑Bradley Micro850 2080-L50E and Micro870 2080-L70E controller firmware revision 23 using the latest Connected Components Workbench software version 23 release from Rockwell Automation.

The improved controllers offer easy monitoring of controller variable modifications with the latest remote LCD connectivity support. The 3.5” remote LCD display supports expanded controller functionalities such as mode changes, program backup and restore, user-defined screens, and more. With the ability to retain the MicroLogix controller embedded LCD display functions, the Micro850 and Micro870 2080-Lx0E controllers provide a familiar user interface with reduced conversion risk.

Volga Reduces Control Panel Wiring Time by 66% with Rockwell Automation’s EtherNet/IP In-cabinet Solution

Volga, a Rockwell Systems Integrator Partner and Brazil-based manufacturer of electrical panels and automation systems, reduced control panel wiring time by 66% using Rockwell Automation’s newly released EtherNet/IP™ In-cabinet Solution. The result highlights how Ethernet-enabled technology can help manufacturers more efficiently design and build sustainable, higher-quality control panels.

Hardwiring a control panel can be a time-intensive, error-prone and costly process – particularly in markets where quick customer decisions and rapid delivery are crucial for maintaining a competitive advantage. As a manufacturer that has experienced these challenges, Volga was well-positioned to conduct a time study comparing traditional wiring methods to the new EtherNet/IP In-cabinet Solution. The results: a 66% reduction in wiring time, alongside a 36% smaller panel footprint and a 32% reduction in weight.

“The EtherNet/IP In-cabinet Solution delivers exactly what panel builders and system integrators need today – faster deployment, simplified wiring and reduced material usage,” said Kelly Passineau, global product manager at Rockwell Automation. “This new technology has proven to be a huge advantage in accelerating smart manufacturing while supporting sustainability goals.”

Learn more here.

Rockwell Automation Launches PharmaSuite 12.00 to Accelerate Secure, Scalable Deployments

Latest MES release helps pharmaceutical and biopharmaceutical manufacturers simplify system management, improve flexibility and speed time-to-value.

Rockwell Automation announced the launch of FactoryTalk® PharmaSuite® 12.00. The latest release of its manufacturing execution system (MES) is designed to support the unique needs of regulated pharmaceutical and biopharmaceutical manufacturing environments, helping companies simplify system management, accelerate deployments and scale production more efficiently.

As the industry seeks to move faster while ensuring compliance, BioPhorum has noted that current MES solutions are often perceived as expensive, slow to implement and lacking flexibility required for modern operations. PharmaSuite 12.00 directly addresses these pain points, providing a simplified, configurable and future-ready platform for regulated life sciences production.

The latest release introduces modular architecture and new cloud-ready capabilities, providing manufacturers with increased agility to help meet rapidly evolving production demands. It also features enhanced cybersecurity to support the stringent compliance and data integrity standards required in regulated life sciences environments.

Rockwell Automation Unveils Powerful New Service to Detect and Respond to OT Cyber Threats

New offering delivers 24/7 real-time threat detection and response to combat rising cybersecurity risks in operational technology environments.

Rockwell Automation announced its Security Monitoring and Response service, which is purpose-built to deliver continuous, real-time monitoring of operational technology (OT) environments. Security Monitoring and Response seamlessly integrates into existing architecture to help industrial organizations stay ahead of cyber threats and build resilient operations.

Securing OT environments is getting more complex due to increasing industrial cybersecurity incidents, vulnerabilities and talent shortages. The recent State of Smart Manufacturing report found cybersecurity risks and a shortage of skilled workers were both among the top external obstacles for critical manufacturing.

“As cyber risk continues to increase, manufacturers need constant vigilance and the right expertise to stay ahead of evolving threats. But they often lack the resources to do so," said Nick Creath, cybersecurity services lead product manager at Rockwell Automation. "Security Monitoring and Response provides the visibility, intelligence and rapid action required to safeguard industrial environments through 24/7 continuous monitoring, real-time threat detection and expert-led response. As a trusted partner, Rockwell is an extension of its customers’ teams, helping bridge skills gaps while enhancing their security posture.”

Learn more here.

Rockwell Automation Brings ROKLive 2025 to Hanoi Vietnam to Showcase the Future of Industrial Operations

Rockwell Automation hosted its ROKLive event in Hanoi, Vietnam on 23 April 2025. With the theme ‘The Future of Industrial Operations’, the event showcased the latest innovations in industrial technology such as AI, automation, digitalization, smart manufacturing and cybersecurity solutions.

ROKLive featured engaging keynotes, customer experience sharing, technology updates, forum discussions, and an interactive expo featuring the latest innovations from Rockwell Automation and members of its PartnerNetwork™.

“Southeast Asia’s smart manufacturing industry is evolving rapidly, driven by a shift toward more agile, interconnected and sustainable ecosystems,” said Marcelo Tarkieltaub, regional director for Southeast Asia, Rockwell Automation. “At Rockwell Automation, we are proud to support this journey by providing solutions that help businesses across the region build smarter, more resilient, and future-ready operations.”

More details here.

Rockwell Automation and AWS Collaborate to Transform Manufacturing Through Advanced Industrial Automation Solutions at Hannover Messe 2025

Rockwell Automation and Amazon Web Services, Inc. (AWS), announced they are working together to help streamline and accelerate the digital transformation of the manufacturing industry. By combining Rockwell’s operational technology (OT) with AWS's advanced cloud services and global infrastructure, manufacturers will be equipped with scalable, secure, and flexible cloud solutions that help optimize asset performance, increase operational visibility, and deliver actionable insights from raw data.

Rockwell's deep industry expertise and innovative automation solutions, combined with AWS's advanced cloud capabilities, empower manufacturers to drive digital progress more effectively. With AWS’s significant investments in industrial business units, its focus aligns with Rockwell's core markets, including life sciences, automotive and battery, consumer packaged goods and other industrial sectors.

As part of this relationship, Rockwell is expanding its software-as-a-service within FactoryTalk® Hub to AWS, making its DataMosaix™ industrial DataOps solution and Fiix® computerized maintenance management system (CMMS) available in AWS Marketplace. Additional FactoryTalk Hub solutions will become available in AWS Marketplace later this year, further expanding Rockwell’s cloud-based offerings.

Learn more here.