What do you wish you knew about your manufacturing process? Is there a process parameter you just can’t measure that holds the key to unlocking your operational goals? What benefits could you deliver if you just had that one missing piece of information? Could you improve your quality, reduce your downtime, increase your throughput?

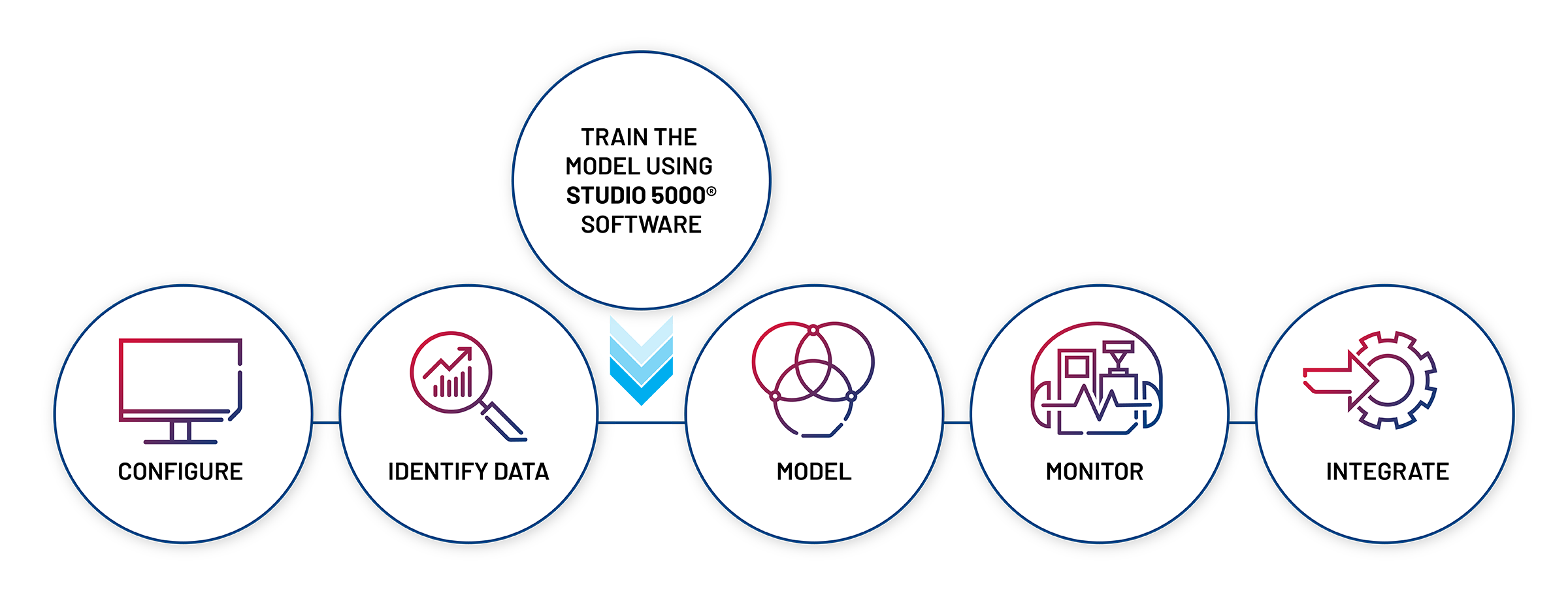

There are many analytic technologies in the market today but most require deep expertise in both data science and industrial processes which often prevents operational technology (OT) professionals from taking advantage of them. FactoryTalk® Analytics™ LogixAI® changes the game. It continuously monitors the production operation and makes predictions about your process, enabling operators and technicians to easily apply machine learning concepts to get ahead of product quality issues and help protect process integrity—all without having to develop, validate or sustain home-grown machine learning algorithms.