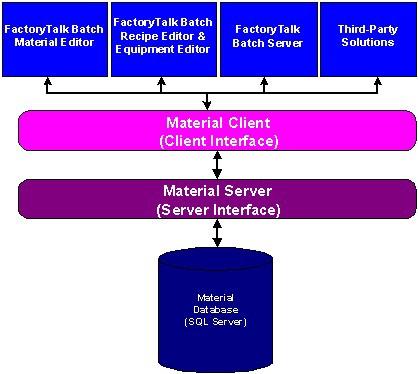

Looking at the Material Server

The

FactoryTalk Batch

Material Server is a group of components that work together to service various client applications. The primary clients that the Material Server services are the Material Editor, FactoryTalk Batch

Server, FactoryTalk Batch

Recipe Editor, and FactoryTalk Batch

Equipment Editor. Also, any third-party application can use custom solutions based on the exposed Material Object Model (MOM). The Material Server also interacts with SQL Server to read to and write from the material database.

Material Server Communications

The Material Server runs with the context of a COM+ component, which is an extension to the Component Object Model (COM). This component resides on the client workstations and provides a rich programming model. See the for more information about the material object model.

FactoryTalk Batch

Material Server API Technical Reference The Material Server coordinates the following functions:

- Records actions to the material database that occur during configuration and run-time in the Activity Journal.

- Loads the material and container lists from the material database to the Batch Server at startup for population of the area model material and container enumeration sets.

- Loads the equipment module/container associations from the area model into the material database.

- Communicates with theFactoryTalk BatchServer during binding.

- During Unit Binding, theFactoryTalk BatchServer communicates with the Material Server to determine if the required materials can be satisfied by the containers within a unit.

- During Phase Binding, theFactoryTalk BatchServer communicates with the Material Server to get a list of containers and equipment modules based on the material to add or distribute in the step. In Prompted Phase Binding, the Operator selects the binding solution from a list of container-equipment pairs. In Automatic Phase Binding, phases are selected based on current container priority.

- In Manual Phase Binding, theFactoryTalk BatchServer communicates with the Material Server to obtain a list of containers, lots and equipment modules that support the required material. The list is presented to the operator for selection of the equipment module to bind to the material step.

- Updates the material database with actual amounts consumed or distributed during a batch run. During an addition or distribution, when the Feed Complete is true, theFactoryTalk BatchServer communicates the actual amount to the Material Server. When the Feed Complete is not true, theFactoryTalk BatchServer communicates the actual amount to the Material Server, which in turn calculates the difference between the promise amount and the actual amount and sends this back to theFactoryTalk BatchServer. TheFactoryTalk BatchServer uses this difference to update the setpoint for the split feed.

This guide also describes the different binding methods and how to handle split feeds.

Provide Feedback