Background

Established in 1985, SAR Elektronic GmbH, based in Dingolfing, near Munich, Germany, specialises in industrial and process automation. Besides its various facilities in Germany, SAR is also present in the USA, South Africa, UK, Switzerland and Slovenia and boasts more than 500 employees worldwide.

The company’s broad range of products and services serves many business segments, including automation, environmental technology, test & measuring technology, IT services, surface-application systems, plastics systems and green energy; together with switchgear assembly, installation and training. Its after-sales services are offered worldwide and customers include well-known global industrial brands, medium-sized businesses and an assortment of municipalities.

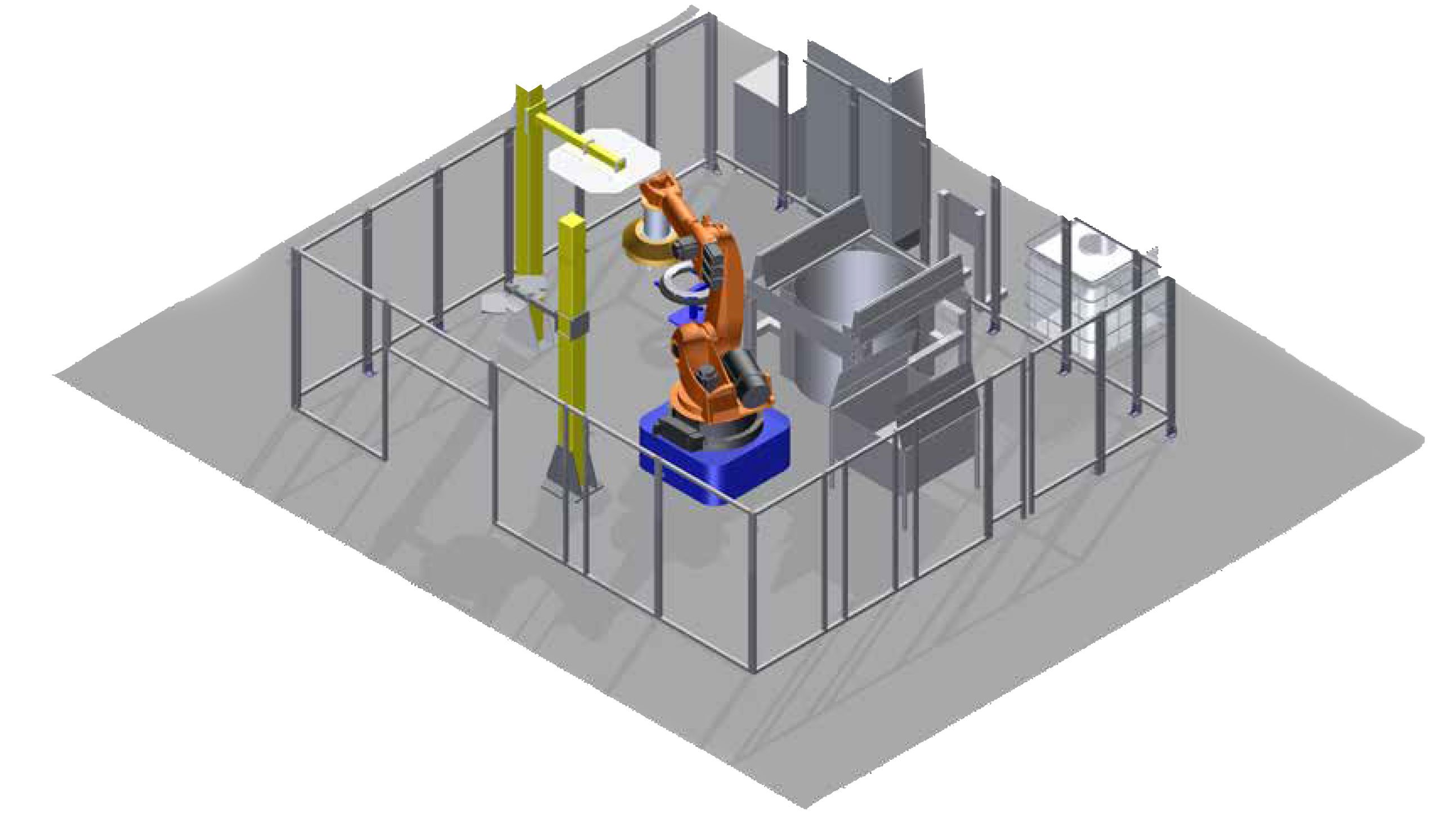

One of its core skills lies in the design, build, commissioning and installation of automated solutions for the automotive industry – for both OEMs, leading Tier Ones and other suppliers. One of its popular solutions is an Automated Tyre Release Agent cell, which applies a coating to the inside of tyres prior to the curing process. The company had always used automation equipment from a German automation supplier, but when a leading international tyre manufacturer approached SAR, it requested an automation infrastructure based around Allen-Bradley® components from Rockwell Automation.

As well as bringing the SAR engineers up to speed on the technological and functional capabilities of the Allen-Bradley components, the engineers from Rockwell Automation in Germany also had to prove that their solution was as good if not better than the incumbent solution from the German supplier.