Working for Iscador AG, Invag AG was tasked with developing a drive solution for a high-speed centrifuge. These devices can only be found in two places worldwide: First, as part of an experimental research facility, and second, for the manufacturing of pharmaceuticals. In this instance, the entire component range, from the water-cooled motor, right up to the bearings, represented a special design for the production of the mistletoe drug, ISCADOR® of the anthroposophic medicine.

Iscador AG is a pharmaceutical company that supplies complementary medicine for integrative cancer treatment. In this context, the focus is on the healing power of the mistletoe within a holistic treatment concept. “The leaves, stems and berries of mistletoe are used for the production of our drug,” explains Dr. Gerhard Schaller, Head of Manufacturing and Member of the Executive Management at Iscador. “We harvest once in the cold and once in the warm season, as evergreens display seasonal variations with regard to the active substances. The lectine concentration is at its highest in winter, and the amount of viscotoxins increases in summer. We concentrate on a specific mix of both.”

Challenge

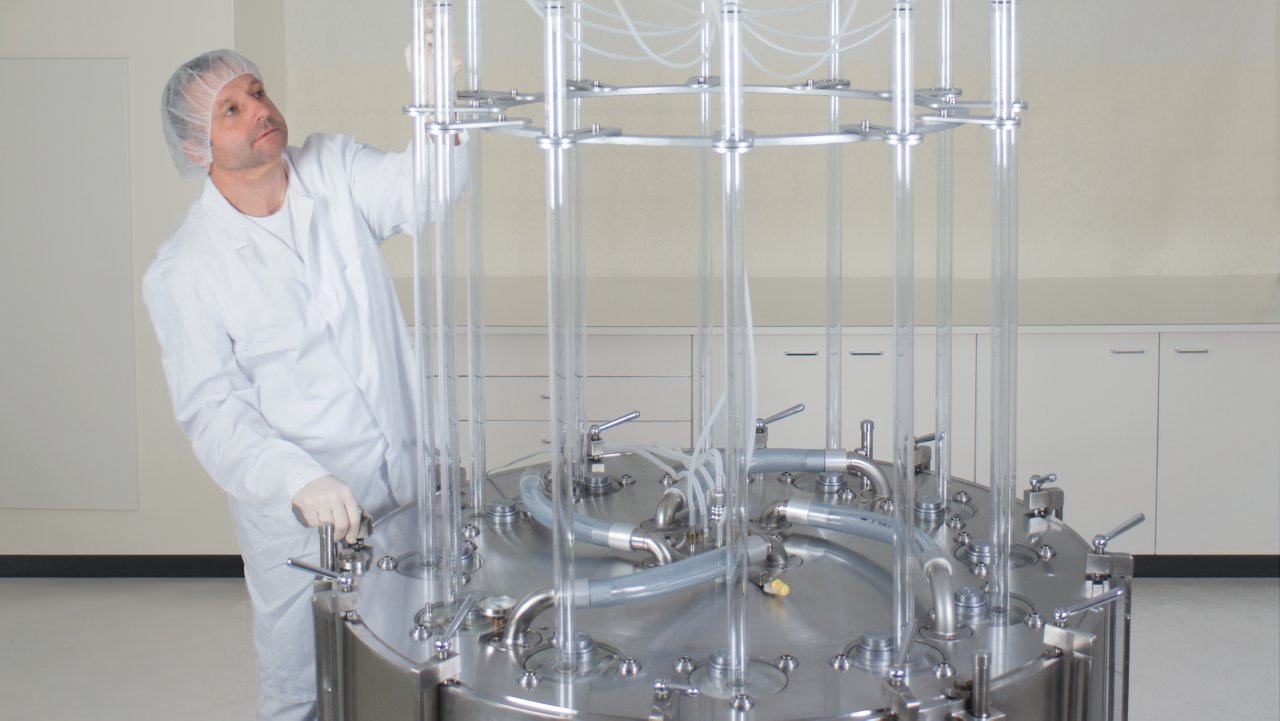

Mixing the two mistletoe extracts is still carried out on the basis of a process that can be traced back to Rudolf Steiner, the founder of Anthroposophy: The extract of mistletoe collected in winter is continuously dosed in the center of a rotating disk, which exhibits a raised lip at its edge, and moves outwards as a thin film towards the outer rim due to centrifugal force. The extract of summer mistletoe, on the other hand, is added drop by drop at certain positions from a height of one meter. Both types of extracts are then thoroughly mixed at the rim of the disk.

“The 1m-diameter titanium disk rotates at a speed of 10,000 RPM throughout the production process,” explains Christian Albisser, Head of Central Services at Iscador. “This results in a rim speed of 1,885 kph and centrifugal forces that are 55,000 times greater than the force of gravity.” This energy had to be mastered in terms of control technology.

In the past, this control has not been optimally achieved. The power supply was subjected to undesired feedback effects as soon as the facility entered the high-rpm-range. In some cases, certain consumers even had to be shut down in order to ensure network stability. With regard to lab equipment, having to sacrifice operating time is far from trivial.