Keeping up with shifting consumer demands presents end users with a formidable challenge – how can they meet demand for a growing product mix while maintaining the productivity that is crucial to their bottom line? The answer starts with automated packaging systems and machines that are more flexible, intuitive and connected than ever before. Our leading hardware and software solutions empower you to design better connected, higher performing automated packaging machines that play critical part in your customer’s transformation. Discover how together we can make the future of automated packaging a reality.

Design Automated Packaging Machines that are Ready for What’s Next

With growing SKUs, compressed project timelines, sustainability targets and more, the packaging space is a complex landscape. End users are looking to win in today's marketplace by scaling up their ability to customize products and leverage digital technologies to increase value and improve efficiency.

Using our domain expertise and full automated packaging solutions toolbox, we can help you keep up with these new demands and provide solutions that accelerate your customers’ packaging transformation.

- Discover how you can deliver more value to your customers by:

- Building more flexible and modular machines that quickly adapt to changing line and product needs

- Adding data access and contextualization to your designs so that teams can act faster and make better informed decisions

- Using digital solutions to reduce design and commissioning risk and accelerate project timelines

And with our extensive experience working with leading companies from around the world, we have a holistic view of end user needs that helps inform our approach to working with you.

What’s Driving the Future of Packaging Automation?

Data-ready machines

Deliver systems that are prepared to harness data that is impactful and easy to access.

Flexibility and modularity

Design machines that can meet demand for customized products and rapid changeovers.

Digital-first optimization

Act faster and reduce risk by designing, testing and commissioning machines virtually before physical implementation.

Let’s Take Your Automated Packaging Solutions to the Next Level

Discover how our leading hardware and software technologies can be applied to help you add more value to your machines, differentiate your solutions and maximize customer satisfaction.

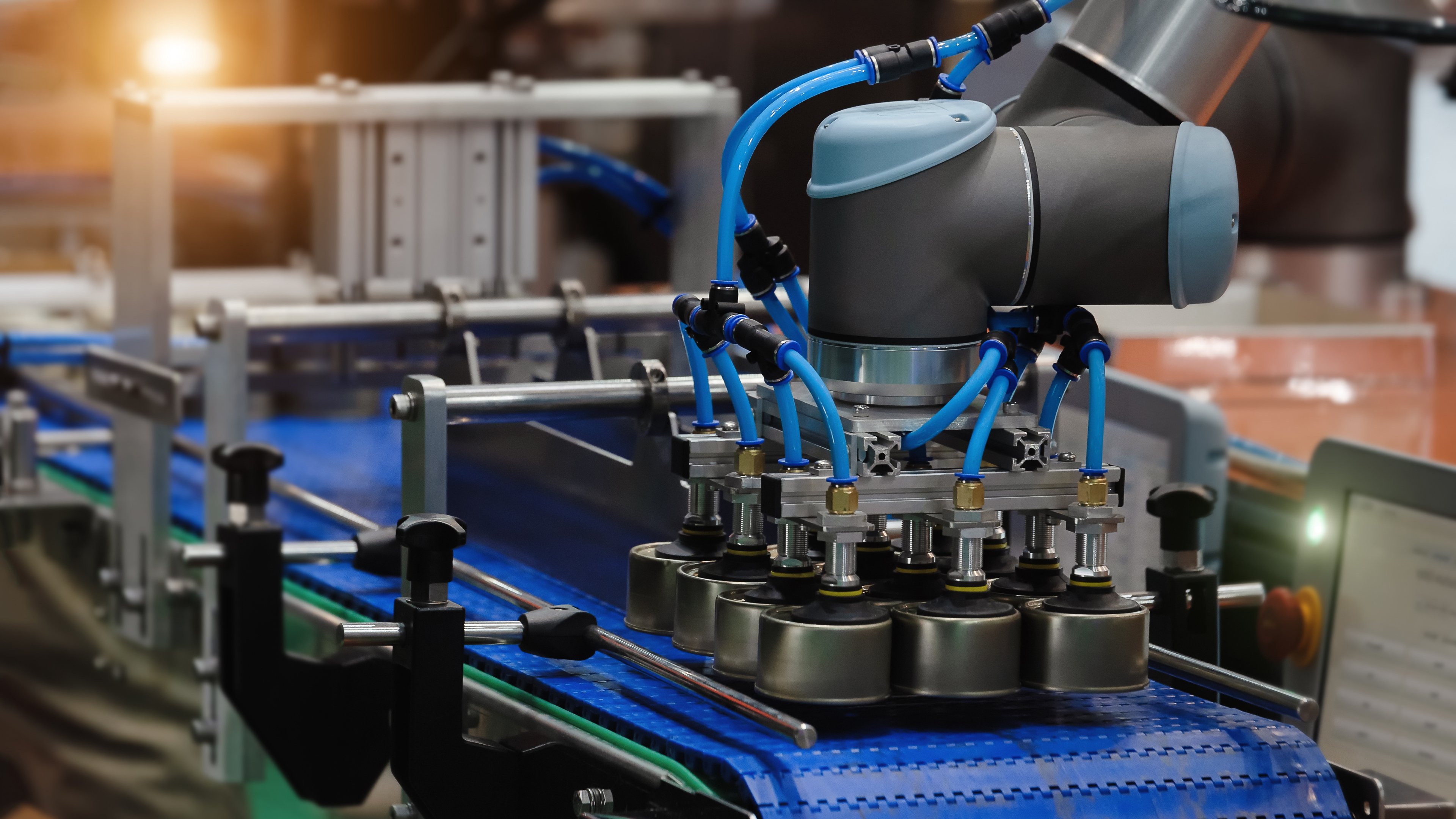

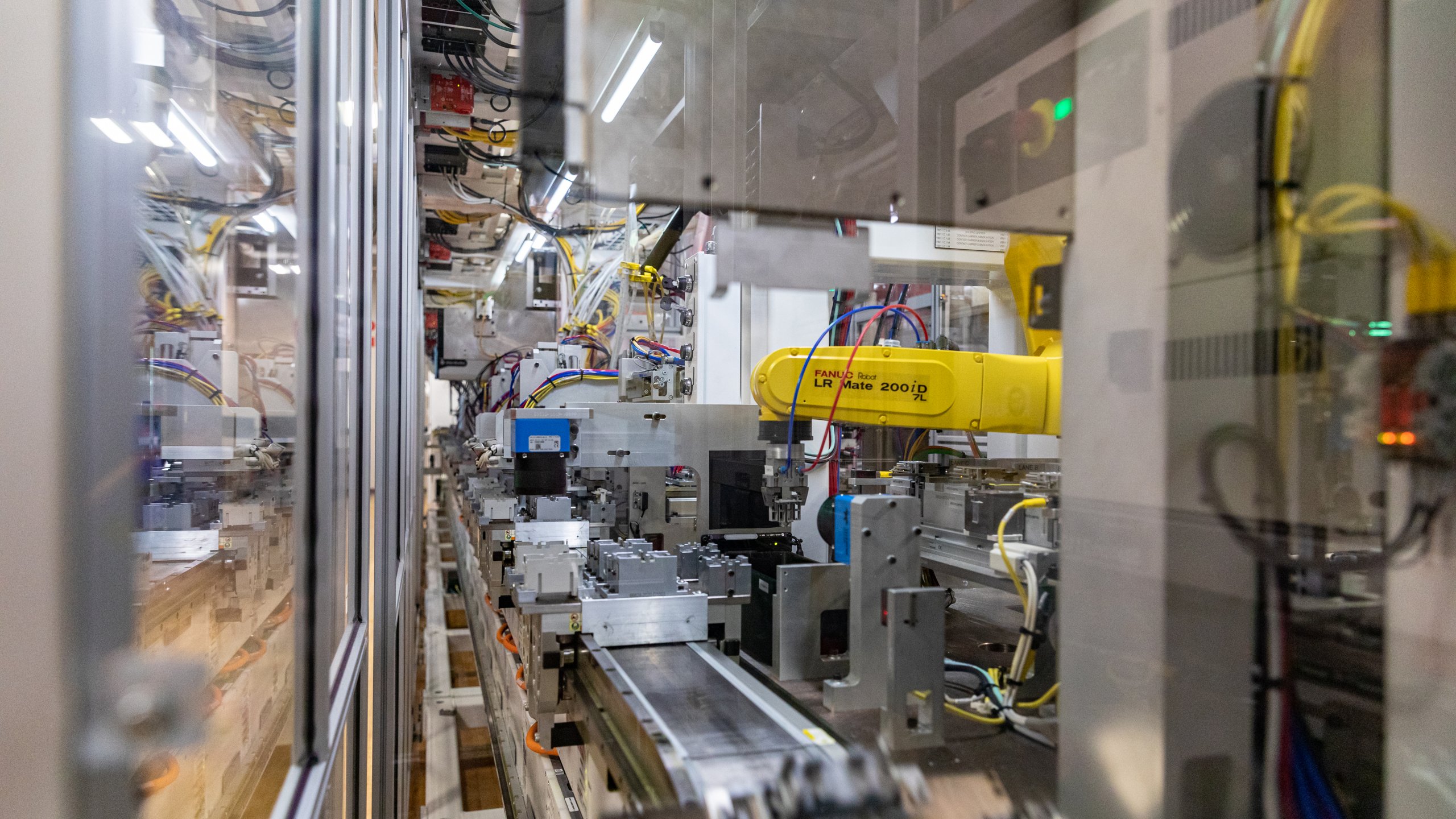

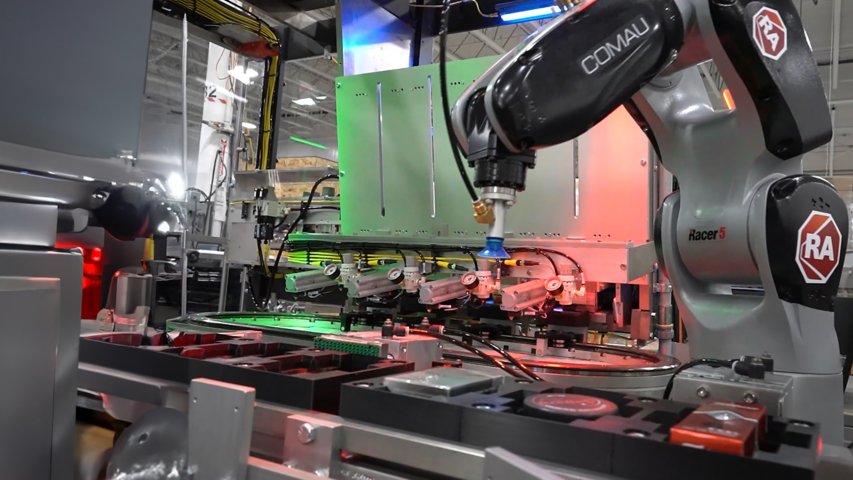

See our Automated Packaging Systems in Action

Leading Packaging OEMs are Delivering New Possibilities with Smarter Machines

Your customers are looking to you for innovative packaging machines that drive their key performance goals forward. Together, we can meet, exceed and transform expectations with automated packaging solutions that help to optimize operations, improve OEE and drive profitable growth.

Increase Productivity using Smart Safety Technology

Meet Customer Demand For Machines Designed with Safety in Mind

Safety in today’s packaging environments means more than simply hard guarding and e-stops. your customers are looking for innovative solutions where safety is addressed to maximize the productivity of workers in all machine scenarios.

By choosing our innovative safety products, you can meet industry standards while helping your customers increase safety, efficiency and productivity.

From controllers that feature integrated safety to presence-sensing safety devices and beyond, we offer one the broadest safety portfolios in the industry to help you improve the functional operation of your machinery while helping to increase personnel safety, efficiency and productivity.

With our safety solutions you can :

- Enhance machine safety and help protect workers

- Increase productivity

- Reduce safety-related downtime

- Improve compliance

Explore What’s Next in the Industries You Serve

What is Packaging Automation?

Packaging automation refers to the use of machines, software and integrated systems to perform packaging tasks that would otherwise be done manually. This can include everything from filling, sealing, labelling and palletizing to quality inspection and tracking. By streamlining these processes, packing automation reduces labor costs, increases consistency, minimizes errors and boosts overall production speed. For manufacturers, automated packaging systems not only improve efficiency but also enhance safety and scalability, making it easier to handle higher volumes and adapt to fluctuating product demands.

Benefits of Packaging Automation

Automated packaging systems offer manufacturers a faster, safer and more consistent way to manage their packaging operations. Key benefits include:

- Improved accuracy and consistency: Automated packaging reduces human error and ensures every product is packaged to the same standard.

- Higher throughput and scalability: Systems can handle greater volumes without the need for proportional increases in labor.

- Lower labor costs: Automated packaging machines take over repetitive tasks, allowing teams to focus on higher-value work.

- Enhanced safety: Automation minimized worker exposure to repetitive motions and potentially hazardous processes.

- Better workflow optimization: Automated packaging solutions provide real-time data that helps identify bottlenecks and improve efficiency.

- Reduced downtime: Intelligent systems help predict maintenance needs and keep production running smoothly.

- More cost-effective operations: Overall efficiency gains lead to lower long-term operating costs and a stronger return on investment.

Key Components of Packaging Automation

Key components of an automated packaging system work together to create a streamlined, efficient and reliable packaging workflow. Here are the essential elements:

- Case packer: Automates the process of placing products into cases, improving speed and consistency.

- Cartoner: Forms, fills and seals cartons, ensuring secure and uniform packaging.

- Conveyors: Move products between stages to maintain a steady flow and reduce manual handling.

- Labeling and coding equipment: Applies barcodes, dates, and product information with precision.

- Inspection and quality control systems: Use sensors, cameras or scanners to detect defects and ensure accuracy.

- Palletizers: Stack finished cases onto pallets for efficient storage and shipping.

- Control systems and software: Coordinate machine operations and provide real-time data for monitoring and optimization.

Others also viewed

Based on your activity