Our innovative safety products and solutions improve the functional operation of your machinery while helping to increase personnel safety, efficiency and productivity. We offer one the broadest safety portfolios in the industry to help you achieve both safety and productivity goals in process and discrete manufacturing applications.

- Overview

- Products

Products

Showing

1

-

1

of

0

Results

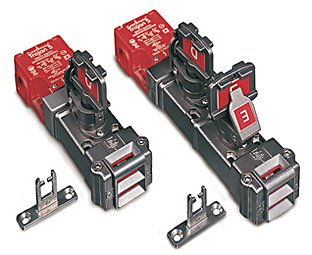

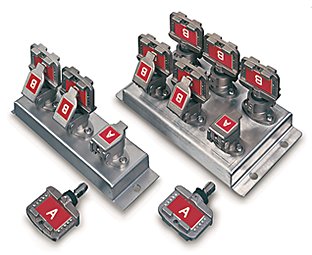

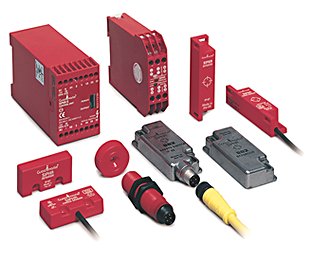

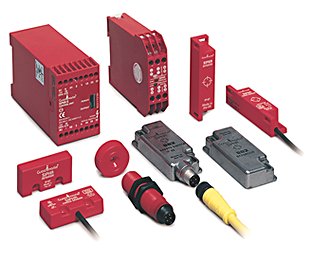

GuardLink Technology

Allen-Bradley® Guardmaster® smart safety devices that feature GuardLink technology deliver information, advanced functionality, and flexibility. This technology helps enhance safety and increase machine- and plant-wide efficiency.

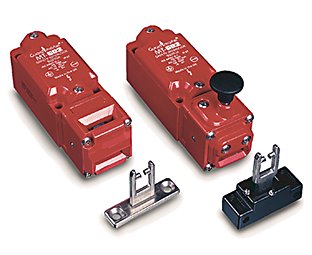

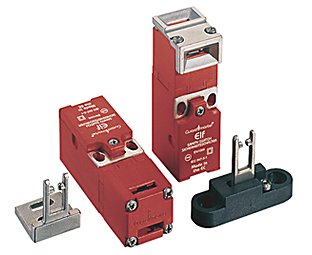

440G-MZ

Our Bulletin 440G-MZ Guard Locking Switches allow full body access to the safeguarded area, where a high holding force and a wide tolerance to guard misalignment, and an escape release option are commonly required.

445L Guardshield POC Type 4 Micro 400 Safety Light Curtains

These safety light curtains are economical three-box safety light curtains in a small housing.

440L Guardshield POC Type 4 Standard Safety Light Curtains

Our Bulletin 440L Guardshield™ POC Type 4 safety light curtains are applied in applications where a formal risk assessment has determined that the hazard poses a moderate to high risk of operator injury.

450L GuardShield PAC Safety Light Curtains

These safety light curtains are for whole-body detection, as a person or object passes through a sensing field.

440L and 445L Guardshield POC Type 2 Low Risk Safety Light Curtains

Our Bulletin 440L and 445L Guardshield™ POC Type 2 Low Risk safety light curtains are applied in applications where a formal risk assessment has determined that the hazard poses a low risk of operator injury.

450L GuardShield POC Safety Light Curtains

These safety light curtains offer technology that allows each transceiver to be used as a transmitter or receiver via an innovative plug-in module.

440L Type 4 and 445L Safe 4 GuardShield PAC Safety Light Curtains

These safety light curtains are applied in applications where a formal risk assessment has determined that the hazard poses a moderate to high risk of operator injury.

440L Area Access Control Single Beam Sensors

Our Bulletin 440L Area Access Control Single Beam sensors provide whole-body access detection for hazardous areas.

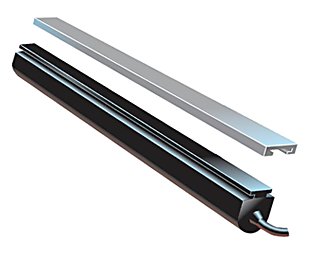

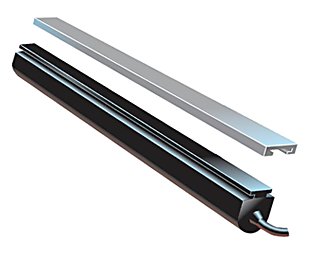

440F Safedge Safety Edge Profiles

Our Bulletin 440F Safedge™ Safety Edge Profiles come in three different cushion factors and two different materials. They have no rigid internal parts that can break through or cause fatigue failures after prolonged use.

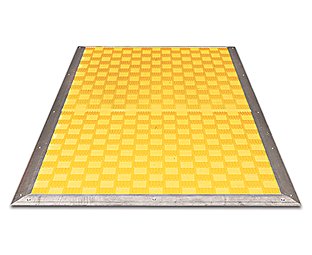

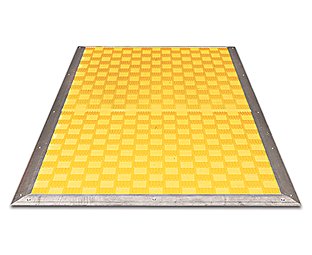

440F MatGuard Safety Mats

Our Bulletin 440F MatGuard™ Safety Mats are pressure-sensitive safeguarding products that we designed to detect the presence of people on the sensing surfaces.

442L SafeZone Safety Laser Scanners

Our SafeZone™ Safety Laser Scanners are compact devices that have switchable,

configurable fields and field sets (warning and safety).

440C-CR30

Our Guardmaster® 440C-CR30 Software Configurable Safety Relay is flexible, cost-effective, and easy to use.

GuardLink EtherNet/IP Interface

The GuardLink® EtherNet/IP module monitors three independent channels of GuardLink-enabled devices and communicates the status of those devices to a safety-rated controller over a CIP Safety EnterNet/IP network.

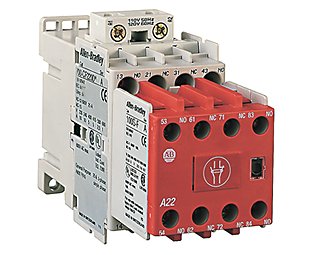

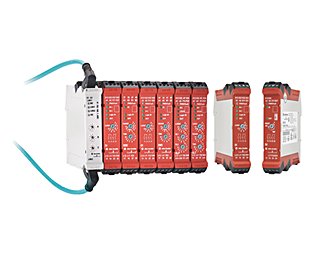

440R Guardmaster Safety Relays

Our Guardmaster® single-function safety relays are designed to meet functional safety standards, such as ISO 13849-1 or IEC 62061, and they offer key functions to simplify installation and system complexity.

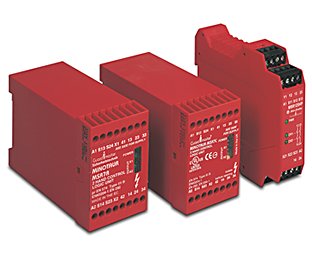

Safety Relays Single-Function

Our MSR100 Single-function Safety Relays are ideal for relatively small safety applications and single zone control and available in electromechanical version, or solid-state models for applications involving high cycle rates.

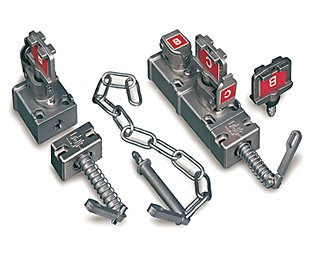

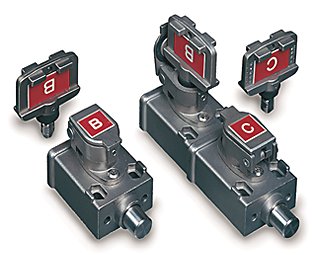

Safety Relays Sipha

Our Sipha™ Control Units monitor and control Sipha non-contact safety sensors. For high-risk applications, the control unit is used with a single Sipha sensor to give a high-integrity system. For other applications, multiple sensors (including mechanical switches) can be connected to a single Sipha control unit.

440F Safedge Controllers

Our Bulletin 440F Safedge™ Controllers operate with our Bulletin 440F Safedge Safety Edge Profiles. The controllers continuously monitor the profile for actuation, and they generate an output signal when the profile is depressed.

Safety Relays Mat Controllers

Our MatGuard™ Control Unit monitors all of the mats that are connected together to form a safeguarded zone. The safeguarded zone can be up to a total of 100 m² and made from any number of mats.

Muting Light Curtain Monitoring Safety Relays

Our Muting Light Curtain Monitoring Relays allow the automatic temporary suspension of the safety function if certain conditions are met.

Speed Monitoring Safety Relays

Our MSR57P Speed Monitoring Safety Relays are designed for motion applications that require interaction by personnel during operation. Our MSR55P Speed Monitoring Safety Relays are used for standstill detection on single and three phase motors without the need for sensors.

Two-hand Control Monitoring Safety Relays

Our Two-hand Control Monitoring Safety Relays detect faults in two-hand controls, wiring, and contactors safety circuits.

MSR132 Monitoring Expansion Safety Relays

Our monitoring expansion safety relays have single or dual channel input with either immediate or time off delayed outputs.

Safety Relays Single-Function Delayed

Our Single-function Safety Relays with Delayed Outputs are used in applications where power must be maintained for a fixed duration after an input signal is received.