Rockwell Automation Releases 2024 Sustainability Report

Rockwell Automation published its 2024 Sustainability Report, which highlights the company’s sustainability strategy, outcomes, and progress to help build sustainable customers, a sustainable company, and sustainable communities.

“We are proud of our Environmental, Social, and Governance (ESG) efforts, which provide the foundation for creating a more sustainable future,” said Rockwell Chairman and CEO Blake Moret. “We continue to challenge ourselves and strive to meet or exceed our commitments. We help our customers do the same, providing the tools they need to navigate new challenges and requirements, helping them track and reduce their energy, water, and waste, and produce innovative new products and technologies at scale.”

In addition to showcasing how Rockwell is helping manufacturers in their sustainability efforts, the report also highlights the company’s ESG initiatives and how it’s creating innovative, sustainable products and solutions while fostering a culture that empowers employees to operate safely, sustainably, and responsibly. The report also outlines how Rockwell supports sustainable communities with a purpose-driven strategy designed to create opportunities and expand human possibilities through investments in people and meaningful action.

Ethisphere Names Rockwell Automation as One of the 2025 World’s Most Ethical Companies®

Ethisphere, a global leader in defining and advancing the standards of ethical business practices has recognized Rockwell Automation as one of the 2025 World’s Most Ethical Companies.

This is the 17th time Rockwell has been included on this prestigious list which honors companies that demonstrate exceptional leadership and a commitment to business integrity through best-in-class ethics, compliance, and governance practices.

“The work that we do every day makes our customers more resilient, agile, and sustainable, and how we do the work matters,” said Rockwell Chairman and CEO Blake Moret. “We are proud to be recognized once again by Ethisphere for our commitment to integrity, responsible operations, and meeting the highest ethical standards.”

Learn more here.

Rockwell Automation Revolutionizes Motor Controls with Smarter and Safer M100 Electronic Motor Starter

Rockwell Automation launched the M100 Electronic Motor Starter, enabling industrial organizations to simplify panel wiring and reduce component and engineering complexities with advanced functional safety solutions and more refined motor starting capabilities.

Rockwell’s traditional motor starters lay a robust foundation for customizable motor control solutions including starting, stopping and protecting motors. Building on this legacy, the new M100 Electronic Motor Starter seamlessly integrates into intelligent motor control setups, boosting productivity and minimizing downtime. It serves as a cost-effective, space-efficient option, boasting an extensive range of features designed to improve performance across various applications. Notably, the M100 incorporates point-on-wave (POW) switching technology.

The new M100 Electronic Motor Starter offers zero stacking with no derating up to 55C, providing flexibility in installation without compromising performance. Removable terminal blocks, available in both screw and push-in variants, add convenience and adaptability. The M100 also supports direct-on-line (DOL), reversing, and safety capabilities in the same form factor, showcasing its flexibility in various operational scenarios.

Learn more about the M100 Electronic Motor Starter.

Rockwell Automation Showcases Emulate3D Factory Test for the First Time at NVIDIA GTC 2025

Enterprise-scale digital twins unlock new possibilities for virtual controls testing

Rockwell Automation Showcases Emulate3D Factory Test for the First Time at NVIDIA GTC 2025. (Photo: Business Wire)

Rockwell Automation debuted its new Emulate3D® Factory Test ™ capabilities at NVIDIA GTC 2025. This first public showcase demonstrates how the solution enables factory-scale virtual controls testing, helping manufacturers conduct Factory Acceptance Testing to validate automation systems before deployment. Attendees got an exclusive look at how Factory Test, integrated with NVIDIA Omniverse ™ APIs and OpenUSD, is redefining digital twin technology with high-fidelity simulation and real-time collaboration.

“Manufacturers need scalable, high-fidelity digital twins to optimize system performance and accelerate commissioning times,” said Matheus Bulho, senior vice president, software and control, Rockwell Automation. “With the launch of Emulate3D Factory Test, we’re providing a solution that allows engineering teams to test, iterate and validate automation systems at full factory scale – leveraging the power of NVIDIA Omniverse to deliver unprecedented visualization and collaboration capabilities.”

Learn more here.

Rockwell Automation Expands Signaling Devices Portfolio with New On-Machine LED Indicators

Rockwell Automation is excited to unveil the Allen‑Bradley 852C and 852D On-Machine LED Indicators, a powerful and compact solution for indicating machine status. Maximizing machine uptime requires a clear understanding of equipment and processes, and when critical conditions arise, effective communication is essential to address issues swiftly and avoid costly downtime.

The new On-Machine LED Indicators are designed for more reliable status reporting, featuring a robust build that fits seamlessly into space-constrained environments. Thanks to plug-and-play connectivity, these devices significantly lower maintenance, commissioning and troubleshooting costs by reducing the need for complex hard wiring.

Learn more here.

Lisi Automotive Implements Plex ERP at Shanghai Facility

Automotive supplier expands use of Plex to China

Plex, by Rockwell Automation, a leader in cloud-delivered smart manufacturing solutions, today announced multi-specialist supplier, Lisi Automotive, has chosen the Plex Smart Manufacturing Platform to digitally transform and streamline operations at its Shanghai-based facility. Lisi Automotive’s selection of Plex Enterprise Resource Planning (ERP) will connect the factory from the front office to the shop floor, offering unprecedented insight into data and production.

The selection of Plex ERP signaled a larger commitment by Lisi Automotive to digitizing its operations at a global level—the company previously deployed Plex at facilities in the United States and Mexico. At its Shanghai factory, the team is hopeful Plex ERP will provide:

- Automated and digitized workflows

- Greater accuracy and product traceability

- Streamlined operations connecting people, suppliers, and customers

- Financial consolidation and reporting

- Increased production and inventory insight

Learn more here.

Rockwell Automation Partners with PFi To Streamline Wastewater Treatment for Major Beverages Company

Australian industrial innovator, Products for Industry (PFi), recently developed what is believed to be a world-first, pure titanium, cross-flow membrane solution for wastewater treatment. This solution has uptime, environmental, and yield benefits compared with traditional wastewater treatment methods.

PFi turned to Rockwell to help with automation hardware – using Rockwell Automation’s CompactLogix control system and PanelView Plus graphic terminal – to make the solution streamlined, repeatable, and easy to integrate for its industrial manufacturing customers.

PFi conducted extensive pilot tests at a wastewater treatment plant in New Zealand finding that the titanium solution allowed very high flow and flux rates; an easier and faster clean-in-place (CIP) process; and no fouling or long-term issues with fats, oils, and greases. The pilot tests also showed that running costs and energy use would be reduced over the system’s lifetime.

Learn more here.

Cisco & Rockwell Automation Partner to Close Digital Skills Gap in Manufacturing

Cisco, the worldwide leader in networking and security, and Rockwell Automation signed a Memorandum of Understanding (MoU) to expand their strategic partnership and launch the ‘Digital Skills for Industry’ program.

Addressing the growing skills gap in India’s manufacturing sector, the program aims to empower the next generation of workers with essential digital skills, combining IT and OT curriculums in the areas of cybersecurity, networking, IoT, data science, AI, programming and automation technologies. To meet the evolving demands of the industry, the program aims to improve digital literacy in industry, attract new talent, enhance workforce productivity, help accelerate career growth and bridge the global digital divide.

Learn more here.

Rockwell Helps Alternative Protein Manufacturers Meet Global Demands

This year, the world’s population will top 10 billion people—and finding new ways to sustainably produce food is a priority. One option to meet increasing demand is alternative proteins—meat made from plants, cultivated from animal cells, or produced via fermentation.

Rockwell Automation is working with U.S. Federal Drug Administration (FDA)-approved alternative protein manufacturing facilities to help grow this emerging sector. The goal: create products that taste the same as conventional products yet cost the same or less to produce, reducing the draw on natural resources.

One of the biggest challenges facing alternative protein manufacturing facilities is taking a proven idea and scaling production—or going from growing a few cells at a bench-top to cultivating thousands of liters of cells for mass production.

A solid first step is having the right technology to collect, record, and analyze data early in the product development stage to allow for better testing and modeling using digital inputs.

Rockwell technology, including PlantPAx® modern distributor control system and model configuration using FactoryTalk® Batch software, is helping producers move from manually testing to automation. This means instead of testing hundreds of batches to see which product is the most effective, manufacturers can quickly find the product option that is the most nutritious, profitable, and repeatable—and therefore most likely to be successful—all while saving time and cost.

Learn more here.

Rockwell Automation Achieves Industry Benchmark with IEC 62443-4-2 Cybersecurity Certification for Variable Frequency Drives

New certification recognizes the PowerFlex 755T-series and PowerFlex 6000T VFDs for adherence to the stringent IEC 62443-4-2 cybersecurity standards' guidelines.

Rockwell Automation has been recognized for achieving the International Electrotechnical Commission (IEC) 62443-4-2 Security Level Capability 1 certification from TÜV Rheinland, an independent and globally respected certification body. This certification recognizes the Allen‑Bradley PowerFlex 755T-series and PowerFlex 6000T drives for adherence to the stringent cybersecurity standards outlined in the IEC 62443-4-2 guidelines.

The IEC 62443-4-2 standard is part of the ISA/IEC 62443 series of standards, which focus on the security for industrial automation and control systems. Achieving this certification for drive families demonstrates the robustness against cyber threats and their capability to help protect industrial systems from unauthorized access and potential cyberattacks.

Read more here.

Rockwell Helps Dairy Processor Miraka Streamline Operations and Live Their Values

New Zealand-based Miraka, the world’s first dairy processor to get its power from renewable geothermal energy, has chosen Plex, by Rockwell Automation, to become even more efficient and sustainable.

The company will use Plex to integrate its enterprise resource planning (ERP) systems. ERP is a software system that helps organizations streamline and automate their core business processes—including financial management, human resources, supply chain, sales, and customer relations—across the entire enterprise.

Miraka says its use of geothermal energy enables it to “emit 92% less manufacturing carbon emissions than traditional coal-fired factories, giving Miraka one of industry’s lowest global carbon footprints.” The dairy company will now use Plex to connect, automate, track, and analyze its operations—from the pasture to the factory floor— to take its core values of excellence and innovation to the next level.

Mahindra Accelo Selects Rockwell Automation to Help Digitalize Manufacturing Operations

Rockwell Automation will work with Mahindra Accelo, a high-end component manufacturer for mobility and energy, and automotive recycling, to advance their digitalization and decarbonization efforts.

Mahindra Accelo, a Tier-0.5 / 1 supplier for the automotive industry, will leverage Rockwell’s expertise to enhance operational efficiency and promote environmental stewardship by implementing cloud-based Plex manufacturing solutions to achieve real-time plant visibility, optimize production schedules, improve error-proofing, enhance quality, and streamline audits. Plex is a scalable solution that integrates seamlessly across the enterprise and provides a shorter timeline for implementation.

Learn more here.

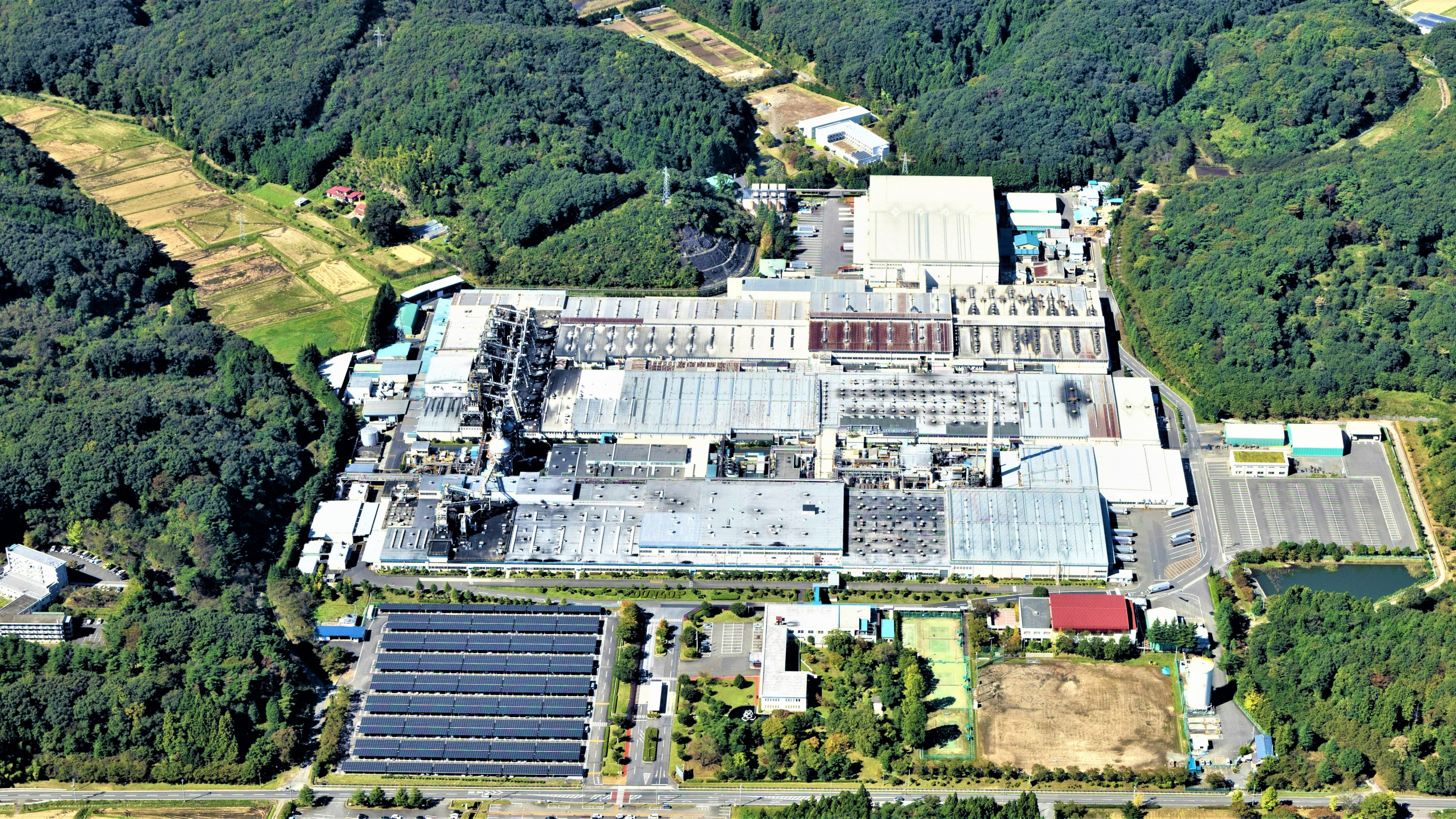

Sumitomo Rubber Industries Selects Rockwell Automation to Standardize Global Plant Operations

Rockwell’s FactoryTalk ProductionCentre to drive operational efficiency and digital transformation for leading tire manufacturer

Rockwell Automation has been selected by Sumitomo Rubber Industries, a leading global tire and rubber manufacturer, to support the company’s digital transformation efforts across plant floors globally.

Sumitomo Rubber, known for its DUNLOP and FALKEN brands, will deploy Rockwell’s FactoryTalk® ProductionCentre®, a manufacturing execution system (MES) platform, as part of its strategy to integrate and standardize business and production data. Deployment will begin at the company’s Shirakawa plant in Fukushima Prefecture, Japan, and expand to other plants worldwide following evaluation.

Sumitomo Rubber is addressing growing business challenges, including material cost increase and labor shortages, by implementing highly efficient production systems through digital technology. The company aims to standardize production across its global sites, which handle high-mix, low-volume production. To enhance integration with its enterprise resource planning (ERP) system, Sumitomo Rubber chose Rockwell’s FactoryTalk ProductionCentre for its seamless compatibility with existing systems and its specialized knowledge in tire manufacturing.

Ceylon Can Collaborates with Rockwell to Transform Manufacturing Process

The project aims to enhance production efficiency while providing real-time visibility with Plex Cloud-Based Manufacturing Execution System

Rockwell Automation announced a collaboration with Ceylon Can Manufacturing, a leading beverage can and end manufacturing company in Sri Lanka. Rockwell will implement its cloud-based Plex Manufacturing Execution System (MES), empowering Ceylon Can to transition to digital manufacturing.

This collaboration is Rockwell’s first Plex MES installation in Sri Lanka and its first in the Consumer Packaged Goods (CPG) sector in the Indian subcontinent. With Ceylon Can’s plans to expand operations with new facilities in India, this pilot site will serve as a crucial foundation for the company's digital transformation initiatives.

Celyon Can Manufacturing exports 80% of its products globally. The digital transformation program will be implemented at Ceylon Can's existing site in Sri Lanka, serving as a pilot for broader digital initiatives, as the company prepares to expand its manufacturing operations through two greenfield plants in India.

Learn more here.

Rockwell Automation Names Paolo Butti Regional President Global Industries

(Photo: Business Wire)

Paolo Butti has been named regional president, Global Industries. Butti will report to Scott Genereux, SVP and Chief Revenue Officer, and he succeeds Jane Barr, who has taken on the role of President, Americas Region.

In this role, Butti will provide sales leadership and strategic direction for global account sales teams. He joined Rockwell in 2012. In his most recent role as global vice president, Original Equipment Manufacturer (OEM) Segments and Emerging Industries, he led a high performing team of Industry and OEM segment directors. Butti brings a diverse career of experience spanning more than 25 years, including extensive global experience in automotive, robotics, and industrial automation.

Learn more about Paolo.

Rockwell’s Medium-Voltage Drive Technology Helps West Fraser Reduce Annual Energy Bill

Industrial applications that run things like pumps, fans, conveyors, and compressors are responsible for more than 50% of the world’s total electricity consumption. One option to dramatically reduce that drag on resources is variable frequency drives (VFDs). These devices can adjust the frequency and voltage of the power supply, which can help improve the motor’s efficiency and even extend the life of the motor.

Rockwell Automation helped West Fraser, a diversified wood products company, make significant gains towards energy saving targets through an Intelligent Packaged Power (IPP) solution featuring VFDs. An IPP solution simplifies the integration between process and electrical systems—giving workers immediate access to real-time data on the equipment and how it is operating so they can make better decisions faster.

West Fraser’s plant in Cowie, Scotland, began using a CENTERLINE® 1500 medium-voltage motor control center (MCC) and three PowerFlex® 6000T medium-voltage VFDs across three of the site’s energy-intensive fan applications. As a result of reducing motor speed by 25%, West Fraser lowered the motor’s energy consumption by approximately 60%, translating into an annual savings of more than $266,000.