By Sean O'Grady, Product Manager – Valve Terminals and Electronics, Festo Corp.

Editor's Note: This article is adapted from a comprehensive white paper, "Integration of functional pneumatic safety devices into control systems." Visit http://goo.gl/XIr0kg to download the free, full white paper with additional information about reversing a movement on pressing (metal stamping) applications.

Suppliers and OEMs must establish closer communications to achieve optimum safety through new functionally integrated systems. Let's look at two common safety concerns and see how integrated safety solutions can help solve them. The following examples focus on pneumatics, but the same principles apply for electronic actuation.

Example 1. Remove Power from Pneumatic Valves

On its face, this seems like the simplest of applications. As a basic requirement of existing Lockout/Tagout (LOTO) regulations, the ability to remove output power from a valve manifold without interrupting bus communications has been a common feature of valve manifolds for many years. However, two new requirements are emerging.

The first is the finer level of granularity. In the past, it often was acceptable or even desirable to remove power from the entire manifold at once. Modern safety applications often benefit from the ability to remove power only from the valves that are pertinent to a specific segment of the application.

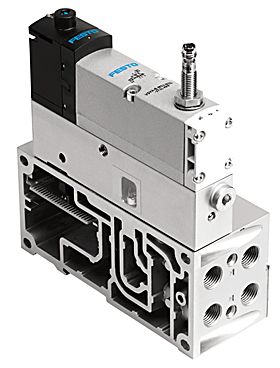

Modern valve manifolds that can segment output power allow the engineer to greatly simplify this common task. A single valve manifold can be supplied that segments output power into several zones. This allows the entire manifold to share a communication adapter (EtherNet/IPTM, DeviceNetTM, etc.) as well as plumbing and mounting elements. Integrated diagnostic feedback also will allow the controls engineer to determine which segment of the valve manifold has power and which does not.

Another common consideration in the application of valve terminals into modern safety machinery is the requirement to be able to remove power at both the 24VDC connector and the 0VDC connector. As simple as this sounds, many common valve terminals share the 0 volt pin between valves and the power for the communications adapter.

True galvanic isolation between these two elements of the system allows for reliable communication during these safe shutdowns. A valve terminal that can combine this feature with the ability to be divided into multiple power zones has the potential to save a design engineer a great deal of time, energy and money.