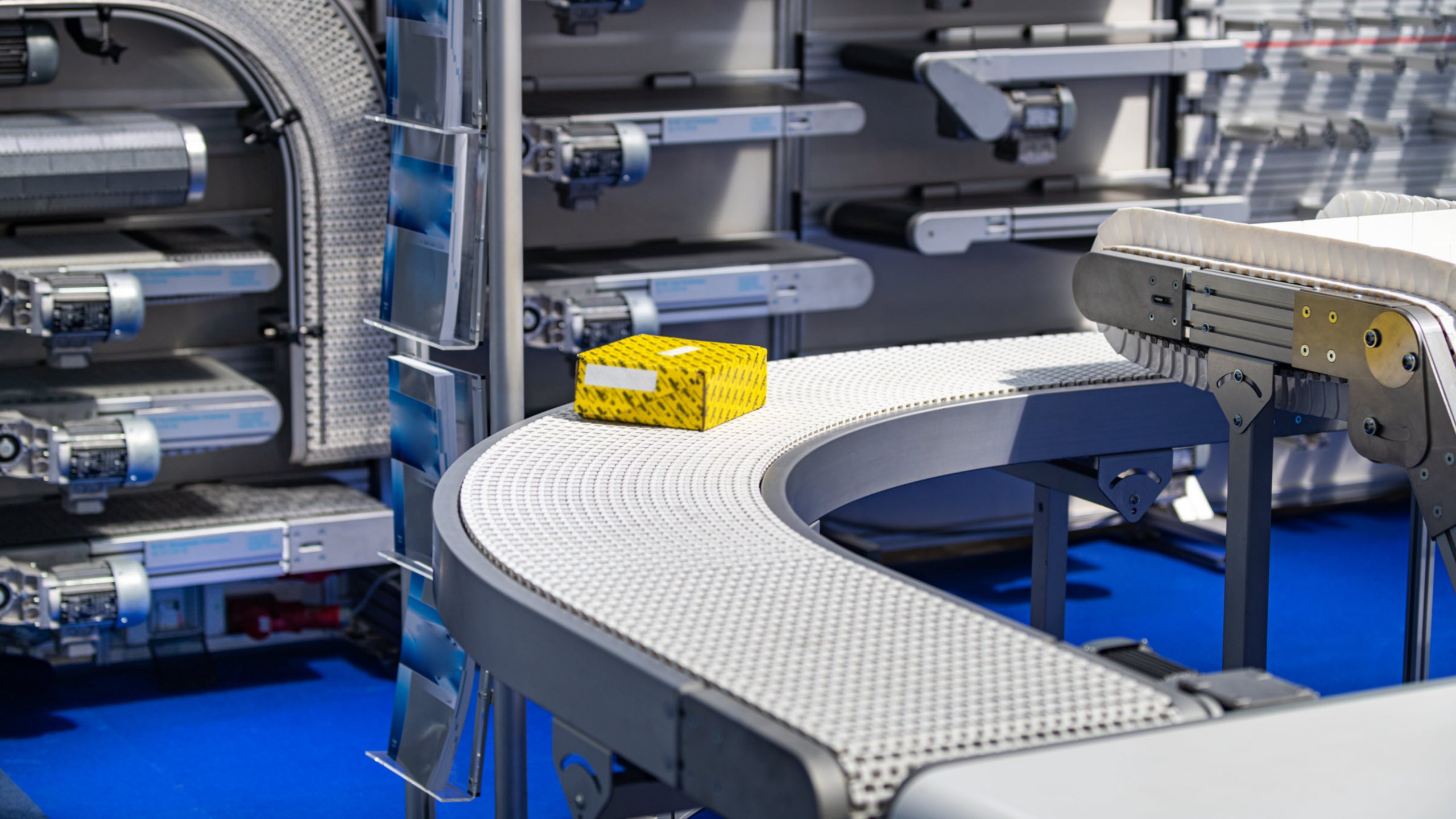

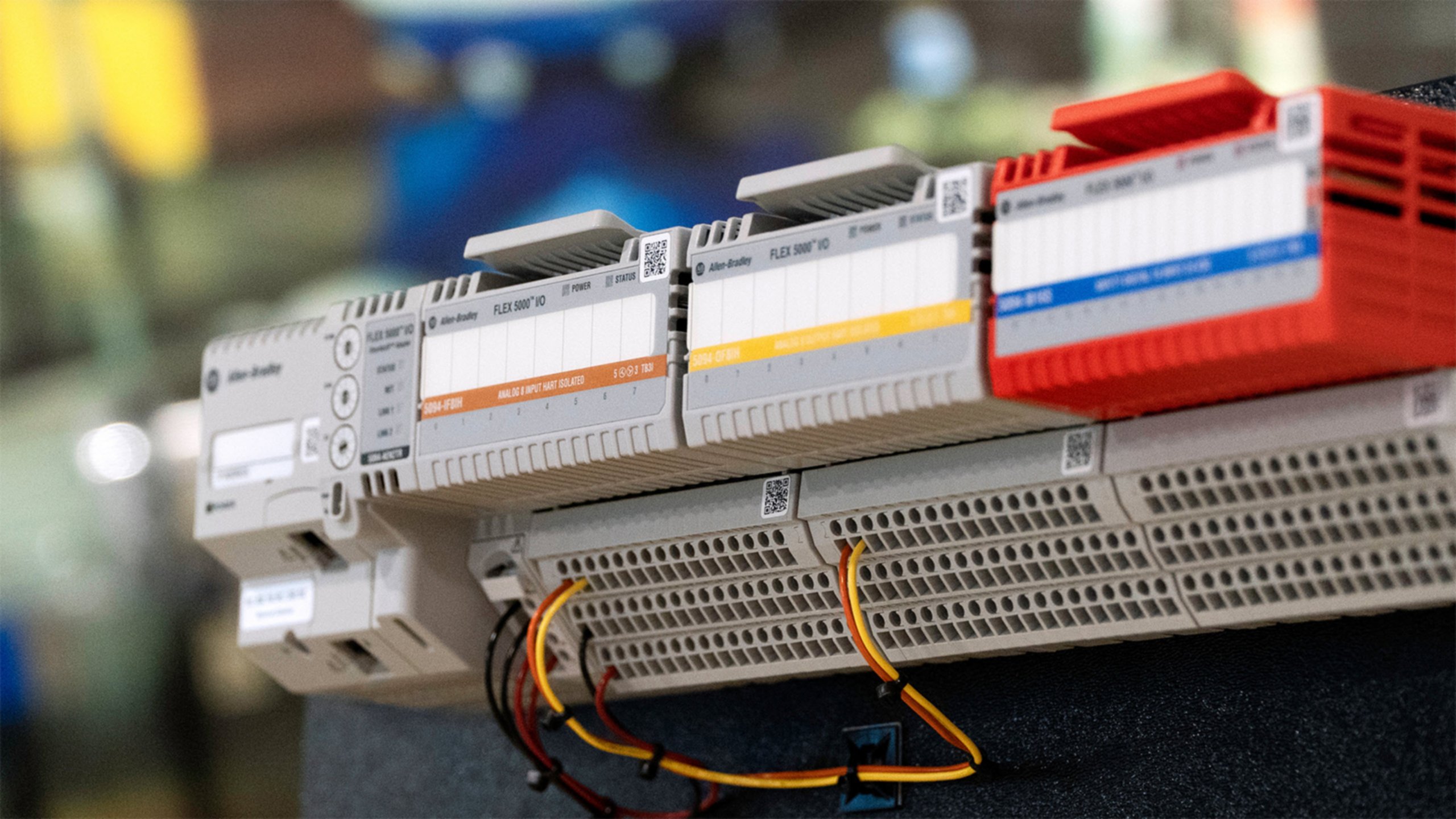

Your plant relies on the machines that power your production – and smart Allen‑Bradley® variable frequency drives (VFDs) help keep them performing at their best. Our devices easily integrate with programmable logic controllers to speed setup and simplify operation. Boost productivity, uptime and energy efficiency with help from PowerFlex® drives and integrated drive motors.

- Overview

- Products

Key Features

Variable Frequency Drives Increase your ROI

From basic speed control to complex process automation, Allen-Bradley variable frequency drives offer a full range of motor control solutions to help increase your uptime and performance.

Low Voltage AC VFDs and Integrated Drive Motors

Medium Voltage AC VFDs

Complete Your Smart Machine

Combine PowerFlex VFDs with these solutions to unlock the greatest value. These integrated technologies work together to accelerate commissioning, reduce downtime and deliver actionable insights – creating smarter, more connected machines that increase productivity and efficiency across your plant.

Unlock Energy Savings with VFDs

Energy costs and sustainability pressures continue to rise. Research shows that industrial motors use at least 30% of the world’s electricity – often using excess energy at a single-speed operation. PowerFlex VFDs help cut costs and emissions by matching motor speed to demand. Use our VFD calculators to quantify savings, estimate payback and compare products. Start building a smarter, greener operation today.

Success is Measured in Results

See how manufacturers, OEMs and system integrators around the world are using PowerFlex VFDs to boost productivity and reduce energy costs.

Simplify Your Processes with the Right Resources and Support

Technical Documentation Center

Technical specifications, manuals and installation instructions

PartnerNetwork

A team of engineering specialists and suppliers that are leaders in the industry.

Lifecycle IQ

Connect, secure, mobilize, and scale your manufacturing operations.

Literature Library

Publications that support Rockwell Automation, FactoryTalk and Allen‑Bradley products, services and solutions.

Knowledgebase

A database of questions and answers on a variety of products and technologies.

Connect with a Rockwell Automation Expert Today

We help you launch faster, reduce risk, and maximize results. Let’s build smarter, together.

Based on Your Activity

.2560.jpg)