Today’s material handling marketplace is dynamic, and end users need the ability to pivot on a moment’s notice. Trying to achieve this using the fixed designs of yesterday’s material handling equipment simply is not possible. Discover how digital-first optimization, distributed control architectures and intelligent material movement enable you to offer the flexibility and scalability your customers require.

Stay Ahead of Rapid Change with a Smarter Design Solution

As an OEM, you are now faced with creating systems that are more flexible and agile than ever before - and must do so under condensed project timelines. With Emulate3D™ software it is possible to transform what’s possible in your machines while making your processes more productive and profitable.

With this software, you can emulate and simulate your equipment in a virtual environment before approving final designs and simplify your path to better optimized systems that can reach the market faster. Now you can validate that your machines are ready to meet demands for flexible operation too. Using functional digital models, you can test system behavior against any number of manufacturing scenarios, confirm performance and catch potential issues before they have an impact.

This model can then increase productivity and reduce costs throughout the machine lifecycle – enabling you to work more efficiently, improve support and confidently deliver more reliable systems.

Discover how you can:

- Reduce risk with a streamlined, virtual design process

- Commission machines with more confidence and speed

- Create more efficient, flexible and productive systems

- Mitigate capital expenditures by testing in a virtual work environment

How are Material Handling OEMs Delivering More Value?

Unlock New Possibilities in Your Material Handling Systems

Discover how our leading hardware and software technologies can be applied to help you add more value to your machines, differentiate your solutions and maximize customer satisfaction.

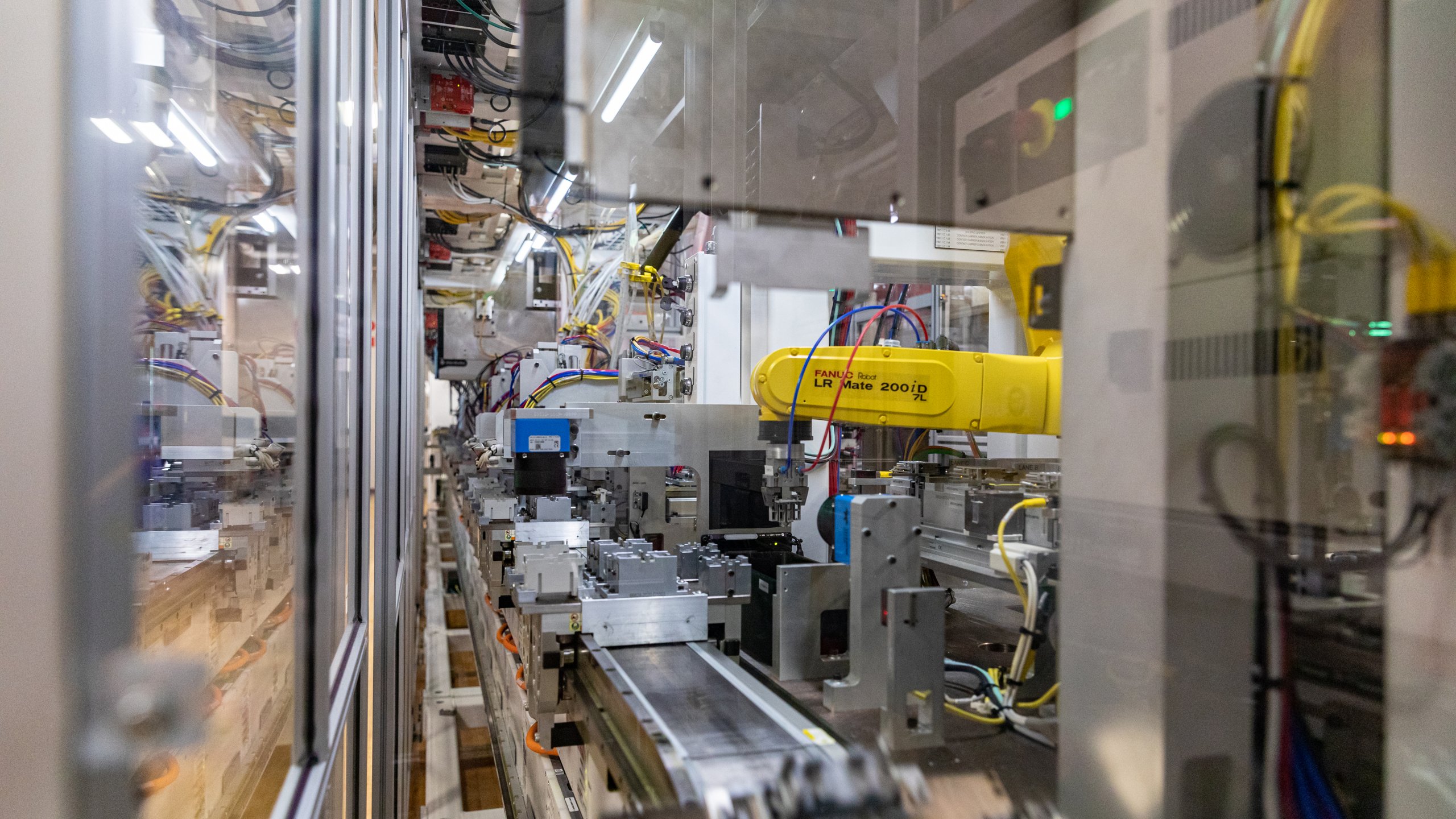

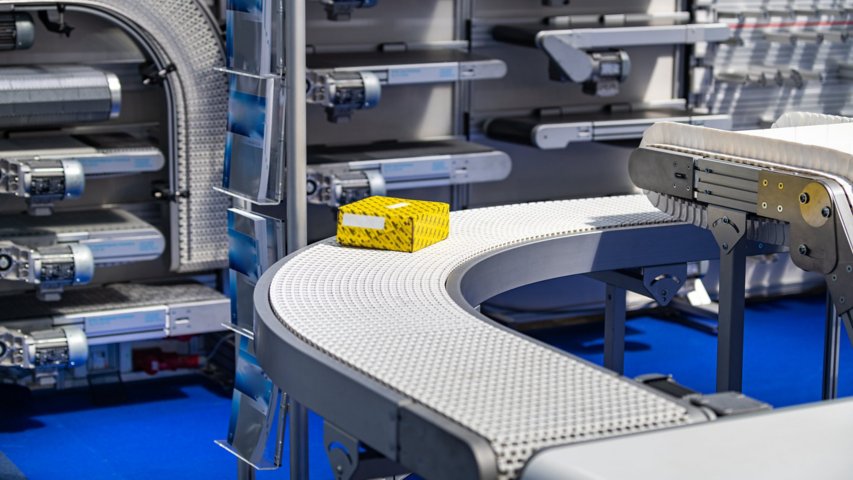

See our Material Handling Solutions in Action

Leading Material Handling OEMs are Making an Impact with Cutting-edge Systems

OEMs that create modern material handling equipment can help their customers stay ahead in a dynamic market. Backed by our technology, we are helping OEMs like you to deliver optimized performance with more scalable and intelligent systems.

Explore What’s Next in the Industries You Serve

Others also viewed

Based on your activity