Integrated Service Agreement

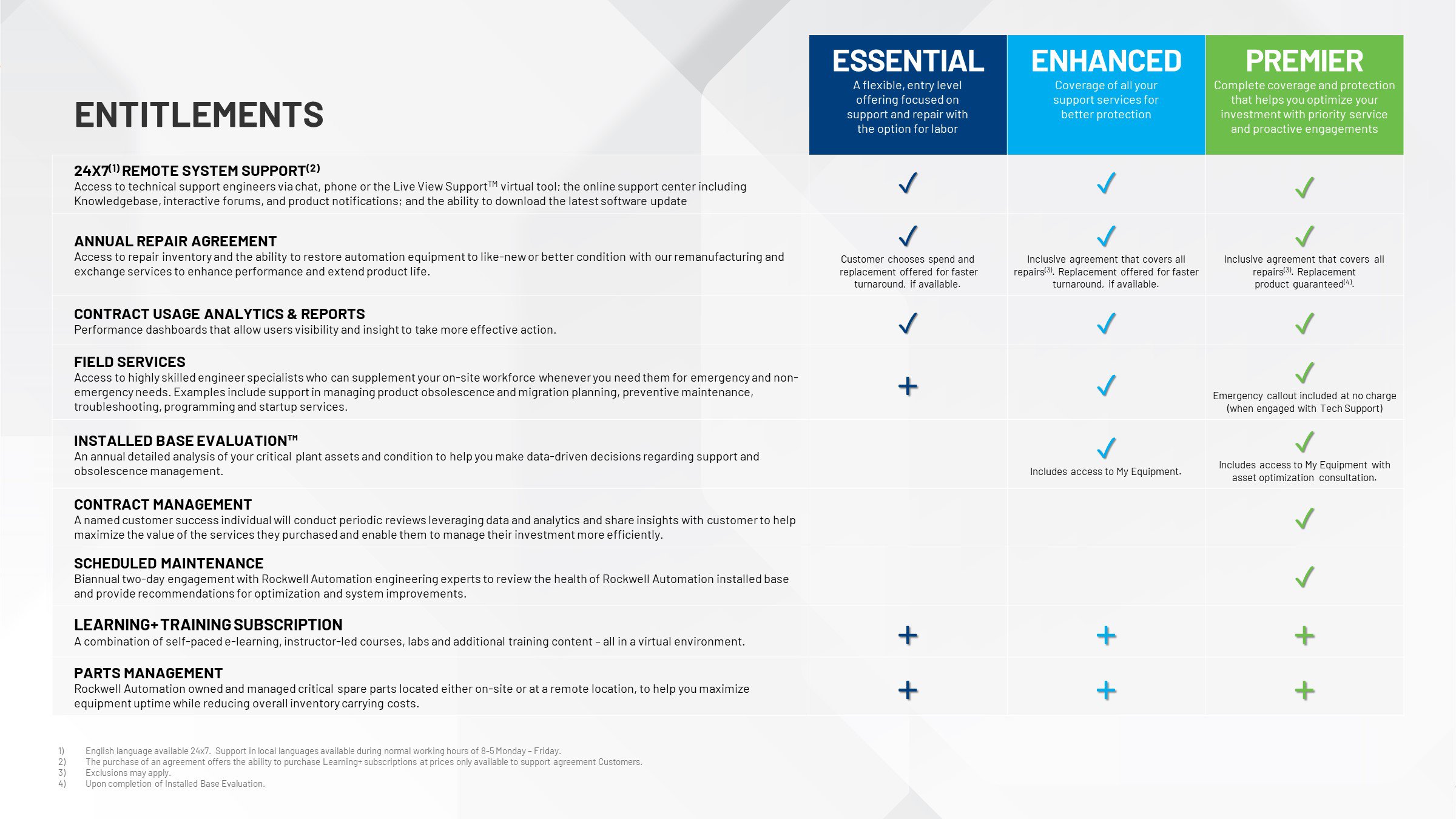

Single agreement, flexible services, one phone number to call. Choose from the tiered service levels to give you the entitlements that are most valuable to your needs.

Integrated Service Agreement

Single agreement, flexible services, one phone number to call. Choose from the tiered service levels to give you the entitlements that are most valuable to your needs.

Remote System Support

Quickly Resolve Production Issues and Get the Most from Your Assets

Whether you need help solving your biggest production problems or want to improve operations, we are here for you. Our remote support services can help optimize control system performance, improve Overall Equipment Effectiveness (OEE), and reduce maintenance costs. We can also help identify and fix issues before they occur, fill skills gaps, and retain knowledge for new workers.

Annual Repair Agreement

A sustainable product recovery strategy with our remanufacturing service

Most customers today leverage repair services to support their production. However, surveys show that using non-authorised repair vendors can result in 3x the failure rate compared to products Remanufactured by Rockwell Automation.

Our Remanufacturing process includes…

Electronic waste represents 2% of solid waste streams BUT makes up 70% of hazardous waste in landfill!

Compared to original manufacturing the ‘Remanufacturing process preserves 85% of energy expended whilst at the same time using 90% fewer raw materials.

Achieve Sustainability Targets

Remanufacturing is a proven ’Sustainable Product Recovery Strategy’ which returns used products to their original state with minimum material and energy wasted.

Reduce Risk

Field Services

Project and on-call services when you need it the most

Hundreds of skilled engineers, located globally, locally available

Learning+ Training Subscriptions

Flexible E-learning and Virtual Training Courses to Help Build the Skills of Your Personnel

Our Learning+ Training subscriptions include both e-learning and virtual training courses. You can access a combination of self-paced e-learning and in-class collaboration with instructors, labs, and additional training content, all in a virtual environment.

Get the flexibility and convenience of learning when and where you need it. We offer easy-to-access training where our Learning+ training courses can be taken on any tablet or PC using Chrome, Safari, IE, Edge, or Firefox, and all content is narrated, and has a viewable transcript.

Ready Access to the Spare Parts You Need, Without the Headaches

Your spare parts inventory is at your site, so you have 24x7 access, while we own and manage the inventory for a fixed fee. The agreement is backed by our remanufacturing and renewal parts services to replenish any inventory used. A vendor-managed inventory service offers you these benefits:

Lifecycle Services Modernization Promotion

Assess, Plan and Execute with LifecycleIQTM Services

A modernization project with LifecycleIQTM Services will include the Assessment, Plan, Code Conversion, Installation and final Testing.

With every project, we are providing a limited time incentive program consisting of:

Additional incentive available by returning your SLC500 hardware to Rockwell Automation as part of the modernization package:

Gain in functionality, equipment utilization and production flexibility whilst lowering overall operation, maintenance, and energy costs.

Extend the lifecycle of your machines and equipment through modernization of the control system.

A unified architecture means a faster time to market, greater flexibility, and access to smart data to speed business decisions.

Legacy systems operate in isolation, are a barrier to digitalisation and smart factories, as well as being a potential cybersecurity risk through un-patchable firmware.

| Active | Most current offering within a product category. |

| Active Mature | Product is fully supported, but a newer product or family exists. Gain value by migrating. |

| End of Life | Discontinued date announced - actively execute migrations and last time buys. Product generally orderable until the discontinued date.1 |

| Discontinued | New product no longer manufactured or procured.2 Repair/exchange services may be available. |

1Outages on specific items may occur prior to the Discontinued date.

2 Limited stock may be available in run-out mode, regionally.

Steps to Modernization

Assess, Plan and Execute with LifecycleIQTM Services

What makes up your operation and where do your risks lie?

Identify technology-driven functionality you may not be realizing or opportunities you’re missing because operations or infrastructure can’t support it.

What are your current number of applications, processors, I/O, servers, clients, etc?

Is your network capable to meet increased communication and security demands?

Are you suffering from excess downtime due to equipment failures and maintenance shutdowns?

Does your workforce need training for new technology?

Document your goals, scope, budget, schedule/timing, and personnel needed.

Rank applications based on complexity and prioritize critical lines.

Consider your system set-up, and incorporate risk mitigation strategies.

Do you want to Migrate and keep the same functionality and user experience as the existing platform or Modernize and take advantage of increased functionality and capabilities?

Is funding currently available?

No funding? – Secure support services for legacy installed base.

Installed Base Evaluation

Gain real insights into your Install Base to help understand your industrial asset inventory

The Installed Base EvaluationTM makes it easy for you as we collect and analyze your assets across your facilities.

Use installed base lifecycle data and insights to develop your capital expenditure plan.

Identify aging equipment and implement strategies to extend the life of assets if not critical.

Eliminate risk with obsolete assets your identifying gaps in your storeroom.

LifecycleIQTM Services – SLC500 EOL Support Services

Learn how our LifecycleIQ Services can help you with your journey into Modernization.

We recently announced select Allen Bradley SLC500 controllers and SLC I/O modules to be discontinued and no longer available for sale. To support your transition, we recommend Engineered Replacement by modernizing to CompactLogix™ 5380 controllers and Compact 5000™ I/O or our ControlLogix platform, dependent on the size of your application.

Remote System Support

The SLC500 product family and associated programming software will continue to be supported through a TechConnect or Integrated Service Agreement as part of our Legacy Product Family.

Experience the same standard of support as current equipment through our 24x7x365 Technical Support Centers, our informative and educational Knowledgebase and our online chat facility.