Industry 4.0 Is Reframing the Automotive Value Chain

The fast lane to efficiency is a smart, connected EV factory. From the mine to the dispatch bay, a connected operation achieves optimized production faster, for less costs, with less risk.

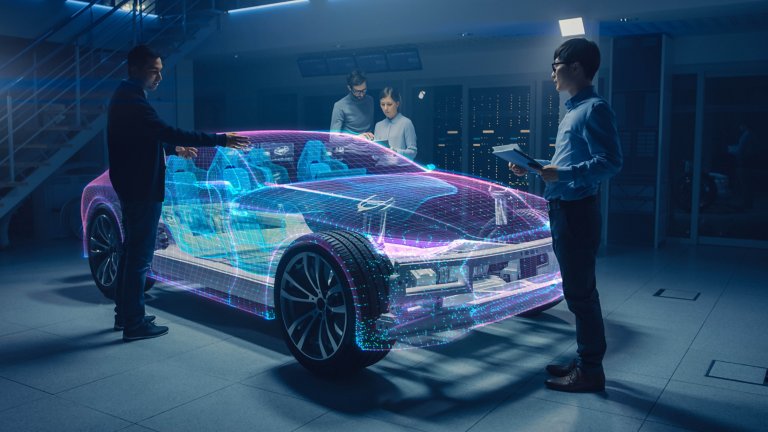

Right now, leading automakers are already using smart machines, analytics and augmented reality (AR) to gain a competitive edge. And at Rockwell Automation, we’re pushing the boundaries to arm you with today’s smartest technologies. Separate yourself from the pack to:

- Make better, faster business decisions on the plant floor and in the board room with scalable analytics

- Improve quality and OEE with an MES to guide workers through production

- Get to market faster with a Connected Enterprise to share data real time across processes, facilities and suppliers

- Reduce downtime with AR delivered machine diagnostics and work instructions

- Improve speed and reliability by moving vehicle bodies and batteries with intelligent conveyance

Smart automotive manufacturing brings optimized manufacturing, responsiveness to customer demands and lower capital costs down the road. Start realizing these benefits today.