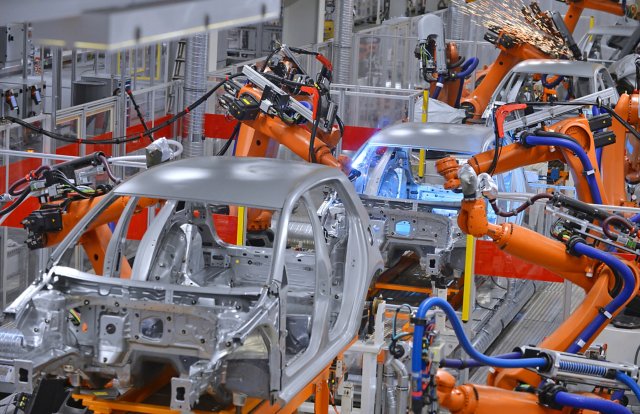

Global leaders in Digital Transformation and Industrial Automation

Global leaders in Digital Transformation and Industrial Automation

We meet you where you are in your journey with market leading hardware, software, and services to make you more resilient, agile, and sustainable.

Rockwell Automation News