| Sub Brand |

NEMA

|

|---|

| Voltage type for actuating |

AC

|

|---|---|

| Suitable for emergency stop |

Yes

|

| External reset possible |

Yes

|

| With short-circuit release |

Yes

|

| Rated control supply voltage at AC 60 Hz |

230 V

|

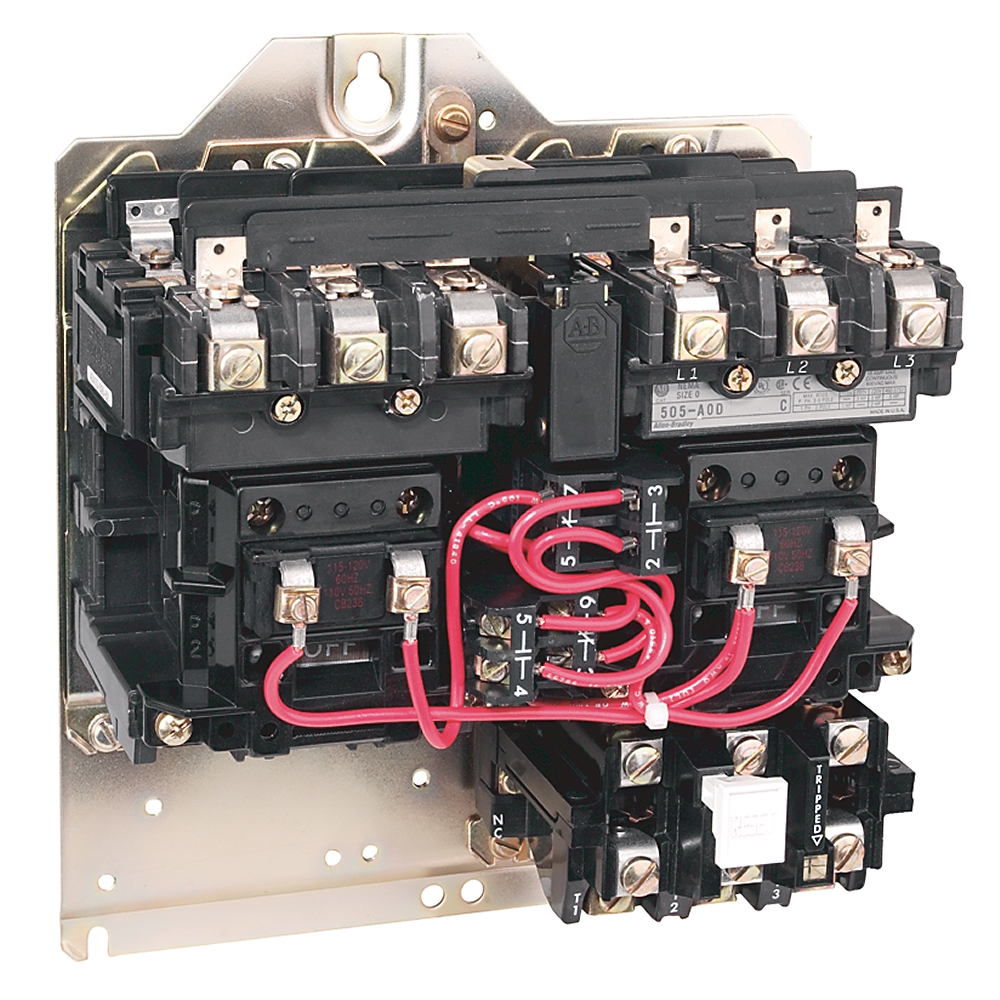

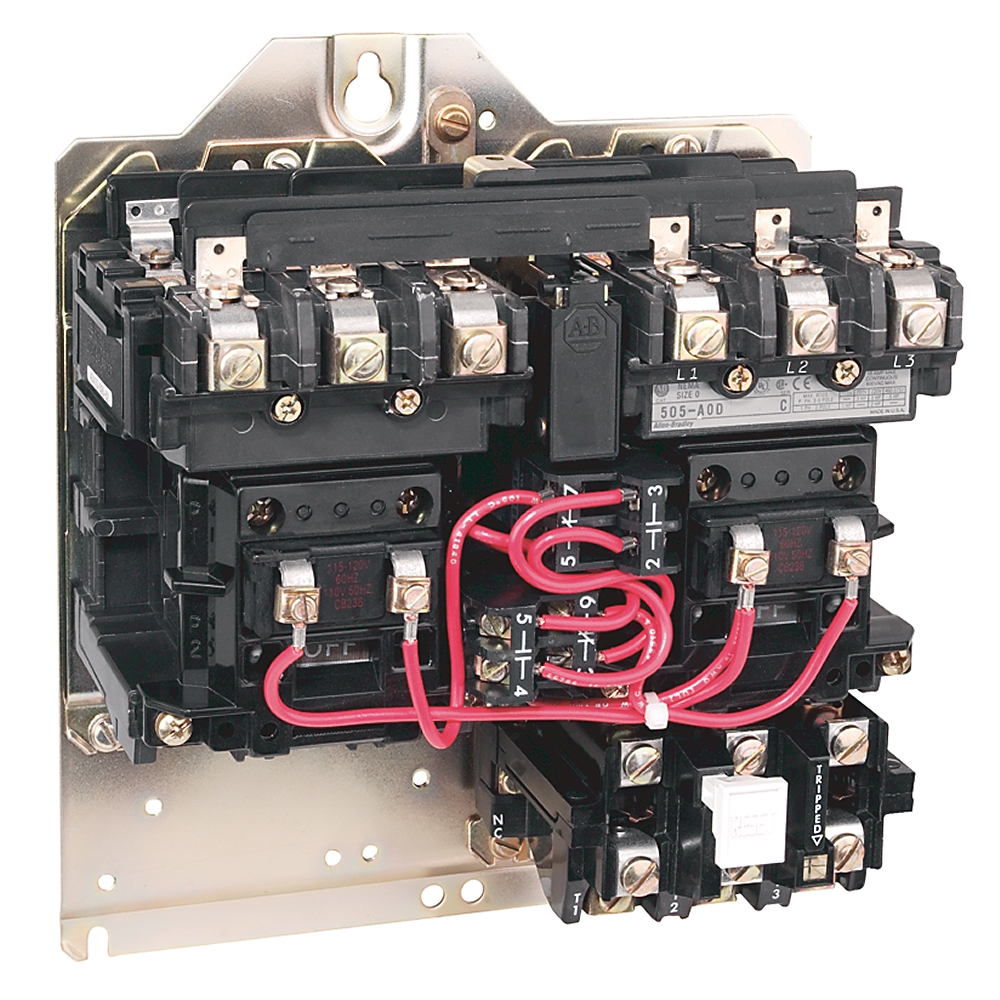

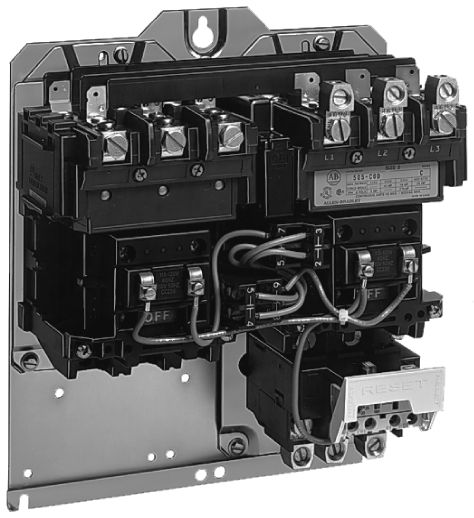

| Type of motor starter |

Reversing starter

|

| Service limit current rating |

32 A

|

| Continuous current |

27 A

|

| Circuit closing inrush current peak including offset, max |

288 A

|

| Heat dissipation |

5.9 W

|

| Coil operating limits |

85...110%

|

| Coil voltage |

120V AC @ 60Hz (transformer control)

|

| Operating volt amperes burden |

Sealed: 38VA, 60 Hz coils (4...5 poles)

|

| Hp rating, max |

7.5Hp @ 230V load voltage, 3-phase (non-plugging and non-jogging duty)

|

| Transformer primary switching kVA rating |

8.5 kVA @ 460V load voltage, 3-phase (inrush current ≤20 times continuous current)

|

| Capacitor switching kVAR |

6 kVAR @ 230V, 3-phase (If maximum available current (at capacitor terminals) is greater than 3000 A, contact your local Rockwell Automation sales office, Allen-Bradley distributor, or NEMA ICS-2 standard)

|

| Type of electrical connection of main circuit |

Screw connection

|

| Type of electrical connection for auxiliary- and control current circuit |

Screw connection

|

| Number of auxiliary contacts, max |

8

|

|---|---|

| Mechanical life operations |

5000000

|

| Operating time, drop-out |

13 ms

|

| Operating time, pick-up |

37 ms

|

| Enclosure type |

Open

|

| Required torque on power terminal wire clamps and pressure connectors or lugs |

150 in-lb

|

|---|---|

| Auxiliary contact material |

Silver

|

| Type of power terminal |

Pressure terminals

|

| Wire size |

For power terminals: 8...1 AWG

|

| Power contact material |

Silver alloy

|

| Requirements for sizing of wire |

All wire rated 167 °F (75 °C) or higher must be sized per the local electrical code for 167 °F (75 °C) wire

|

| NEMA size |

Size 1

|

|---|---|

| Operating position |

Vertical

|

| Altitude |

10000 ft before derating

|

| Operating temperature |

Starters with eutectic alloy overload relay (provided condensation is prevented): -13...149 °F (-25...65 °C)

|

| Overload relay |

Eutectic alloy overload relay

|

| Corrosion-resistance |

All metal parts are treated for corrosion-resistance

|

| Type | Ressource | Publication |

|---|---|---|

| Général | Product Cutsheet | -- |

Vous recherchez plus de documentation ?

Recherchez une documentation technique organisée pour ce produit dans le Centre de documentation technique ou recherchez dans notre bibliothèque documentaire complète.

Rechercher dans la bibliothèque littéraire

Vous recherchez plus de notes techniques ?

Trouvez des questions et des réponses des experts techniques de Rockwell Automation pour ce produit dans notre base de connaissances.

Rechercher dans la base de connaissances

Spécifications techniques

| Sub Brand |

NEMA

|

|---|

| Voltage type for actuating |

AC

|

|---|---|

| Suitable for emergency stop |

Yes

|

| External reset possible |

Yes

|

| With short-circuit release |

Yes

|

| Rated control supply voltage at AC 60 Hz |

230 V

|

| Type of motor starter |

Reversing starter

|

| Service limit current rating |

32 A

|

| Continuous current |

27 A

|

| Circuit closing inrush current peak including offset, max |

288 A

|

| Heat dissipation |

5.9 W

|

| Coil operating limits |

85...110%

|

| Coil voltage |

120V AC @ 60Hz (transformer control)

|

| Operating volt amperes burden |

Sealed: 38VA, 60 Hz coils (4...5 poles)

|

| Hp rating, max |

7.5Hp @ 230V load voltage, 3-phase (non-plugging and non-jogging duty)

|

| Transformer primary switching kVA rating |

8.5 kVA @ 460V load voltage, 3-phase (inrush current ≤20 times continuous current)

|

| Capacitor switching kVAR |

6 kVAR @ 230V, 3-phase (If maximum available current (at capacitor terminals) is greater than 3000 A, contact your local Rockwell Automation sales office, Allen-Bradley distributor, or NEMA ICS-2 standard)

|

| Type of electrical connection of main circuit |

Screw connection

|

| Type of electrical connection for auxiliary- and control current circuit |

Screw connection

|

| Number of auxiliary contacts, max |

8

|

|---|---|

| Mechanical life operations |

5000000

|

| Operating time, drop-out |

13 ms

|

| Operating time, pick-up |

37 ms

|

| Enclosure type |

Open

|

| Required torque on power terminal wire clamps and pressure connectors or lugs |

150 in-lb

|

|---|---|

| Auxiliary contact material |

Silver

|

| Type of power terminal |

Pressure terminals

|

| Wire size |

For power terminals: 8...1 AWG

|

| Power contact material |

Silver alloy

|

| Requirements for sizing of wire |

All wire rated 167 °F (75 °C) or higher must be sized per the local electrical code for 167 °F (75 °C) wire

|

| NEMA size |

Size 1

|

|---|---|

| Operating position |

Vertical

|

| Altitude |

10000 ft before derating

|

| Operating temperature |

Starters with eutectic alloy overload relay (provided condensation is prevented): -13...149 °F (-25...65 °C)

|

| Overload relay |

Eutectic alloy overload relay

|

| Corrosion-resistance |

All metal parts are treated for corrosion-resistance

|

Documents

|

Product Cutsheet

Général

-- |

| Type | Ressource | Publication |

|---|---|---|

| Général | Product Cutsheet | -- |

Vous recherchez plus de documentation ?

Recherchez une documentation technique organisée pour ce produit dans le Centre de documentation technique ou recherchez dans notre bibliothèque documentaire complète.

Rechercher dans la bibliothèque littéraire

Accessoires

Produits alternatifs

Notes techniques

Vous recherchez plus de notes techniques ?

Trouvez des questions et des réponses des experts techniques de Rockwell Automation pour ce produit dans notre base de connaissances.

Rechercher dans la base de connaissances

Loading

Copyright ©2026 Rockwell Automation, Inc.