View all NEMA Open/Enclosed Full Voltage Starters

Preferred

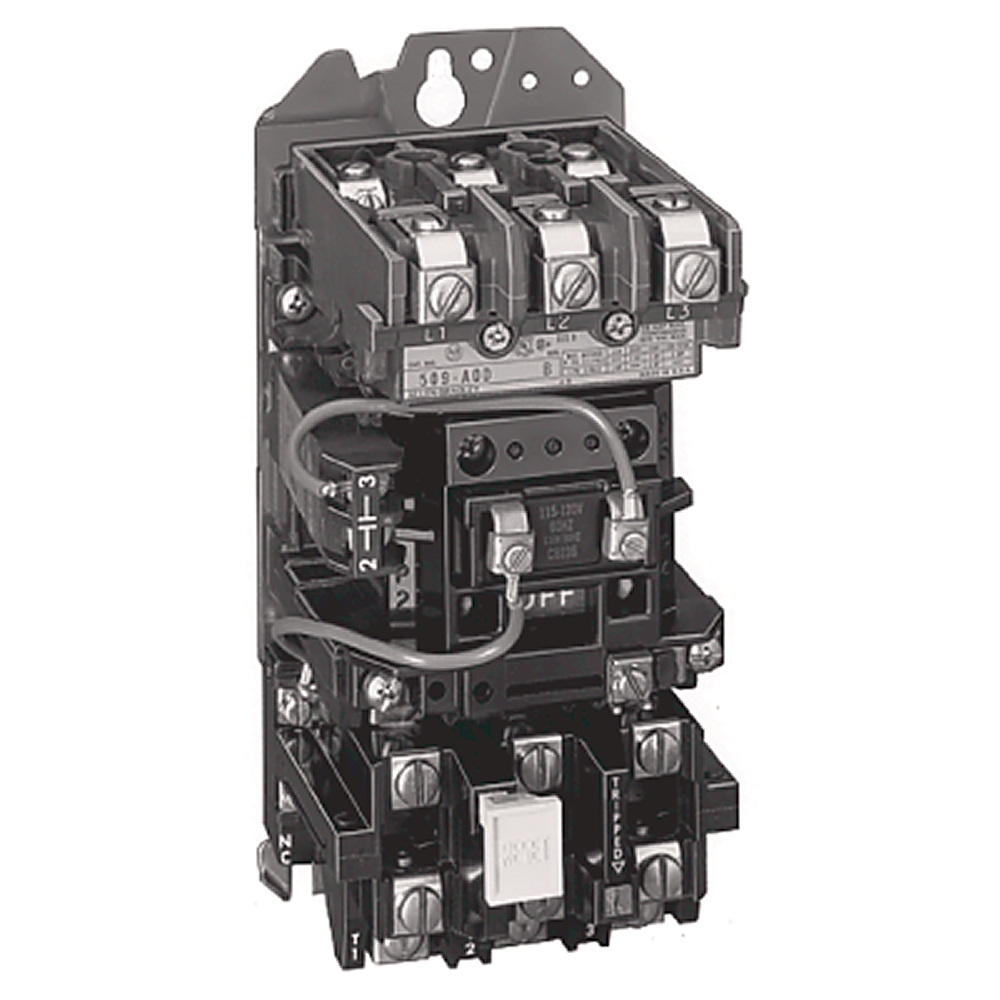

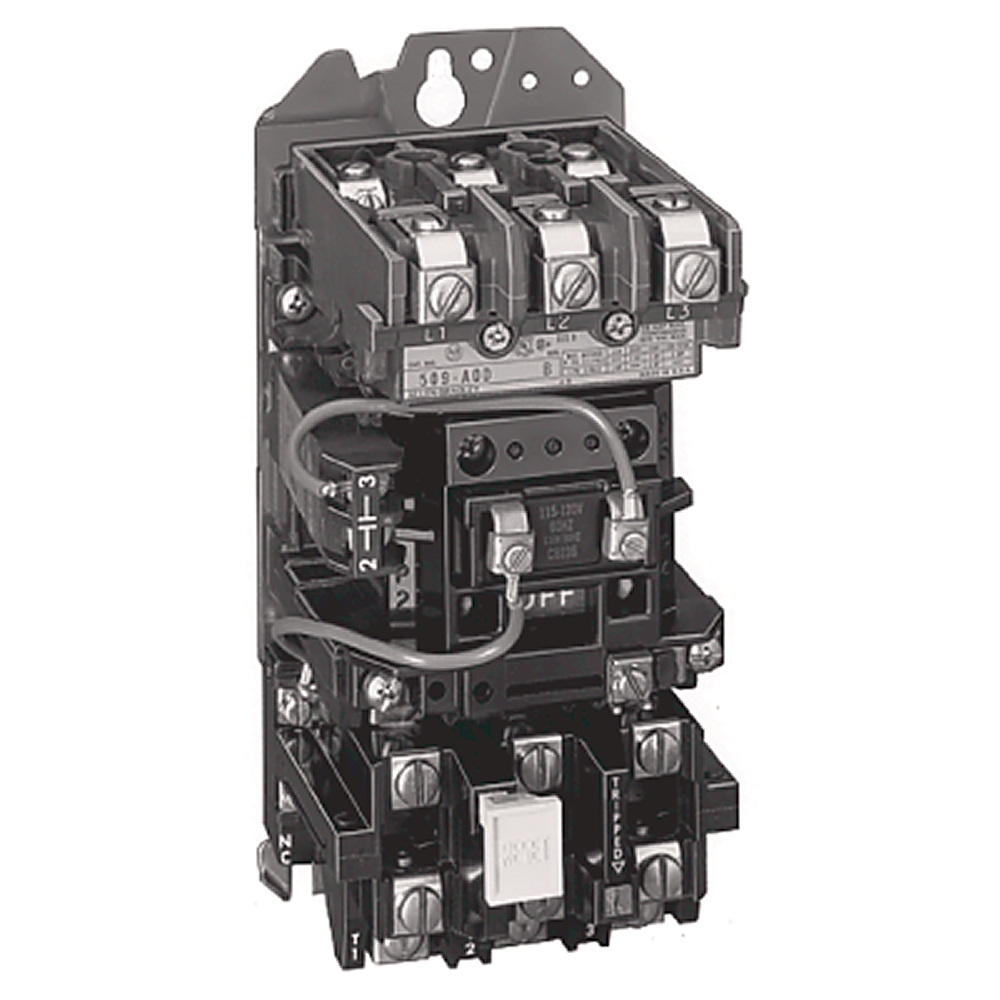

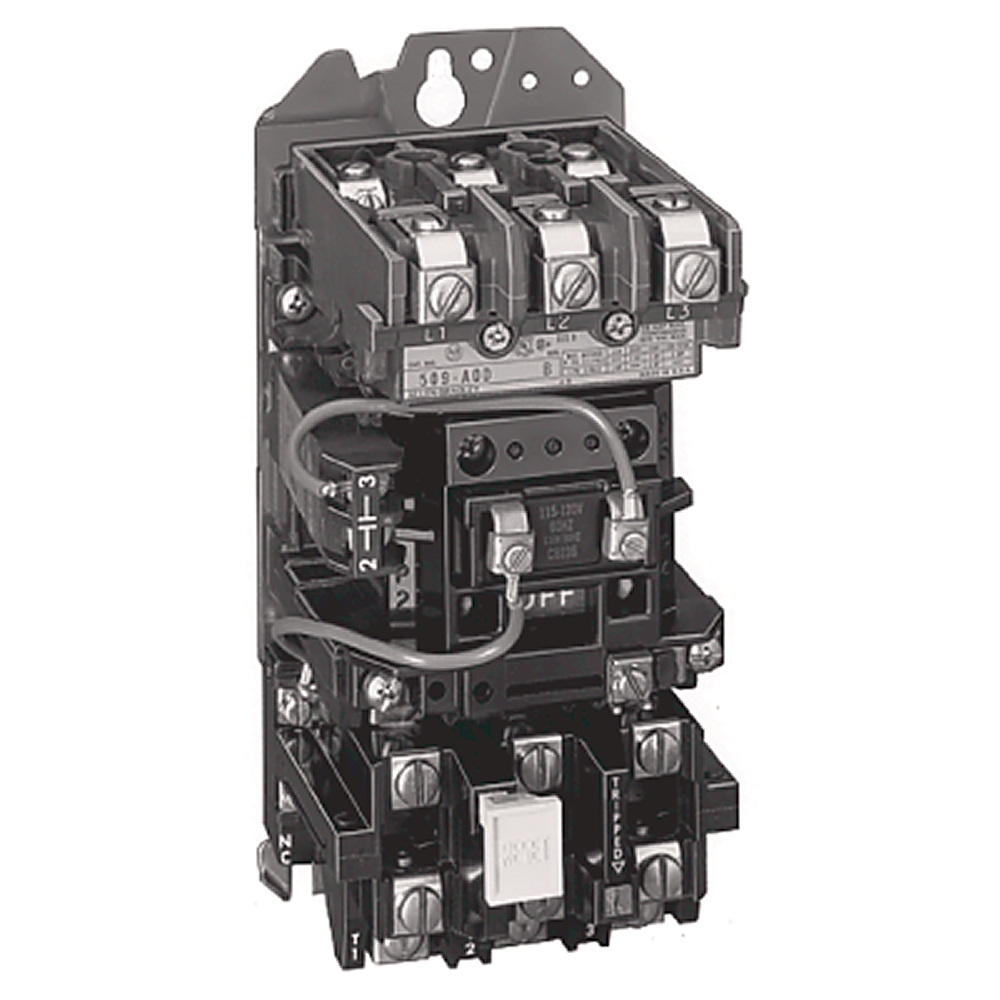

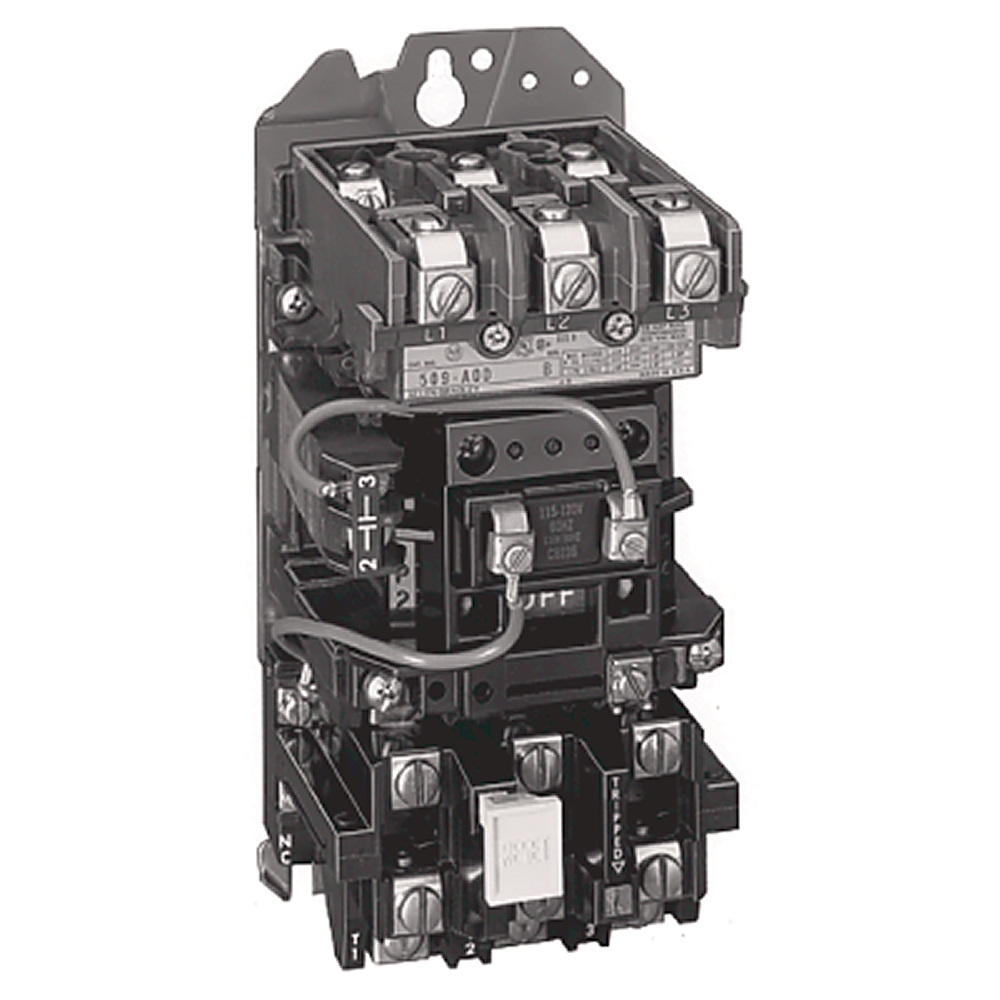

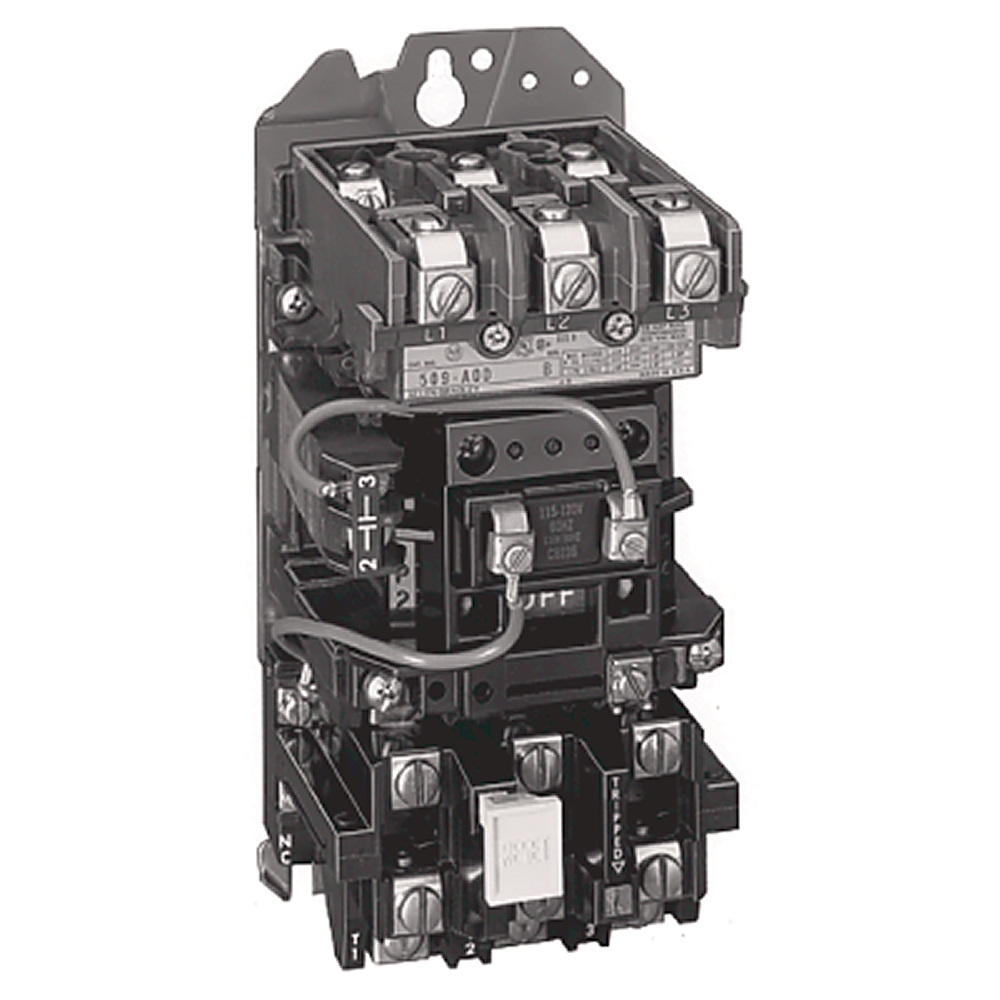

509-BOD-A2F

NEMA 3 Phase Non-Reversing Starter

| Number of indicator lights |

0

|

|---|---|

| Voltage type for actuating |

AC

|

| With transformer |

False

|

| Suitable for emergency stop |

True

|

| Supporting protocol for PROFIBUS |

False

|

| External reset possible |

True

|

| With short-circuit release |

True

|

| With fuse |

False

|

| Supporting protocol for EtherNet/IP |

False

|

| Rated control supply voltage at AC 50 Hz |

110 V

|

| Rated control supply voltage at AC 60 Hz |

120 V

|

| Release class |

Adjustable

|

| Overload release current setting |

3.2 A

|

| Type of motor starter |

Direct online starter (DOL)

|

| Service limit current rating |

32 A

|

| Continuous current |

27 A

|

| Circuit closing inrush current peak including offset, max |

288 A

|

| Heat dissipation |

5.9 W

|

| Coil operating limits |

85...110%

|

| Operating volt amperes burden |

Sealed: 29VA, 60 Hz coils

|

| Hp rating, max |

7.5Hp @ 230V load voltage, 3-phase (non-plugging and non-jogging duty)

|

| Transformer primary switching kVA rating |

8.5 kVA @ 460V load voltage, 3-phase (inrush current ≤20 times continuous current)

|

| Capacitor switching kVAR |

6 kVAR @ 230V, 3-phase (If maximum available current (at capacitor terminals) is greater than 3000 A, contact your local Rockwell Automation sales office, Allen-Bradley distributor, or NEMA ICS-2 standard)

|

| Supporting protocol for DeviceNet |

True

|

| Temperature compensated overload protection |

True

|

| Coordination class according to IEC 60947-4-3 |

Class 2

|

| Type of electrical connection of main circuit |

Screw connection

|

| Type of electrical connection for auxiliary- and control current circuit |

Screw connection

|

| Rail mounting possible |

True

|

|---|---|

| Number of auxiliary contacts, max |

8

|

| Mechanical life operations |

1.0E7

|

| Average operating time, pick-up |

22 ms

|

| Average operating time, drop-out |

14 ms

|

| Required torque on power terminal wire clamps and pressure connectors or lugs |

20 in-lb

|

|---|---|

| Auxiliary contact material |

Silver

|

| Type of power terminal |

Saddle or wire clA

|

| Wire size |

For power terminals: 14...8 AWG

|

| Enclosure |

Open type

|

| Power contact material |

Silver Alloy

|

| Requirements for sizing of wire |

All wire rated 167 °F (75 °C) or higher must be sized per the local electrical code for 167 °F (75 °C) wire

|

| NEMA size |

Size 1

|

|---|---|

| Operating temperature |

55 °C

|

| Operating position |

Vertical

|

| Altitude |

10000 ft before derating

|

| Overload relay |

Overload relay, full load current adjustment range 3.2...16 A

|

| Corrosion-resistance |

All metal parts are treated for corrosion-resistance

|

| Drawings | |

|---|---|

| 2D Drawing (PDF) | Download (PDF) |

| 3D STEP Model (STP) | Download (ZIP) |

| Product Drawing | Drawing (DWG) |

| Product Drawing | Drawing (DXF) |

| Drawings |

|---|

| 2D Drawing (PDF) Download (PDF) |

| 3D STEP Model (STP) Download (ZIP) |

| Product Drawing Drawing (DWG) |

| Product Drawing Drawing (DXF) |

| General | Publication |

|---|---|

| Product Cutsheet | -- |

| Repair Parts List | -- |

| Circuit Protection Design and SCCR Tables | -- |

Looking for more documentation?

Find curated technical documentation for this product in the Technical Documentation Center, or search our full Literature Library.

Search the Literature Library

- UL Listed

This product was certified with the above certifications as of {}. Products sold before or after this date might carry different certifications. Please review the product label to check for the certifications your specific product carries.

| Technotes |

|---|

Looking for more Technotes?

Find questions and answers from Rockwell Automation technical experts for this product in our Knowledgebase.

Search Knowledgebase

Technical Specifications

| Number of indicator lights |

0

|

|---|---|

| Voltage type for actuating |

AC

|

| With transformer |

False

|

| Suitable for emergency stop |

True

|

| Supporting protocol for PROFIBUS |

False

|

| External reset possible |

True

|

| With short-circuit release |

True

|

| With fuse |

False

|

| Supporting protocol for EtherNet/IP |

False

|

| Rated control supply voltage at AC 50 Hz |

110 V

|

| Rated control supply voltage at AC 60 Hz |

120 V

|

| Release class |

Adjustable

|

| Overload release current setting |

3.2 A

|

| Type of motor starter |

Direct online starter (DOL)

|

| Service limit current rating |

32 A

|

| Continuous current |

27 A

|

| Circuit closing inrush current peak including offset, max |

288 A

|

| Heat dissipation |

5.9 W

|

| Coil operating limits |

85...110%

|

| Operating volt amperes burden |

Sealed: 29VA, 60 Hz coils

|

| Hp rating, max |

7.5Hp @ 230V load voltage, 3-phase (non-plugging and non-jogging duty)

|

| Transformer primary switching kVA rating |

8.5 kVA @ 460V load voltage, 3-phase (inrush current ≤20 times continuous current)

|

| Capacitor switching kVAR |

6 kVAR @ 230V, 3-phase (If maximum available current (at capacitor terminals) is greater than 3000 A, contact your local Rockwell Automation sales office, Allen-Bradley distributor, or NEMA ICS-2 standard)

|

| Supporting protocol for DeviceNet |

True

|

| Temperature compensated overload protection |

True

|

| Coordination class according to IEC 60947-4-3 |

Class 2

|

| Type of electrical connection of main circuit |

Screw connection

|

| Type of electrical connection for auxiliary- and control current circuit |

Screw connection

|

| Rail mounting possible |

True

|

|---|---|

| Number of auxiliary contacts, max |

8

|

| Mechanical life operations |

1.0E7

|

| Average operating time, pick-up |

22 ms

|

| Average operating time, drop-out |

14 ms

|

| Required torque on power terminal wire clamps and pressure connectors or lugs |

20 in-lb

|

|---|---|

| Auxiliary contact material |

Silver

|

| Type of power terminal |

Saddle or wire clA

|

| Wire size |

For power terminals: 14...8 AWG

|

| Enclosure |

Open type

|

| Power contact material |

Silver Alloy

|

| Requirements for sizing of wire |

All wire rated 167 °F (75 °C) or higher must be sized per the local electrical code for 167 °F (75 °C) wire

|

| NEMA size |

Size 1

|

|---|---|

| Operating temperature |

55 °C

|

| Operating position |

Vertical

|

| Altitude |

10000 ft before derating

|

| Overload relay |

Overload relay, full load current adjustment range 3.2...16 A

|

| Corrosion-resistance |

All metal parts are treated for corrosion-resistance

|

Drawings

| Drawings | |

|---|---|

| 2D Drawing (PDF) | Download (PDF) |

| 3D STEP Model (STP) | Download (ZIP) |

| Product Drawing | Drawing (DWG) |

| Product Drawing | Drawing (DXF) |

| Drawings |

|---|

| 2D Drawing (PDF) Download (PDF) |

| 3D STEP Model (STP) Download (ZIP) |

| Product Drawing Drawing (DWG) |

| Product Drawing Drawing (DXF) |

Documents

|

Product Cutsheet

General

-- |

|

Repair Parts List

General

-- |

|

Circuit Protection Design and SCCR Tables

General

-- |

| General | Publication |

|---|---|

| Product Cutsheet | -- |

| Repair Parts List | -- |

| Circuit Protection Design and SCCR Tables | -- |

Looking for more documentation?

Find curated technical documentation for this product in the Technical Documentation Center, or search our full Literature Library.

Search the Literature Library

Certifications

- UL Listed

This product was certified with the above certifications as of {}. Products sold before or after this date might carry different certifications. Please review the product label to check for the certifications your specific product carries.

Alternative Products

Technotes

| Technotes |

|---|

Looking for more Technotes?

Find questions and answers from Rockwell Automation technical experts for this product in our Knowledgebase.

Search Knowledgebase

Copyright ©2026 Rockwell Automation, Inc.