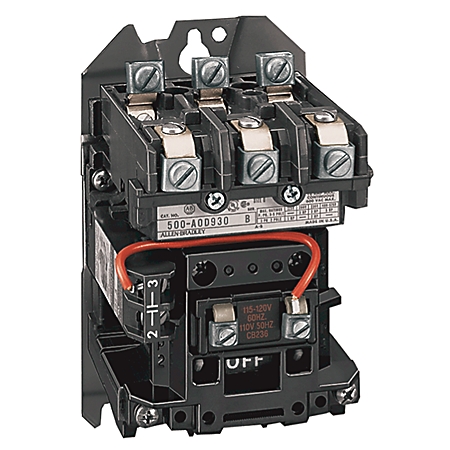

| Product Family | NEMA Contactor |

|---|

| Voltage type for actuating | AC |

|---|---|

| Rated control supply voltage at AC 50 Hz | 110 V |

| Rated control supply voltage at AC 60 Hz | 120 V |

| Type of electrical connection of main circuit | Screw connection |

| Service limit current rating | 21 A |

| Continuous current | 18 A |

| Heat dissipation | 5.9 W |

| Circuit closing inrush current peak including offset, max | 140 A |

| NEMA size | Size 0 |

| Pole configuration | 3 power poles with 1 NO auxiliary contact |

| Factory installed models | 1 NO & 1 NC auxiliary contact on the contactor |

| Operating volt amperes burden | Sealed: 29VA, 60 Hz coils |

| Hp rating, max | 5Hp @ 575V load voltage, 3-phase (non-plugging and non-jogging duty) |

| Transformer primary switching kVA rating | 5.2 kVA @ 575V load voltage, 3-phase (inrush current ≤20 times continuous current) |

| Modular version | True |

| Coil operating limits | 85 % |

| Number of auxiliary contacts, max | 8 |

|---|---|

| Mechanical life operations | 1.0E7 |

| Average operating time, pick-up | 21 ms |

| Average operating time, drop-out | 16 ms |

| Required torque on power terminal wire clamps and pressure connectors or lugs | 20 in-lb |

|---|---|

| Type of power terminal | Saddle or wire clA |

| Wire size | For power terminals: 14...10 AWG |

| Enclosure | Open Type |

| Power contact material | Silver Alloy |

| Auxiliary contact material | Silver |

| Requirements for sizing of wire | All wire rated 167 °F (75 °C) or higher must be sized per the local electrical code for 167 °F (75 °C) wire |

| Operating position | Vertical |

|---|---|

| Altitude | 10000 ft before derating |

| Operating temperature | -13 to 149 °F (-25 to 65 °C) @ starters with eutectic alloy overload relay, -13 to 131 °F (-25 to 55 °C) @ starters with electronic overload relay, (provided condensation is prevented) |

| Corrosion-resistance | All metal parts are treated for corrosion-resistance |

| Drawings | |

|---|---|

| 2D Drawing (PDF) | Download (PDF) |

| 3D Model (STP) | Download (ZIP) |

| Product Drawing | Drawing (DXF) |

| Drawings |

|---|

| 2D Drawing (PDF) Download (PDF) |

| 3D Model (STP) Download (ZIP) |

| Product Drawing Drawing (DXF) |

| Type | Resource | Publication |

|---|---|---|

| General | Repair Parts for Enclosure | -- |

| General | Repair Parts for Control Circuit Terminal | -- |

| General | Circuit Protection Design and SCCR Tables | -- |

| General | Product Cutsheet | -- |

| Technical Data | 500-td014_-en-p | 500-TD014 |

Looking for more documentation?

Find curated technical documentation for this product in the Technical Documentation Center, or search our full Literature Library.

Search the Literature Library

Looking for more Technotes?

Find questions and answers from Rockwell Automation technical experts for this product in our Knowledgebase.

Search Knowledgebase

Technical Specifications

| Product Family | NEMA Contactor |

|---|

| Voltage type for actuating | AC |

|---|---|

| Rated control supply voltage at AC 50 Hz | 110 V |

| Rated control supply voltage at AC 60 Hz | 120 V |

| Type of electrical connection of main circuit | Screw connection |

| Service limit current rating | 21 A |

| Continuous current | 18 A |

| Heat dissipation | 5.9 W |

| Circuit closing inrush current peak including offset, max | 140 A |

| NEMA size | Size 0 |

| Pole configuration | 3 power poles with 1 NO auxiliary contact |

| Factory installed models | 1 NO & 1 NC auxiliary contact on the contactor |

| Operating volt amperes burden | Sealed: 29VA, 60 Hz coils |

| Hp rating, max | 5Hp @ 575V load voltage, 3-phase (non-plugging and non-jogging duty) |

| Transformer primary switching kVA rating | 5.2 kVA @ 575V load voltage, 3-phase (inrush current ≤20 times continuous current) |

| Modular version | True |

| Coil operating limits | 85 % |

| Number of auxiliary contacts, max | 8 |

|---|---|

| Mechanical life operations | 1.0E7 |

| Average operating time, pick-up | 21 ms |

| Average operating time, drop-out | 16 ms |

| Required torque on power terminal wire clamps and pressure connectors or lugs | 20 in-lb |

|---|---|

| Type of power terminal | Saddle or wire clA |

| Wire size | For power terminals: 14...10 AWG |

| Enclosure | Open Type |

| Power contact material | Silver Alloy |

| Auxiliary contact material | Silver |

| Requirements for sizing of wire | All wire rated 167 °F (75 °C) or higher must be sized per the local electrical code for 167 °F (75 °C) wire |

| Operating position | Vertical |

|---|---|

| Altitude | 10000 ft before derating |

| Operating temperature | -13 to 149 °F (-25 to 65 °C) @ starters with eutectic alloy overload relay, -13 to 131 °F (-25 to 55 °C) @ starters with electronic overload relay, (provided condensation is prevented) |

| Corrosion-resistance | All metal parts are treated for corrosion-resistance |

Drawings

| Drawings | |

|---|---|

| 2D Drawing (PDF) | Download (PDF) |

| 3D Model (STP) | Download (ZIP) |

| Product Drawing | Drawing (DXF) |

| Drawings |

|---|

| 2D Drawing (PDF) Download (PDF) |

| 3D Model (STP) Download (ZIP) |

| Product Drawing Drawing (DXF) |

Documents

|

Repair Parts for Enclosure

General

-- |

|

Repair Parts for Control Circuit Terminal

General

-- |

|

Circuit Protection Design and SCCR Tables

General

-- |

|

Product Cutsheet

General

-- |

|

500-td014_-en-p

Technical Data

500-TD014 |

| Type | Resource | Publication |

|---|---|---|

| General | Repair Parts for Enclosure | -- |

| General | Repair Parts for Control Circuit Terminal | -- |

| General | Circuit Protection Design and SCCR Tables | -- |

| General | Product Cutsheet | -- |

| Technical Data | 500-td014_-en-p | 500-TD014 |

Looking for more documentation?

Find curated technical documentation for this product in the Technical Documentation Center, or search our full Literature Library.

Search the Literature Library

Accessories

Technotes

Looking for more Technotes?

Find questions and answers from Rockwell Automation technical experts for this product in our Knowledgebase.

Search Knowledgebase

Loading

Copyright ©2025 Rockwell Automation, Inc.