| Type of accessory/spare part |

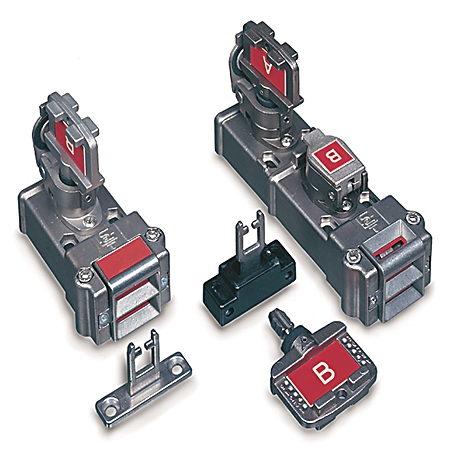

Mechanical locking

|

|---|---|

| Width |

58 mm

|

| Height |

183 mm

|

| Depth |

34 mm

|

| Type of switch |

Slamlock electrical, single key, primary trapped

|

| Operating temperature |

-20 °C

|

|---|---|

| Pollution degree |

3

|

| Current, min |

5mA @ 5V DC

|

|---|---|

| Utilization category |

AC-15 (Ue/Ie: 240V/3A @ 120V/6A) DC-13 (Ue/Ie: 24V/2A

|

| Thermal current (Ith) |

10 A

|

| Rated impulse voltage (Uimp) |

2500 V

|

| Auxiliary contacts |

1 NO

|

| Insulation voltage |

Rated 500V

|

| Color |

Red/Stainless

|

| Electrical life cycle |

Dependant on load

|

| Safety contacts |

2 NC positive break

|

| Switching current, max |

500V/500VA @ voltage

|

| Torque settings, max |

Terminal screws: 1.0 Nm

|

|---|---|

| Key code 1 position 1 |

Code 1 position 1 - code 0

|

| Key code 1 position 2 |

Code 1 position 2 - code D

|

| Weight |

SSE: 1.17 kg (2.6 lb)

|

| Operating radius, min |

175 mm (6.88 in) (60 mm (2.36 in) with flexible actuator)

|

| Mounting |

SSS: 4 x M5 counterbored from top or 4 x M5 from underside with nuts

|

| Key condition |

Key trapped to release fully flexible actuator

|

| Features |

Electrical safety contacts combined with trapped key/enforced sequence feature, Most of unit constructed from 316L stainless steel, Selection of actuator types available, Single or dual key versions available, Direct drive ops, Replaceable code barr

|

| Actuator travel for positive opening |

5 mm

|

| Torque to key |

14

|

| Break contact force, min |

12 N

|

| Relative humidity |

95 %

|

| Releasable load, max |

100 N

|

| Shear force to key |

15.1

|

| Holding force, max |

2000 N

|

| Actuation speed, max |

1 m/s

|

| Mechanical life operations |

200000

|

| Conduit entry |

3 x M20

|

| Actuation frequency, max |

2 cycle/s

|

| Actuator material |

Stainless Steel

|

| Safety contact gap |

>2 x 2 mm (0.07 in)

|

| Case material |

316L Stainless Steel, UL approved glass-filled Polyester

|

Sign in to your Rockwell Automation account to view and download technical drawings.

Sign In

| Type | Resource | Publication |

|---|---|---|

| General | Product Cutsheet | -- |

Looking for more documentation?

Find curated technical documentation for this product in the Technical Documentation Center, or search our full Literature Library.

Search the Literature Library

- UNITED KINGDOM SAFETY CERTIFICATE

This product was certified with the above certifications as of 2025-12-16. Products sold before or after this date might carry different certifications. Please review the product label to check for the certifications your specific product carries.

Looking for more Technotes?

Find questions and answers from Rockwell Automation technical experts for this product in our Knowledgebase.

Search Knowledgebase

Technical Specifications

| Type of accessory/spare part |

Mechanical locking

|

|---|---|

| Width |

58 mm

|

| Height |

183 mm

|

| Depth |

34 mm

|

| Type of switch |

Slamlock electrical, single key, primary trapped

|

| Operating temperature |

-20 °C

|

|---|---|

| Pollution degree |

3

|

| Current, min |

5mA @ 5V DC

|

|---|---|

| Utilization category |

AC-15 (Ue/Ie: 240V/3A @ 120V/6A) DC-13 (Ue/Ie: 24V/2A

|

| Thermal current (Ith) |

10 A

|

| Rated impulse voltage (Uimp) |

2500 V

|

| Auxiliary contacts |

1 NO

|

| Insulation voltage |

Rated 500V

|

| Color |

Red/Stainless

|

| Electrical life cycle |

Dependant on load

|

| Safety contacts |

2 NC positive break

|

| Switching current, max |

500V/500VA @ voltage

|

| Torque settings, max |

Terminal screws: 1.0 Nm

|

|---|---|

| Key code 1 position 1 |

Code 1 position 1 - code 0

|

| Key code 1 position 2 |

Code 1 position 2 - code D

|

| Weight |

SSE: 1.17 kg (2.6 lb)

|

| Operating radius, min |

175 mm (6.88 in) (60 mm (2.36 in) with flexible actuator)

|

| Mounting |

SSS: 4 x M5 counterbored from top or 4 x M5 from underside with nuts

|

| Key condition |

Key trapped to release fully flexible actuator

|

| Features |

Electrical safety contacts combined with trapped key/enforced sequence feature, Most of unit constructed from 316L stainless steel, Selection of actuator types available, Single or dual key versions available, Direct drive ops, Replaceable code barr

|

| Actuator travel for positive opening |

5 mm

|

| Torque to key |

14

|

| Break contact force, min |

12 N

|

| Relative humidity |

95 %

|

| Releasable load, max |

100 N

|

| Shear force to key |

15.1

|

| Holding force, max |

2000 N

|

| Actuation speed, max |

1 m/s

|

| Mechanical life operations |

200000

|

| Conduit entry |

3 x M20

|

| Actuation frequency, max |

2 cycle/s

|

| Actuator material |

Stainless Steel

|

| Safety contact gap |

>2 x 2 mm (0.07 in)

|

| Case material |

316L Stainless Steel, UL approved glass-filled Polyester

|

Drawings

Sign in to your Rockwell Automation account to view and download technical drawings.

Sign In

Documents

|

Product Cutsheet

General

-- |

| Type | Resource | Publication |

|---|---|---|

| General | Product Cutsheet | -- |

Looking for more documentation?

Find curated technical documentation for this product in the Technical Documentation Center, or search our full Literature Library.

Search the Literature Library

Certifications

- UNITED KINGDOM SAFETY CERTIFICATE

This product was certified with the above certifications as of 2025-12-16. Products sold before or after this date might carry different certifications. Please review the product label to check for the certifications your specific product carries.

Alternative Products

Technotes

Looking for more Technotes?

Find questions and answers from Rockwell Automation technical experts for this product in our Knowledgebase.

Search Knowledgebase

Loading

Copyright ©2026 Rockwell Automation, Inc.