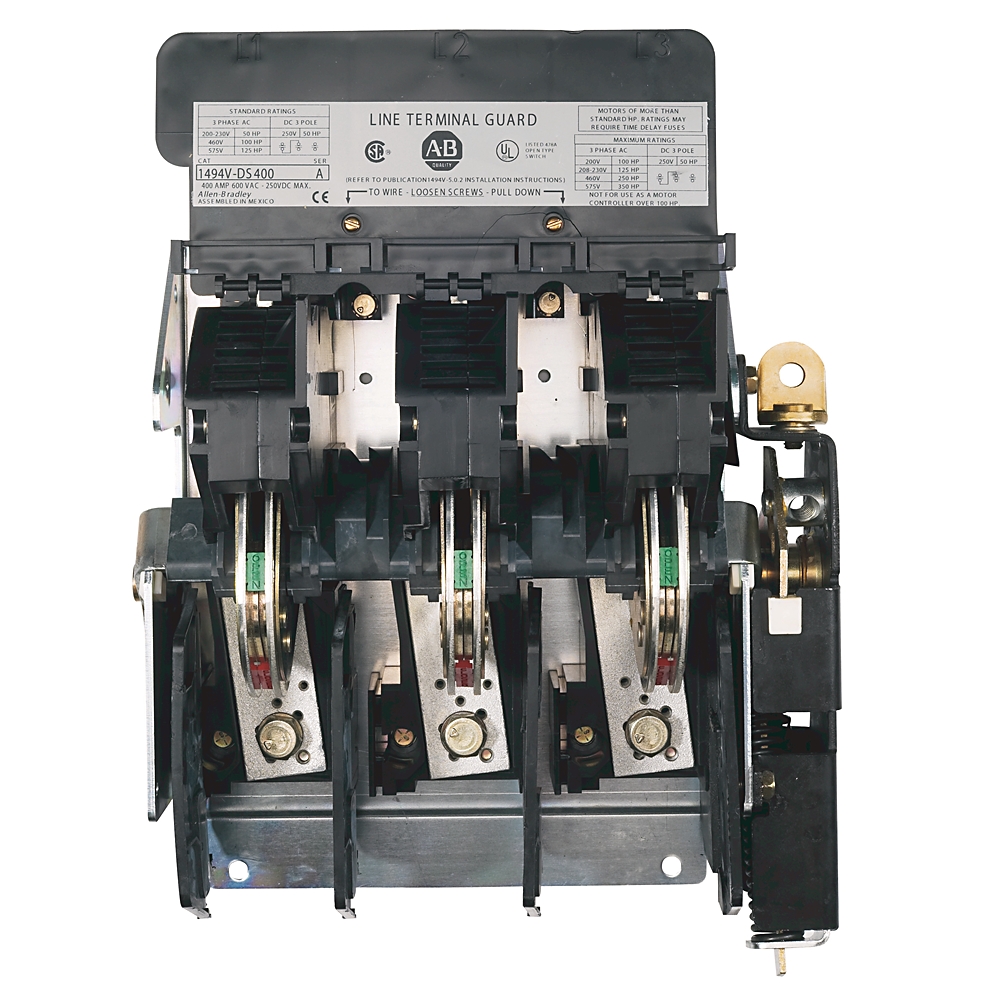

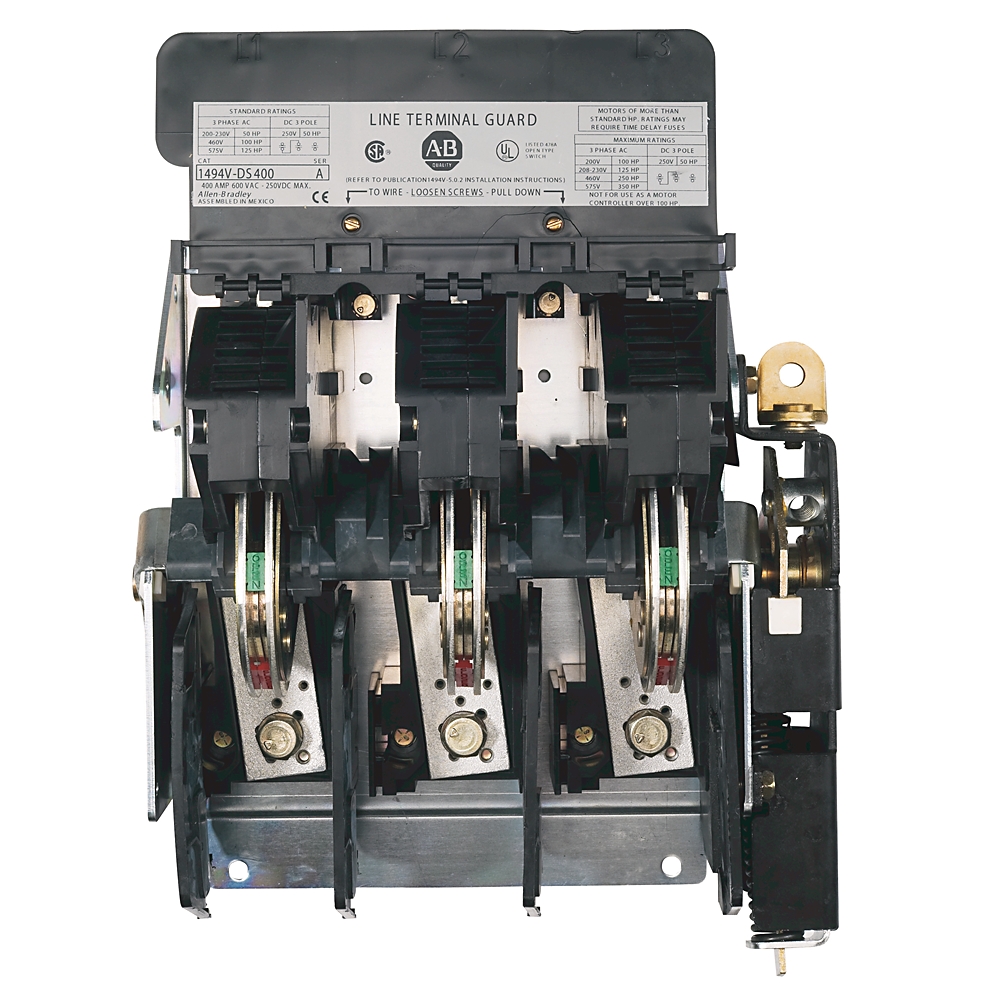

1494V-DJ606

NEMA 600 A Flange Mtd Rod Switch

Rockwell Automation announces that as of May 31, 2019, the NEMA 600 A Flange Mtd Rod Switch will be discontinued and no longer available for sale. Customers are encouraged to remove references to the affected product(s)

Discontinued Date:

May 31, 2019

Replacement Category:

Engineering Replacement

Replacement Product:

1494U-J600-CR-LC-M

[https://www.rockwellautomation.com/en-us/products/details.1494U-J600-CR-LC-M.html]

Product at a glance

Rockwell Automation announces that as of May 31, 2019, the NEMA 600 A Flange Mtd Rod Switch will be discontinued and no longer available for sale. Customers are encouraged to remove references to the affected product(s)

Discontinued Date:

May 31, 2019

Replacement Category:

Engineering Replacement

Replacement Product:

1494U-J600-CR-LC-M

[https://www.rockwellautomation.com/en-us/products/details.1494U-J600-CR-LC-M.html]

Product at a glance

| Product Family |

NEMA

|

|---|---|

| Product Type |

Flange Mtd Rod Switch

|

| Rated permanent current Iu |

600 A

|

|---|---|

| Max. rated operation voltage Ue AC |

600 V

|

| Type of control element |

Long turning handle

|

| Switching frequency, max |

3 ops/m

|

| Fuse clip type |

Class J fuse clips

|

| Continuous current rating |

600A @ 600V AC

|

| Number of switches |

1

|

| Motor drive integrated |

False

|

| Motor drive optional |

False

|

| Voltage release optional |

False

|

| Type of electrical connection of main circuit |

Screw connection

|

| Switch and fuse rating (fusing) |

600V 600 A switch, 600 A clips

|

| Short circuit withstand capability |

200000A @ 600V AC: with Class J or Class R fuses

|

| KW rating, max |

375 Kw per AC23 (IEC) @ 500...600V AC, 3-phase, 50 Hz

|

| Hp rating, max |

500 Hp per UL and CSA @ 575V AC, 3-phase, 60 Hz

|

| Low level auxiliary contact rating 1 NO or 1 NC |

C300, R150 per NEMA/EEMAC

|

| Standard auxiliary contact rating 1 NO or 1 NC |

AC 15, DC 13 to IEC/EN60947-5-1 and UL 508, 17V @ 5mA minimum per IEC

|

| Dielectric strength |

2200V @ 1min

|

| Standard electrical interlock contact rating 2 NO |

10A @ 250V AC, 0.3A @ 250V DC per NEMA/EEMAC

|

| Interlockable |

True

|

|---|---|

| Version as emergency stop installation |

False

|

| Recommended torque, lug to terminal |

275 in-lb

|

| Mechanical life operations |

5000 (typical)

|

| Version as safety switch |

False

|

| Version as reversing switch |

False

|

| Version as main switch |

True

|

| Version as maintenance-/service switch |

True

|

| Material |

Switches, mechanisms and accessory kits: zinc-plated steel, RoHS compliant finish

|

| Recommended torque, switch side |

275 in-lb

|

| Suitable for front mounting 4-hole |

False

|

|---|---|

| Suitable for front mounting centre |

False

|

| Colour control element |

Black

|

| Device construction |

Built-in device fixed built-in technique

|

| Disconnect mechanism |

Right-hand mechanism

|

| Suitable for floor mounting |

False

|

| Suitable for distribution board installation |

True

|

| Suitable for intermediate mounting |

True

|

| Conductor size |

2 of #1 AWG...350 MCM (2 per lug), 2 of 185 mm²...350 MCM or 1 of #4 AWG...500 MCM

|

| Altitude |

2000 m per IEC 337-1

|

|---|---|

| Relative humidity |

90% @ 20°C (68 °F) and 50% @ 40°C (104 °F)

|

| Ambient open temperature, max |

-20 °C

|

| Ambient enclosed temperature, max |

-20 °C

|

| Ambient storage temperature, max |

-40 °C

|

| General | Publication |

|---|---|

| Product Cutsheet | -- |

| Technical Data | Publication |

|---|---|

| 1494-td002_-en-p | 1494-TD002 |

Looking for more documentation?

Find curated technical documentation for this product in the Technical Documentation Center, or search our full Literature Library.

Search the Literature Library

- CE

This product was certified with the above certifications as of {}. Products sold before or after this date might carry different certifications. Please review the product label to check for the certifications your specific product carries.

Looking for more Technotes?

Find questions and answers from Rockwell Automation technical experts for this product in our Knowledgebase.

Search Knowledgebase

Technical Specifications

| Product Family |

NEMA

|

|---|---|

| Product Type |

Flange Mtd Rod Switch

|

| Rated permanent current Iu |

600 A

|

|---|---|

| Max. rated operation voltage Ue AC |

600 V

|

| Type of control element |

Long turning handle

|

| Switching frequency, max |

3 ops/m

|

| Fuse clip type |

Class J fuse clips

|

| Continuous current rating |

600A @ 600V AC

|

| Number of switches |

1

|

| Motor drive integrated |

False

|

| Motor drive optional |

False

|

| Voltage release optional |

False

|

| Type of electrical connection of main circuit |

Screw connection

|

| Switch and fuse rating (fusing) |

600V 600 A switch, 600 A clips

|

| Short circuit withstand capability |

200000A @ 600V AC: with Class J or Class R fuses

|

| KW rating, max |

375 Kw per AC23 (IEC) @ 500...600V AC, 3-phase, 50 Hz

|

| Hp rating, max |

500 Hp per UL and CSA @ 575V AC, 3-phase, 60 Hz

|

| Low level auxiliary contact rating 1 NO or 1 NC |

C300, R150 per NEMA/EEMAC

|

| Standard auxiliary contact rating 1 NO or 1 NC |

AC 15, DC 13 to IEC/EN60947-5-1 and UL 508, 17V @ 5mA minimum per IEC

|

| Dielectric strength |

2200V @ 1min

|

| Standard electrical interlock contact rating 2 NO |

10A @ 250V AC, 0.3A @ 250V DC per NEMA/EEMAC

|

| Interlockable |

True

|

|---|---|

| Version as emergency stop installation |

False

|

| Recommended torque, lug to terminal |

275 in-lb

|

| Mechanical life operations |

5000 (typical)

|

| Version as safety switch |

False

|

| Version as reversing switch |

False

|

| Version as main switch |

True

|

| Version as maintenance-/service switch |

True

|

| Material |

Switches, mechanisms and accessory kits: zinc-plated steel, RoHS compliant finish

|

| Recommended torque, switch side |

275 in-lb

|

| Suitable for front mounting 4-hole |

False

|

|---|---|

| Suitable for front mounting centre |

False

|

| Colour control element |

Black

|

| Device construction |

Built-in device fixed built-in technique

|

| Disconnect mechanism |

Right-hand mechanism

|

| Suitable for floor mounting |

False

|

| Suitable for distribution board installation |

True

|

| Suitable for intermediate mounting |

True

|

| Conductor size |

2 of #1 AWG...350 MCM (2 per lug), 2 of 185 mm²...350 MCM or 1 of #4 AWG...500 MCM

|

| Altitude |

2000 m per IEC 337-1

|

|---|---|

| Relative humidity |

90% @ 20°C (68 °F) and 50% @ 40°C (104 °F)

|

| Ambient open temperature, max |

-20 °C

|

| Ambient enclosed temperature, max |

-20 °C

|

| Ambient storage temperature, max |

-40 °C

|

Documents

|

Product Cutsheet

General

-- |

|

1494-td002_-en-p

Technical Data

1494-TD002 |

| General | Publication |

|---|---|

| Product Cutsheet | -- |

| Technical Data | Publication |

| 1494-td002_-en-p | 1494-TD002 |

Looking for more documentation?

Find curated technical documentation for this product in the Technical Documentation Center, or search our full Literature Library.

Search the Literature Library

Certifications

- CE

This product was certified with the above certifications as of {}. Products sold before or after this date might carry different certifications. Please review the product label to check for the certifications your specific product carries.

Alternative Products

Technotes

Looking for more Technotes?

Find questions and answers from Rockwell Automation technical experts for this product in our Knowledgebase.

Search Knowledgebase

Loading

Copyright ©2026 Rockwell Automation, Inc.