View all Bulletin 100-K Miniature Contactors

Preferred

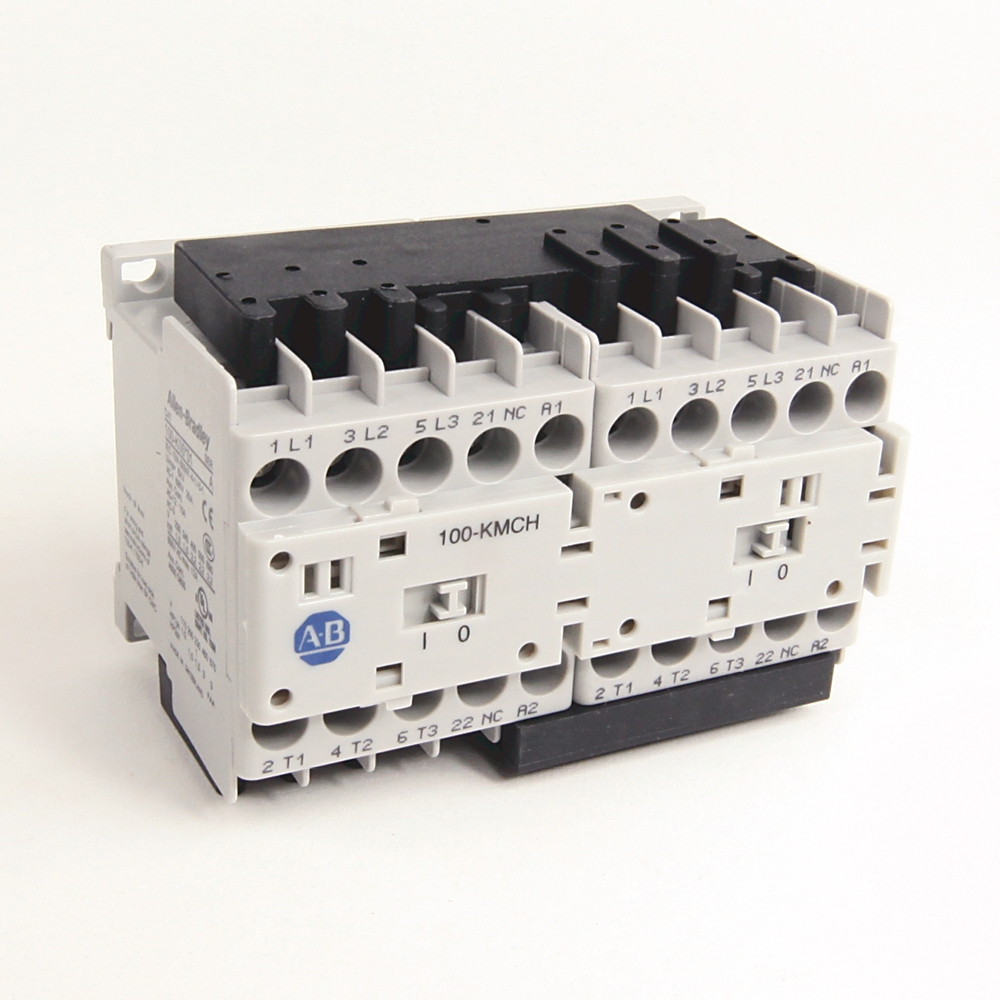

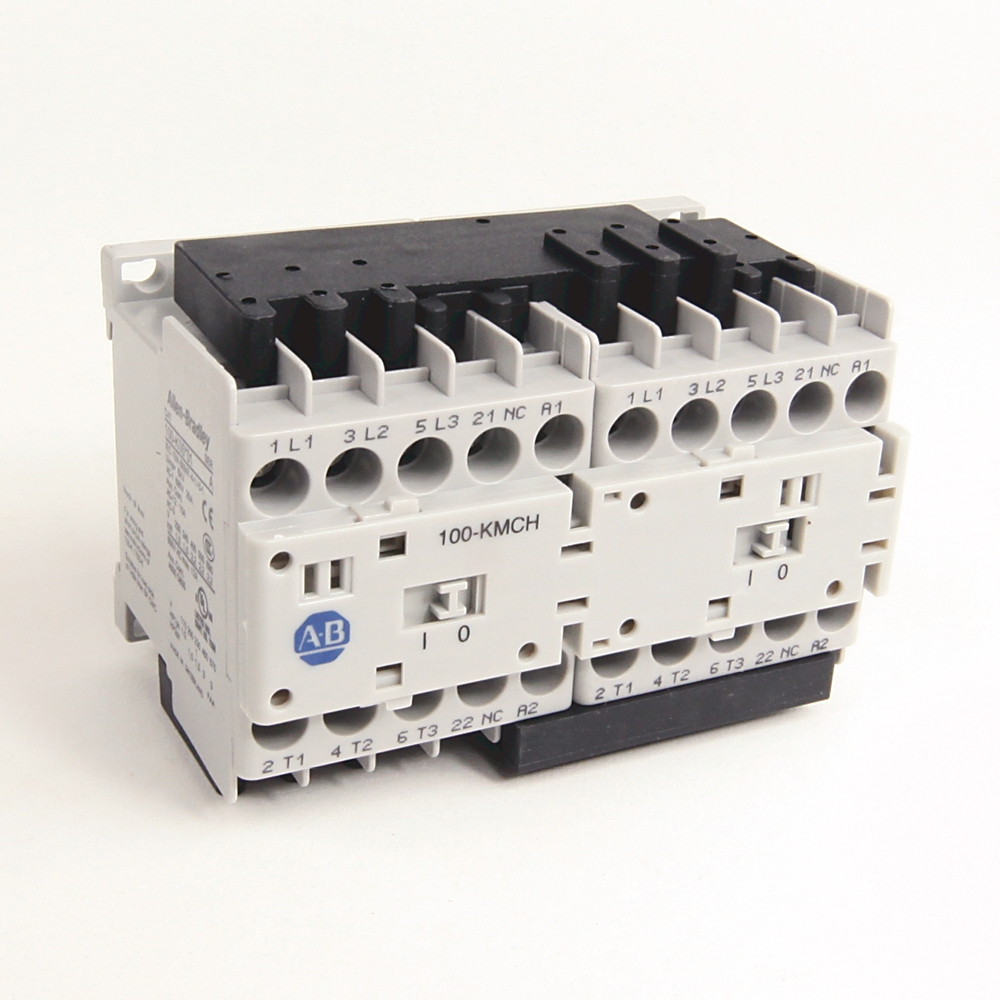

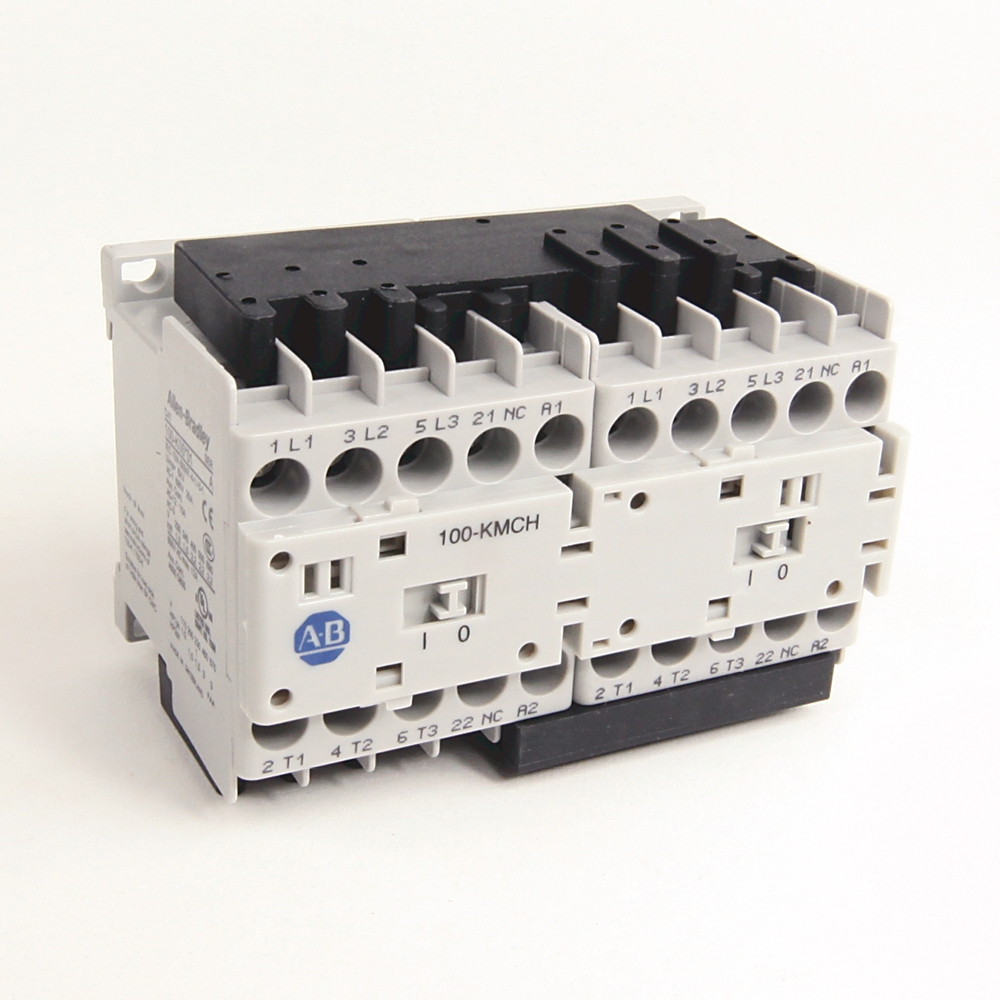

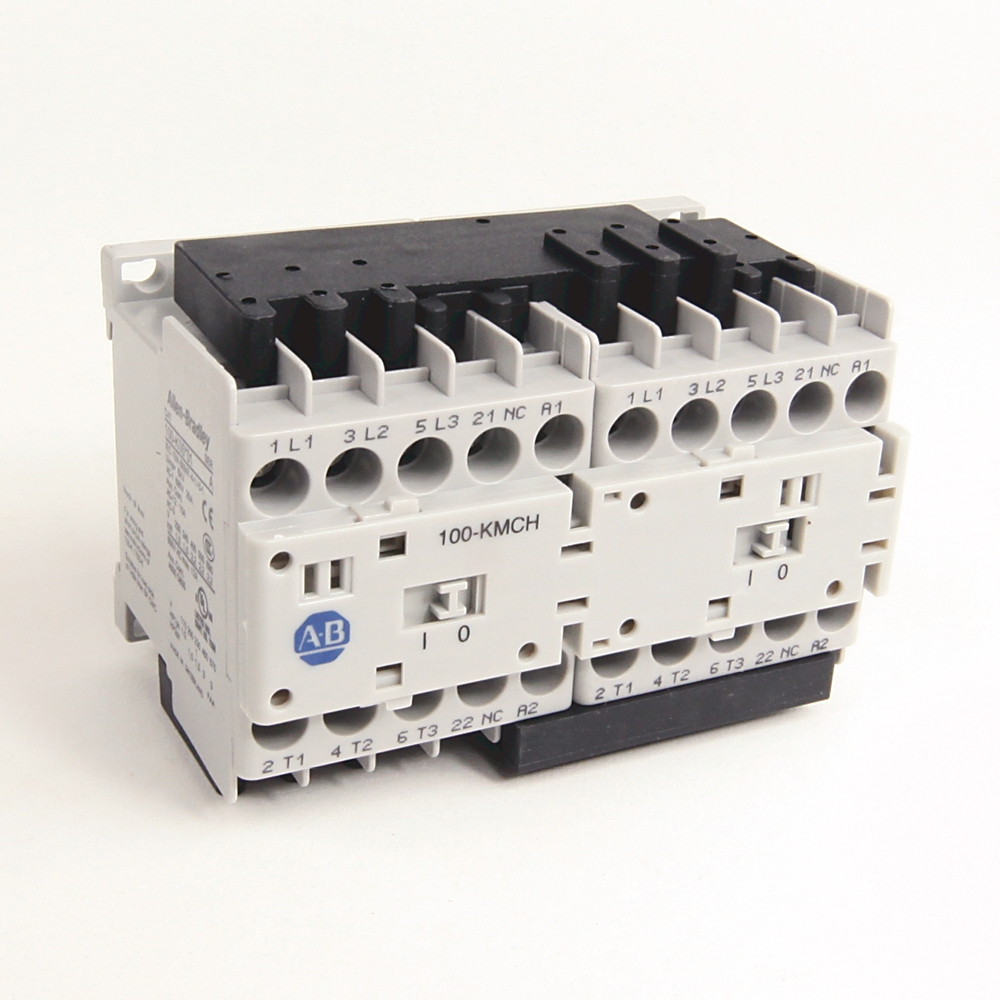

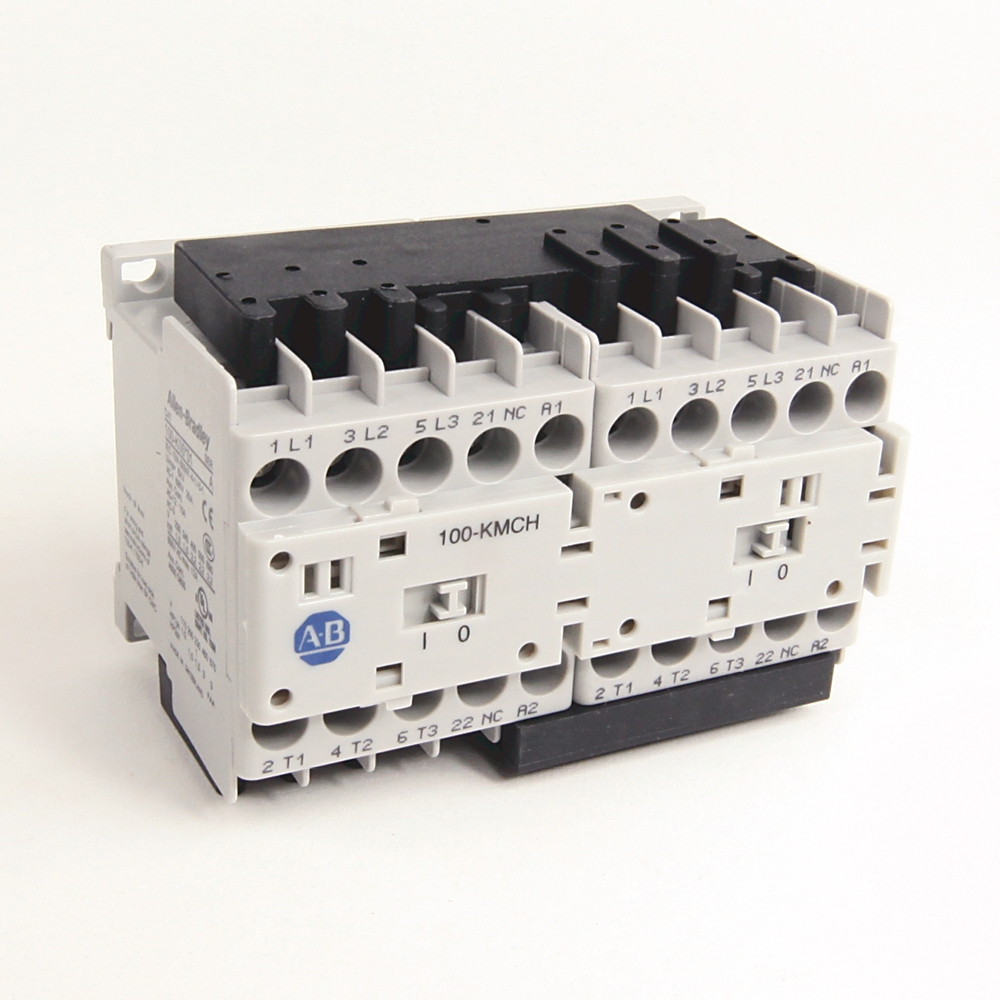

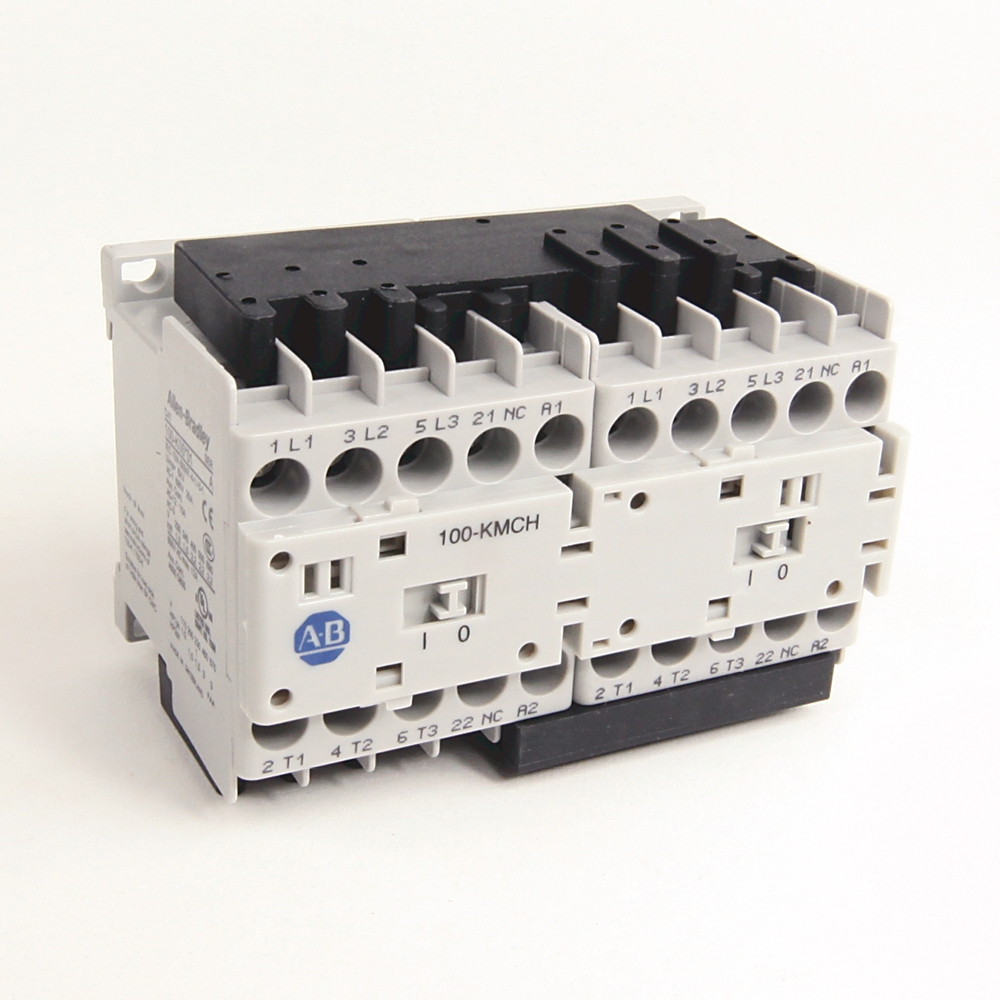

104-K05DJ02

IEC Miniature Reversing Contactor

| Contactor Size |

5 A

|

|---|---|

| Sub Brand |

IEC

|

| Voltage type for actuating |

DC

|

|---|---|

| Rated control supply voltage at AC 50 Hz |

0 V

|

| Rated control supply voltage at AC 60 Hz |

0 V

|

| Rated control supply voltage at DC |

24 V

|

| Rated impulse withstand voltage (Uimp) |

6 kV

|

| Current (Ie), max |

12 A

|

| Power dissipation by all circuits at Ie AC-3/400V |

0.3 W

|

| Main current circuit resistance |

2.2 mohm

|

| Current rating |

5 A

|

| Rated isolation voltage (Ui) |

690V per IEC

|

| Rated voltage (Ue) |

690V @ AC, 50/60 Hz

|

| Auxiliary contact configuration |

1 NC

|

| Rated filament current |

5A @ 230/240V, AC-5b

|

| Switching of motor load for home appliances |

6A @ 400V, AC-7b (50 Hz)

|

| Rated current (enclosed) |

9.8A @ 115V, 1-phase per UL/CSA

|

| Rated power (enclosed) |

3Hp @ 575V, 3-phase per UL/CSA

|

| General purpose current (enclosed) |

12 A per UL/CSA

|

| Switching of low inductive loads in home appliances |

20A @ 400V, AC-7a per IEC 61095 (50 Hz)

|

| Coil operating limits, pick-up |

(0.7...1.25) x Us DC (conventional)

|

| Coil operating limits, dropout |

(0.1...0.75) x Us DC (conventional)

|

| Coil operating time |

8...12 ms, opening delay @ integrated diode

|

| Short time withstand (Icw) |

60A @ 10s, 60 °C

|

| Coil consumption, hold-in |

Cold 3.0 W, warm 2.6 W DC (conventional)

|

| Switching frequency, max |

250 ops/h, AC-4 (approximately 200000 ops)

|

| Coil consumption, pick-up |

Cold 3.0 W, warm 2.6 W DC (conventional)

|

| Total power dissipation |

DC control: 2.9 W @ 400V, AC-3, Ie

|

| Switching of lamps |

Gas discharge lA, open: 18A @ 40°C, AC-5a

|

| Switching of hermetically sealed cooling compressor motors |

11A @ 400V, AC-8a (manual reset of overload release (50 Hz))

|

| Coil insulation class |

Class F per IEC 60085, Class 105 insulation system per UL 508

|

| Rating for switching AC motors |

3-poles: 2.2 kW @ 690V (AC-2, AC-3, AC-4), 3-phase (50 Hz)

|

| UL class K5 and RK5 fuses rating |

40A @ 600V, 5 kA available fault current per UL 508 and CSA 22.2 No. 14

|

| UL class CC and CSA HRCI-MISC fuses rating |

30A @ 600V, 50 kA available fault current per UL 508 and CSA 22.2 No. 14

|

| Coil voltage |

24V (17-30)V DC diode

|

| Rated operational current (Ie) |

8.5A @ 415V, Star-Delta starting (50 Hz)

|

| Rated operational power (Pe) |

8.3 kW @ 240V, AC-1 (50 Hz), ambient temperature 40 °C

|

| DIN fuses (gG, gL) current rating |

Type 2 (per IEC 60947-4-1): 16A @ 400V, 50 kA available fault current

|

| UL class J and CSA HRCI-J fuses rating |

30A @ 600V, 50 kA available fault current per UL 508 and CSA 22.2 No. 14

|

| Switching of power transformers |

Apparent power: 2 kVA @ 690V, AC-6a @ 50Hz (n = 30)

|

| Switching of DC loads |

3-poles in series: 6A @ 48/60V (Non-inductive or slightly inductive loads or resistance furnaces DC-1 at 60 °C)

|

| Contacts |

3 power poles with internal NC auxiliary contact

|

| Function |

Reversing contactor

|

| Conductor cross section per UL/CSA |

18

|

| Terminal type |

Screw terminals

|

| Rated coil frequency |

AC 50/60 Hz, DC

|

| Function or layout |

Nothing specified

|

| Vibration resistance |

IEC 60068-2

|

|---|---|

| Shock resistance |

IEC 60068-2

|

| Recommended torque |

10.6 in-lb

|

| Conductor cross section |

0.75...2.5 mm², 2 conductors @ main contact

|

| Lifespan |

Mechanical DC control: 15000000 ops

|

| Weight |

0.48 kg (1.06 lbs) reverse @ DC

|

| Type of electrical connection of main circuit |

Screw connection

|

| Auxiliary contacts |

IP2X

|

|---|---|

| Altitude of installation site, max |

2000 m (NN), per IEC 60947-4

|

| Ambient temperature |

Storage: -55...80 (-67...176)

|

| Degree of protection (IP) |

IP2X

|

| Optional overload relays |

Bimetallic

|

|---|---|

| Optional accessories |

Front-mount auxiliary contacts, surge suppressors, electronic timers, mechanical interlocks

|

| Features |

Mini-contactors, Uniform panel mounting dimensions, Panel mounting or mounting on 35 mm DIN Rail, Made of environmentally friendly materials

|

| Climatic withstand |

IEC 60068-2-30

|

|---|

| Drawings | |

|---|---|

| 3-Dimensional STEP model (STP) | Download (ZIP) |

| Product Drawing | Drawing (DXF) |

| Drawings |

|---|

| 3-Dimensional STEP model (STP) Download (ZIP) |

| Product Drawing Drawing (DXF) |

Sign in to your Rockwell Automation account to view and download technical drawings.

Sign In

| General | Publication |

|---|---|

| Product Cutsheet | -- |

| Technical Data | Publication |

|---|---|

| 100-td013_-en-p | 100-TD013 |

Looking for more documentation?

Find curated technical documentation for this product in the Technical Documentation Center, or search our full Literature Library.

Search the Literature Library

| Technotes |

|---|

Looking for more Technotes?

Find questions and answers from Rockwell Automation technical experts for this product in our Knowledgebase.

Search Knowledgebase

Technical Specifications

| Contactor Size |

5 A

|

|---|---|

| Sub Brand |

IEC

|

| Voltage type for actuating |

DC

|

|---|---|

| Rated control supply voltage at AC 50 Hz |

0 V

|

| Rated control supply voltage at AC 60 Hz |

0 V

|

| Rated control supply voltage at DC |

24 V

|

| Rated impulse withstand voltage (Uimp) |

6 kV

|

| Current (Ie), max |

12 A

|

| Power dissipation by all circuits at Ie AC-3/400V |

0.3 W

|

| Main current circuit resistance |

2.2 mohm

|

| Current rating |

5 A

|

| Rated isolation voltage (Ui) |

690V per IEC

|

| Rated voltage (Ue) |

690V @ AC, 50/60 Hz

|

| Auxiliary contact configuration |

1 NC

|

| Rated filament current |

5A @ 230/240V, AC-5b

|

| Switching of motor load for home appliances |

6A @ 400V, AC-7b (50 Hz)

|

| Rated current (enclosed) |

9.8A @ 115V, 1-phase per UL/CSA

|

| Rated power (enclosed) |

3Hp @ 575V, 3-phase per UL/CSA

|

| General purpose current (enclosed) |

12 A per UL/CSA

|

| Switching of low inductive loads in home appliances |

20A @ 400V, AC-7a per IEC 61095 (50 Hz)

|

| Coil operating limits, pick-up |

(0.7...1.25) x Us DC (conventional)

|

| Coil operating limits, dropout |

(0.1...0.75) x Us DC (conventional)

|

| Coil operating time |

8...12 ms, opening delay @ integrated diode

|

| Short time withstand (Icw) |

60A @ 10s, 60 °C

|

| Coil consumption, hold-in |

Cold 3.0 W, warm 2.6 W DC (conventional)

|

| Switching frequency, max |

250 ops/h, AC-4 (approximately 200000 ops)

|

| Coil consumption, pick-up |

Cold 3.0 W, warm 2.6 W DC (conventional)

|

| Total power dissipation |

DC control: 2.9 W @ 400V, AC-3, Ie

|

| Switching of lamps |

Gas discharge lA, open: 18A @ 40°C, AC-5a

|

| Switching of hermetically sealed cooling compressor motors |

11A @ 400V, AC-8a (manual reset of overload release (50 Hz))

|

| Coil insulation class |

Class F per IEC 60085, Class 105 insulation system per UL 508

|

| Rating for switching AC motors |

3-poles: 2.2 kW @ 690V (AC-2, AC-3, AC-4), 3-phase (50 Hz)

|

| UL class K5 and RK5 fuses rating |

40A @ 600V, 5 kA available fault current per UL 508 and CSA 22.2 No. 14

|

| UL class CC and CSA HRCI-MISC fuses rating |

30A @ 600V, 50 kA available fault current per UL 508 and CSA 22.2 No. 14

|

| Coil voltage |

24V (17-30)V DC diode

|

| Rated operational current (Ie) |

8.5A @ 415V, Star-Delta starting (50 Hz)

|

| Rated operational power (Pe) |

8.3 kW @ 240V, AC-1 (50 Hz), ambient temperature 40 °C

|

| DIN fuses (gG, gL) current rating |

Type 2 (per IEC 60947-4-1): 16A @ 400V, 50 kA available fault current

|

| UL class J and CSA HRCI-J fuses rating |

30A @ 600V, 50 kA available fault current per UL 508 and CSA 22.2 No. 14

|

| Switching of power transformers |

Apparent power: 2 kVA @ 690V, AC-6a @ 50Hz (n = 30)

|

| Switching of DC loads |

3-poles in series: 6A @ 48/60V (Non-inductive or slightly inductive loads or resistance furnaces DC-1 at 60 °C)

|

| Contacts |

3 power poles with internal NC auxiliary contact

|

| Function |

Reversing contactor

|

| Conductor cross section per UL/CSA |

18

|

| Terminal type |

Screw terminals

|

| Rated coil frequency |

AC 50/60 Hz, DC

|

| Function or layout |

Nothing specified

|

| Vibration resistance |

IEC 60068-2

|

|---|---|

| Shock resistance |

IEC 60068-2

|

| Recommended torque |

10.6 in-lb

|

| Conductor cross section |

0.75...2.5 mm², 2 conductors @ main contact

|

| Lifespan |

Mechanical DC control: 15000000 ops

|

| Weight |

0.48 kg (1.06 lbs) reverse @ DC

|

| Type of electrical connection of main circuit |

Screw connection

|

| Auxiliary contacts |

IP2X

|

|---|---|

| Altitude of installation site, max |

2000 m (NN), per IEC 60947-4

|

| Ambient temperature |

Storage: -55...80 (-67...176)

|

| Degree of protection (IP) |

IP2X

|

| Optional overload relays |

Bimetallic

|

|---|---|

| Optional accessories |

Front-mount auxiliary contacts, surge suppressors, electronic timers, mechanical interlocks

|

| Features |

Mini-contactors, Uniform panel mounting dimensions, Panel mounting or mounting on 35 mm DIN Rail, Made of environmentally friendly materials

|

| Climatic withstand |

IEC 60068-2-30

|

|---|

Drawings

| Drawings | |

|---|---|

| 3-Dimensional STEP model (STP) | Download (ZIP) |

| Product Drawing | Drawing (DXF) |

| Drawings |

|---|

| 3-Dimensional STEP model (STP) Download (ZIP) |

| Product Drawing Drawing (DXF) |

Sign in to your Rockwell Automation account to view and download technical drawings.

Sign In

Documents

|

Product Cutsheet

General

-- |

|

100-td013_-en-p

Technical Data

100-TD013 |

| General | Publication |

|---|---|

| Product Cutsheet | -- |

| Technical Data | Publication |

| 100-td013_-en-p | 100-TD013 |

Looking for more documentation?

Find curated technical documentation for this product in the Technical Documentation Center, or search our full Literature Library.

Search the Literature Library

Accessories

Alternative Products

Technotes

| Technotes |

|---|

Looking for more Technotes?

Find questions and answers from Rockwell Automation technical experts for this product in our Knowledgebase.

Search Knowledgebase

Copyright ©2026 Rockwell Automation, Inc.