By Zayn Aladin, ETO Packaged Solutions Specialist, Sensia

A drop of liquid. An ice formation. So small, yet potentially costly and damaging to gas facilities and pipeline operations. These hydrates and unwanted liquids can clog pipes, reduce process flow and damage equipment.

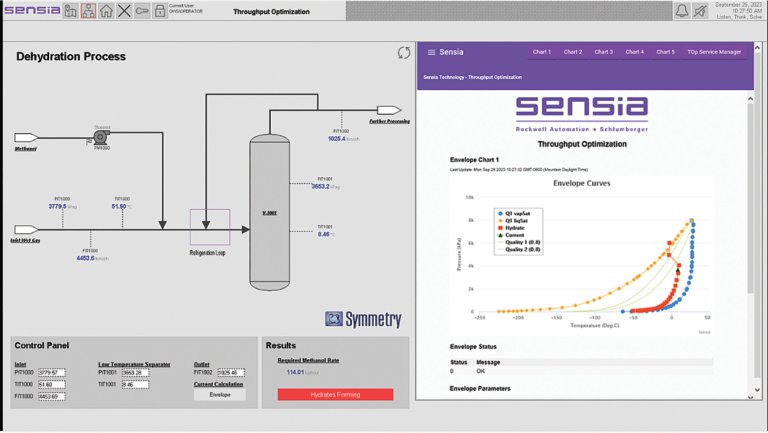

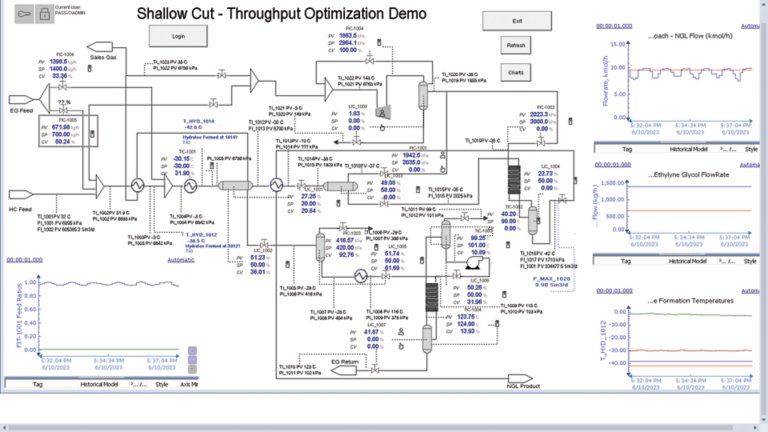

Gas processing technologies depend on understanding the “phase envelope” of the process fluid to operate efficiently and safely. Process engineers implement their designs to manage the worst-anticipated phase envelope, normally resulting in less-than-optimal throughput and using more energy than needed for typical or normal operating conditions.

Most plant or pipeline operators adjust controls well before hydrates form. This can involve injecting chemicals, increasing the temperature of the gas with heaters, reducing temperatures, or operating well below the design capacity. The first three methods increase the operational cost and indirectly reduce throughput, while the latter directly reduces throughput. Consequently, opportunities to improve yield and efficiency dissipate.

In an industry marked by falling budgets for capital and operational expenditures, dealing with these challenges requires intricate calculations and real-time control actions.

Increasing Throughput and Reliability

Until recently, there was no solution for the control system to adjust operations based on real-time conditions. In the past, process engineers used desktop-based spreadsheets to simulate processing fluids, sharing them with control engineers for implementation. While these calculations ensured safe plant operation within expected composition ranges, they focused on worst-case scenarios.