By Evan Kaiser, Director, Warehouse and Logistics and Erik Lange, Senior Product Specialist, Rockwell Automation

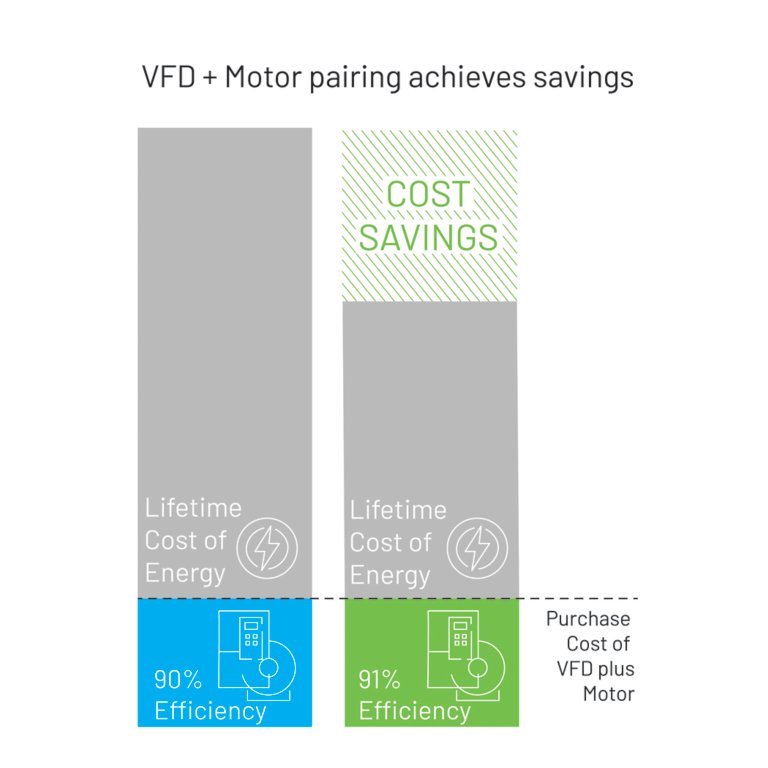

Selecting a variable-frequency drive (VFD) and motor is a critical opportunity to deliver energy efficiency and cost savings to an industrial process. The cumulative energy consumed over the life of an electric motor often is misunderstood and underestimated.

In fact, over their lifespan, a VFD and motor’s energy consumption costs can be as much as 10x or more than the price paid for the system.

Users can get meaningful energy cost savings by performing comparative evaluations and implementing optimized VFD and motor combinations.

Energy Savings Opportunities

Selecting a VFD for improved energy efficiency can be a complex undertaking. Fortunately, with the passage of the EU directive on IEC 61800-9-2 compliance, tools are available to start the process.

IEC 61800-9-2 is the calculated efficiency of a VFD. It provides a basic evaluation of a VFD manufacturer's design choices relative to energy efficiency. This is a static, mathematical calculation. It doesn't consider application-specific dynamic conditions.