By Oliver Haya, Business Manager, Rockwell Automation

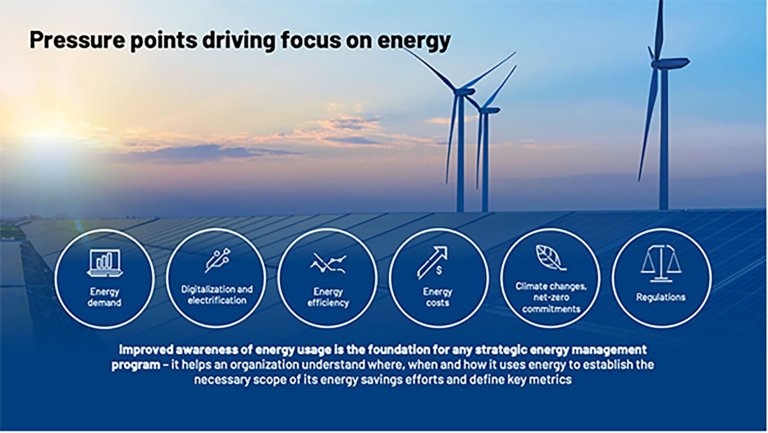

Rising energy costs and increasing demand, the digitalization of energy networks, the need to optimize efficiency, and increasing regulations are pressure points (see Figure 1) creating greater emphasis on energy management. As a result, optimizing energy management is a major focus for manufacturers and producers.

Across manufacturing, energy is one of the fastest-growing production costs, making it vital to improve efficiency. With worldwide power consumption predicted to increase by 300% by 2050, a stable, well-managed energy supply will be key to optimizing critical functions. As manufacturers move toward “net zero,” energy management has become critical.

Improved awareness of energy usage is the foundation for any strategic energy management program. For manufacturers that want to reduce energy costs, improve their sustainability footprint and position themselves to meet the demands of a changing regulatory environment, a solid energy management program helps them understand where, when and how they use energy.

This, in turn, helps establish the necessary scope of energy savings efforts and define key metrics.

Structuring Data

Historically, the distributed and siloed nature of networks and data sources presented challenges to gathering energy data. This lack of connectivity limited an organization’s ability to pull energy performance metrics from specific industrial equipment because the data in question lacked operational technology (OT) context.

For example, important details include production runs, the quantity and types of goods produced, and the specific energy used for each asset. Without OT context, it’s common for manufacturers to get only a monthly report of a site's entire energy usage.