Industry 4.0 is about applying smart practices and technology in manufacturing. It represents a significant shift in outlook and operations, particularly for the automotive industry. It builds on intelligent connected cloud technologies that allow diverse components and systems to work together. This creates a manufacturing framework that delivers consistently refined and scalable process improvements.

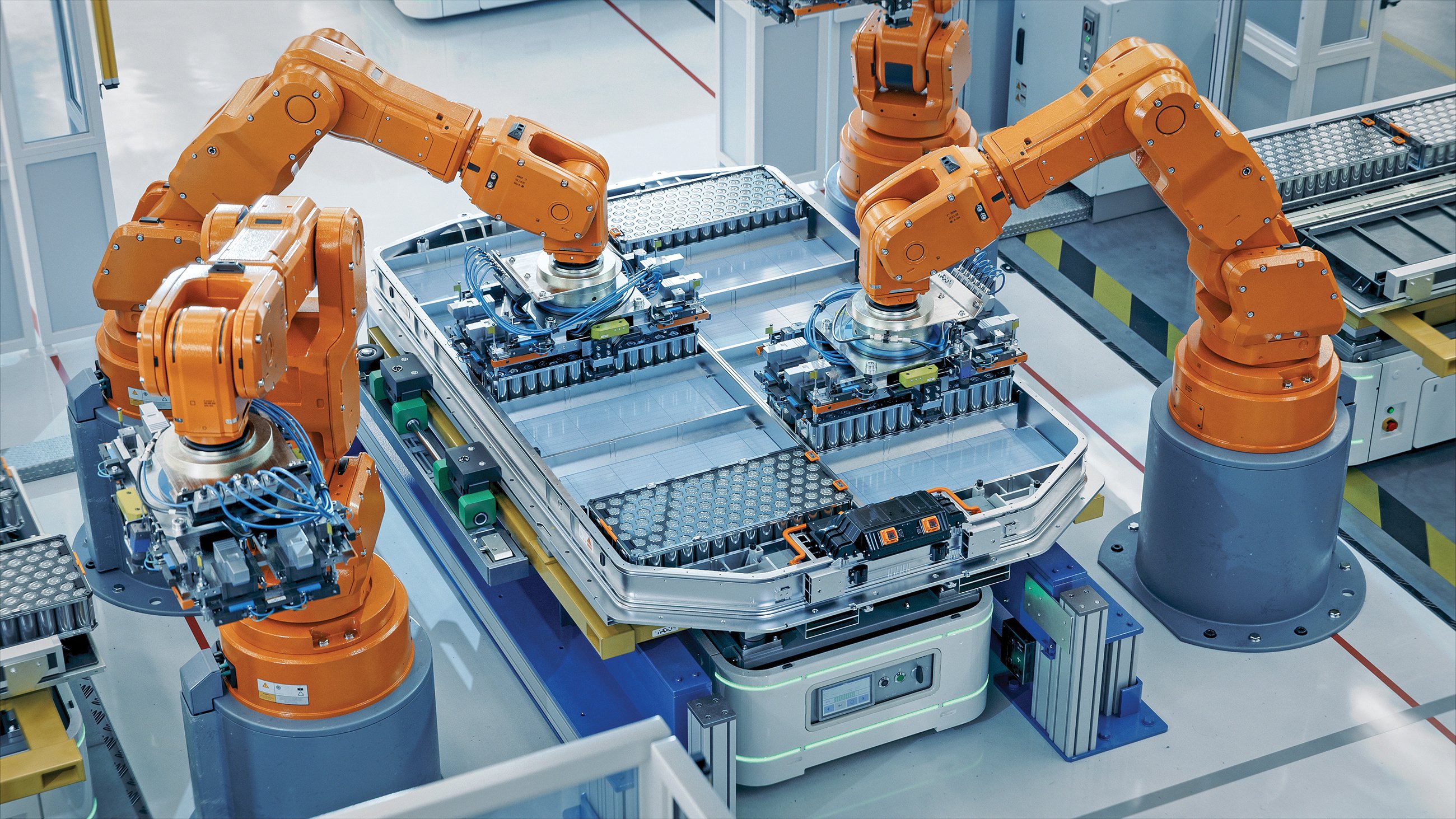

Smart automotive plants use robotics, industrial IoT sensors and machines, together with analytics, to gain a competitive advantage. However, there is an increasing requirement for low-latency and compute-intense decisions to be made near the points of operation. For this reason, there is a growing use of private and hybrid 4G/5G networks to support edge computing and AI on the plant floor.

Why 5G?

The use of private wireless networks using 5G technology supports the concept of small-footprint, low-latency robots and cobots that can be easily reconfigured without any expensive wiring to work safely near workers in assembly cells.

Low-latency messages, crucial to real-time decision making, allow a robot to communicate with a centralized operator framework about the required operations, providing manufacturers with greater visibility over an entire process.

5G networks also offer strong cybersecurity measures, protecting sensitive manufacturing data. 5G’s reliable and fast connectivity also is essential for integrating AI and edge computing into manufacturing operations.