From autonox Robotics

To become more competitive, industrial firms often begin by integrating automation and corresponding solutions into their existing production. Robots have proven highly efficient in this regard. However, due to the closed platforms used by robot manufacturers, different systems must collaborate within production environments, leading to interface problems by increasing the number of control systems in use. This complicates operations and can result in data loss.

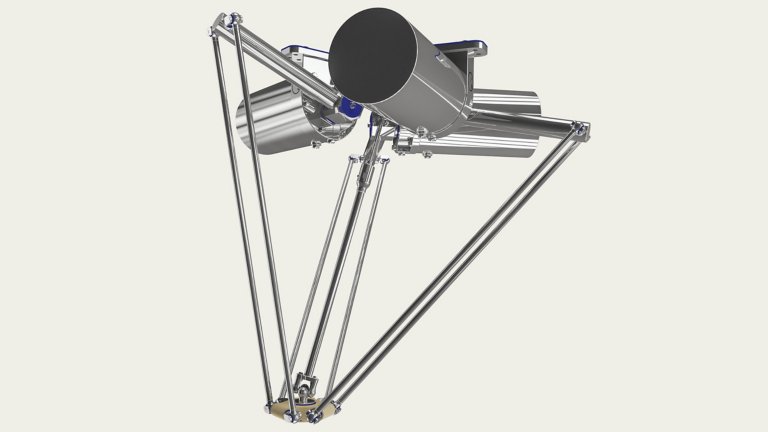

Open mechanics eliminate interfaces and additional controls. With these solutions using unified control, the operator receives a highly integrated and autonomous system capable of performing complex tasks.

Many production areas need to address employee shortages, increase efficiency and maximize flexibility. The following case describes these challenges in packaging for consumer packaged goods, a process that often creates bottlenecks slowing down production throughput.

Consumer Packaged Goods Sorting

In this use case, the machine is used for sorting different goods onto several conveyors with a cycle time of about 1 second per cycle. Requirements include efficiency, speed and precision. Consumers demand high-quality products at acceptable prices, putting pressure on manufacturers to streamline their production and eliminate sources of quality or downtime issues.

An additional requirement is handling consumer goods on moving conveyors, using multi-parallel kinematics with different technical specifications based on varying requirements.