From Advanced Micro Controls Inc. (AMCI)

Editor’s Note: This article is excerpted from the white paper, “Encoders and Resolver Based Encoder Technology,” from Advanced Micro Controls Inc. (AMCI). Download the full paper to learn about common types of encoders, choosing the correct electrical interface, mechanical considerations, resolver-based encoders, communicating to the PLC, application examples, case studies and how to select an encoder.

A modern control system is fundamentally a feedback control system, such as a push button that executes an operation that eventually starts a motor. That push produces an output that rotates a shaft. A feedback loop feeds information back to the controller to verify the operation and make the necessary corrections.

That feedback can be, but is not limited to, limit switches, temperature sensors, or in some cases, position feedback. Position feedback can be used to monitor or adjust the motor.

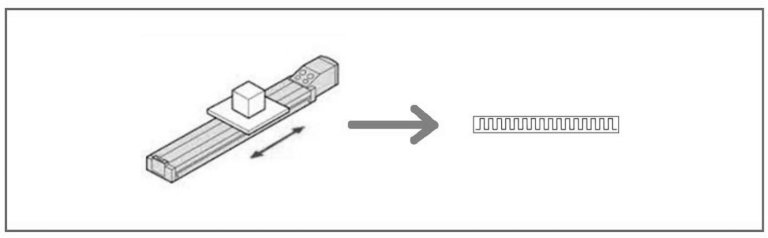

Multiple ways exist to get position feedback, but the most common types are rotary sensors, encoders, resolvers or even potentiometers. For linear applications, magneto restrictive sensors or linear variable transformers (LVTs) are commonly used. And for noncontact applications lasers are often used to provide position feedback for linear measurement.