Solution: Closed-loop Moisture Control Predictive Model to Infer Powder Moisture

The customer wanted a solution that would increase each line’s capacity, while maintaining product quality and reducing energy usage. After considering competing solutions, the customer worked with Rockwell Automation to improve the overall efficiency of its dryers on the caseinate production lines.

The three dryers and other factors of the process that impacted moisture levels were evaluated. Using the Rockwell Automation FactoryTalk® Analytics™ PavilionX™ closed-loop predictive and prescriptive capabilities, process control could be tightened to help achieve consistent moisture levels, thereby optimizing line capacity and resource consumption.

The Rockwell Automation team recommended a closed-loop, moisture-control application to manage product moisture. The solution was designed, developed, and deployed based on its FactoryTalk Analytics PavilionX platform.

The solution used Rockwell Automation models to provide in-line, inferential powder moisture (quality) measurements in real time. By using this sensor data throughout the line, model-based closed-loop controls could respond in a predictive fashion, significantly reducing moisture variability, raising dryer throughput, and reducing the energy needed to dry the casein.

Results: Rockwell Automation Delivers Increased Capacity, Reduced Costs

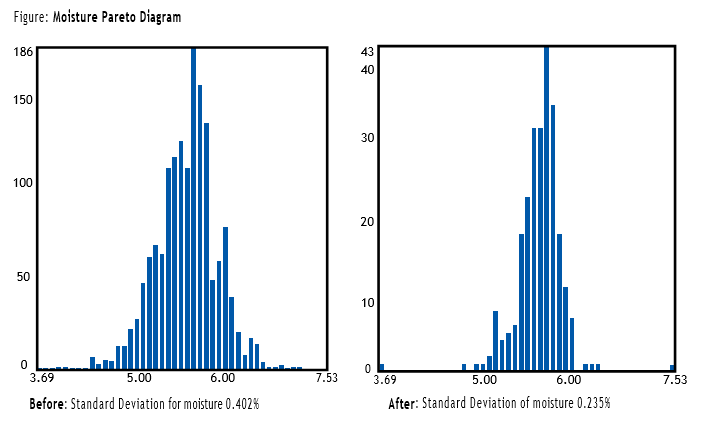

The results of the FactoryTalk Analytics PavilionX solution at the facility’s caseinate lines (3 x spray towers) were beyond expectations. The customer achieved up to a 42% reduction in quality variability and a 0.12%-0.38% increase in average moisture content. In addition, they also achieved a 6–15.8% increase in production throughput.

Thereafter, the Northern European milk producer successfully deployed a total of 19 FactoryTalk Analytics PavilionX closed-loop solutions throughout its ingredient plants.