Background

Located in the south of Denmark, Gram Equipment is one of the world’s leading manufacturers of equipment for the industrial production of ice cream; a position strengthened by the merger of Gram Equipment and WCB Ice Cream in 2014.

With more than 300 employees worldwide and offices in Denmark and the USA, the company delivers complete, tailor-made production lines to ice cream producers and other food-processing firms looking for flexible integrated solutions.

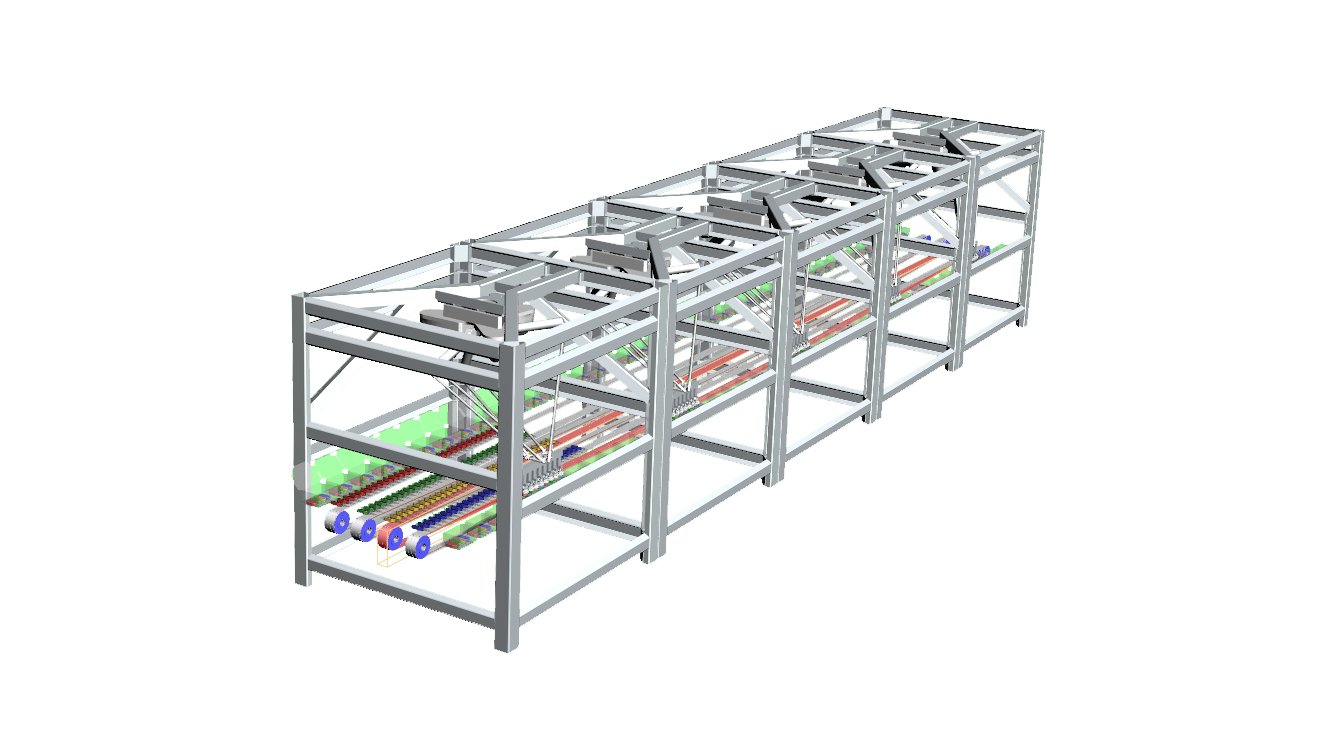

These specially designed solutions cover applications from individual assembly lines all the way up to complete production plants and comprise equipment for moulding, extrusion, filling, wrapping and packing as well as freezers, ingredient feeders and remanufacturing and upgrade kits. Product formats handled include stick ice, cone, sandwich, bulk and cup and dessert/cake.

With more of its customers looking to deploy increasingly agile and more flexible storage, production and packaging solutions, Gram Equipment is always looking for ways to enhance and evolve its product range, to help these customers keep up with the very latest production demands from industry and product demands from consumers.