Incremental Approach to Modernization

Hexcel turned to EOSYS, a Platinum-level system integrator in the Rockwell Automation PartnerNetwork™. Together, Hexcel and EOSYS took a deliberate, step-by-step approach to modernization with each change driven by data and built on previous wins. They began by analyzing the root cause of the equipment failures and proposing a solution using permanent magnet motors—an approach that had been effective in Hexcel’s Decatur, Alabama, facility. To ease the transition, EOSYS initially kept encoders in place to provide Hexcel operators with peace of mind the motors were functioning properly.

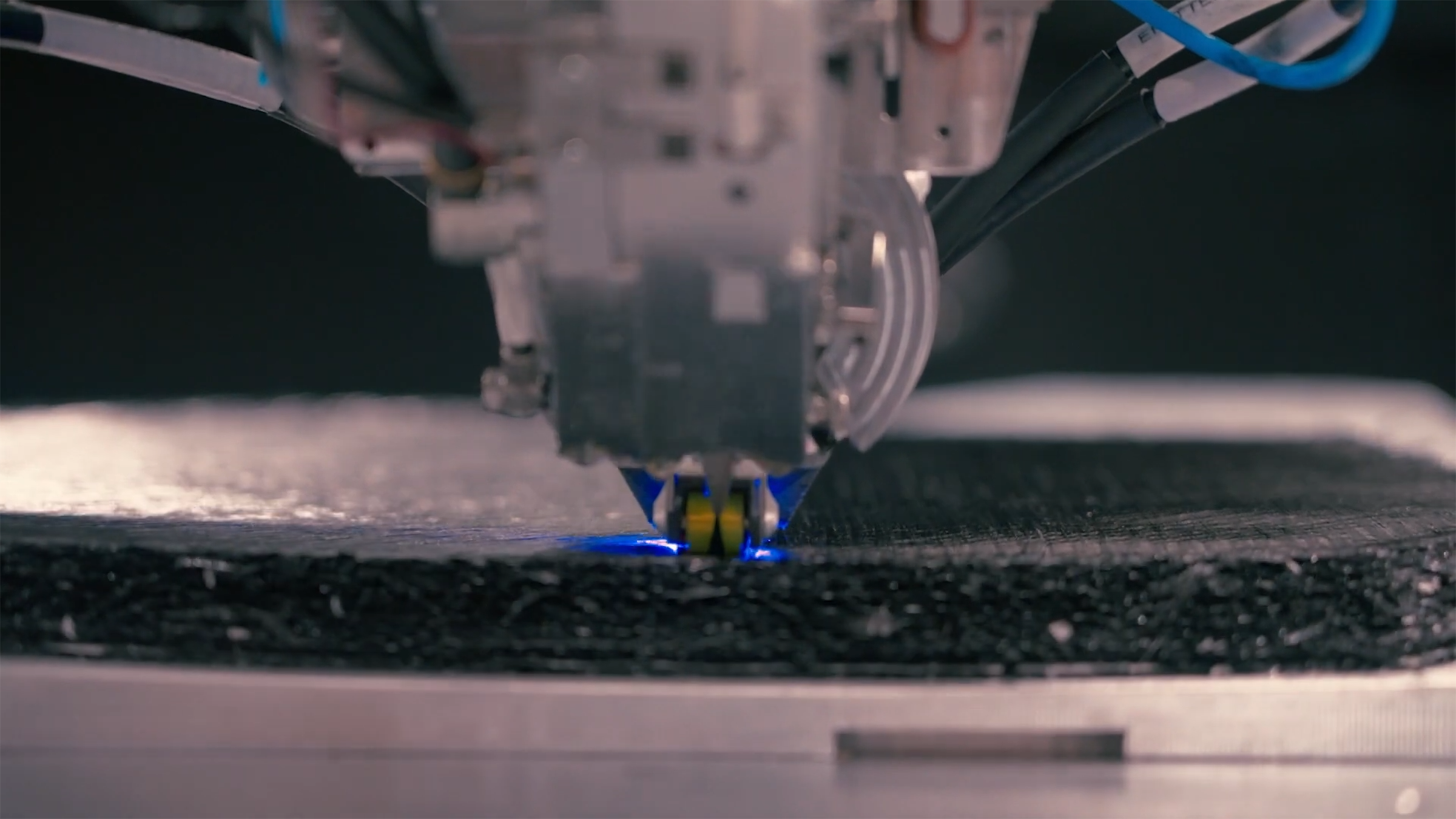

The first phase of the project focused on one smaller manufacturing line at Hexcel’s Salt Lake City facility. This line, installed in 1976, featured a patchwork of outdated technologies. By converting it to AC drives and implementing permanent magnet motors, Hexcel and EOSYS achieved a quick and successful modernization.

With confidence from this early success, the team moved on to a more complex line with 30 motors. This larger line presented a new set of challenges, including overcurrent issues and non-standard motor specifications. To resolve these issues, Hexcel and EOSYS adjusted their approach, eventually transitioning to an open-loop induction motor system that maintained precision without requiring encoders.

By continuously refining their strategy and using each success as a proof point, Hexcel and EOSYS expanded their efforts to two additional lines, applying lessons learned. Specifically, they transitioned control systems from ControlNet to EtherNet/IP™ products to further system reliability and communication protocols. They also deployed PowerFlex® 755TS VFDs with embedded Ethernet/IP, positioning Hexcel to leverage advanced analytics, predictive maintenance, and anomaly detection technologies to drive even greater efficiency in the future.

By version 4.0, Hexcel and EOSYS had developed a solution that worked so well it was established as a standardized model for modernization and rolled out across Hexcel’s remaining Salt Lake City lines. Later, the solution was adopted by their France facility, with plans for further expansion into Spain.