I would never have imagined, just a few years ago, how quickly new technologies would impact the entire lifecycle of the FPSO vessel development process. From seamless connectivity across systems, access to performance and diagnostic data, and robust cybersecurity, the pace of change can be disruptive at times. With digital technologies advancing and becoming more sophisticated, a new FPSO vessel is on the rise - a connected vessel. The traditional process in creating FPSO vessels does not align with what connected vessels, and all production vessels in the future, need to thrive. They must have the flexibility to keep up with ever-changing technology and how it is applied and integrated. Digital technologies are enhancing FPSOs, and it forces us to rethink vessel design.

How to do it better

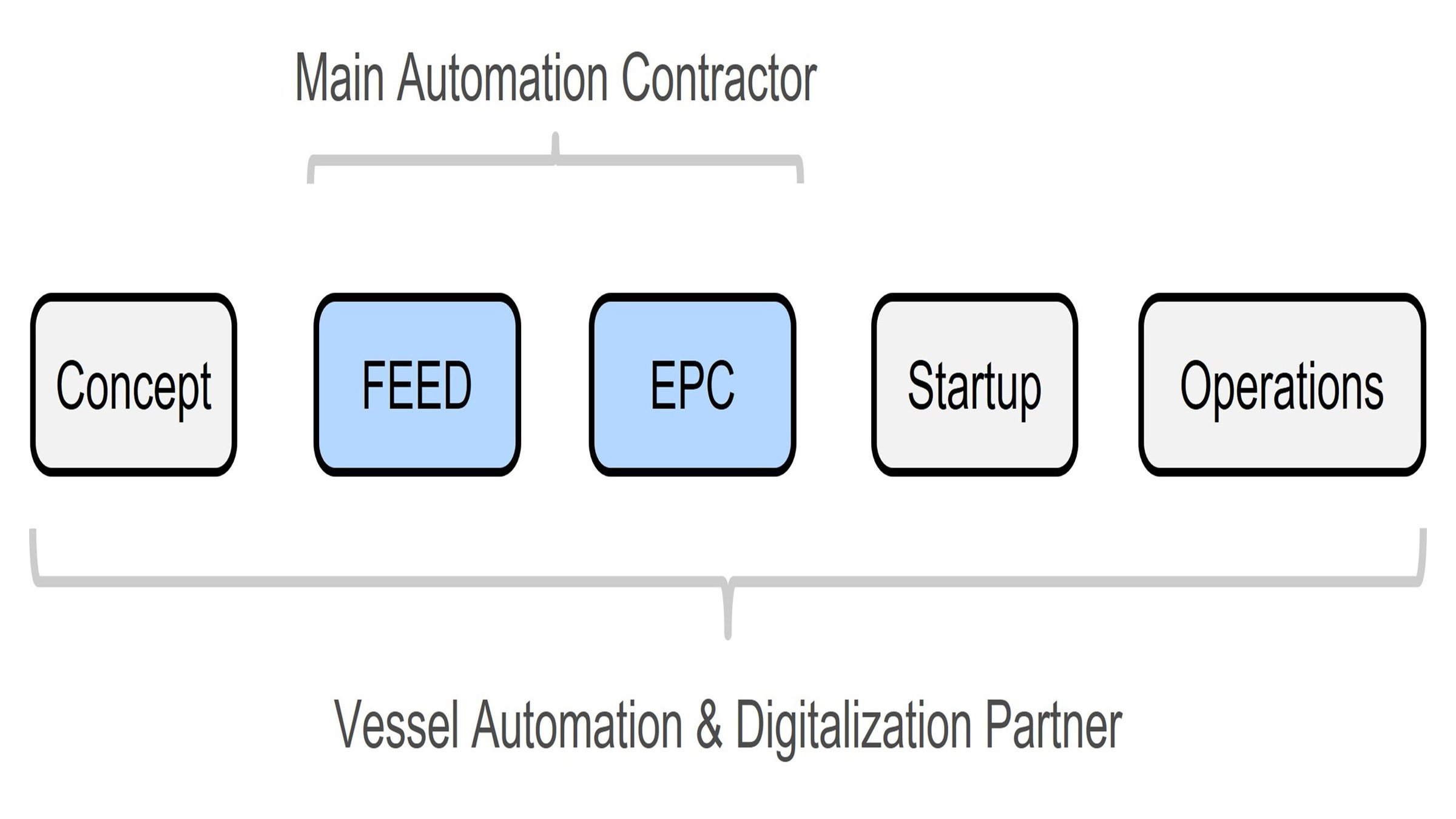

The traditional approach of designing or retrofitting FPSO vessels only focuses on nearsighted goals and does not account for long term effectiveness and performance. Don’t get me wrong, some critical components should still be selected with the traditional approach, but in general, long-term vessel needs are not taken into consideration. Decision makers tend to focus on the lowest cost options upfront, rather than what will benefit the vessel throughout its lifecycle. Also, old project execution methodologies tend to lock an owner/designer into specific technologies, not allowing the vessel to advance along with new technology progression. To protect the long-term future of a vessel, a new approach is needed.