In 2001, Livetech was founded as a designer developer and builder of secondary packaging systems for food industry customers across the globe.

Since its founding, the company has acquired two other companies: CEDA, a chocolate-moulding company, which today has become Livemould; and Fourpack, now Liveflow, which provides distribution systems and flow-packing machines. The group, headquartered in Monticello d'Alba, Italy, now has more than 150 employees.

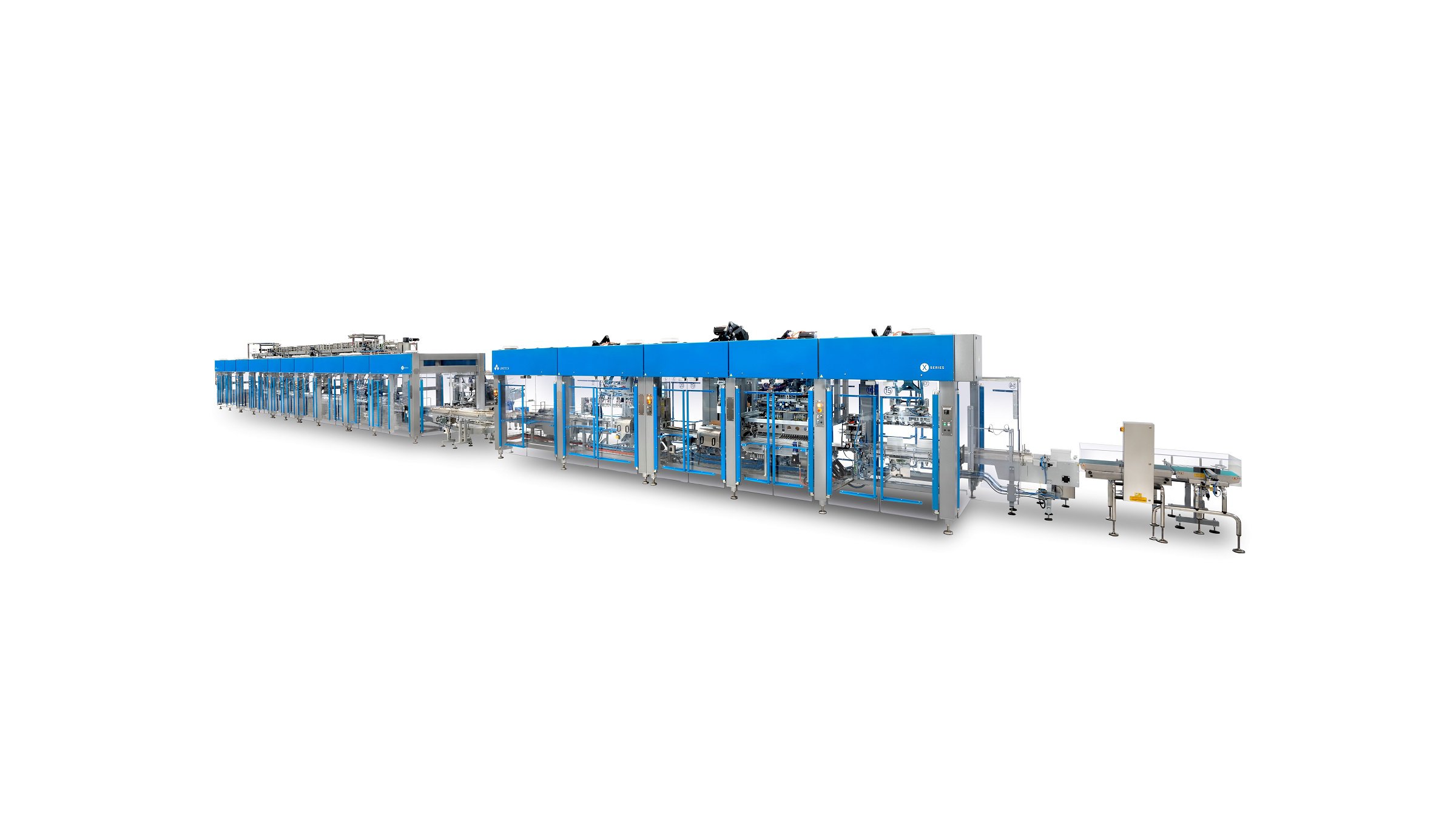

“We are a dynamic company,” explains Federico Scornaienchi, Export Manager at Livetech, “specializing in the engineering and production of complete primary (flowpack) and secondary/tertiary robotized packaging systems, palletizing technology and complete chocolate moulding lines.

R&D investment

“Using our experiences gained working with multinationals groups in the food sector,” he continues, “coupled to our continual investment in research and development, we can create and deliver high-performance and environmentally friendly solutions and consultancy across the length and breadth of the food technology, confectionary and packaging sectors.”

Livetech’s ethos is to help customers to translate their needs – in terms of packaging design and technology – into an automatic application, with the addition of comprehensive consulting capabilities differentiating them from other companies in the market.

“We cover multiple verticals,” Scornaienchi explains, “including bakery, confectionery, sweets/chocolates, pet food, dairy and baby food. In all cases we have to deliver maximum production flexibility, so our customers can quickly and easily adapt to market needs in terms of formats, flavours, packaging counts and product evolutions.

Merging deliverables

“We do much more than just machine design,” he adds. “Indeed, the merging of different deliverables, such as customizing, consulting and service, creates a complete environment around single solutions that make our customers feel more secure about their investment. We give them the flexible architectures and tailored designs that deliver the right answer to their specific needs.”

With the help of Rockwell Automation, Livetech has been able to optimize its production processes. “Rockwell Automation smart solutions makes the programming and interfacing much easier, especially when you consider the number of components on a typical packaging machine,” Scornaienchi adds. “And alongside these capabilities, we can count on its global presence and its own commitment to being a high-quality automation and information systems supplier.

Preferred supplier

“Many of our customers and other companies in the markets we serve also ask for Rockwell Automation, as it is a preferred supplier to many of the leading global companies. We’re fully in line with this perspective and feel confident that we can deliver state-of-the-art automation solutions that reflect the quality we put into the rest of our system’s components.”

The deployment of solutions from Rockwell Automation has helped Livetech streamline its development and programming efforts, while also creating a stable and adaptable platform for future machine evolutions. It has also delivered many benefits to Livetech’s end users, including greater flexibility, higher throughput, easier remote and local maintenance and reduced changeover times.

Discover our comprehensive portfolio of OEM and machine design solutions, here