When a noted and iconic food and beverage company with a global reputation of being a trusted producer of delicious foods puts its trust in Rockwell Automation, then there’s every chance that this is a good recipe for success.

The challenges experienced with information sharing over a number of manufacturing sites all around the world would require an innovative solution to align multiple processes, people and geographies - laying the foundations for their journey towards a connected enterprise.

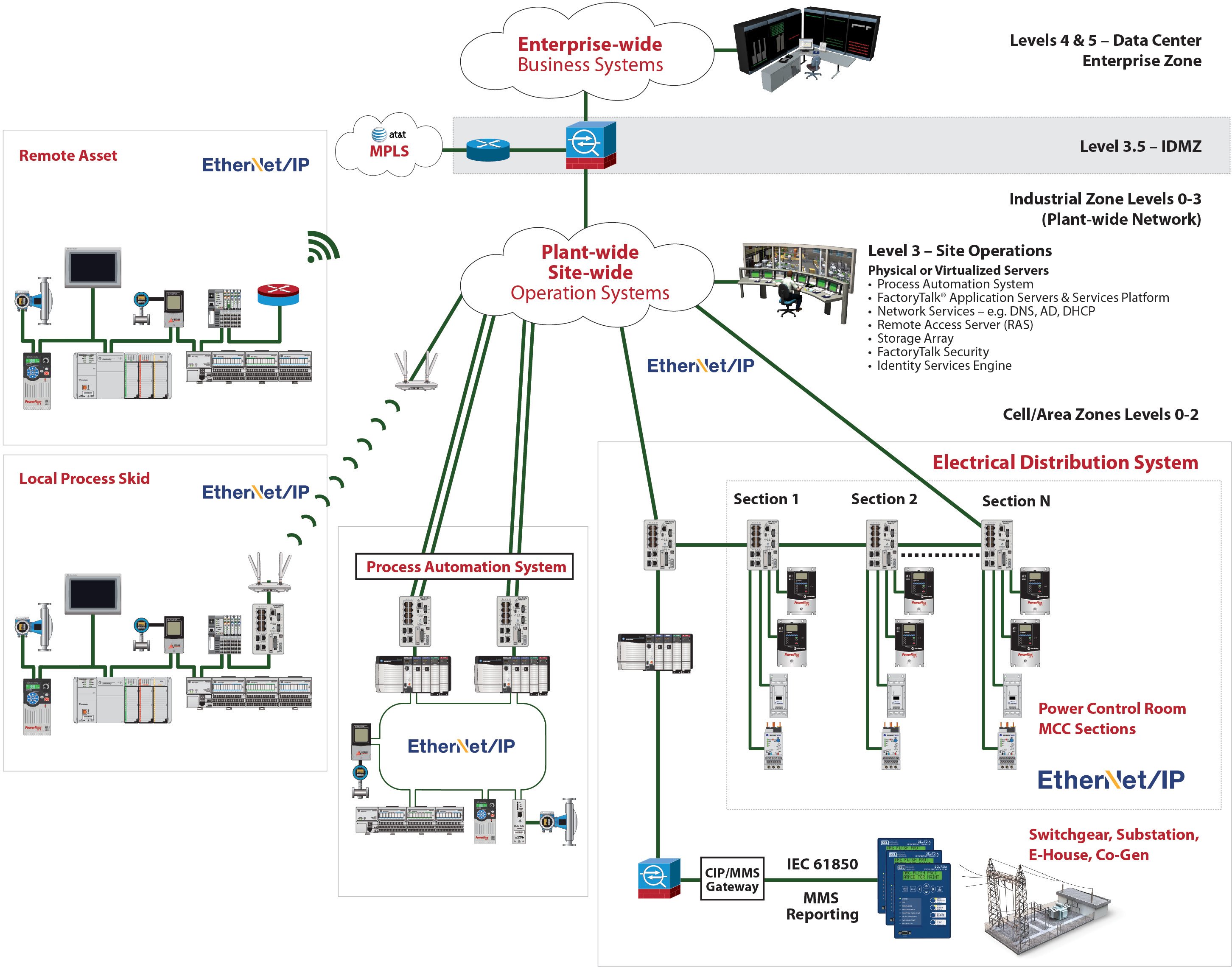

Given the size of the organisation, converging the plant floor operational technology with the office layer IT infrastructure globally was not a small undertaking but it was certainly a very important one to meet growing production and business goals.

Smart manufacturing drives productivity and profitability. It requires highly connected plants so devices and processes can be continually monitored and optimised.

Through The Connected Enterprise®, Rockwell Automation helps food and beverage manufacturers offer a more agile response to changing manufacturing and consumer demands. The company works with customers to help them converge plant-level and enterprise networks, and securely connects people, processes and technologies.