Weight-based control is an excellent choice for many machine builders and system integrators due to higher productivity and consistency of results when compared to other means. Moreover, an added benefit is that weight sensors or scales do not physically contact the products that they are measuring; this avoids cleaning and risk of cross contamination.

While this method can be used for processes measured in minutes or hours, it can also offer significant advantages for high-throughput systems with processes measured in seconds or less.

There are eight key considerations to take into account when crafting machines that functions along the automation measuring chain. These considerations are:

1. Industrial Network Connectivity

Over the years, Industrial Ethernet (IE) has seen tremendous adaptation in factory automation due to its transmission speed and deterministic nature. IE is a key requirement to ensure good product quality and throughput in automated weighing process. Furthermore, IE devices facilitate easy, seamless and accurate integration into PLC control systems.

Unlike TCP/IP Ethernet, there are many specifications for IE defined by the automation company or sponsor. A common IE in process control for Rockwell Automation is EtherNet/IP. An ideal smart weighing automation system should support multiple IE protocols, be flexible to connect to different IE networks yet communicate in the same standardized manner.

2. Ultra High Processing Speed with Continuous Accuracy

Consider how fast your device, or system, reacts to a change in weight. If you are a designer who expects higher productivity and better quality, speed also known as PLC update rate is your most critical factor. High update rate devices can provide the highest accuracy (trueness and repeatability) in the shortest time so your control system can make precise decisions at the right moment.

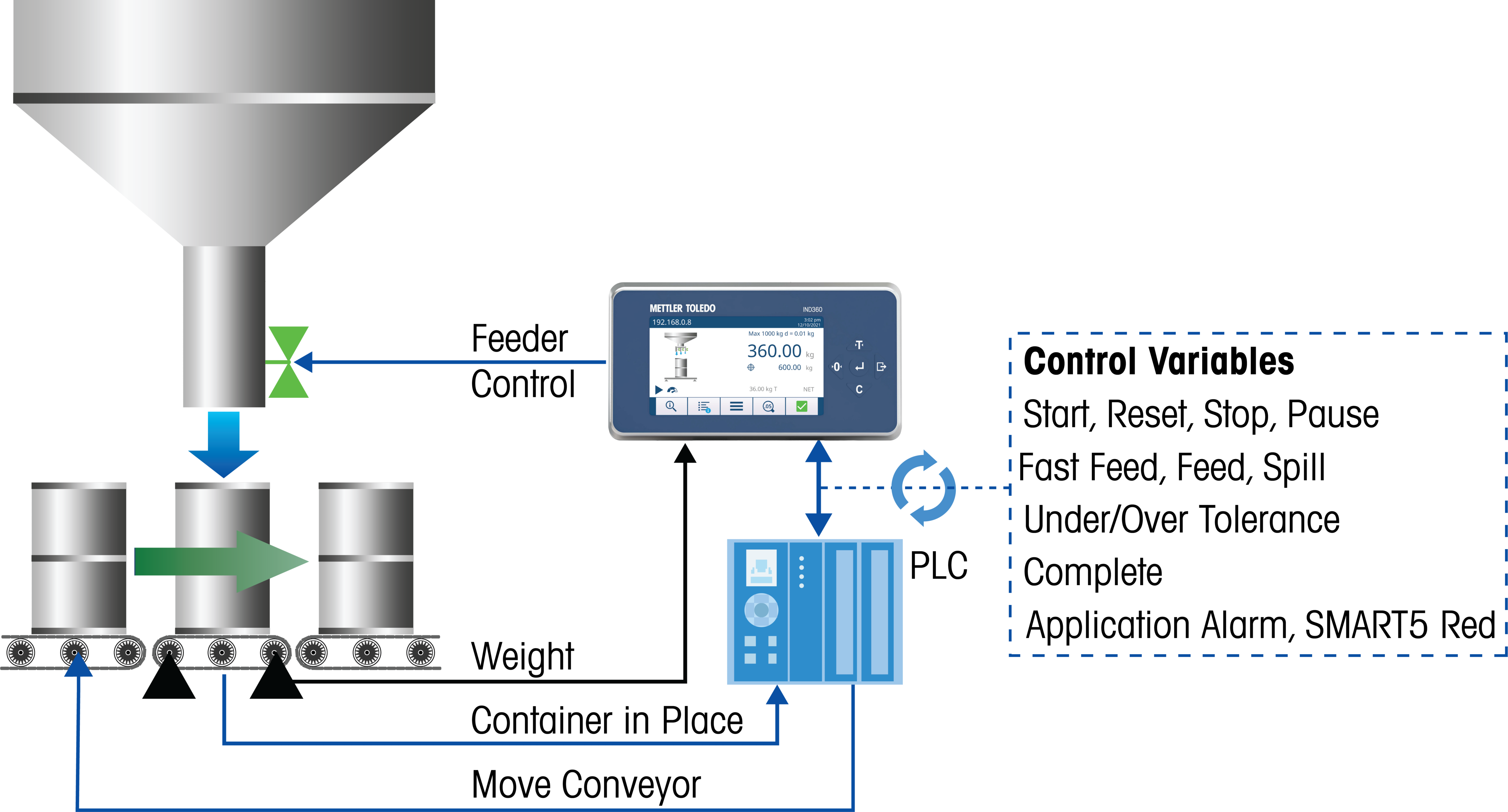

High update rate devices allow you to profile material flow so precise that you can refine your control variables and algorithms. With 960Hz ultra-high cyclical update rate from METTLER TOLEDO’s IND360, your PLC will be able to make milliseconds control decisions.

You will also be able to automate your machine using lesser hardware such as extra feeders or valves while helping your customers achieve the highest level of processing quality with simpler maintenance.

3. Plug and Weigh Communication Protocol

A smart, future-proof automated weighing system should be able to communicate to both Operational Technology (OT) and Information Technology (IT) networks or cloud services. Time-critical and deterministic process control data packets travel in the OT network, while process or machine condition monitoring data is sent via the IT networks, consumed by different business intelligence functions.

The weighing data in OT has to follow certain tested and optimized protocol to streamline communication with the PLC. This is why METTLER TOLEDO developed the Standard Automation Interface (SAI). SAI was designed to make it easy for customers to quickly connect to METTLER TOLEDO's industrial automation components such as terminals, transmitters and automatic precision-weighing sensors. This protocol is developed for high-speed IE communication such as EtherNet/IP. SAI works with all strain gauge scales and smart devices like high-precision bench scales, floor scales, METTLER TOLEDO's POWERCELL® weigh modules, and scales that facilitate weighing from 11 grams to 1,000 tons without changing the automation controller program.

SAI also supports condition monitoring and RedAlert™ alarming that automatically notifies the automation system when the sensor or scale is incapable of sending accurate weight.

4. Simplified Integration into Control System

Utilizing Certified Automation Interface will help to save you valuable engineering hours. Hence leveraging available Add-On Profiles (AOPs), Add-on-Instructions (AOIs), EDS device description files, PLC programming sample code, and expert level support make integration simplified, quick and easy.

AOP: When integrating a new weighing system into a Rockwell Automation control system, the weighing device that is equipped with AOP shortens the configuration time needed to get the module up and running. AOP is a product of collaboration between Rockwell Automation and partners such as METTLER TOLEDO.

AOI: AOI is a set of ready-to-use instructions which can reduce the PLC programming effort by at least 50% based on existing customer feedback.

Furthermore, having a built-in web server makes setup and maintenance hassle-free whether you are remote or on-site. It reduces button pushing, errors and offers backup, restore and cloning. With this feature, your maintenance team can reduce the number of proprietary software tools to manage all equipment in the plant.

All these integration tools ensure the weighing devices send accurate weight and device condition data to your PLC/ DCS for reliable operation, maximum uptime, and ultimate visibility.