PowerFlex® 755T drive products provide harmonic mitigation, regeneration, non-regenerative, and common bus solutions that help reduce energy costs, gain flexibility, and increase productivity. PowerFlex drives use TotalFORCE® technology to achieve motor control through precise, adaptive control of torque, velocity, and position. TotalFORCE technology incorporates several patented features that are designed to help optimize your system and maintain productivity through improved machine uptime.

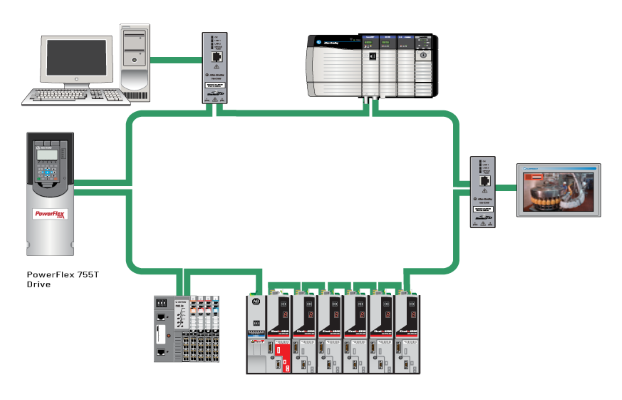

Reference Architectures

- Standard System

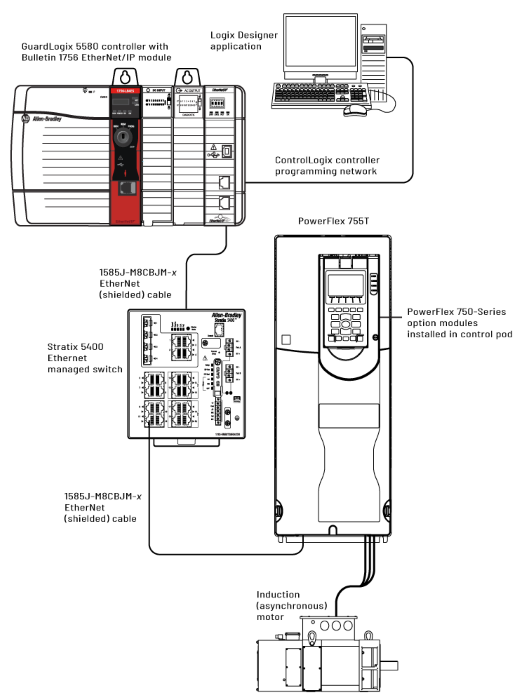

- Safety System

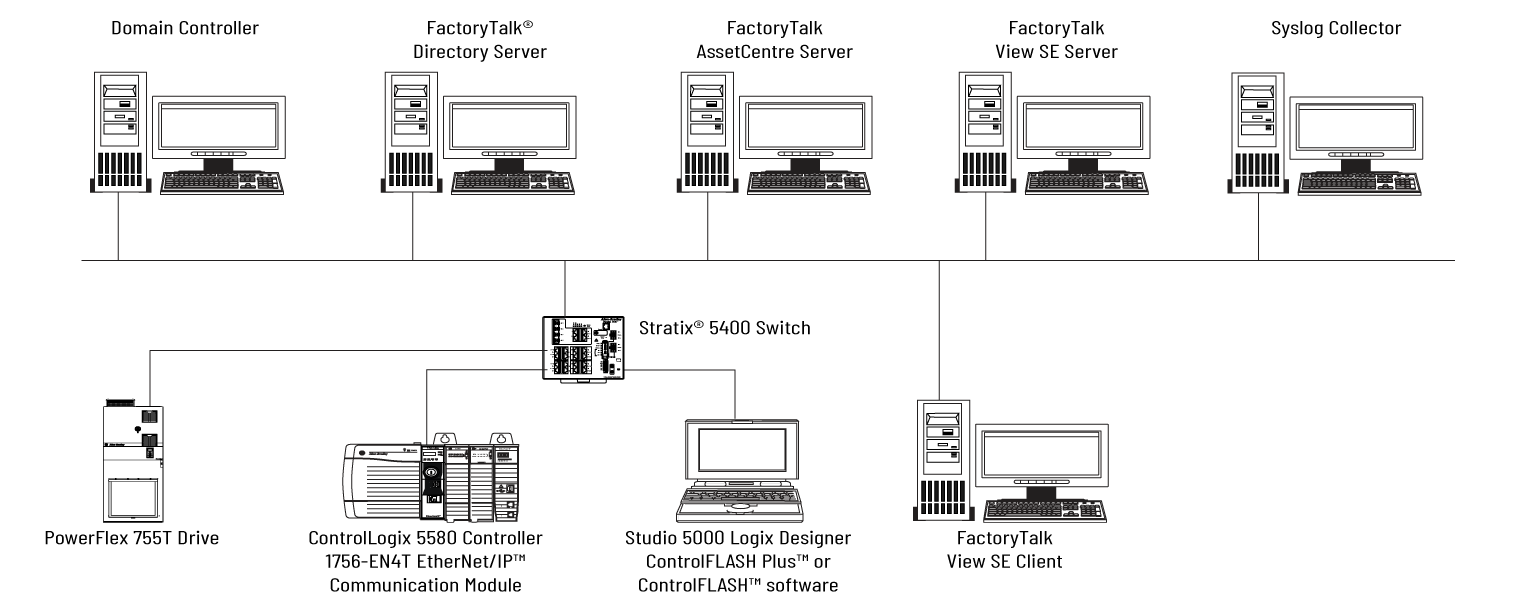

- Security 62443-4-2 Certified System

Standard System

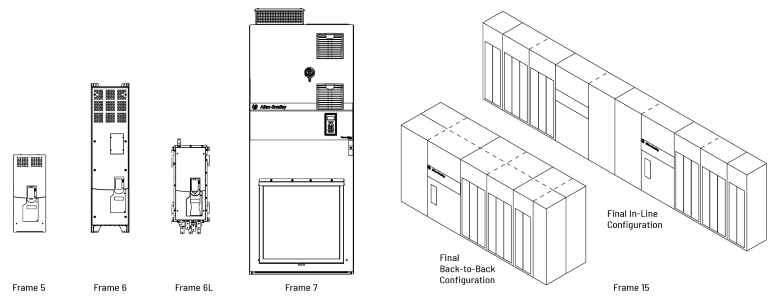

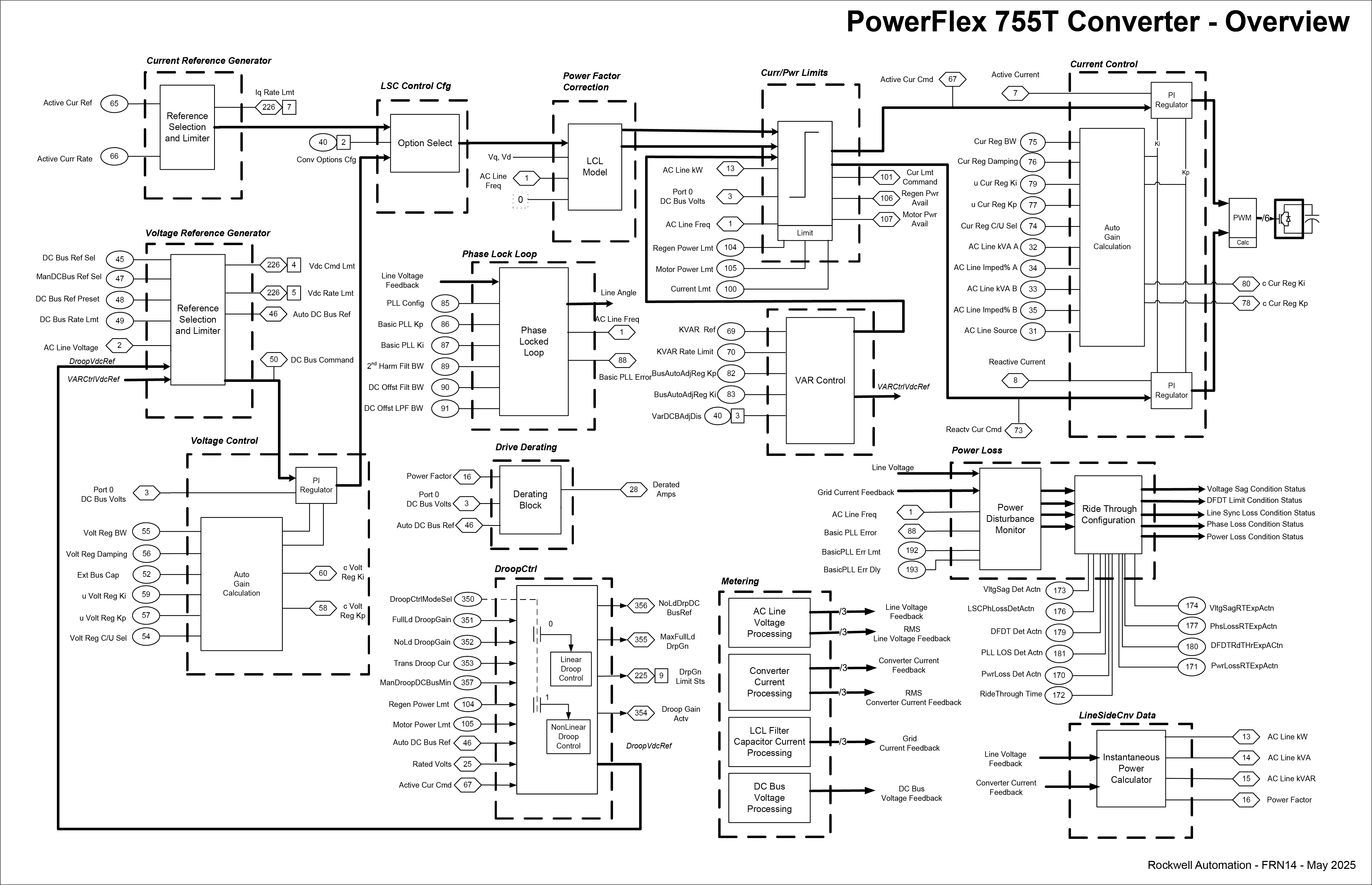

PowerFlex 755T Drives Overview

Safety System

Safe Stop Functional Safety

Security 62443-4-2 Certified System

Develop Secure Applications

Use and Operation

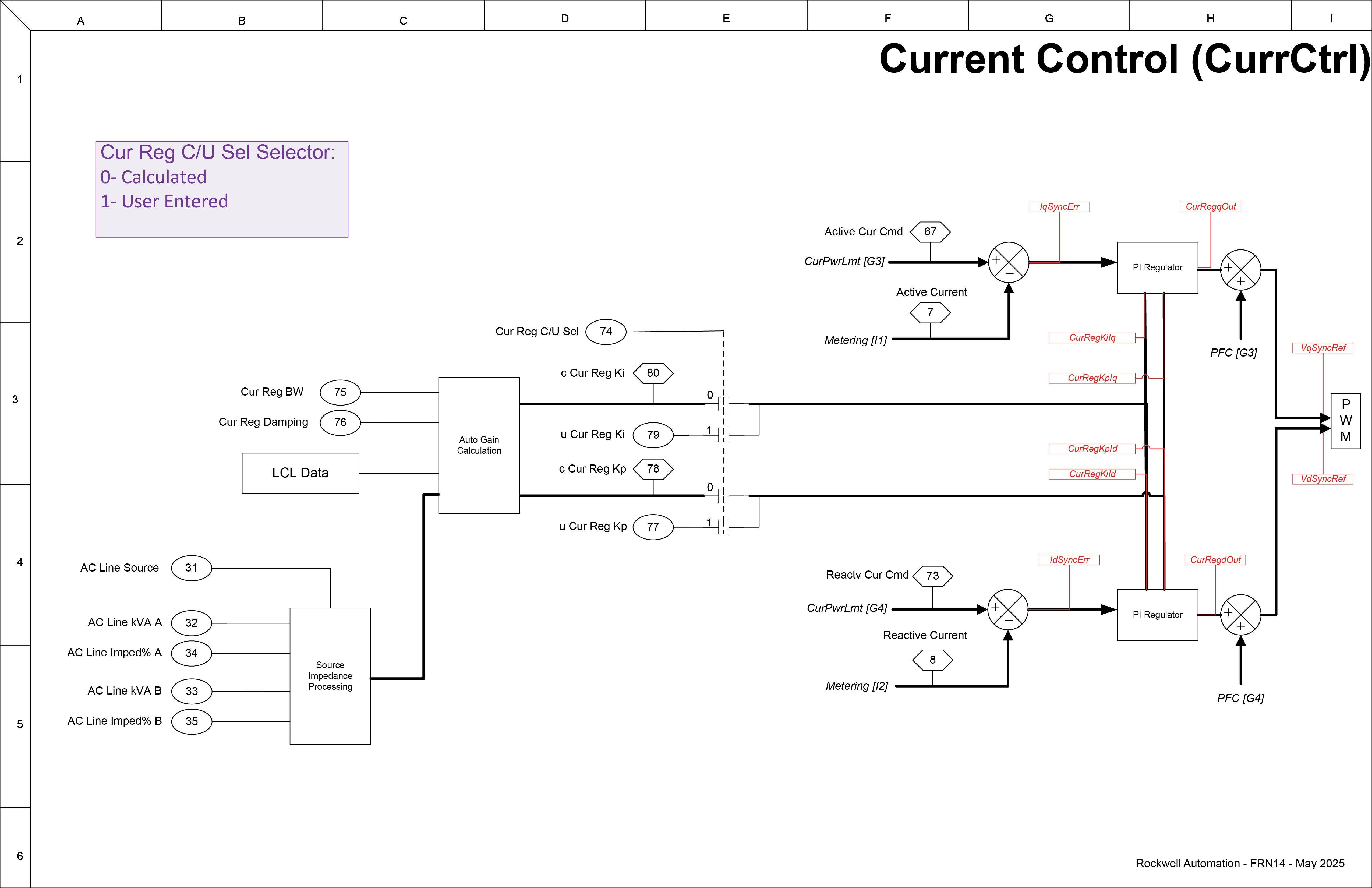

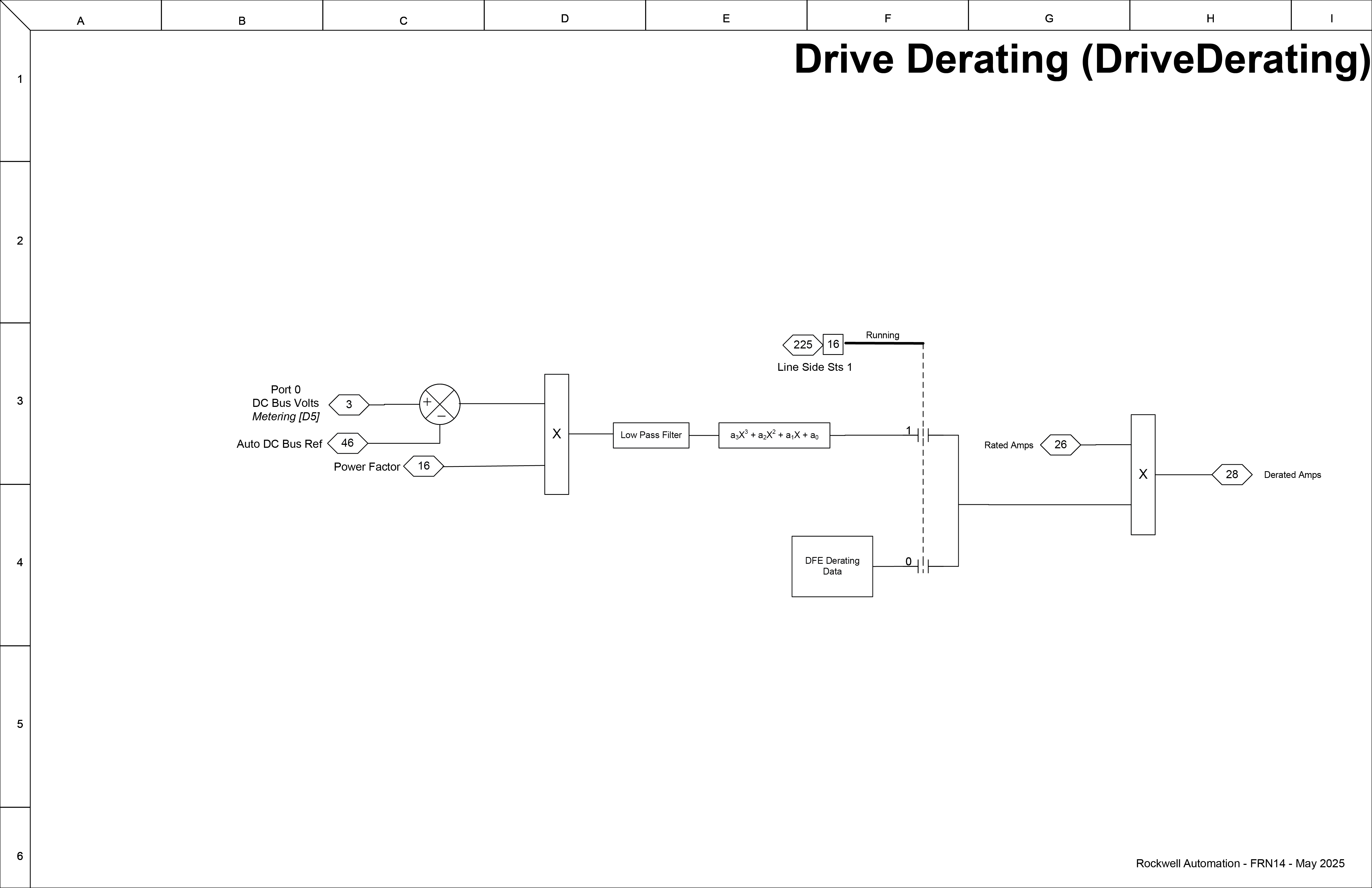

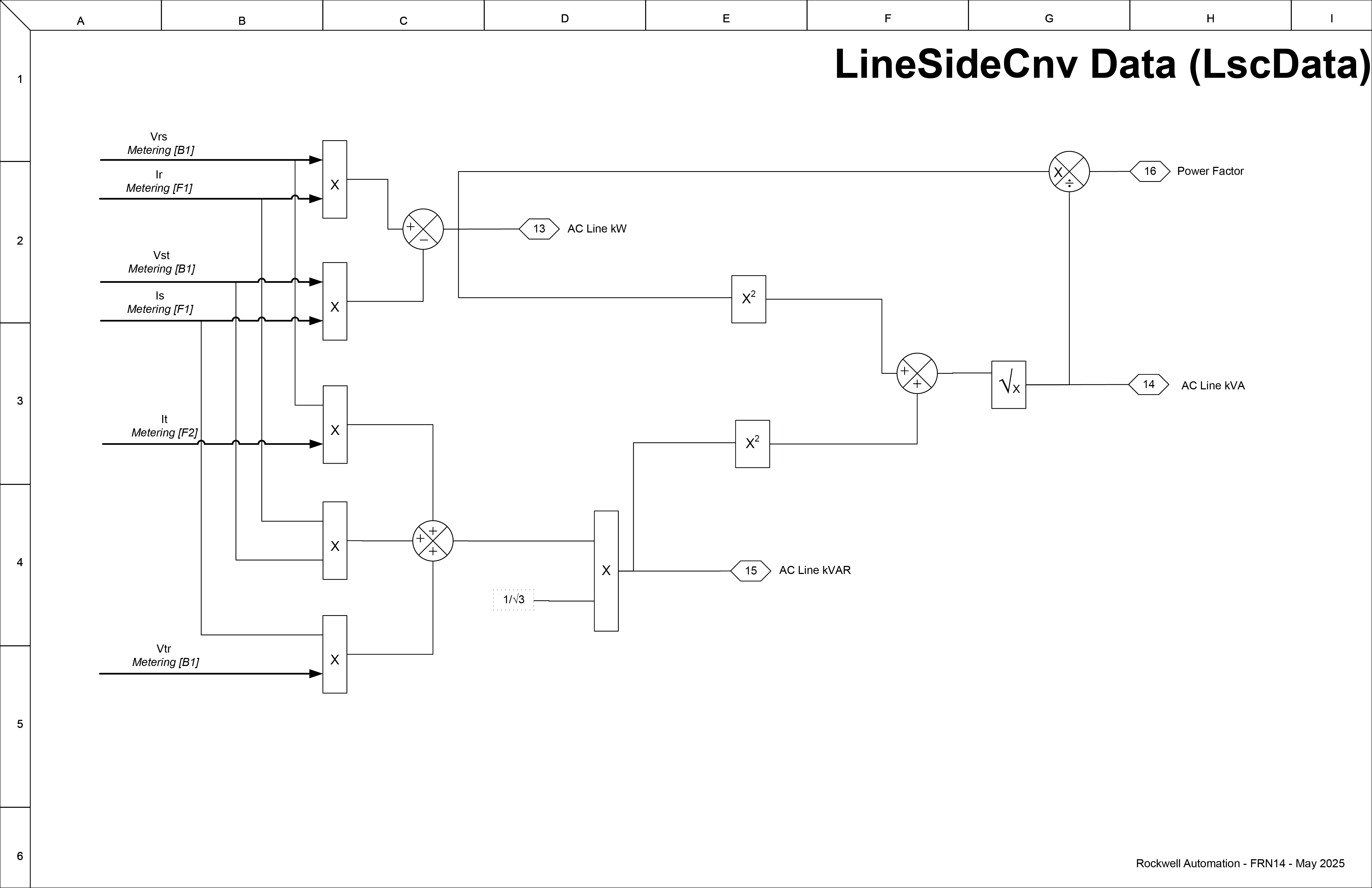

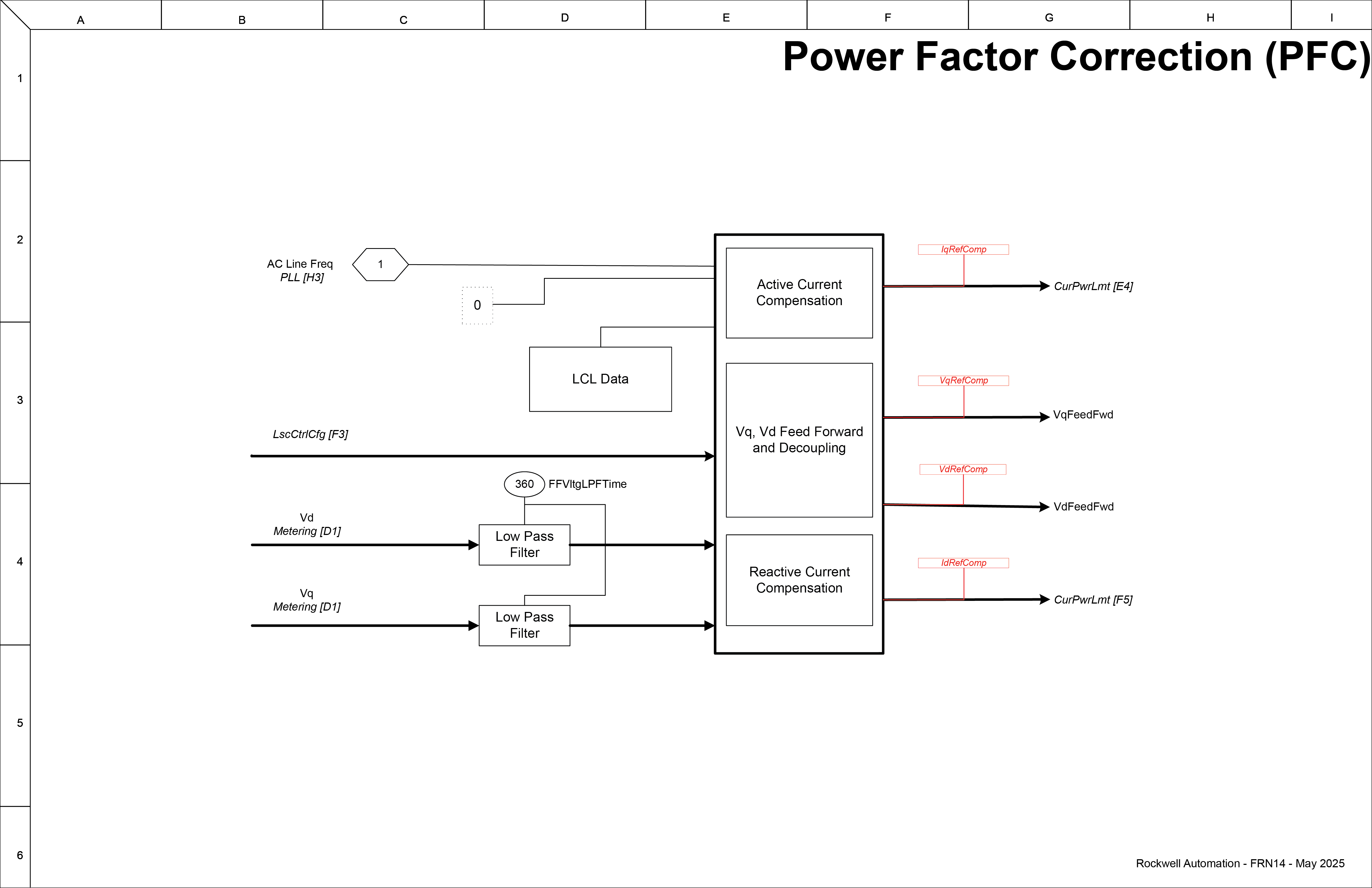

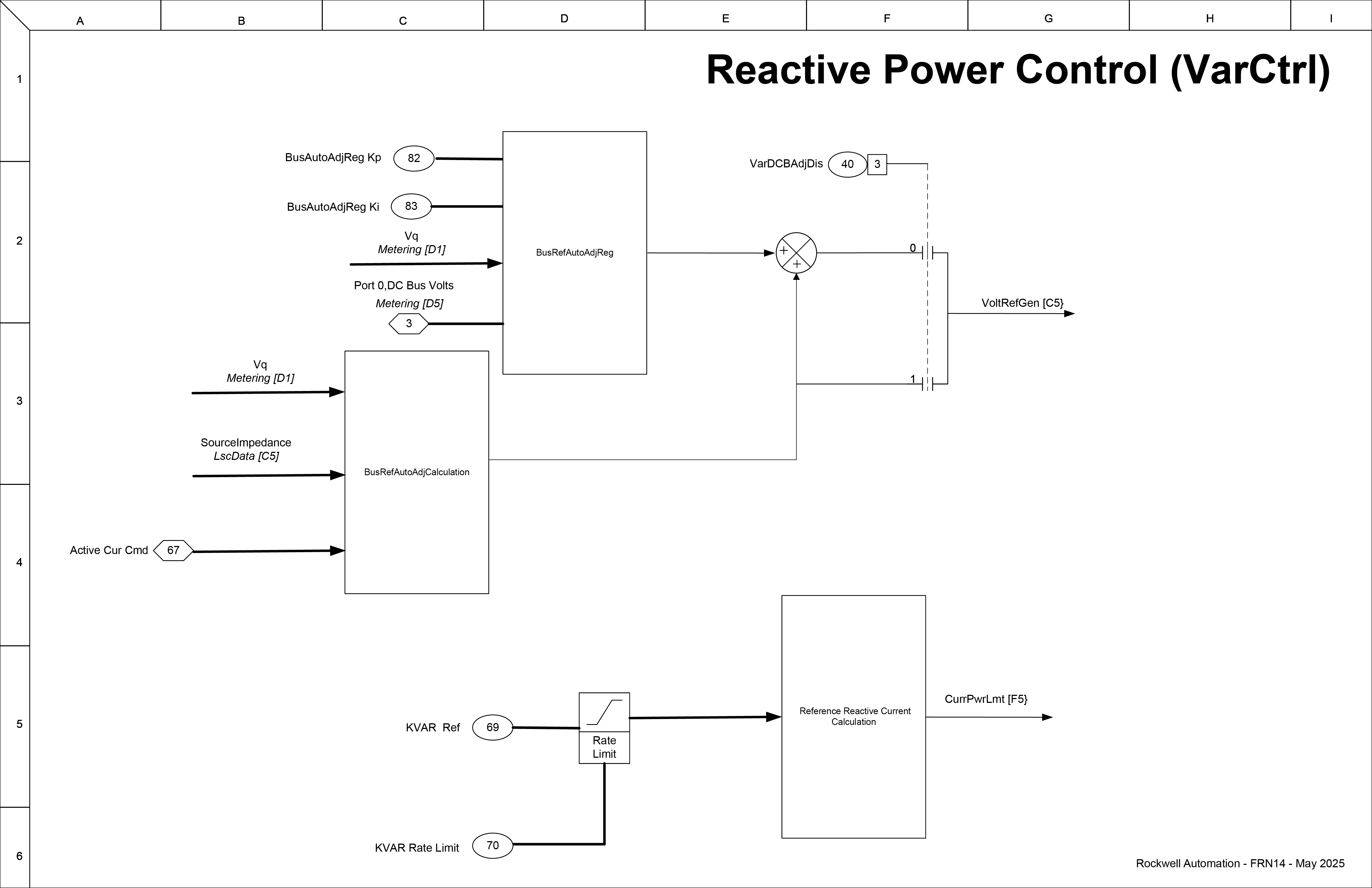

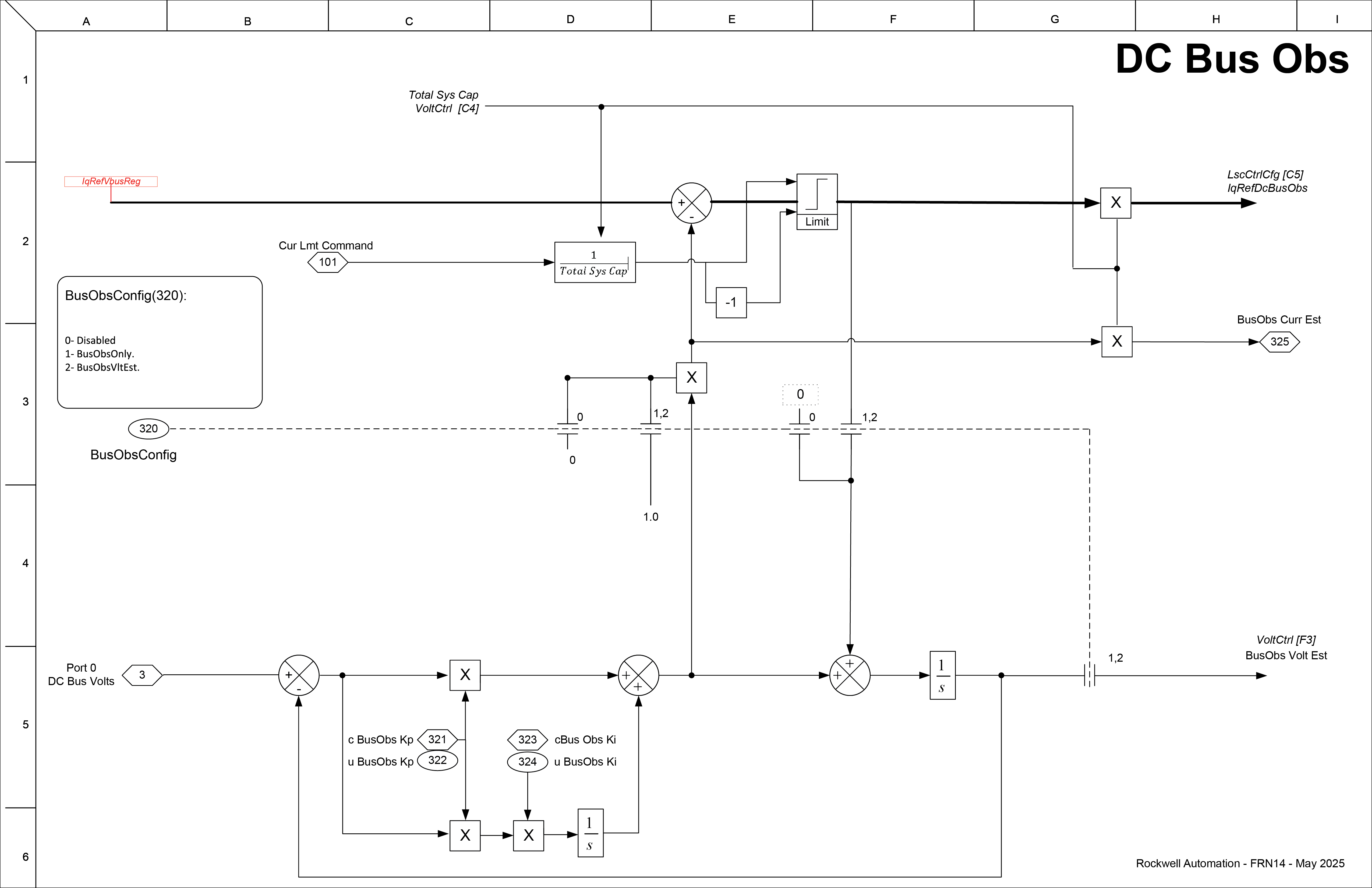

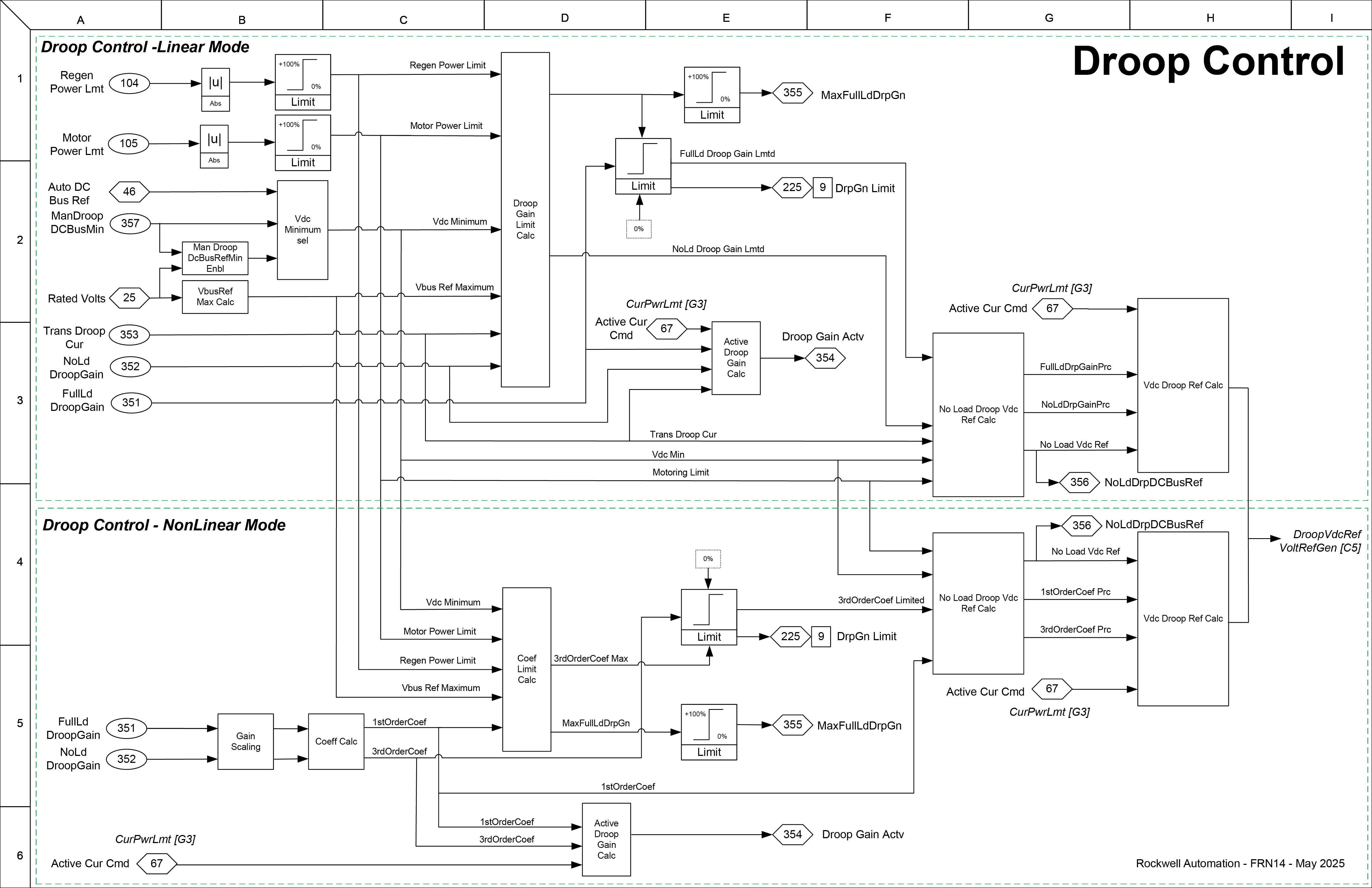

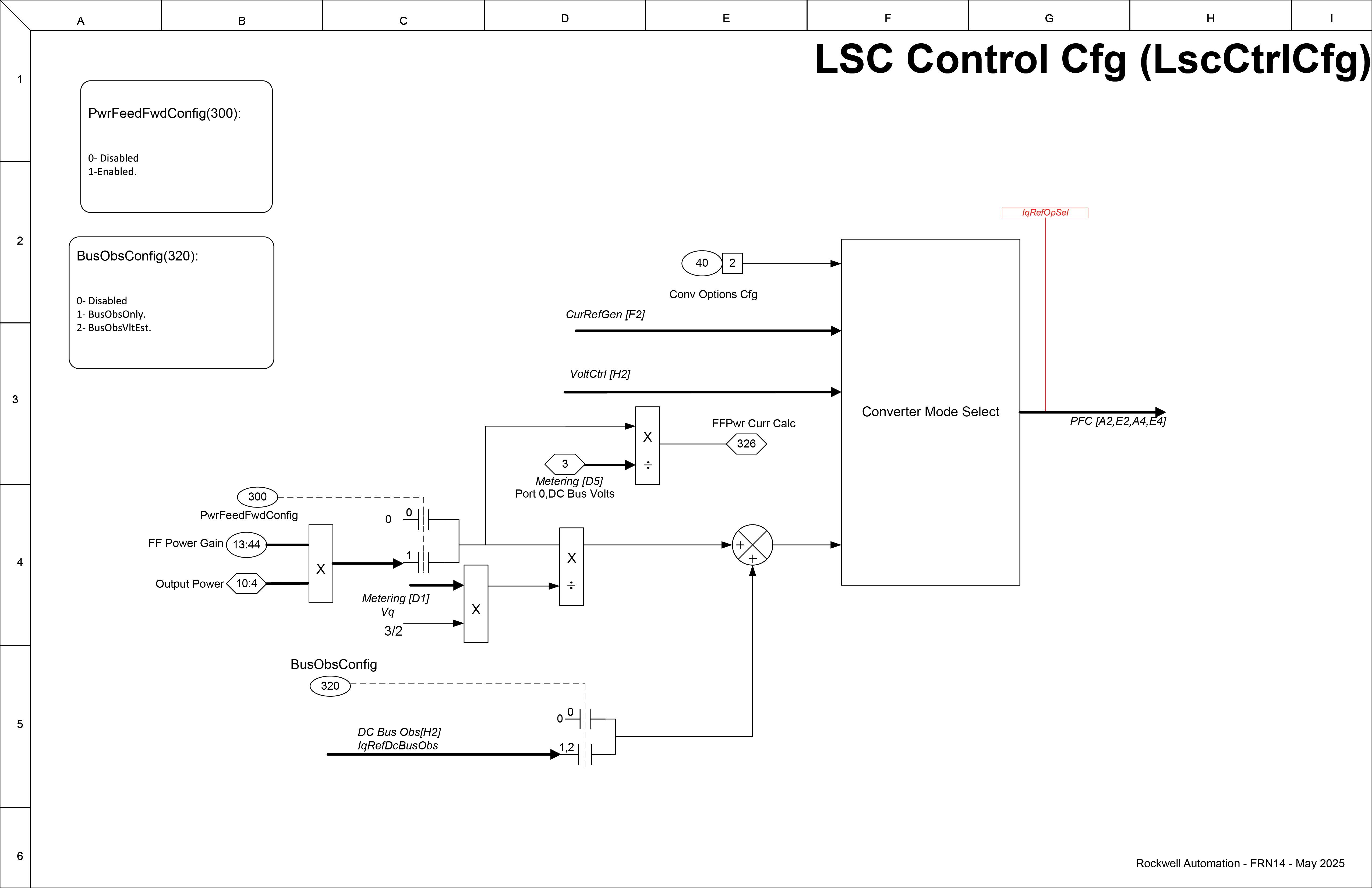

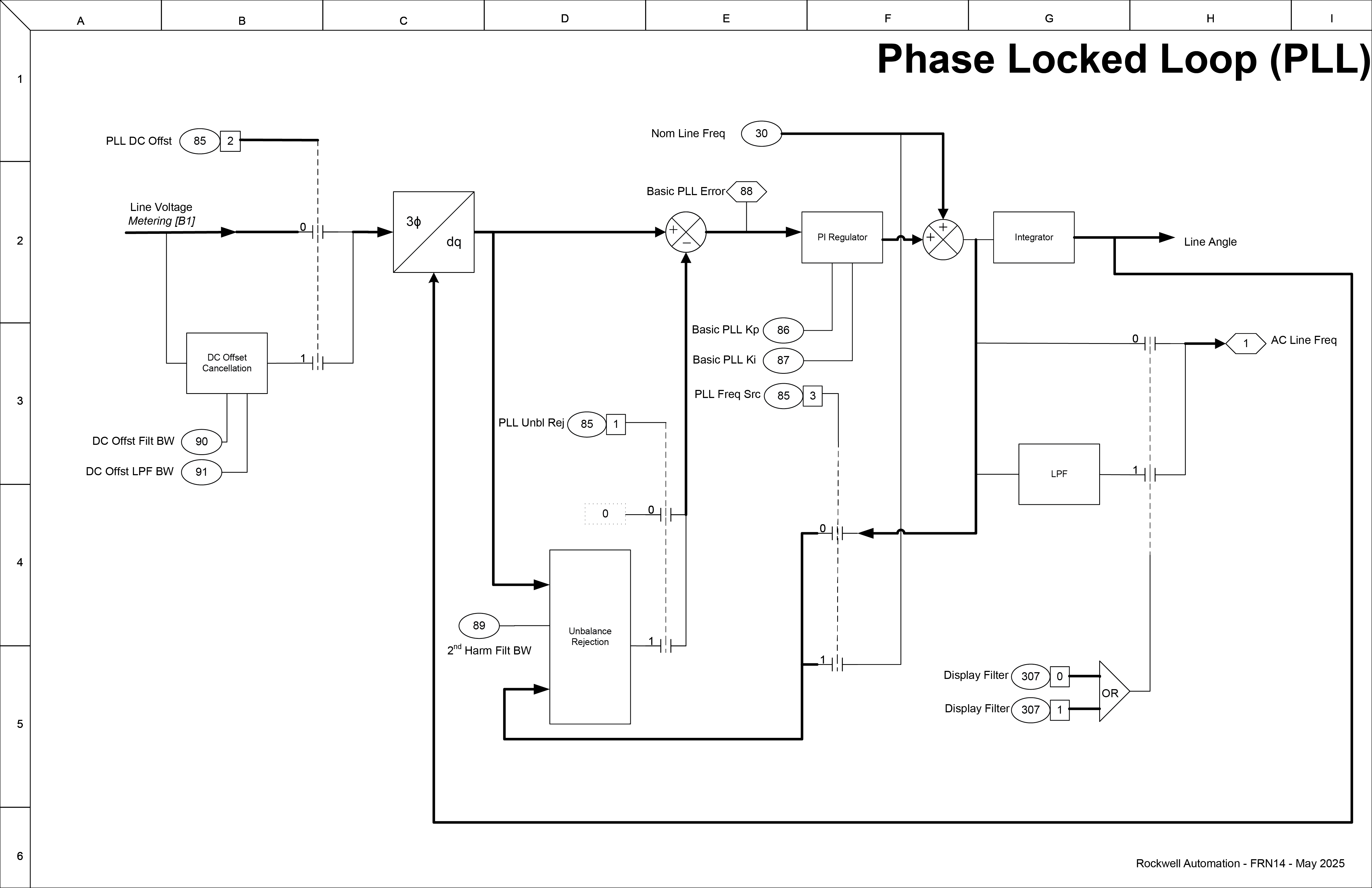

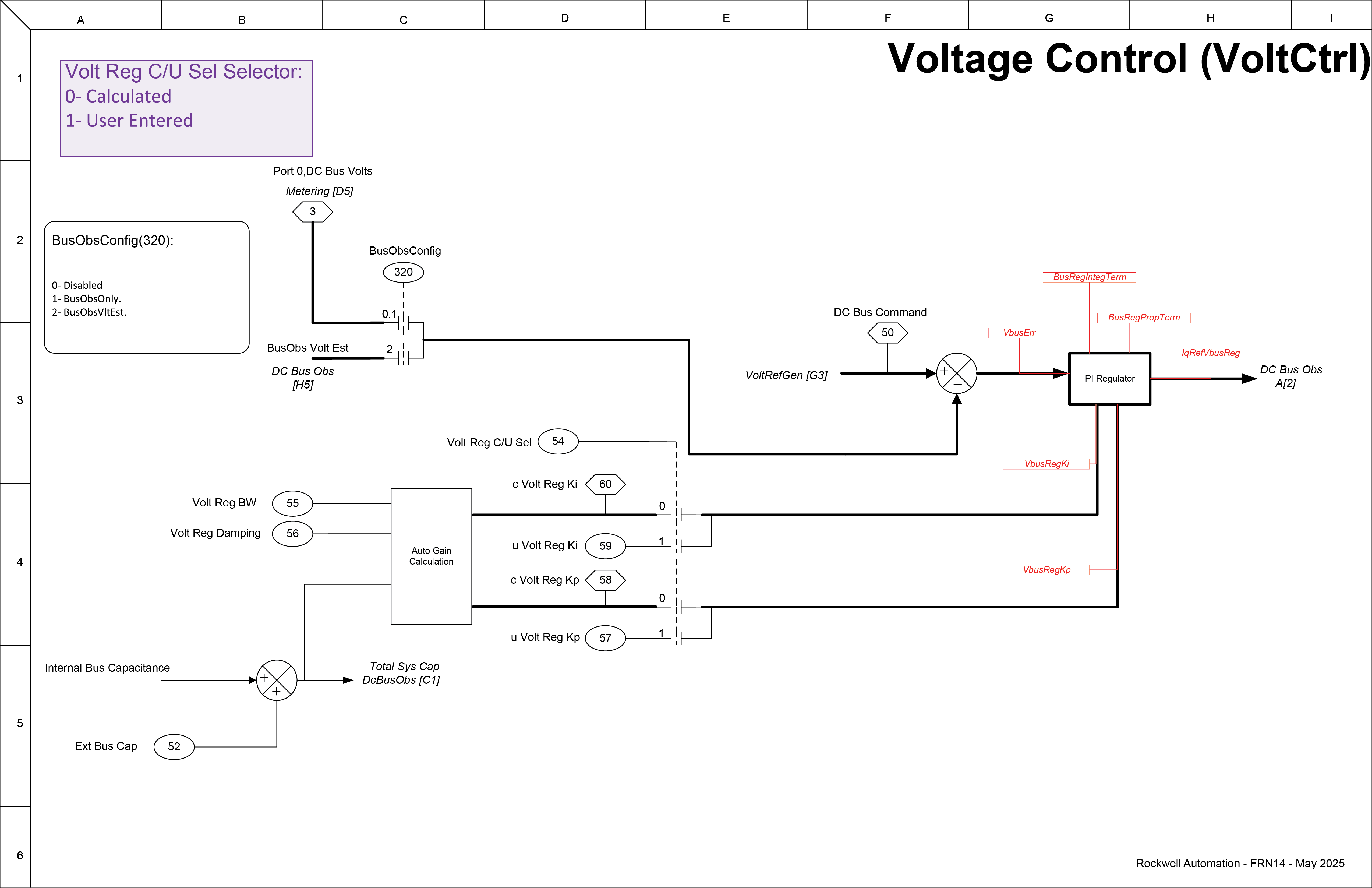

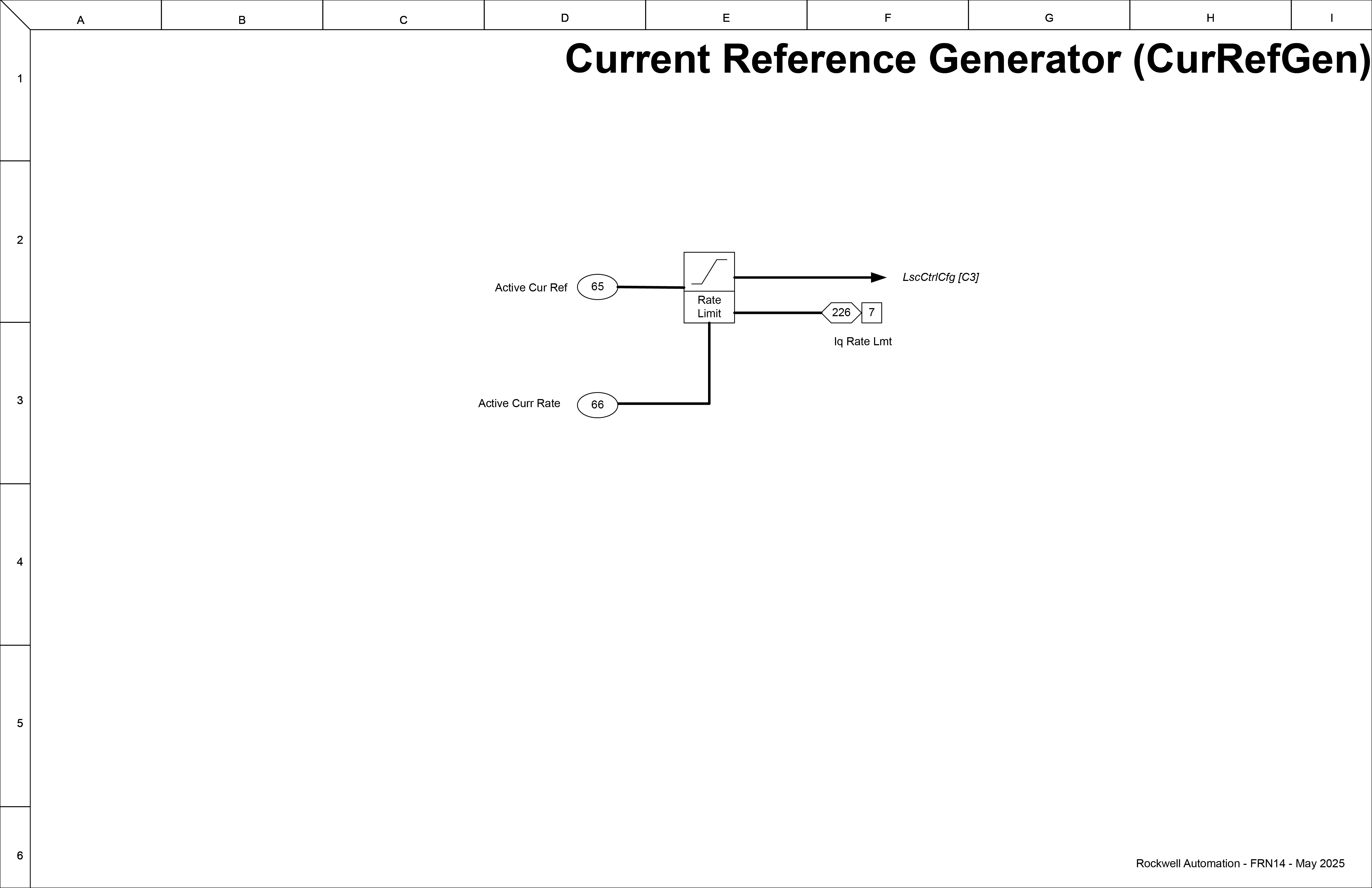

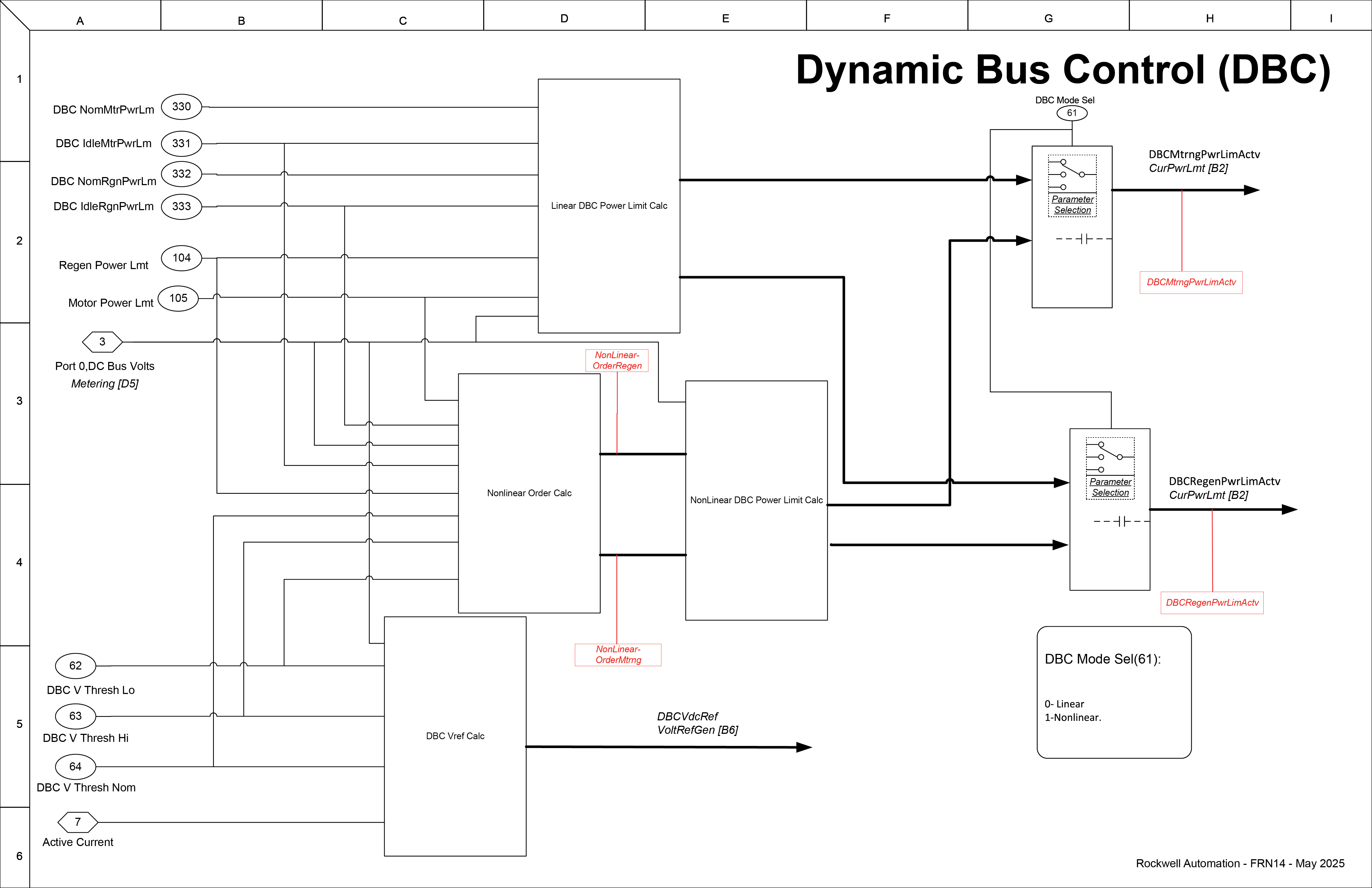

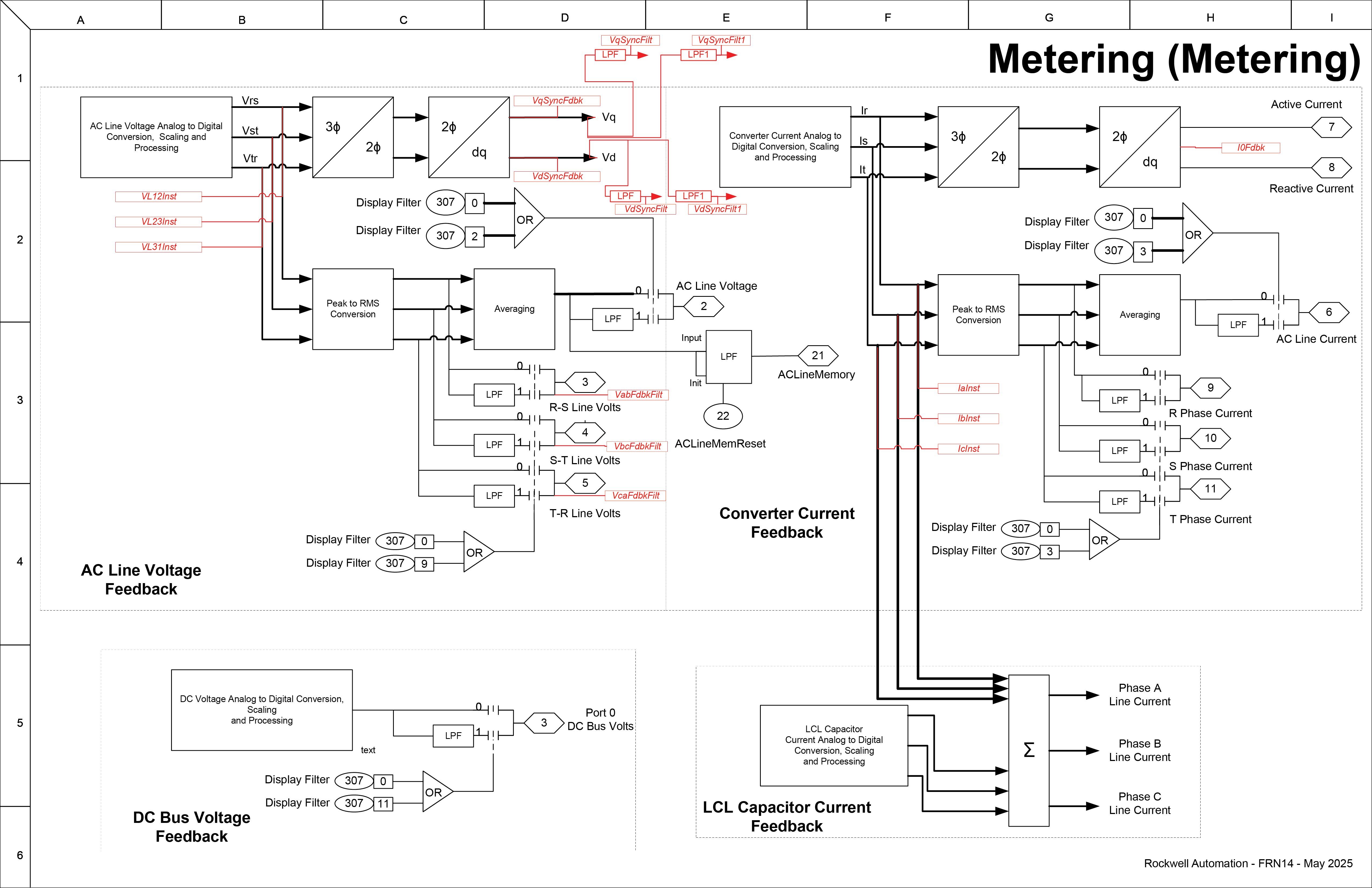

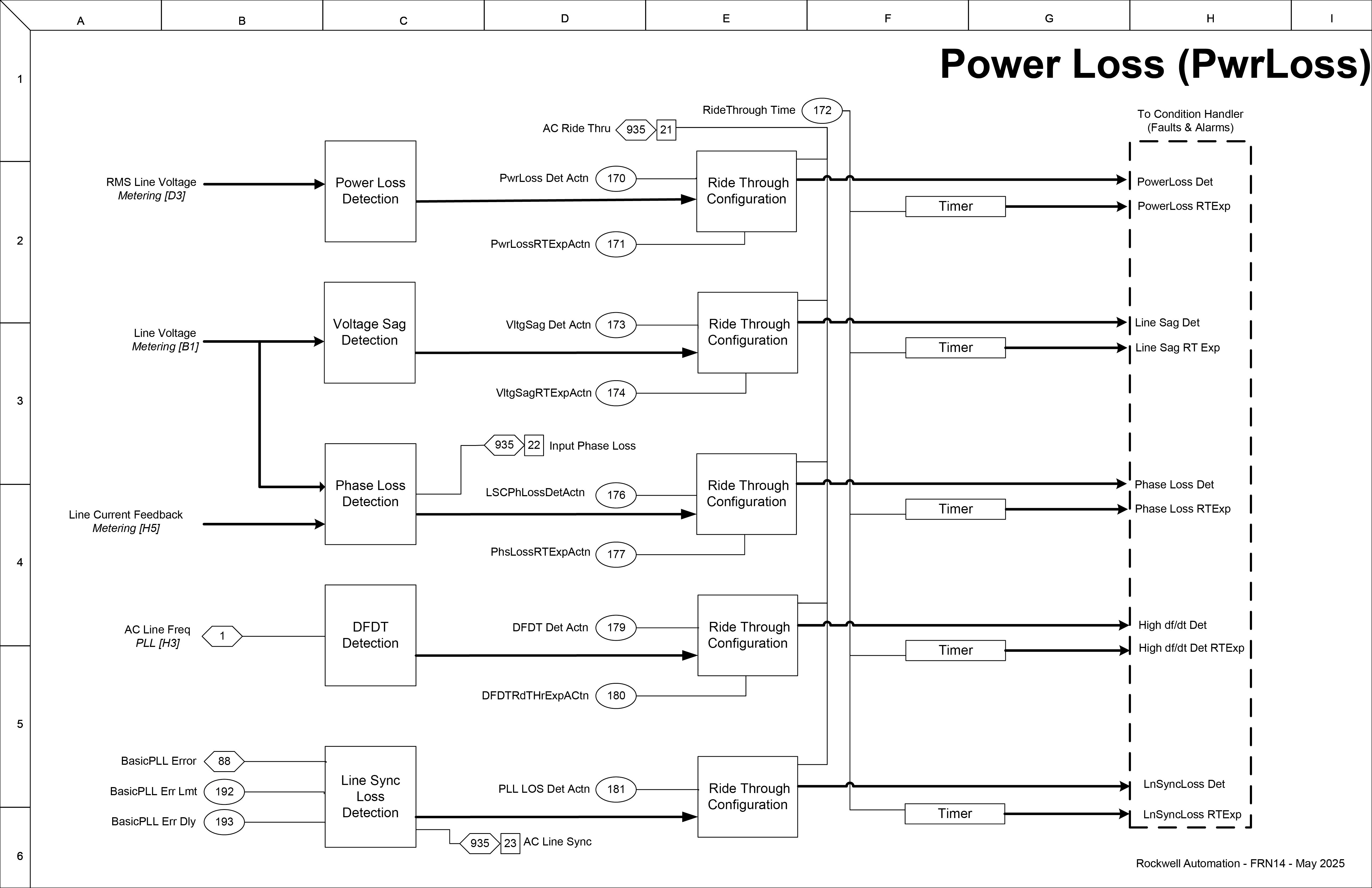

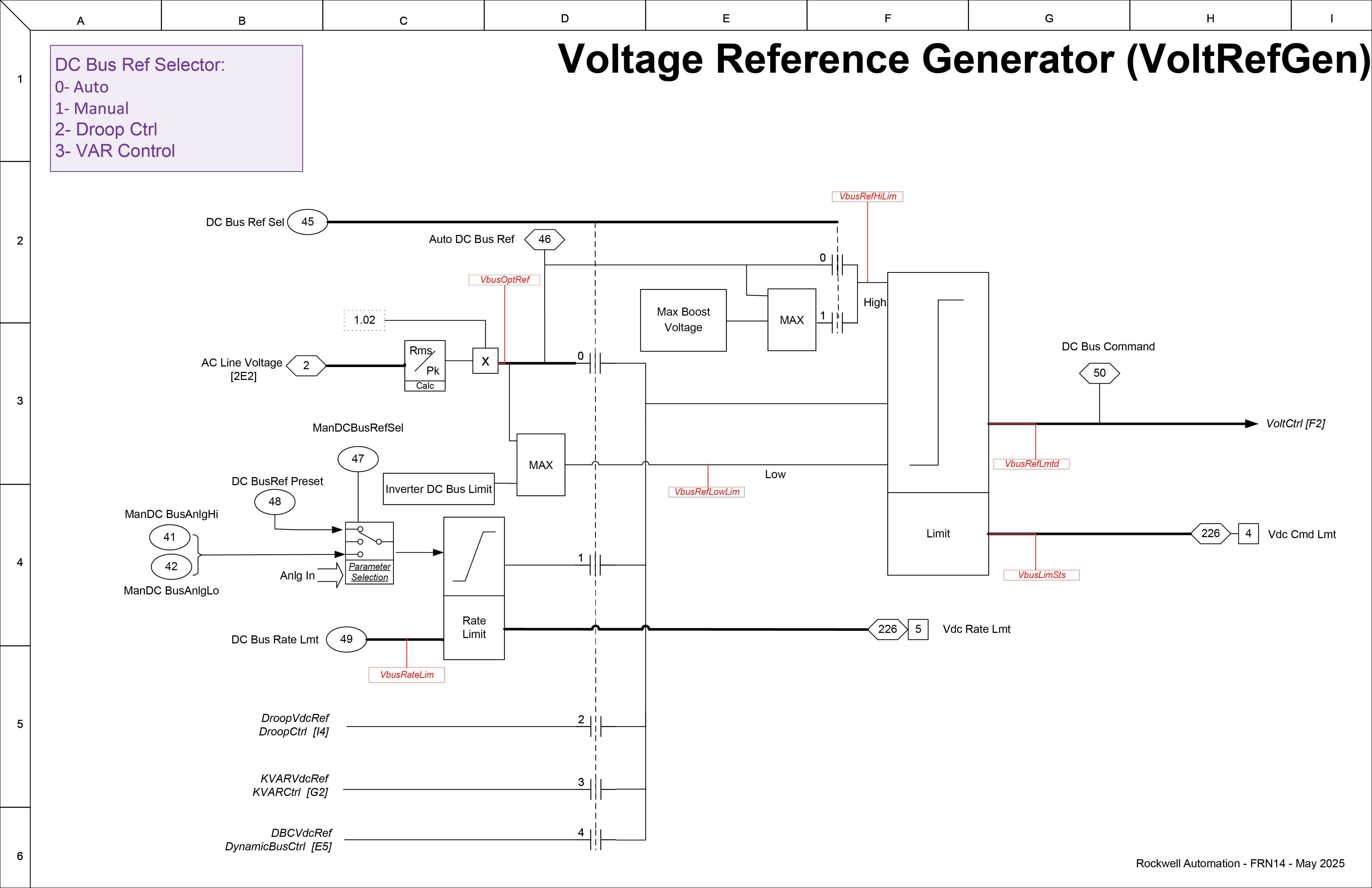

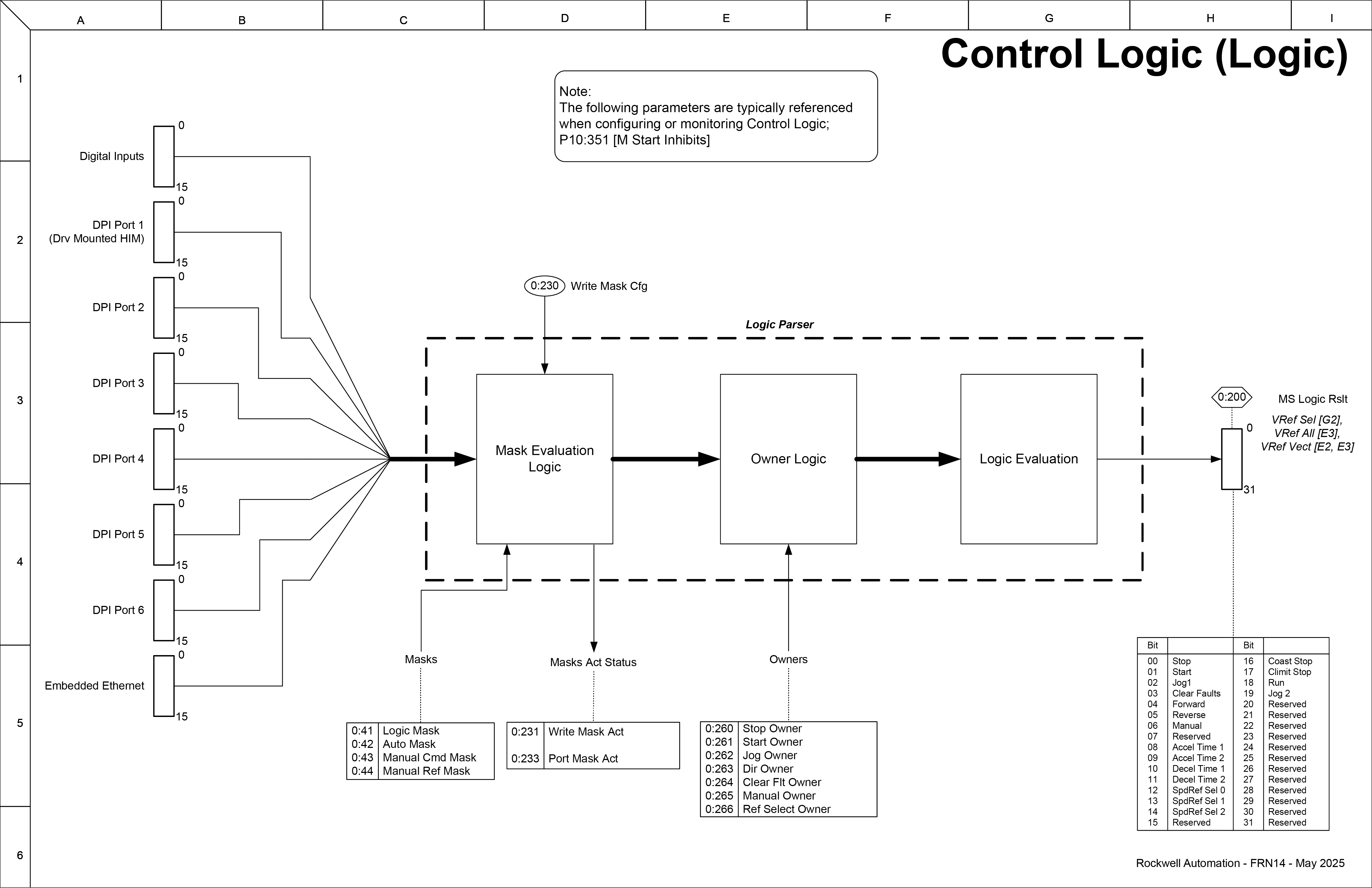

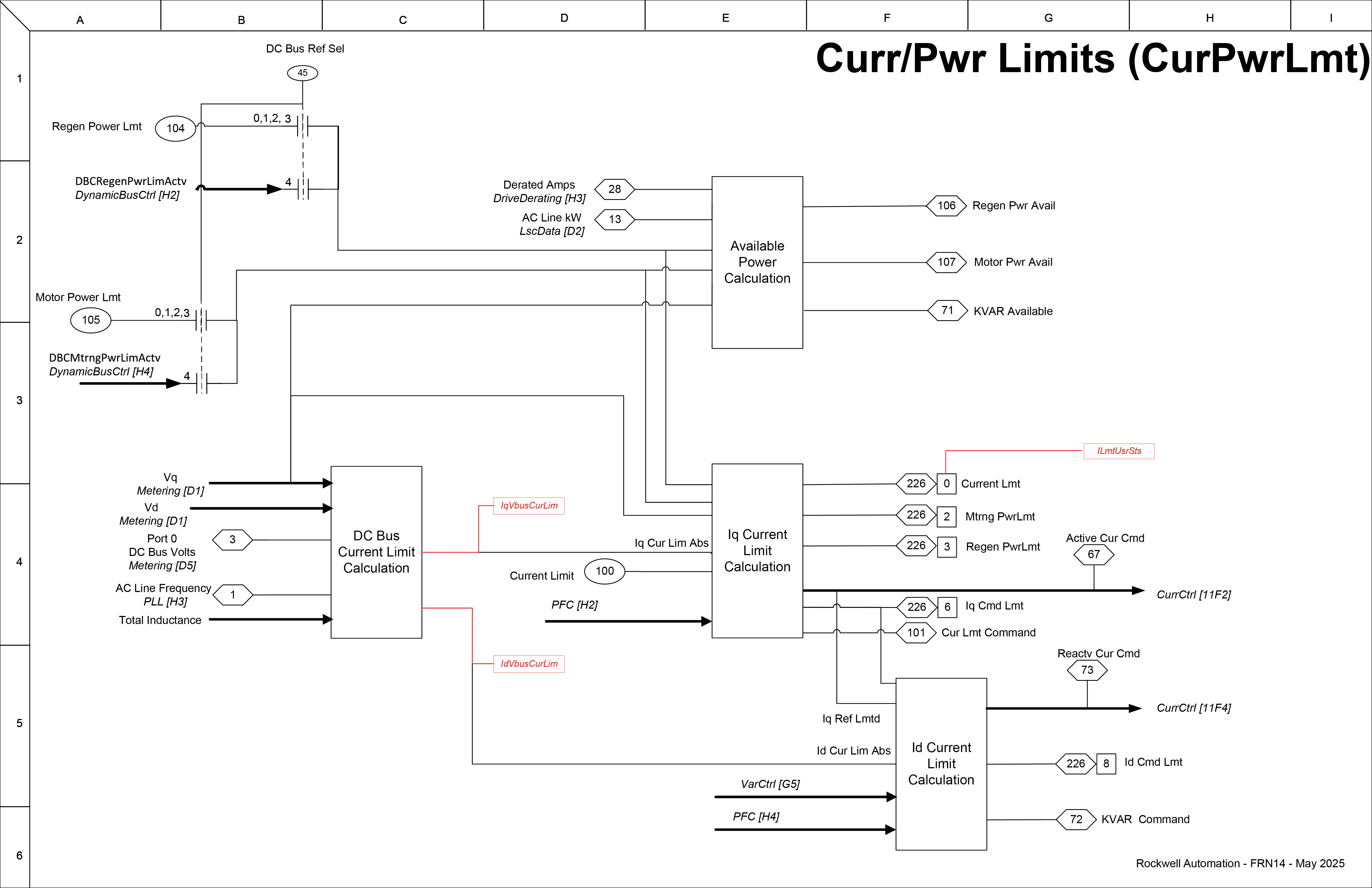

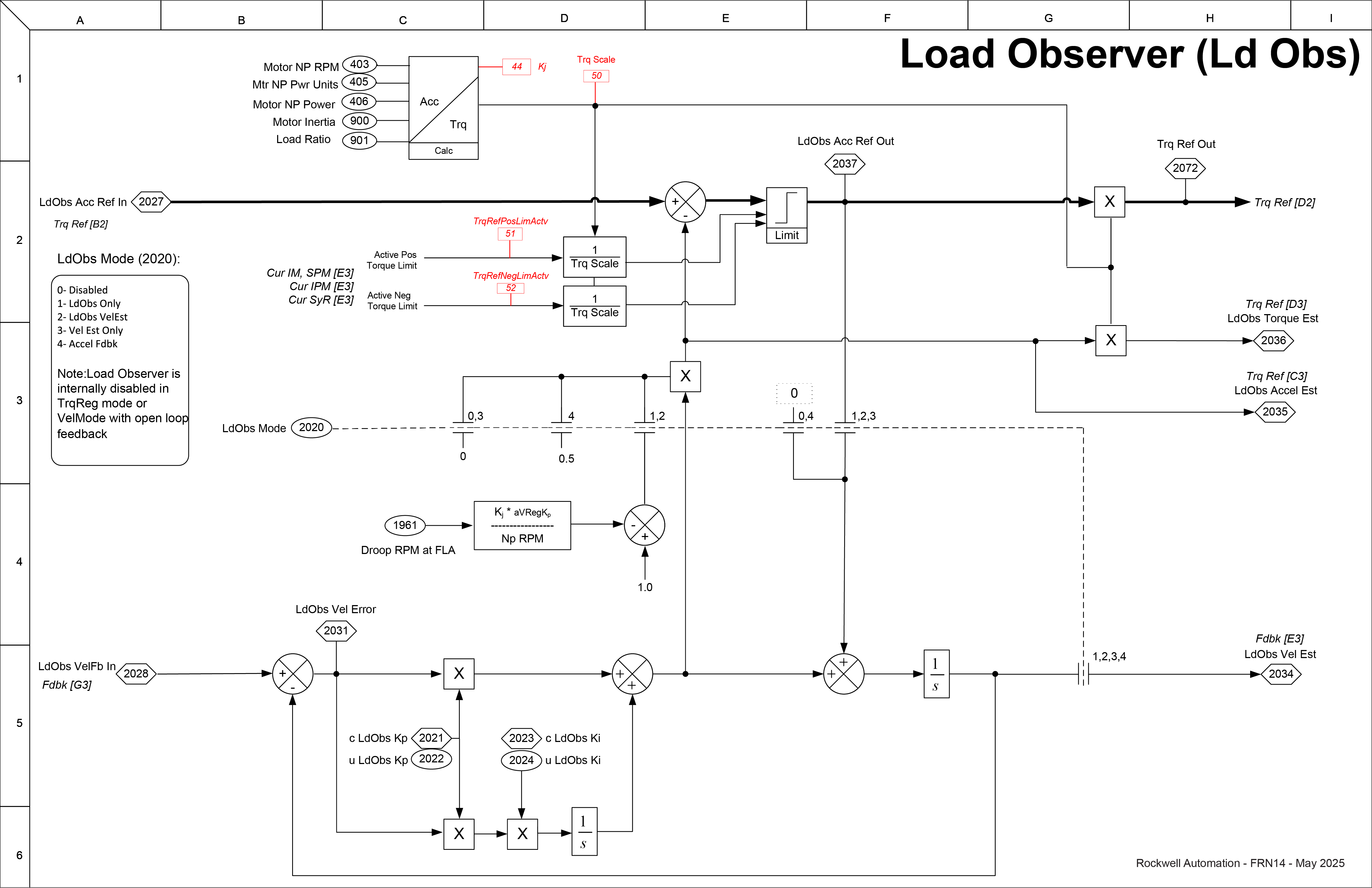

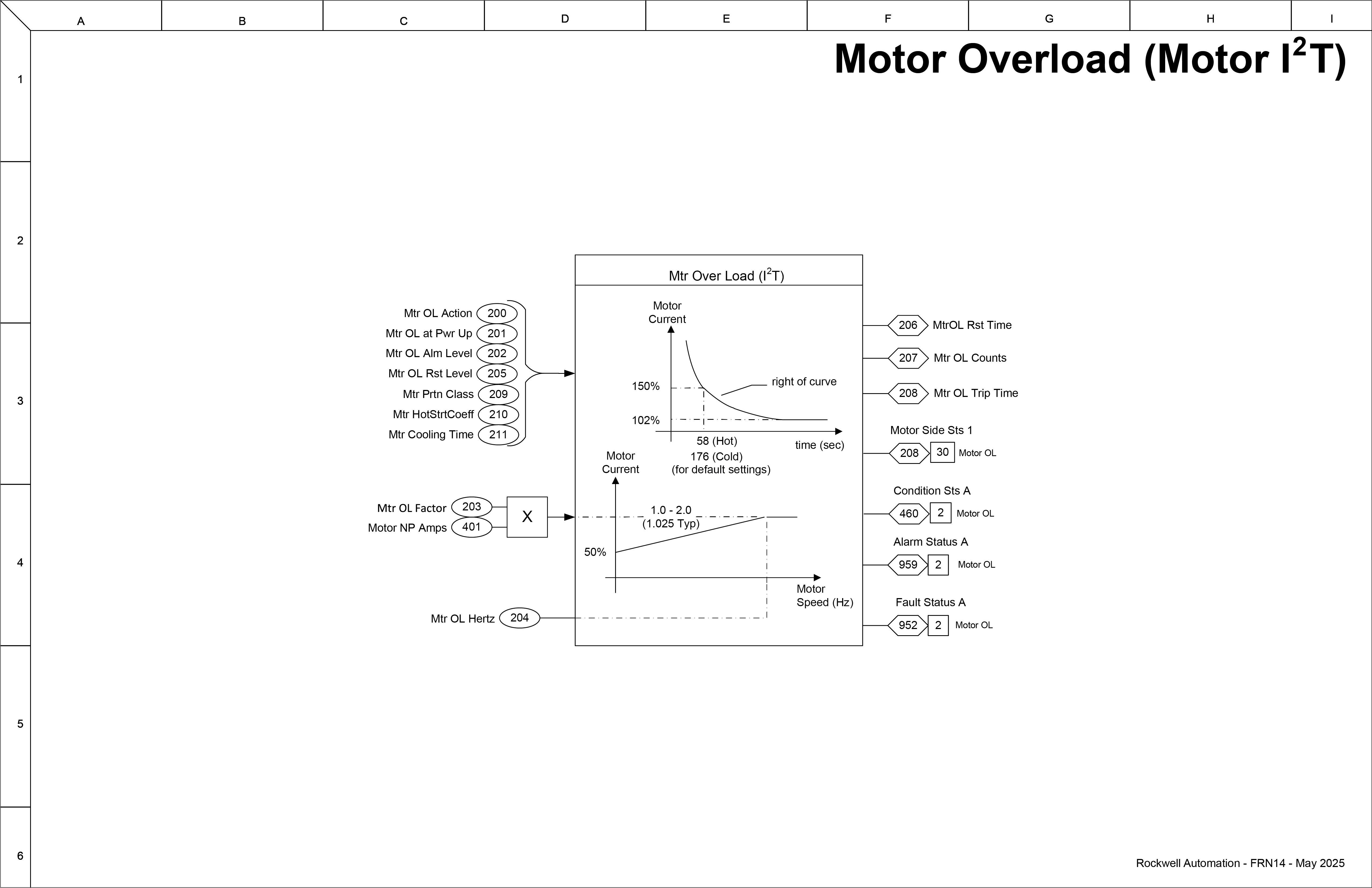

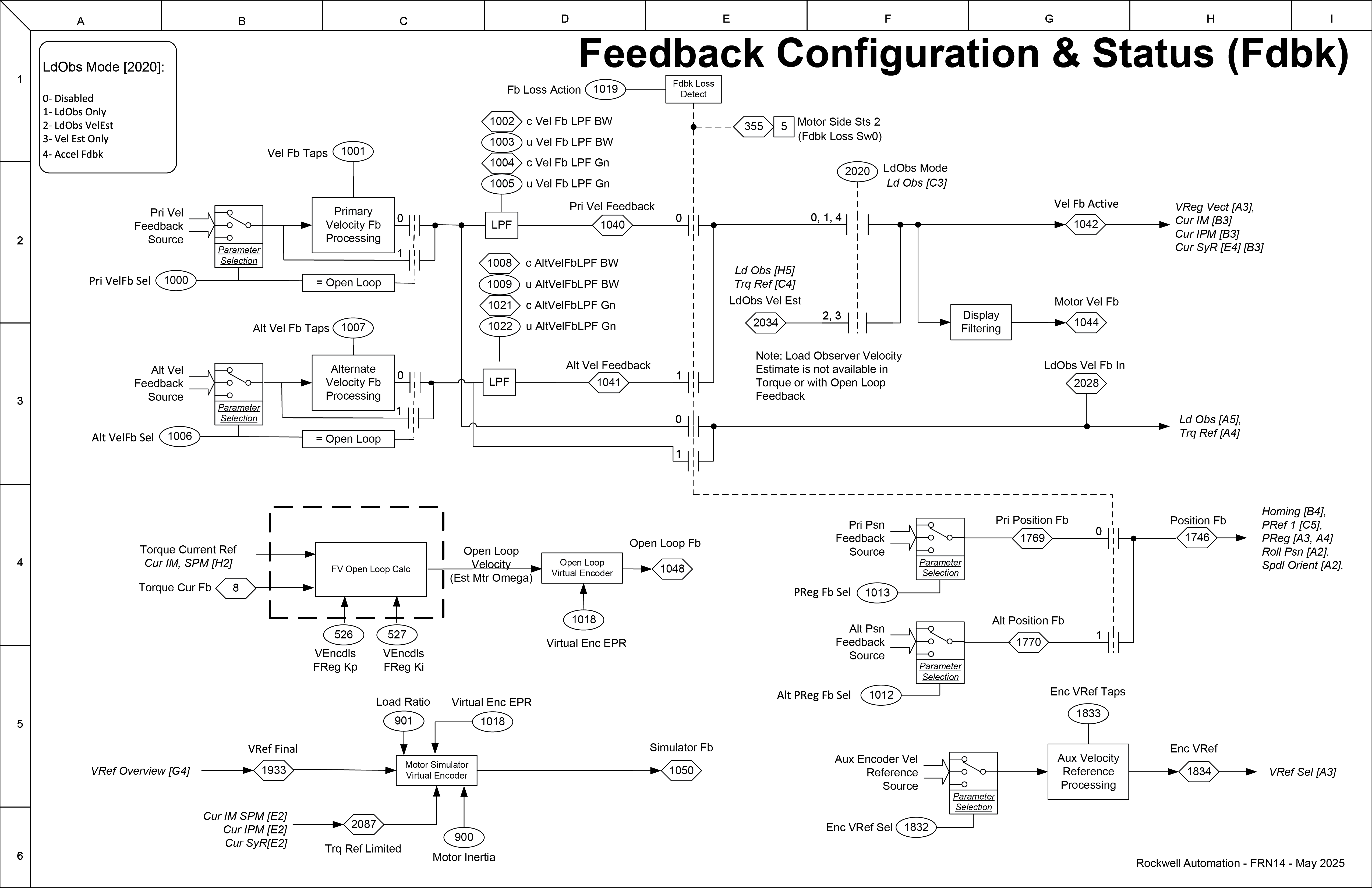

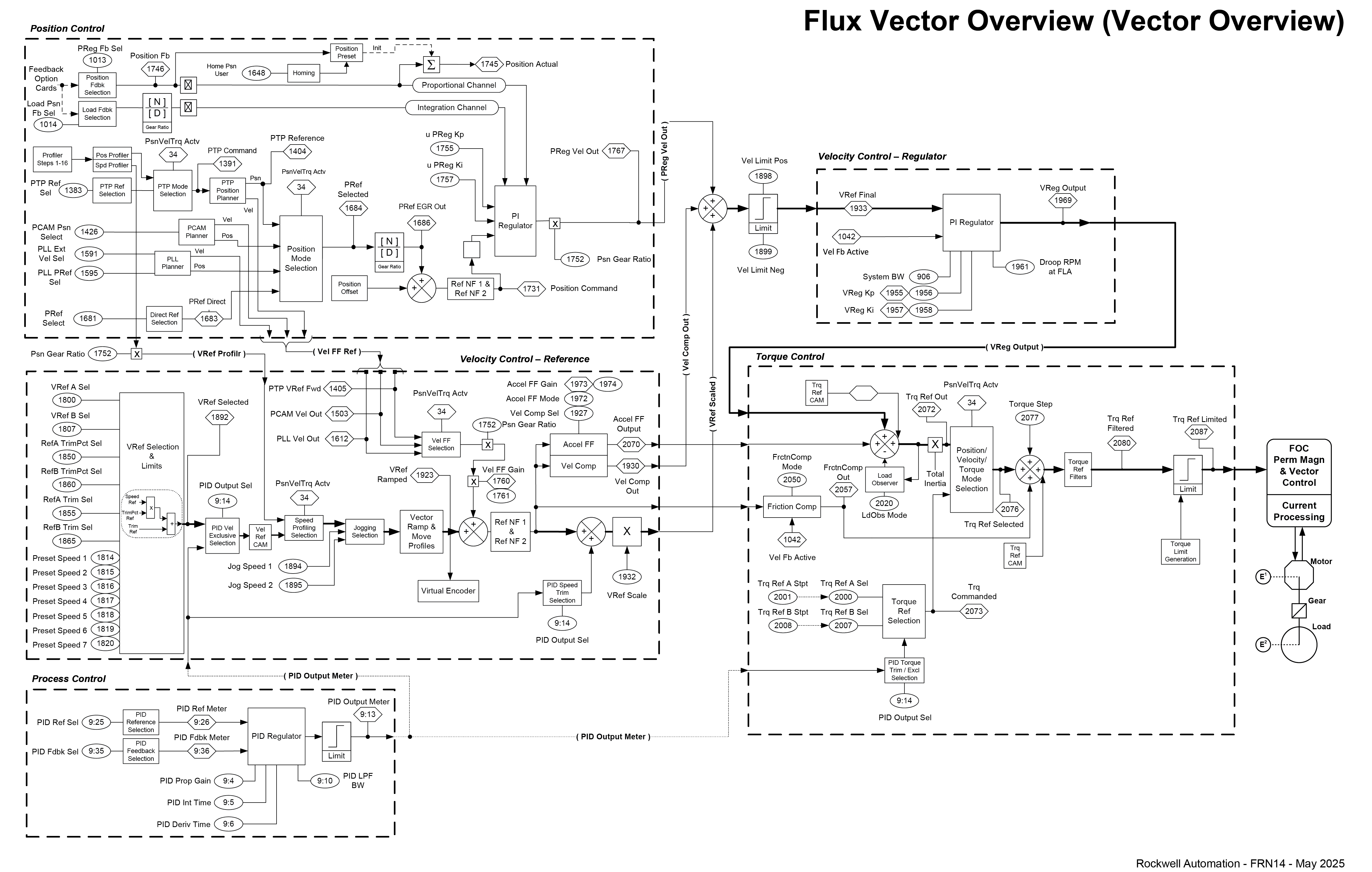

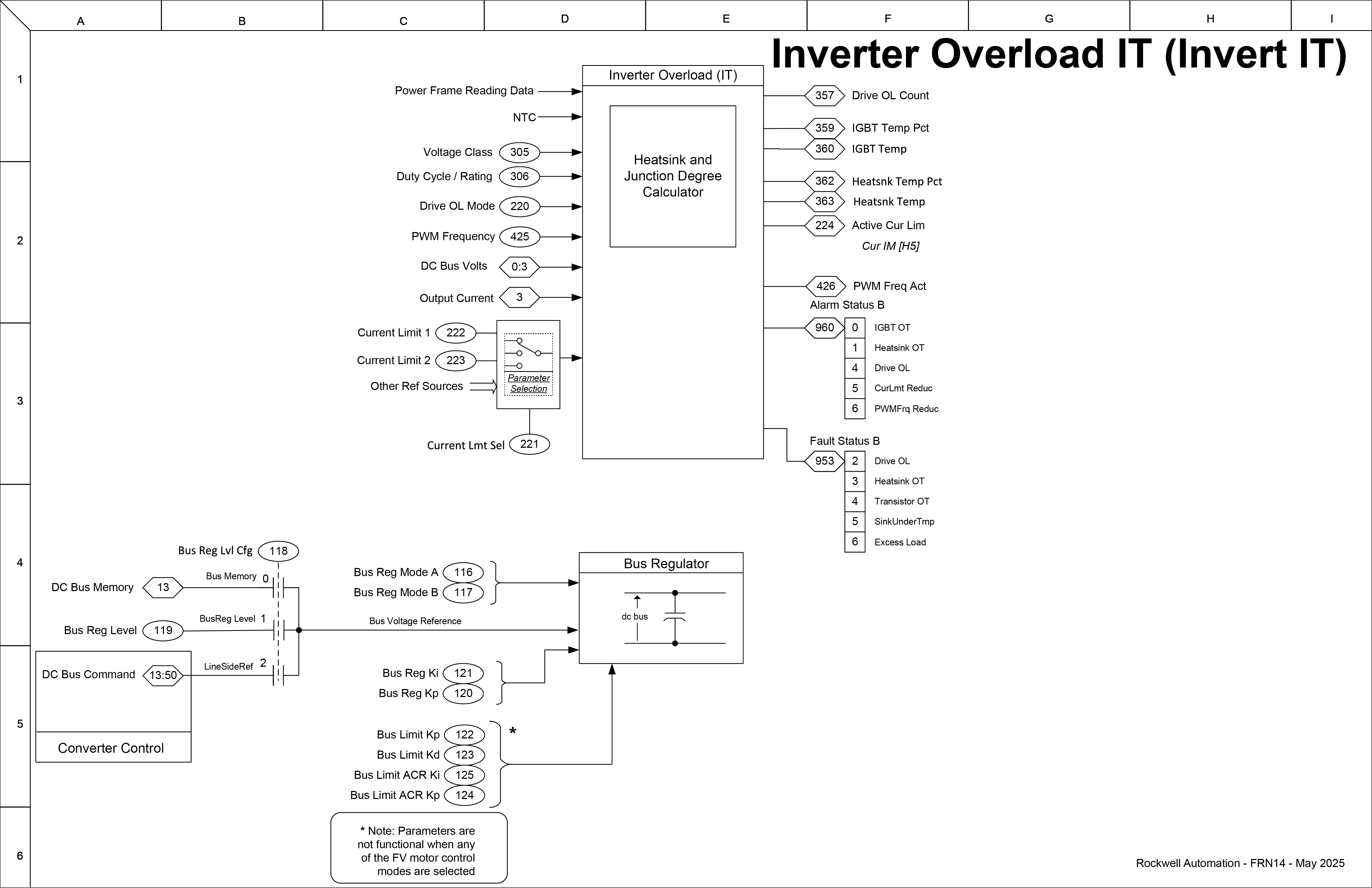

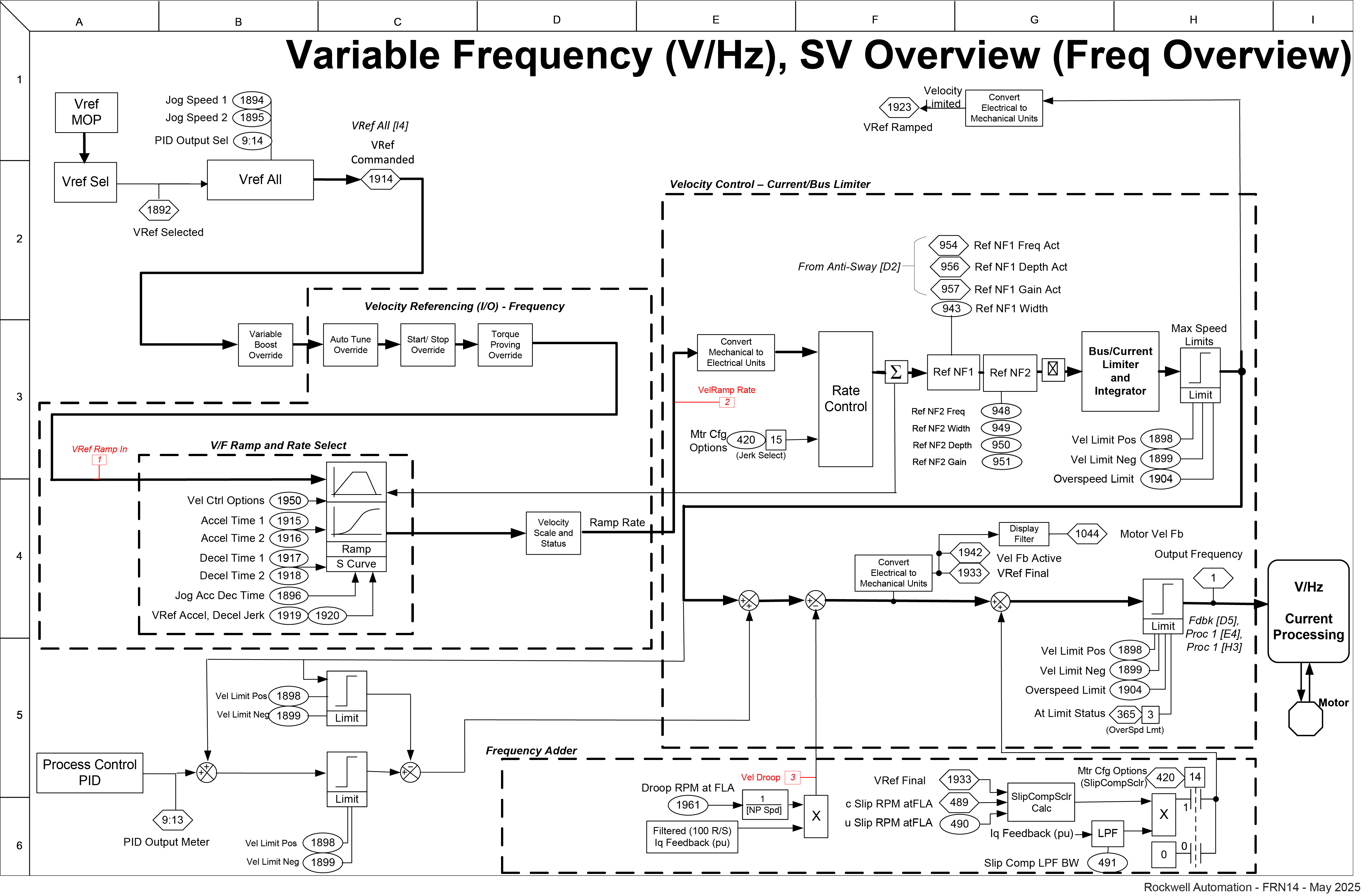

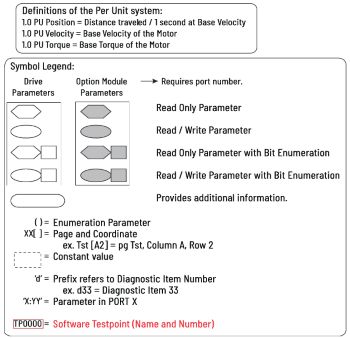

Control Block Diagrams

- Line Side Converter (PowerFlex 755TL Drives, 755TR Drives, and 755TM Bus Supplies)

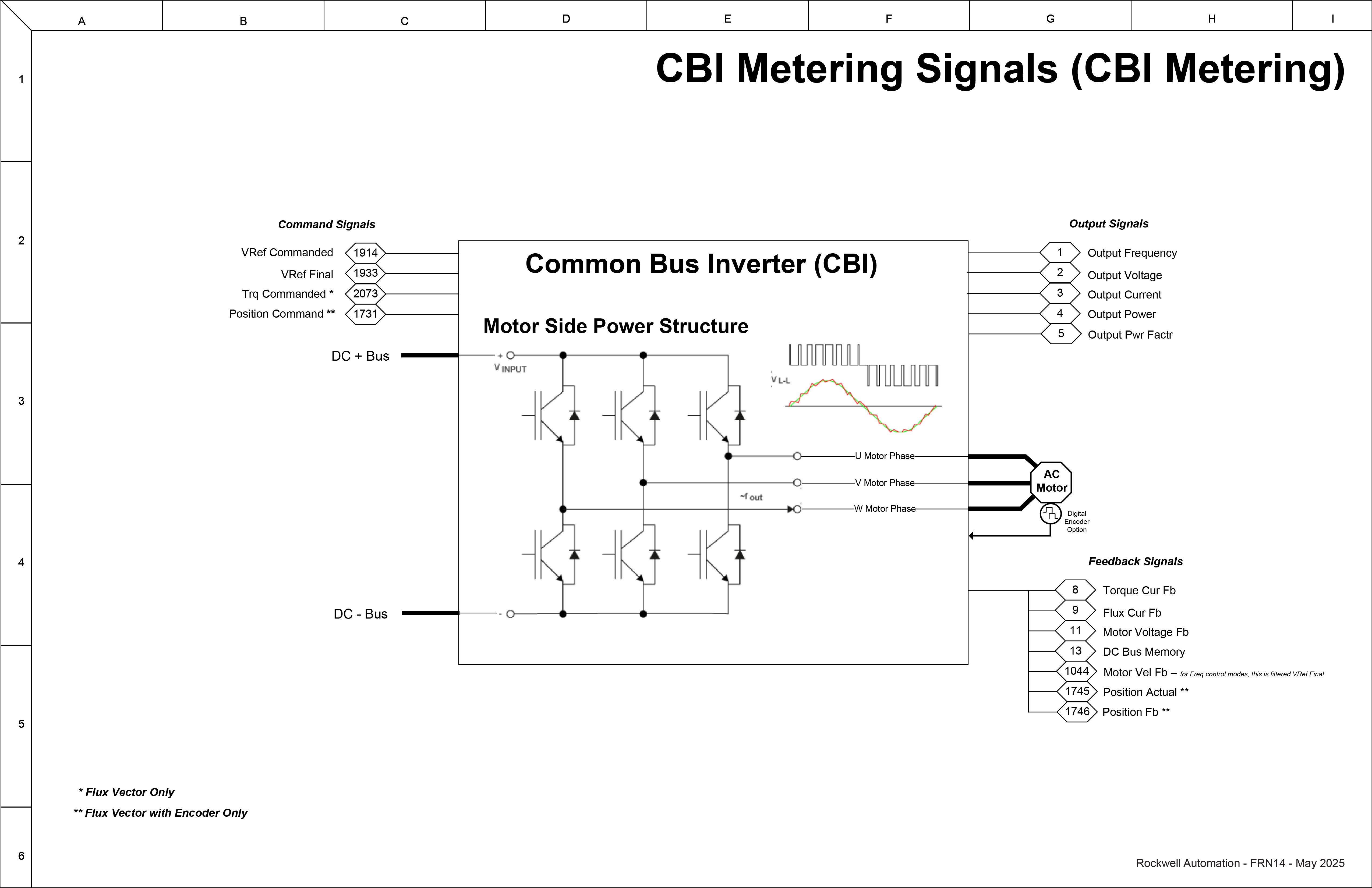

- Motor Side Inverter

Motor Side Inverter

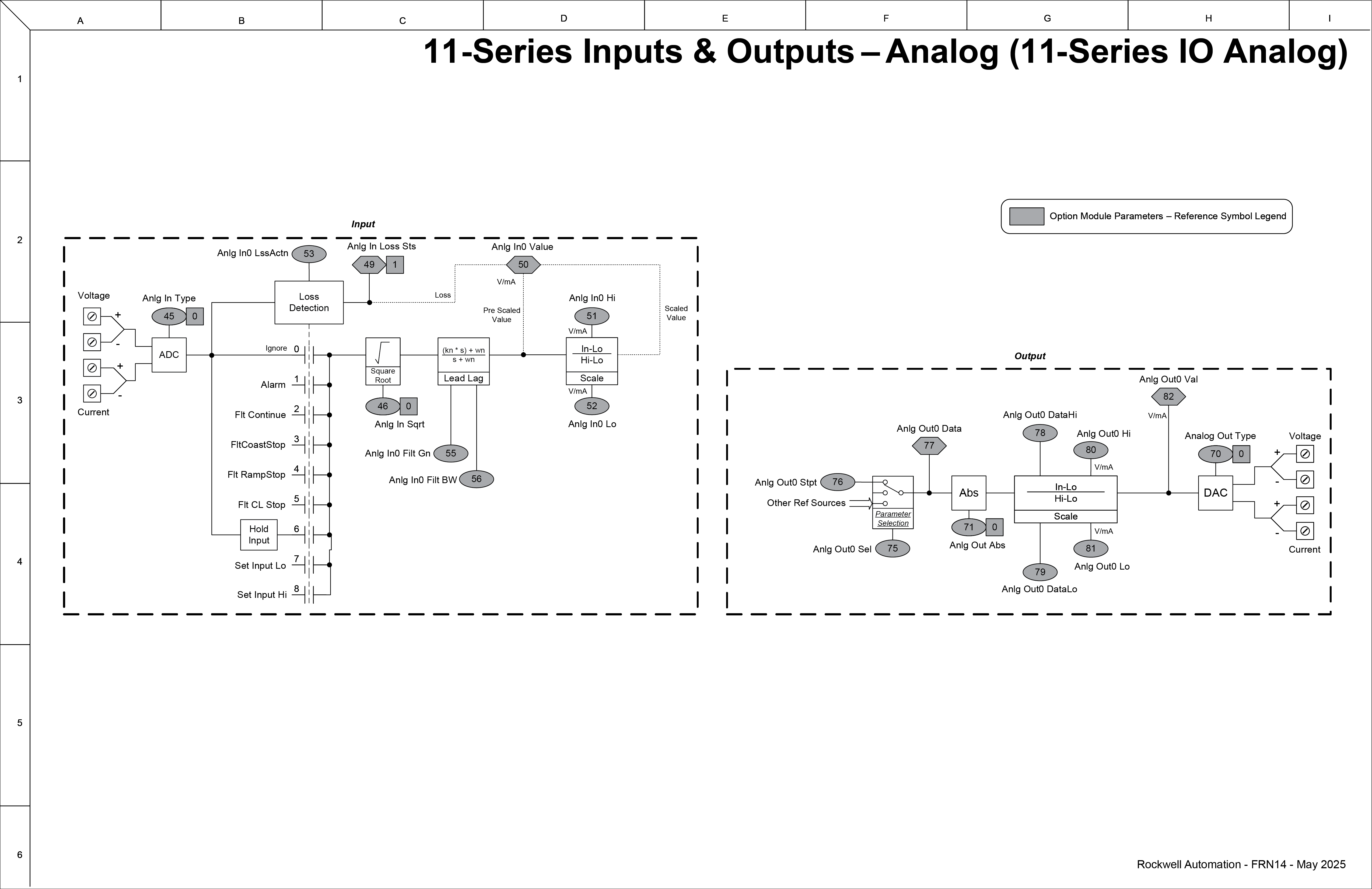

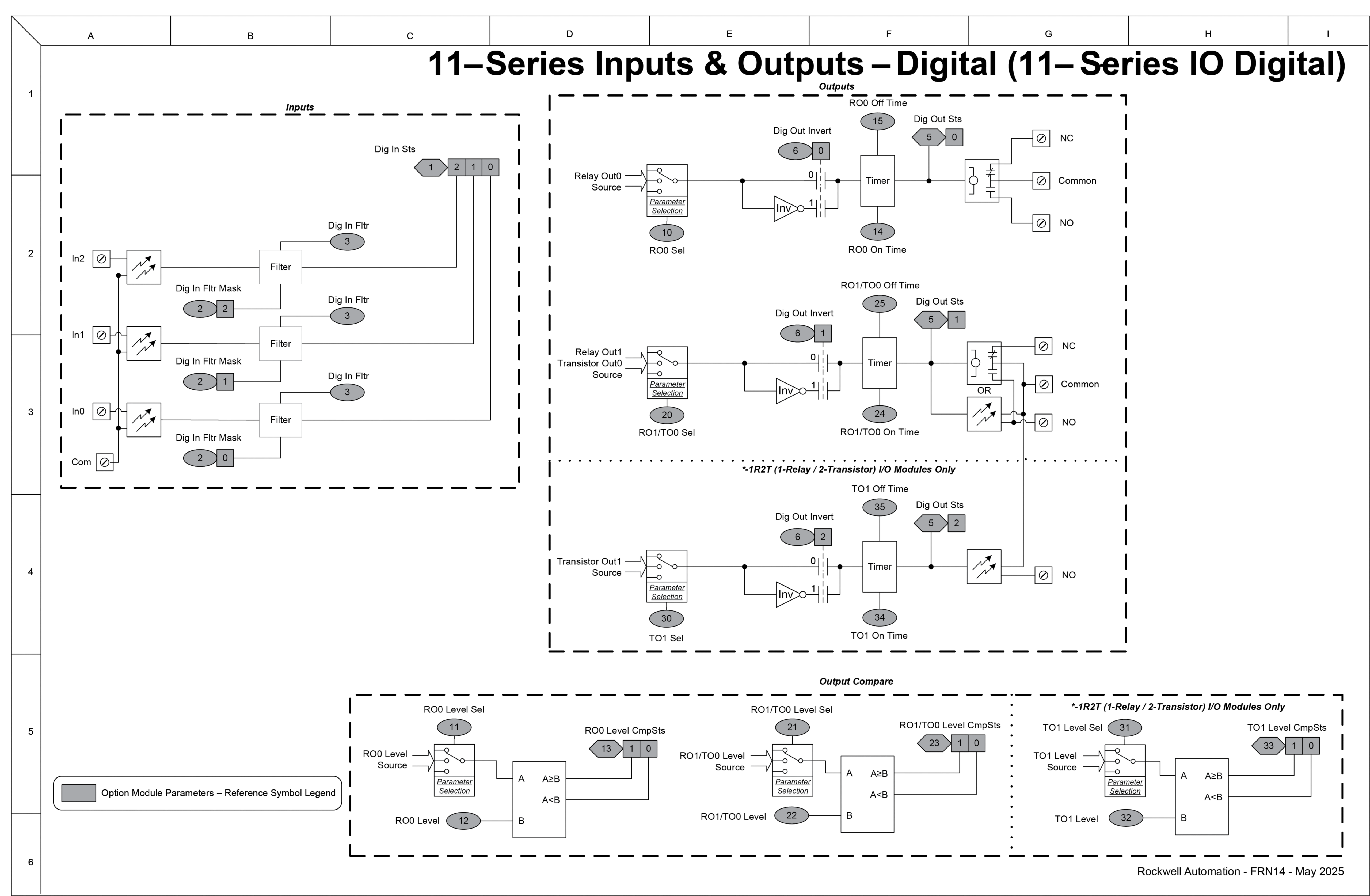

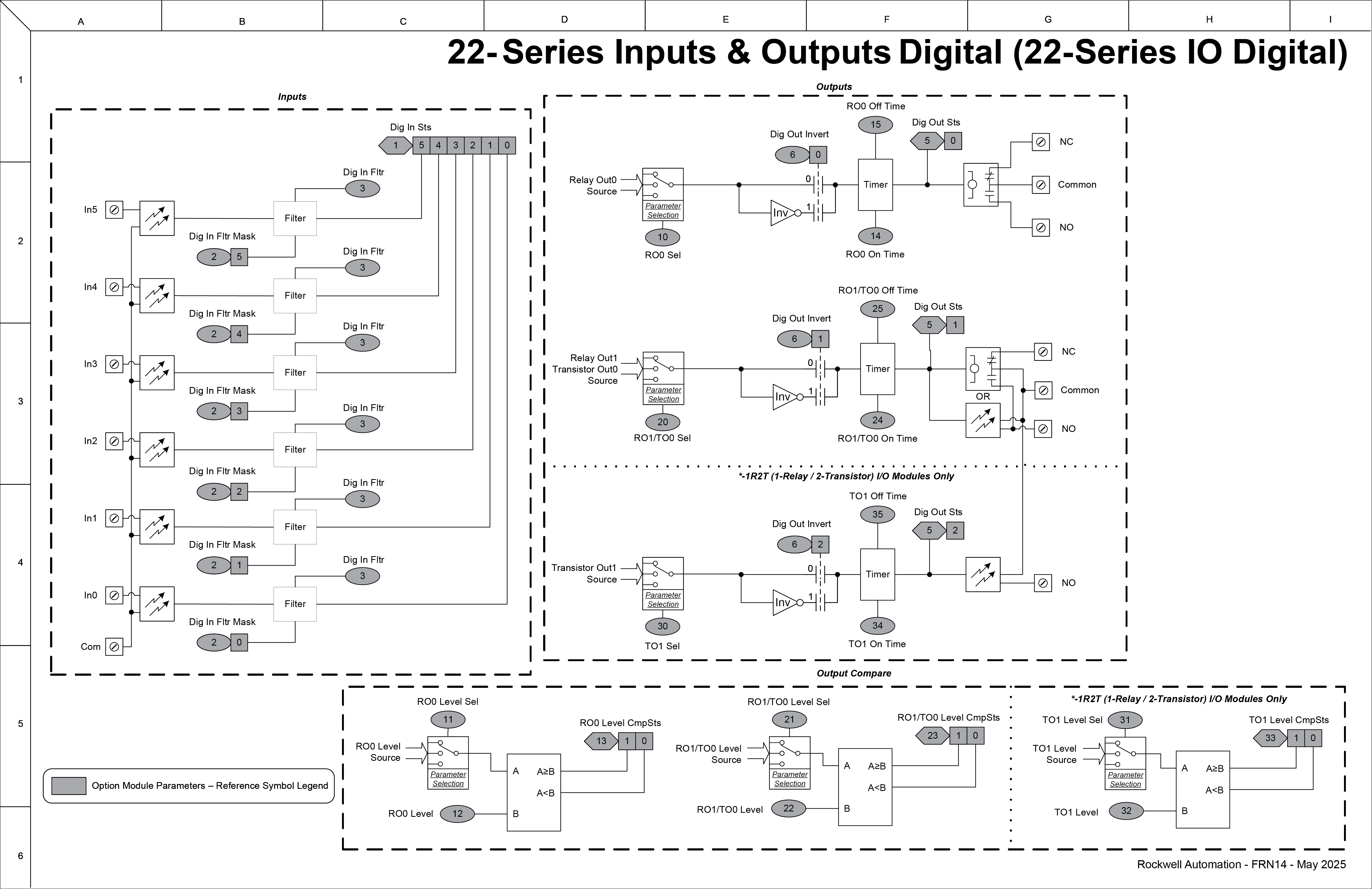

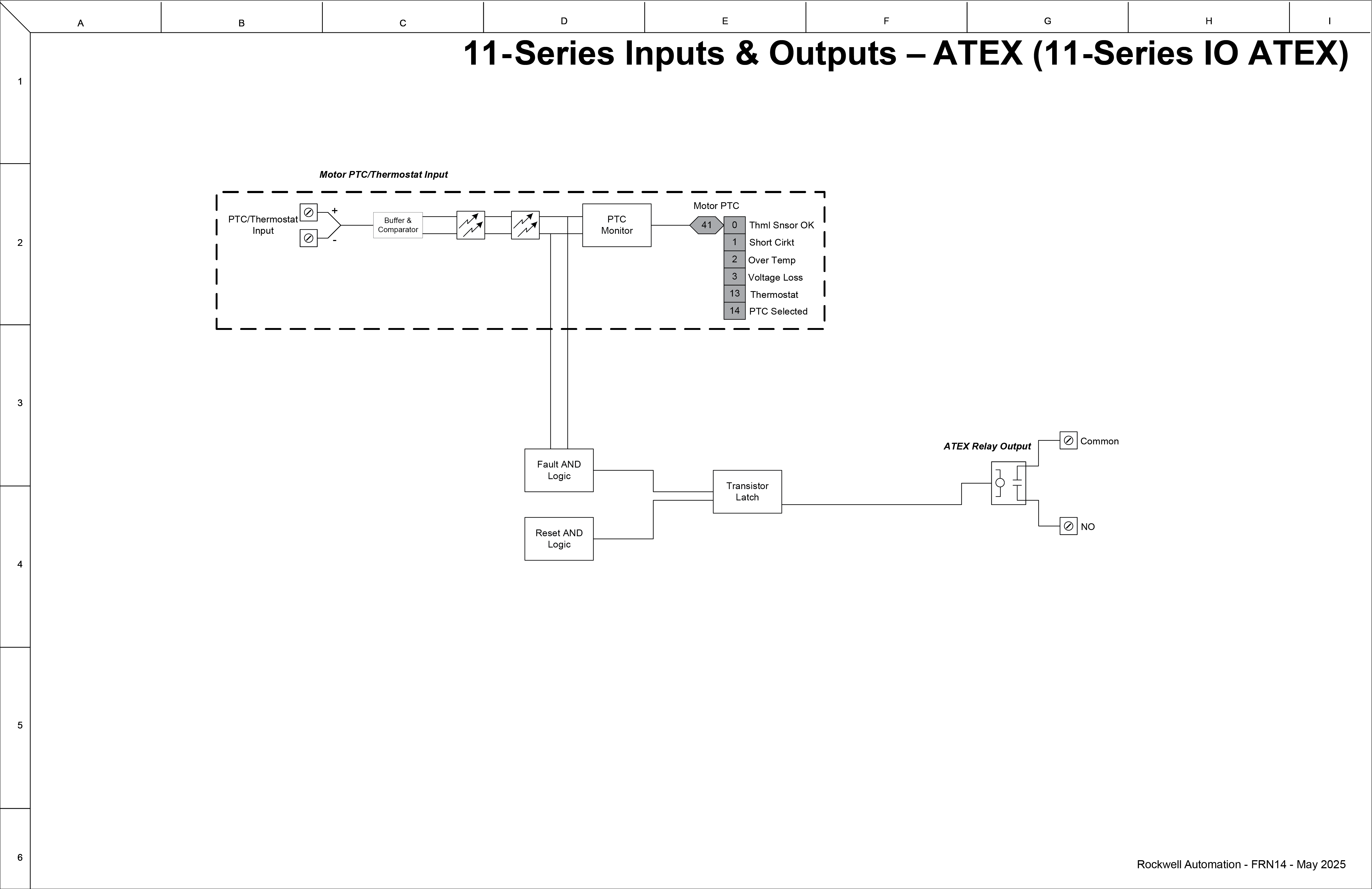

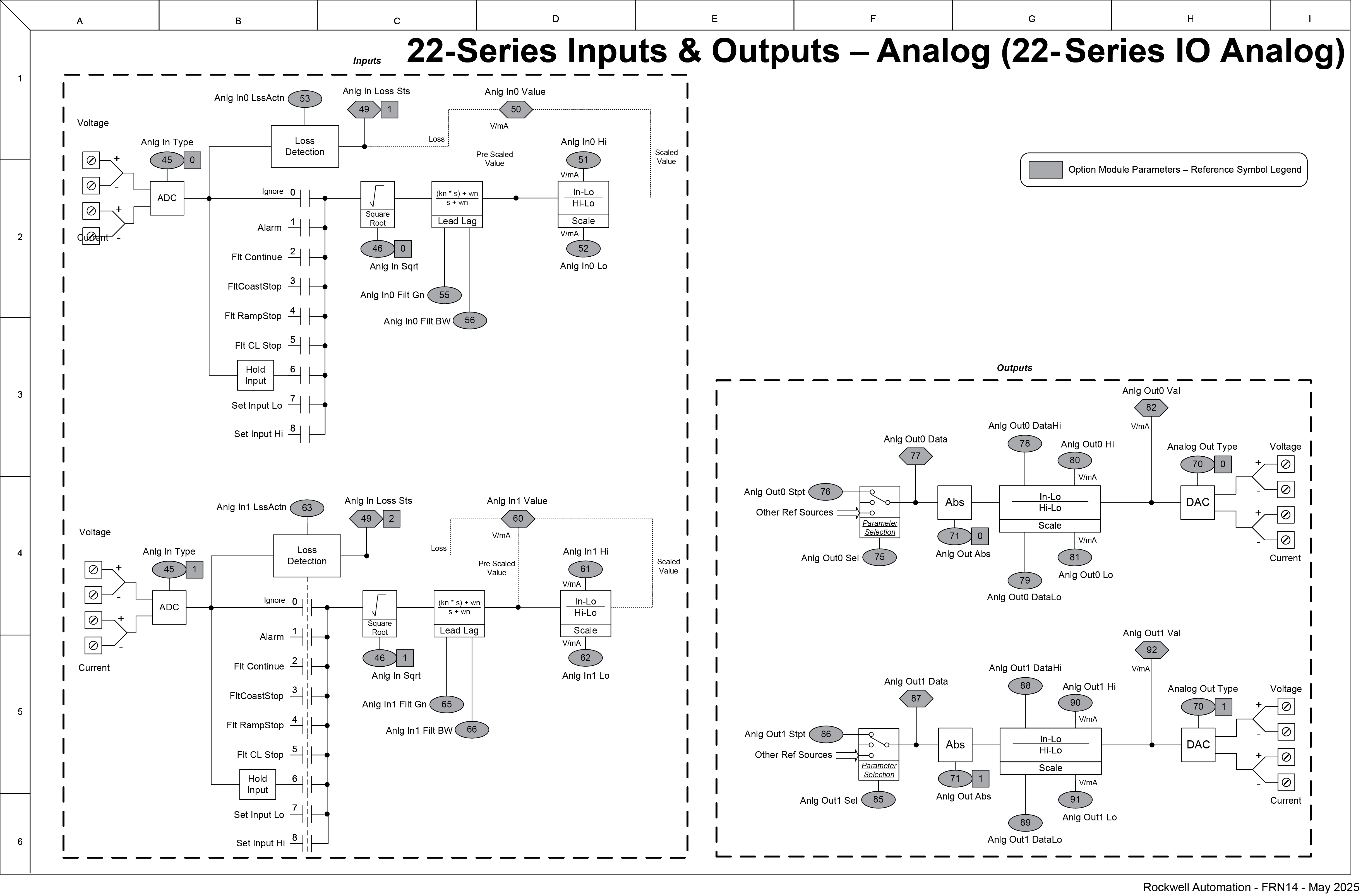

11-Series & 22-Series Inputs & Outputs Diagrams

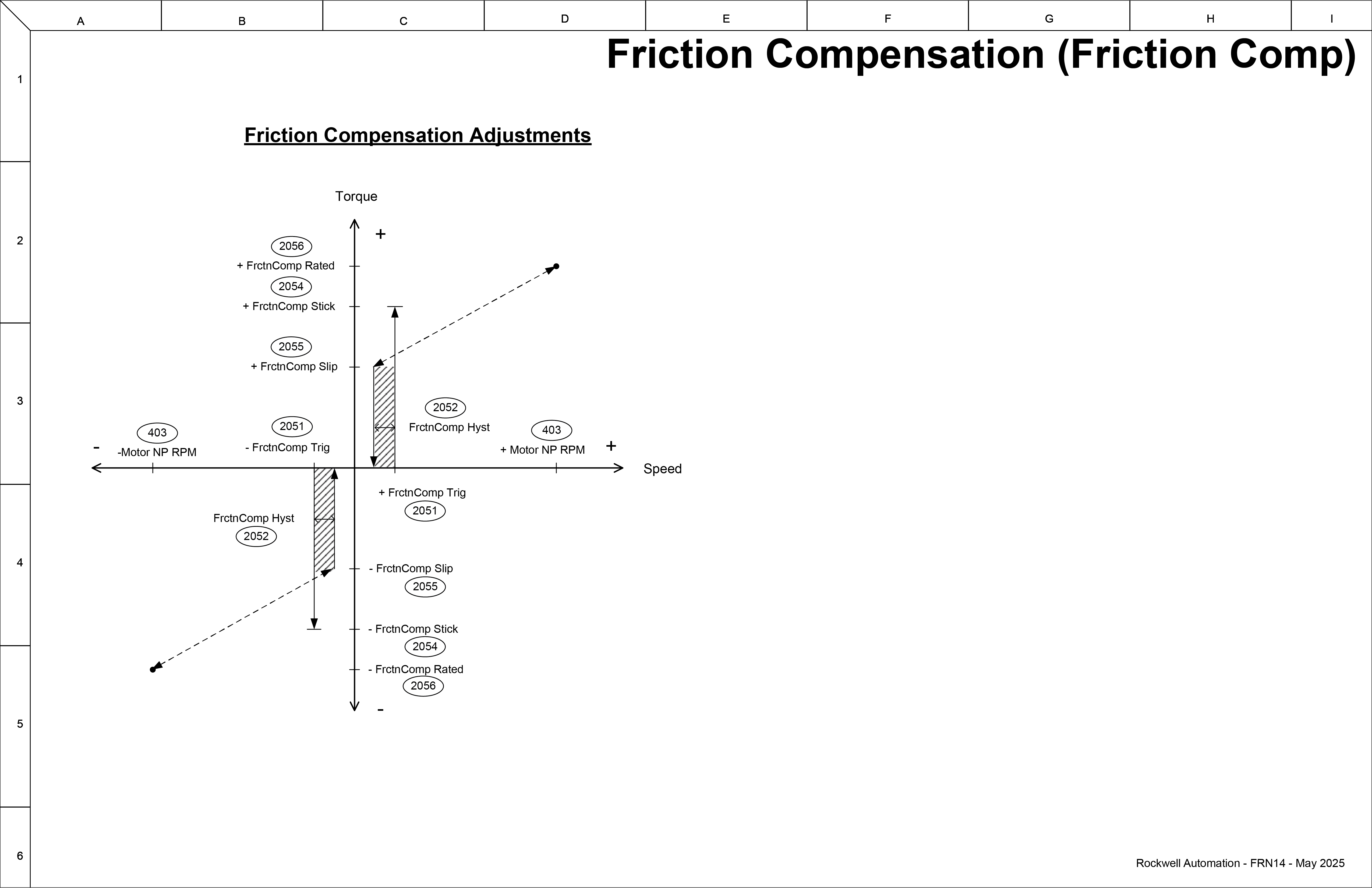

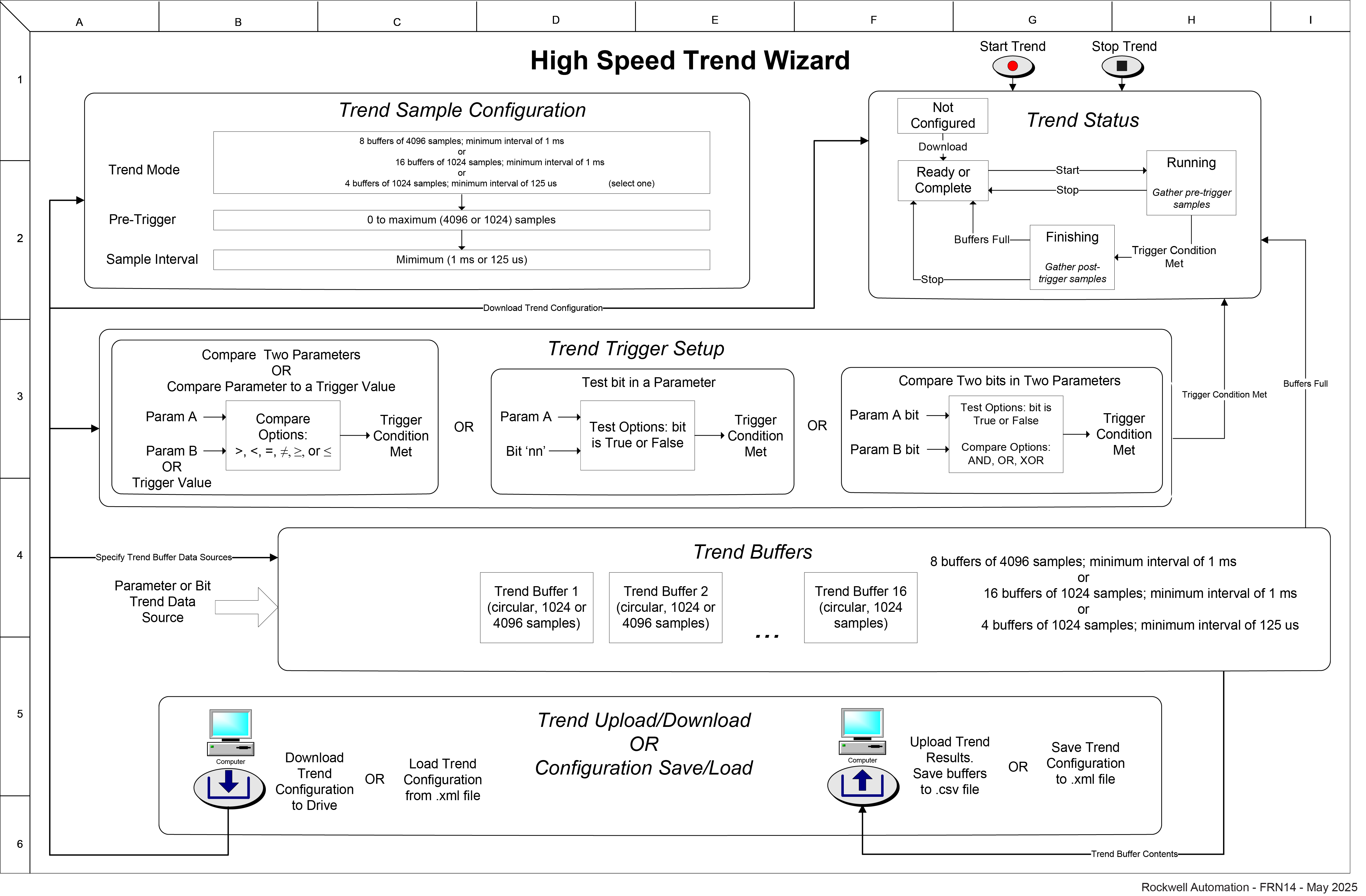

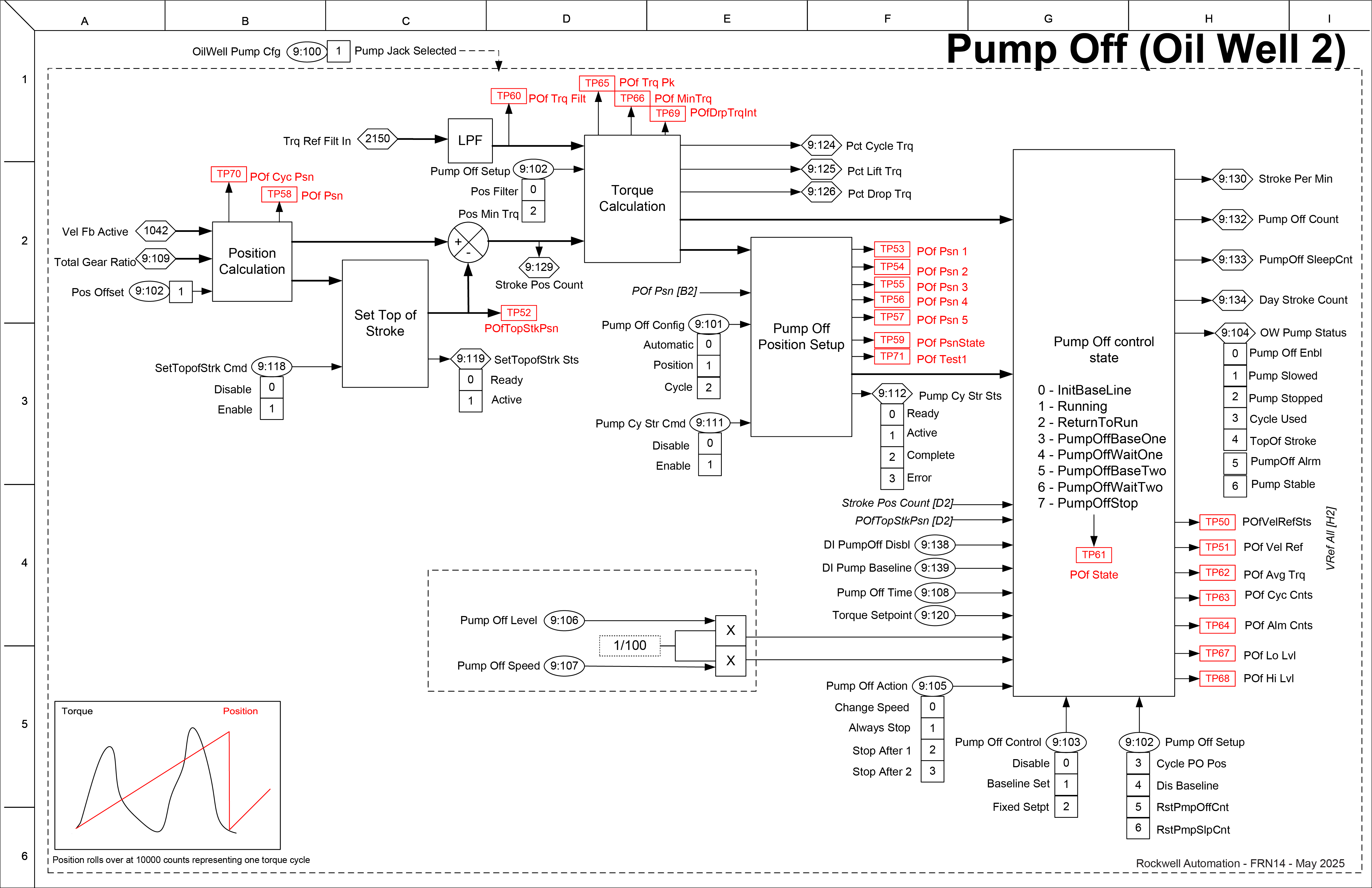

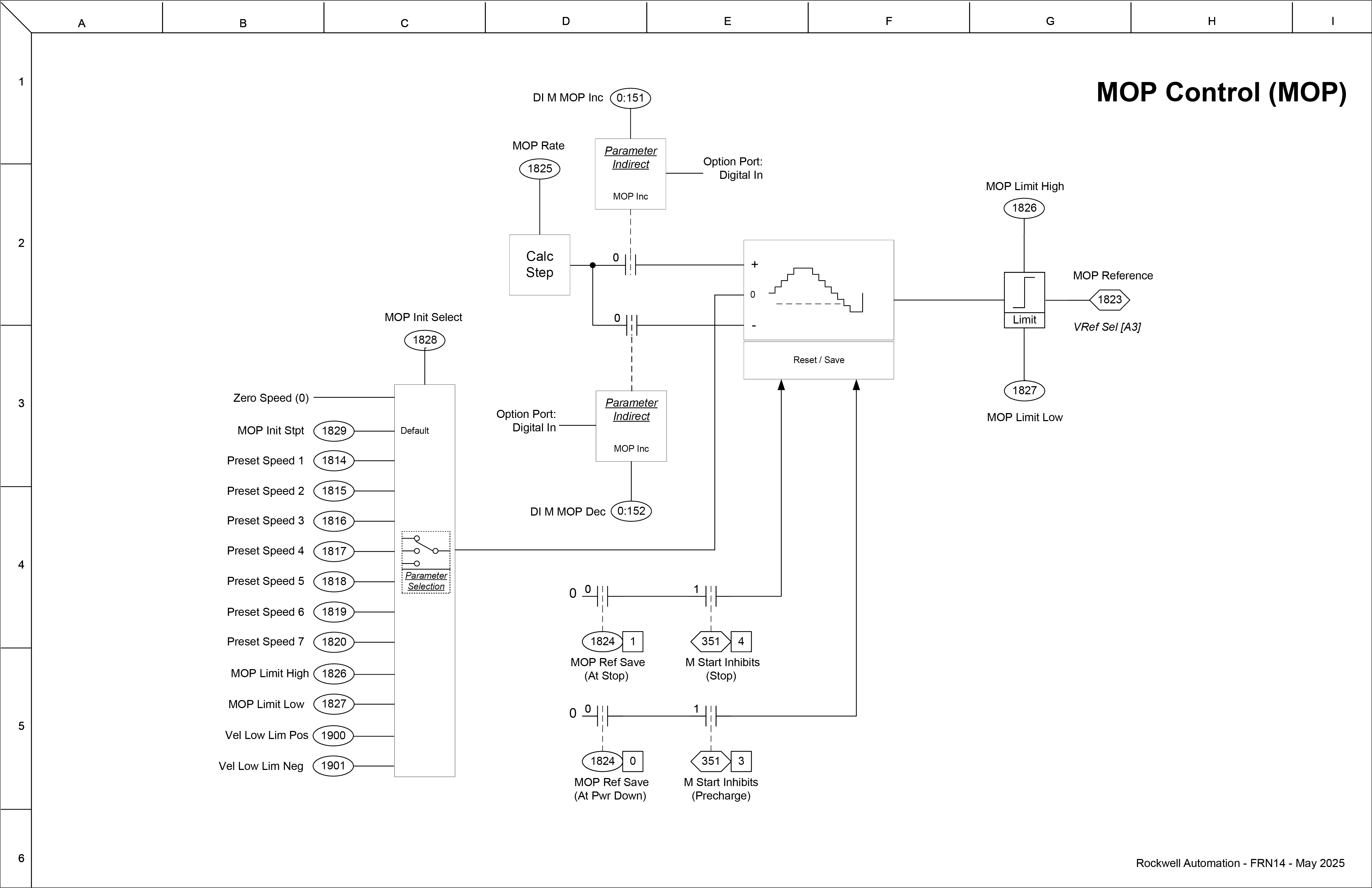

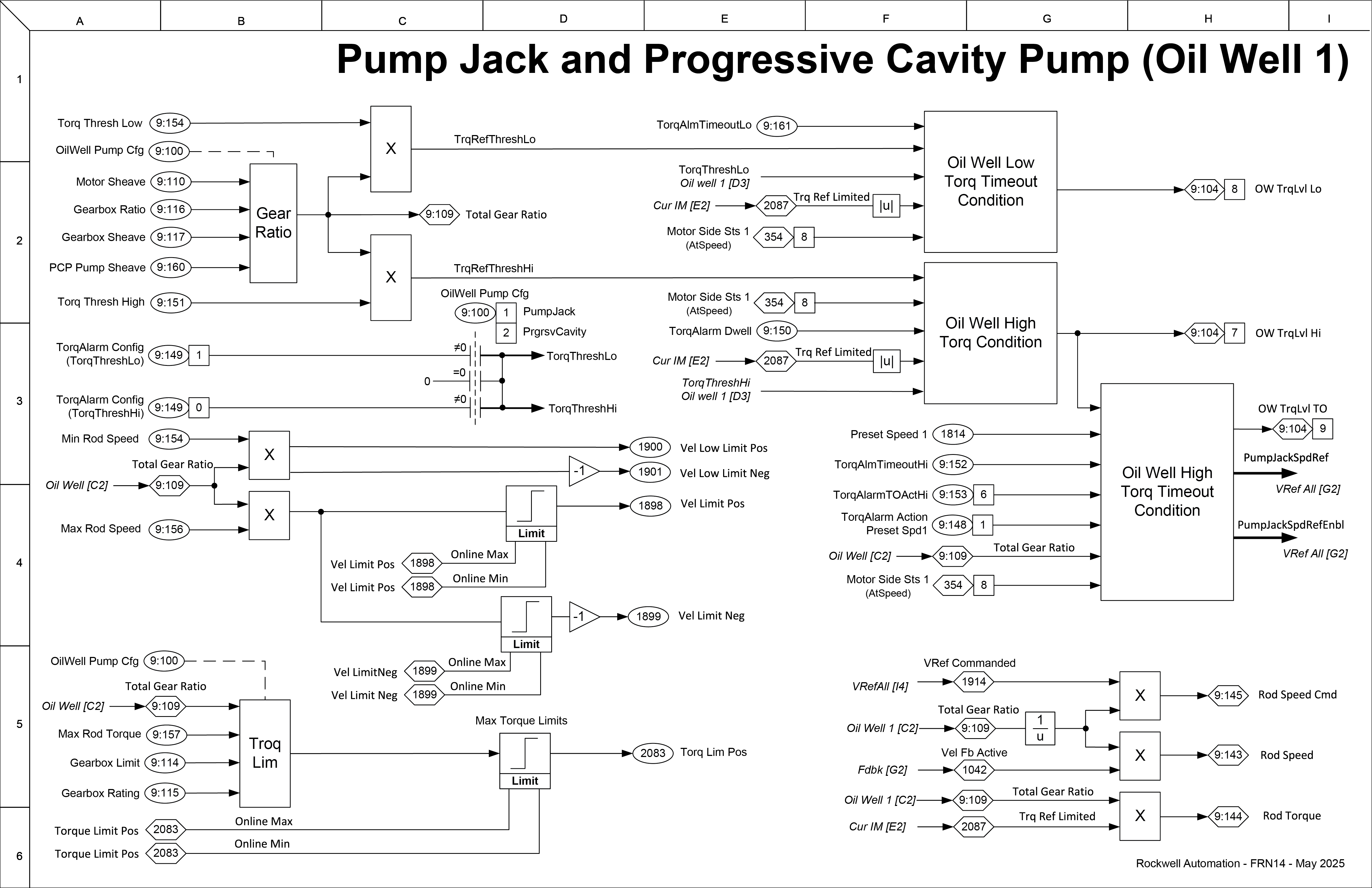

Miscellaneous Diagrams

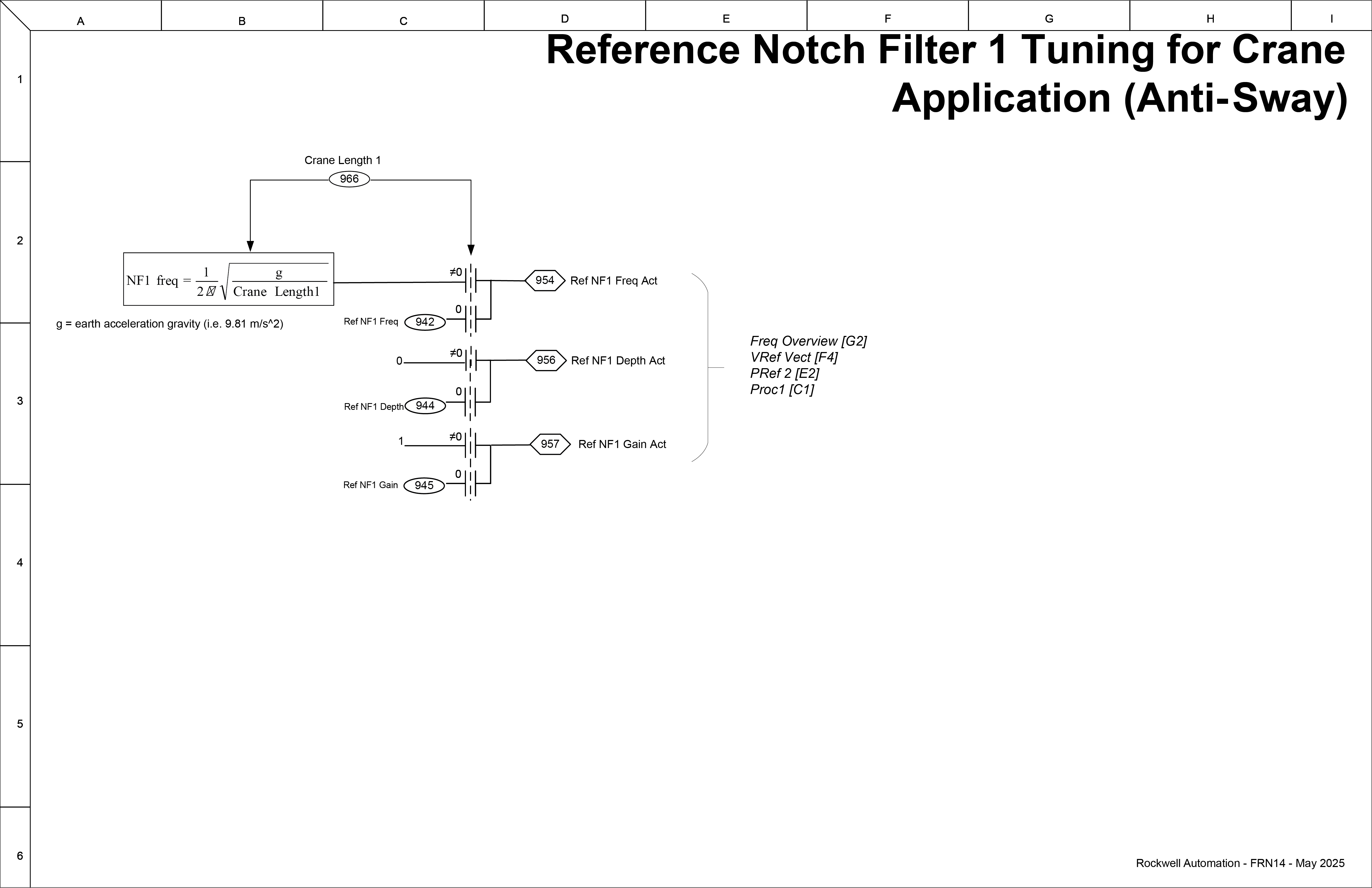

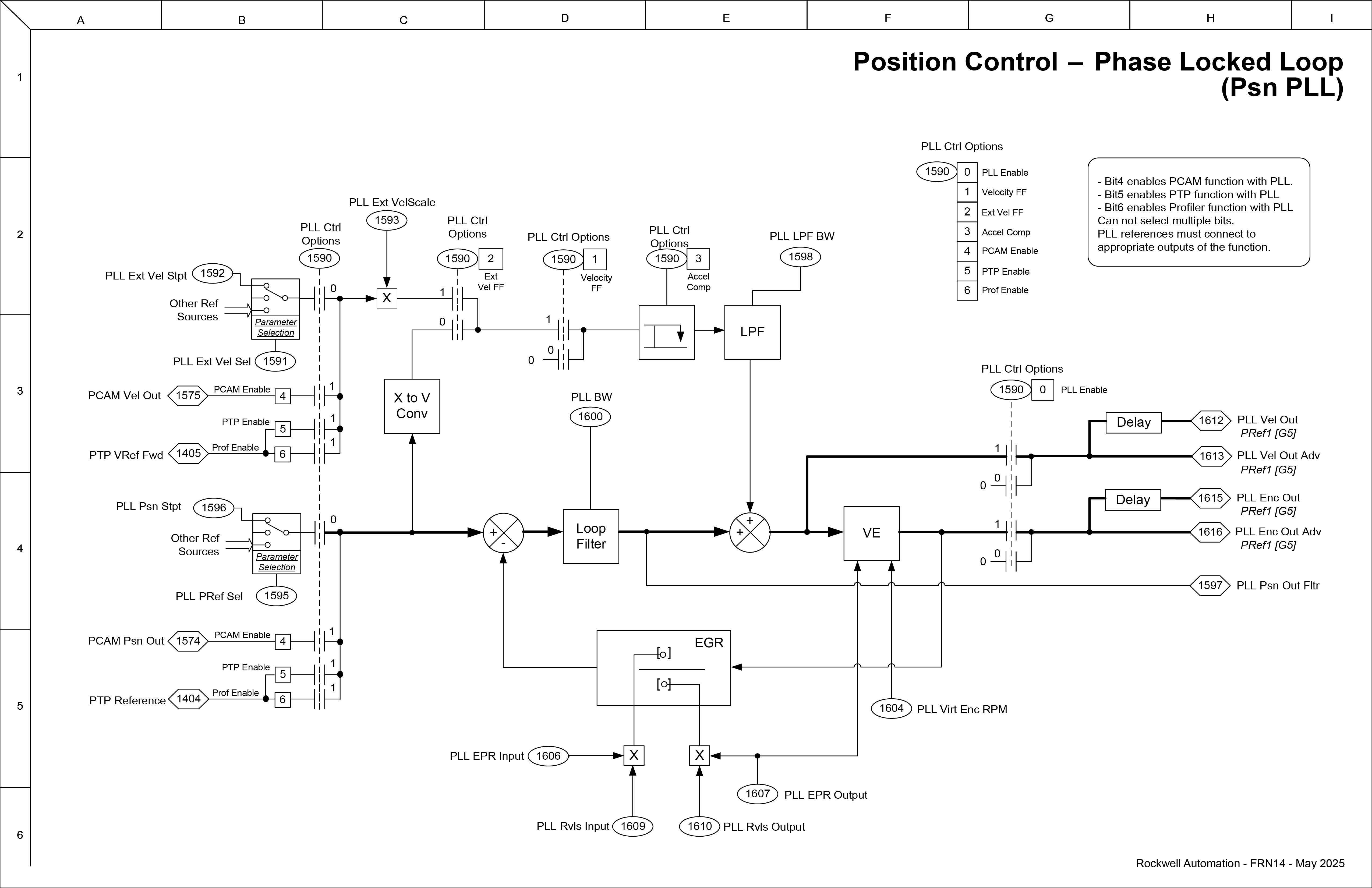

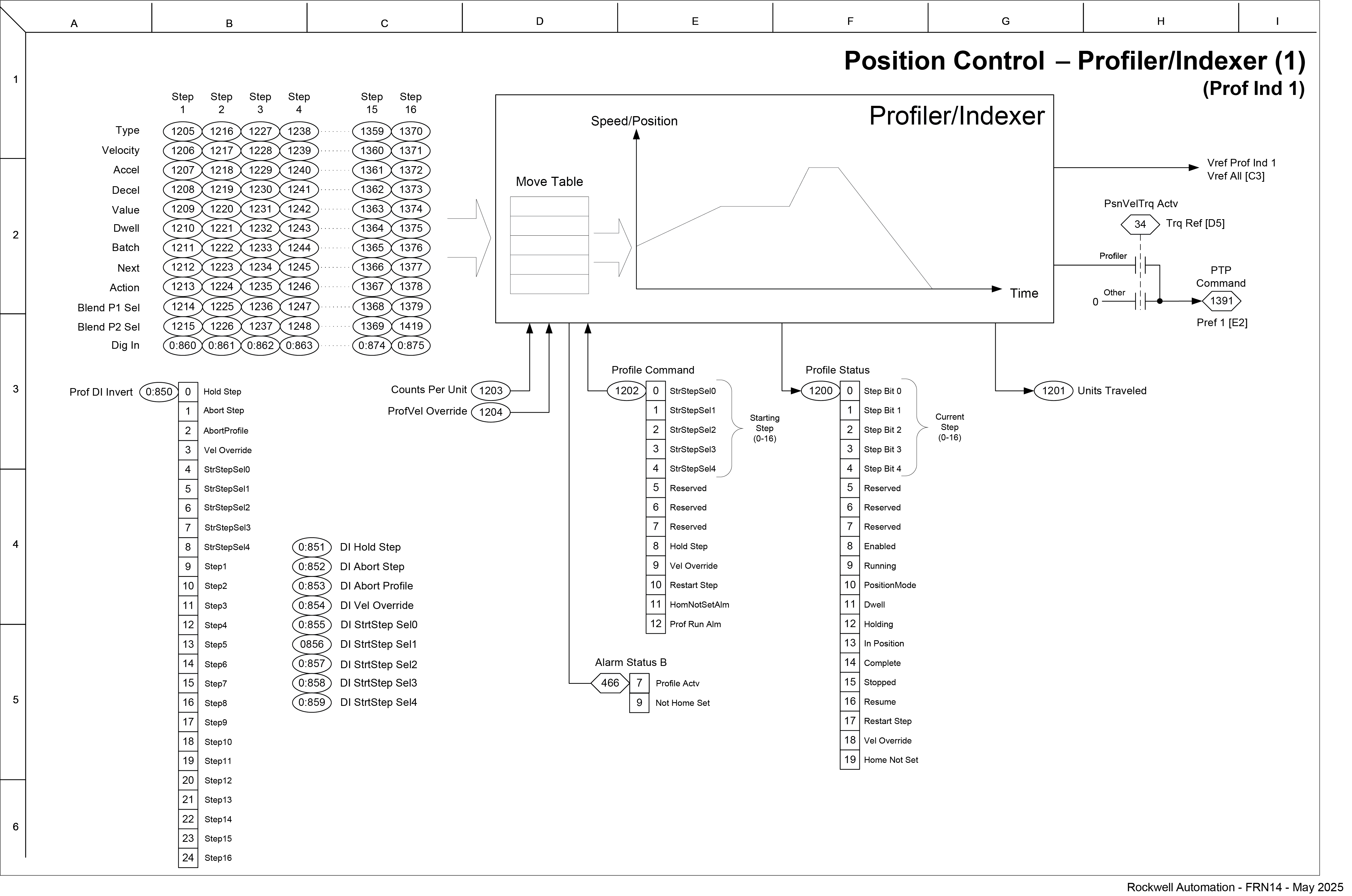

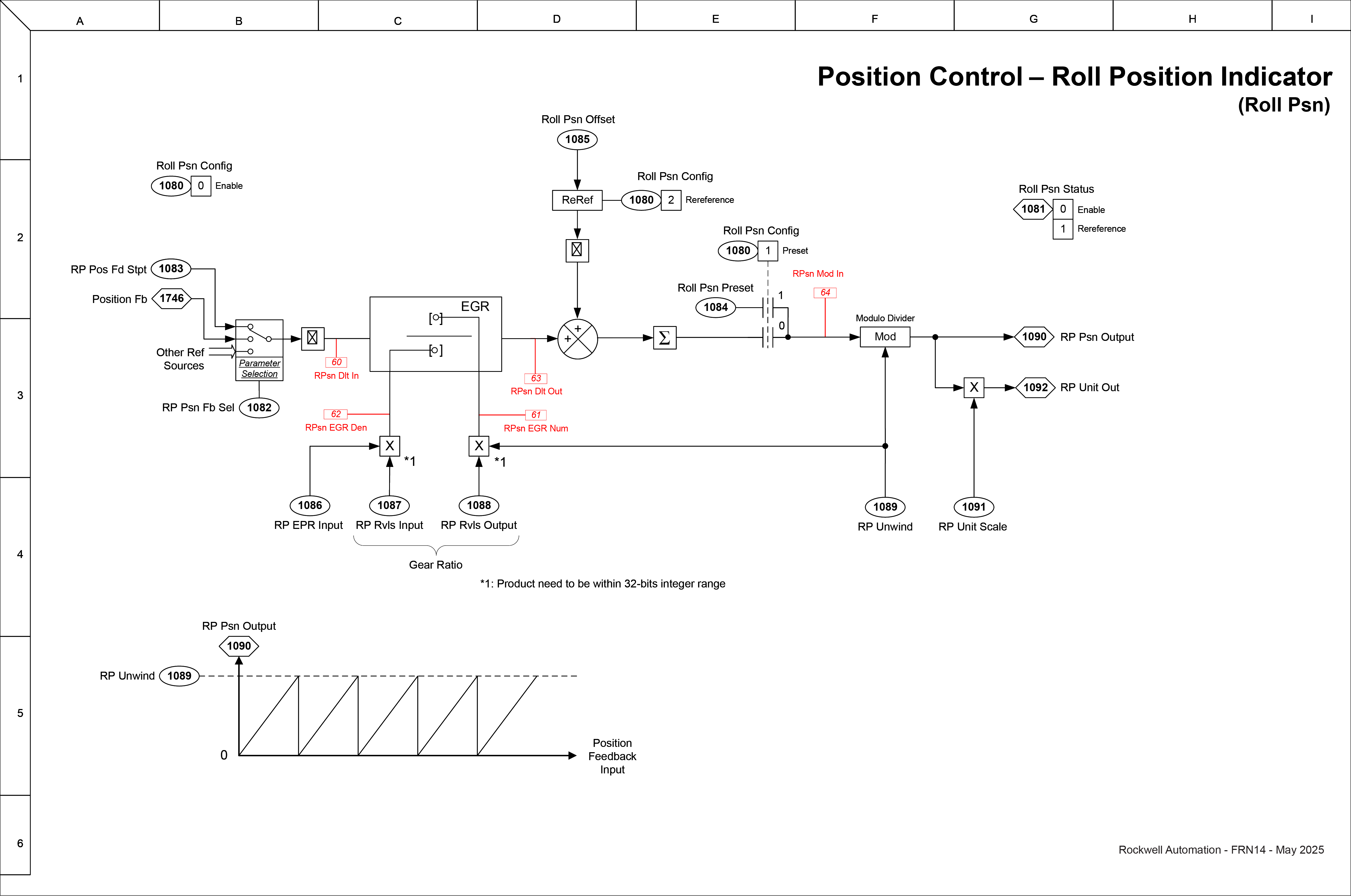

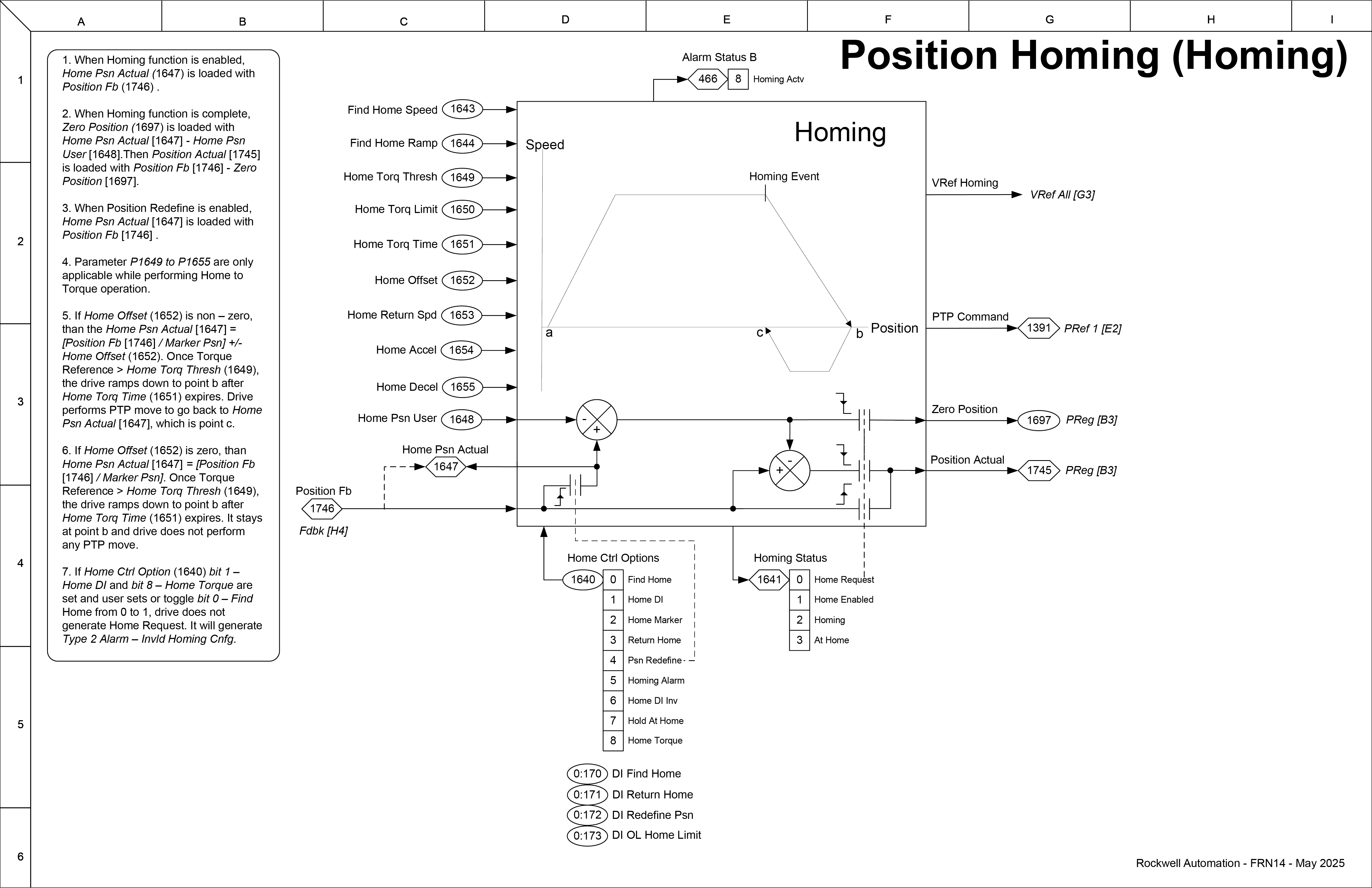

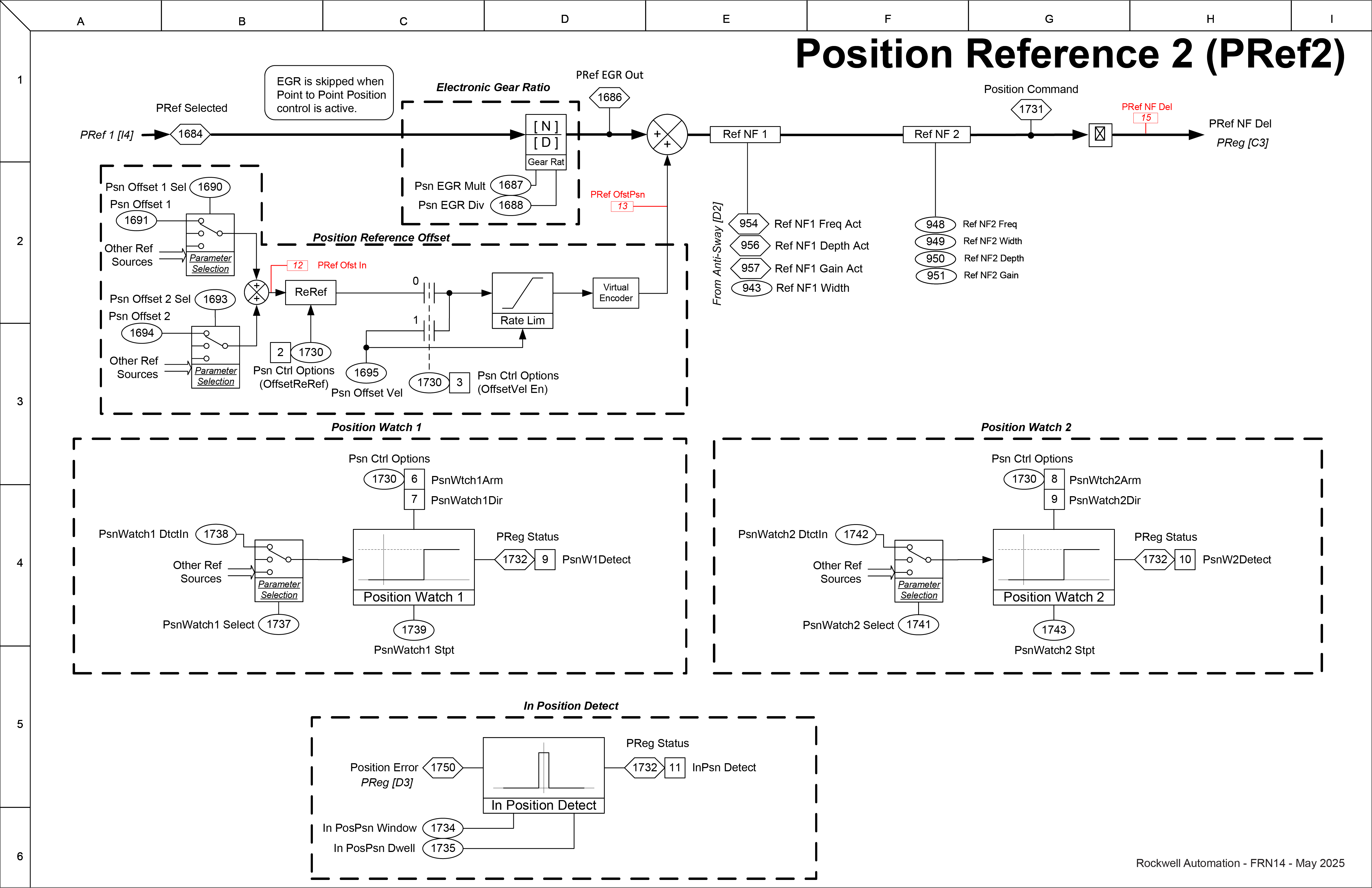

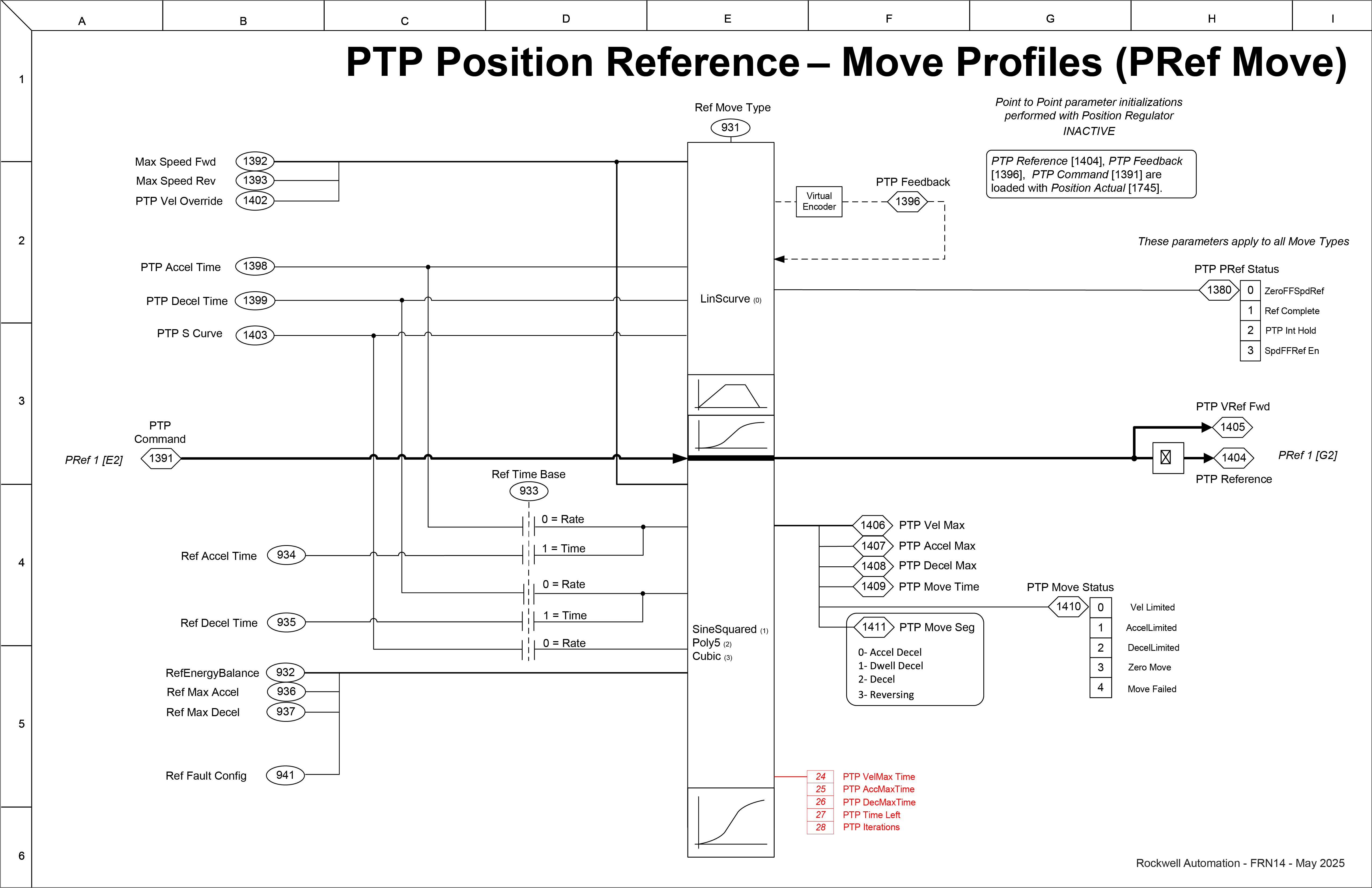

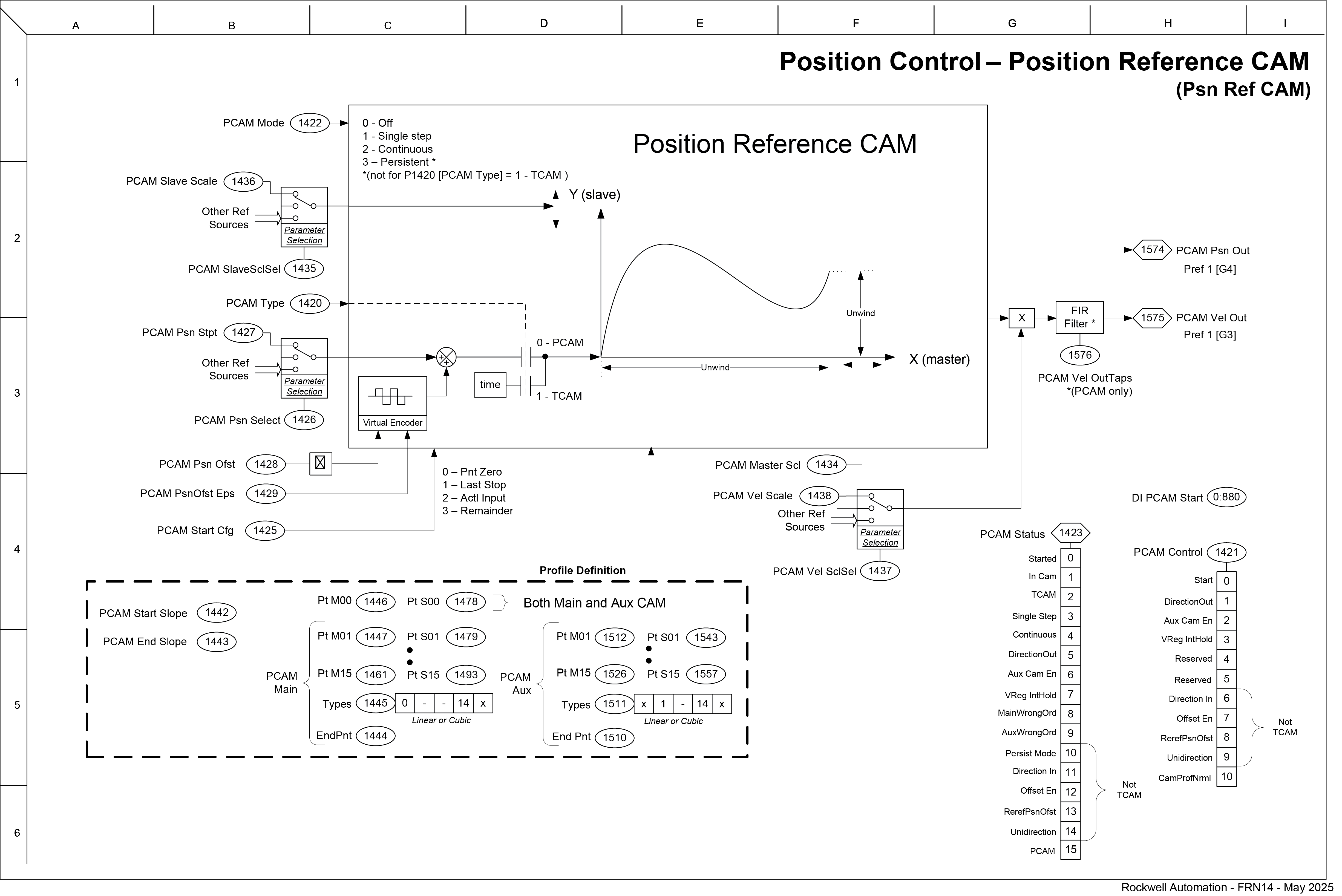

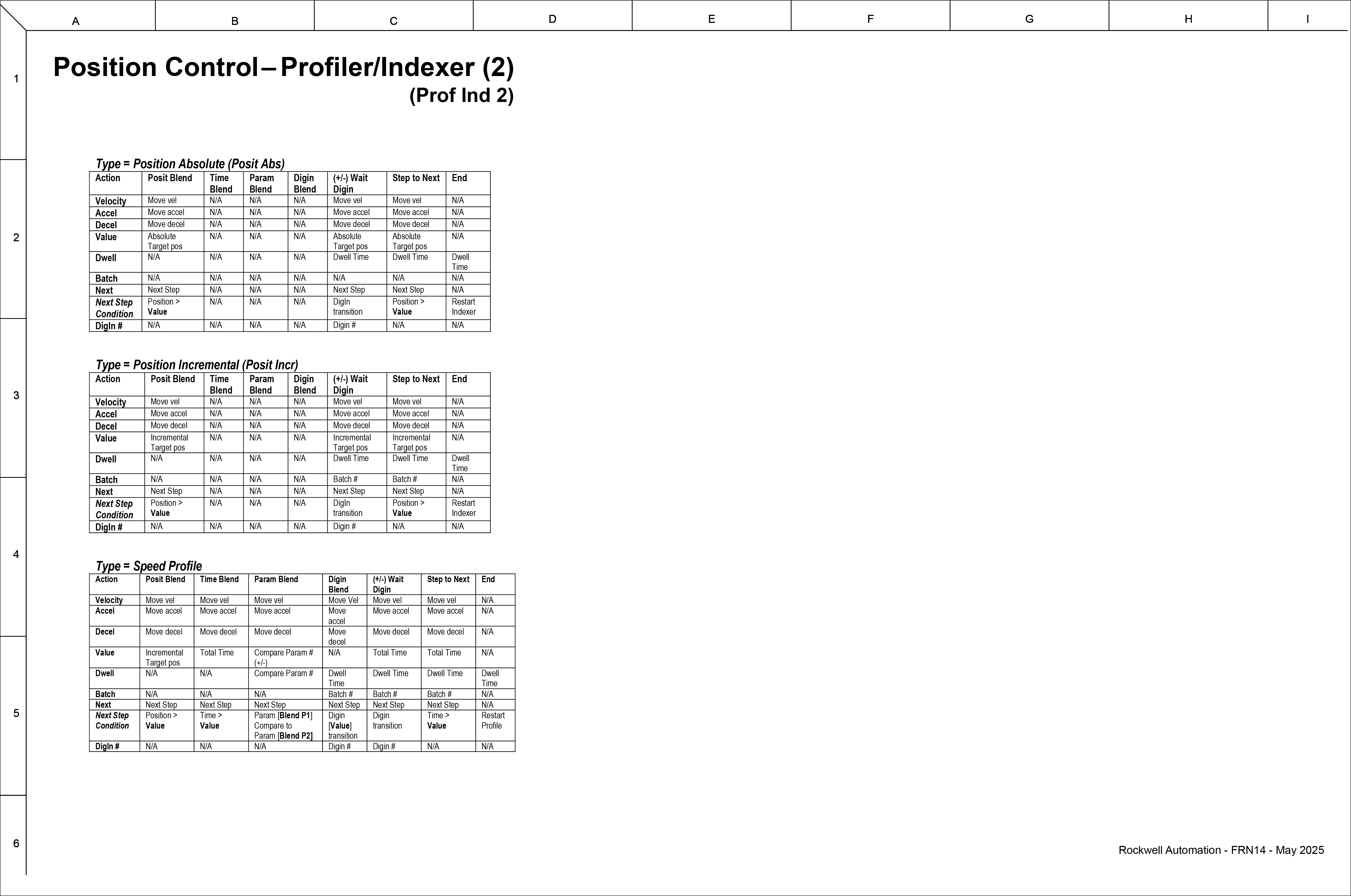

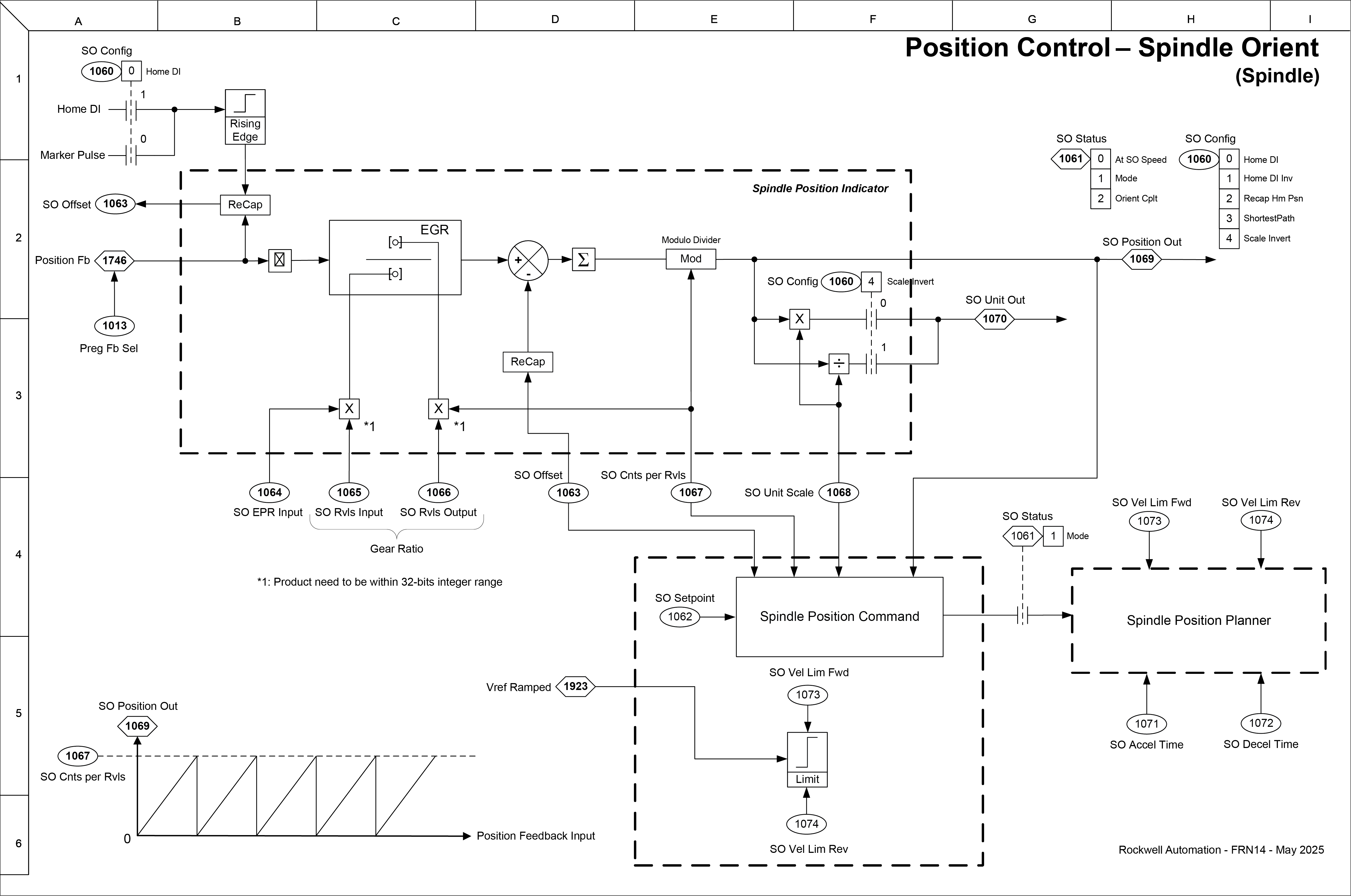

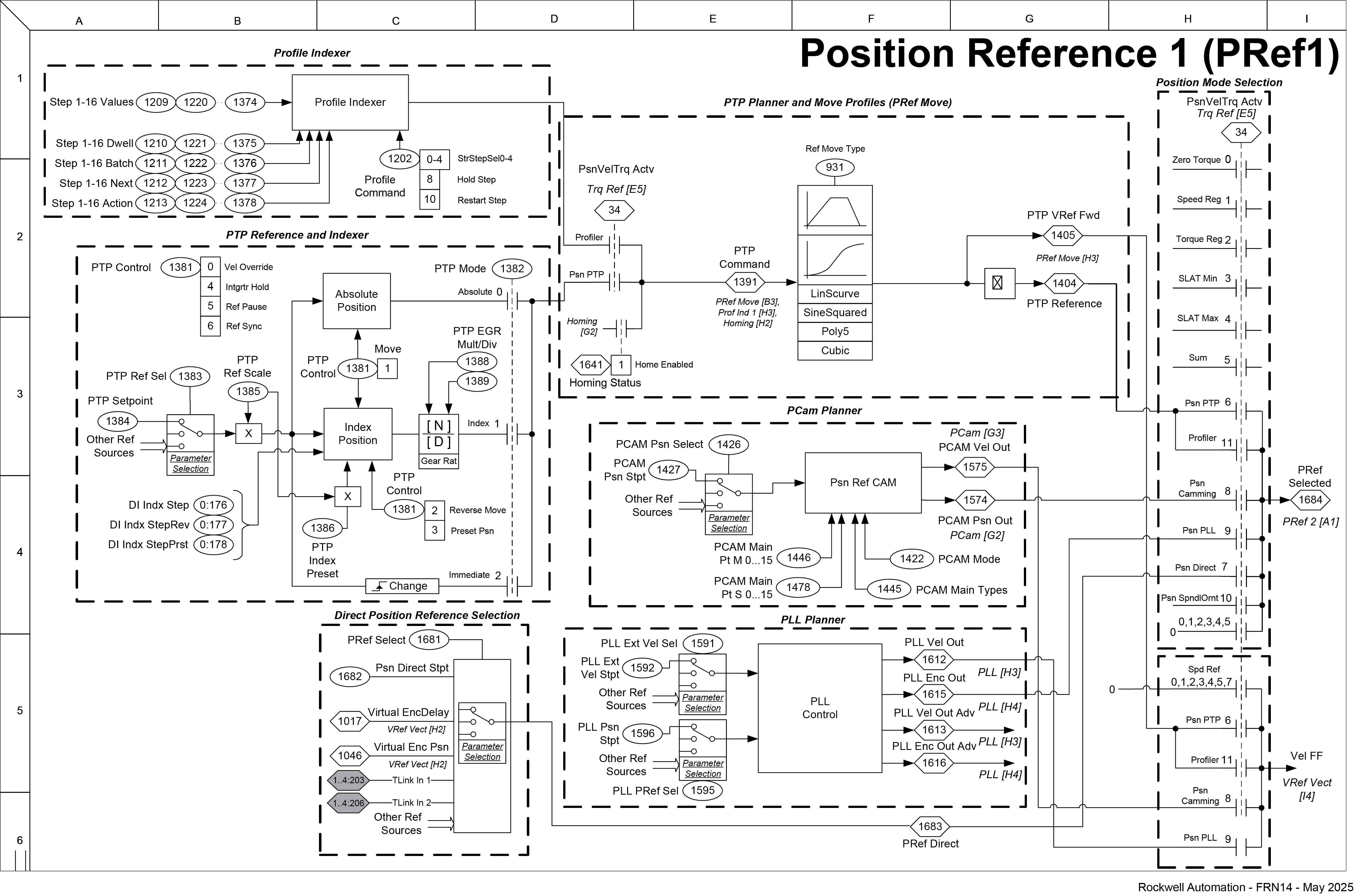

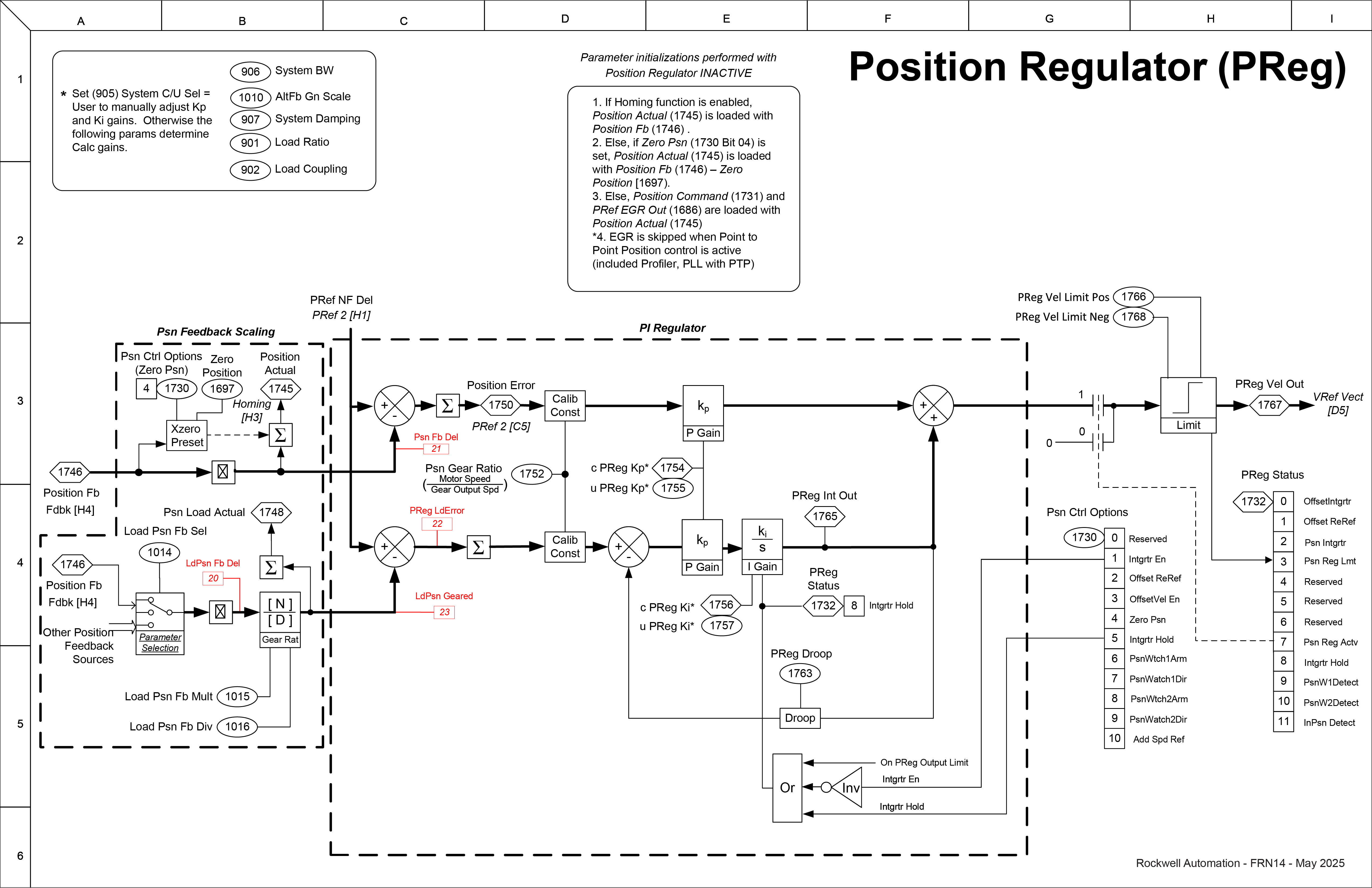

Position Control, Homing, Reference, and Regulator Diagrams

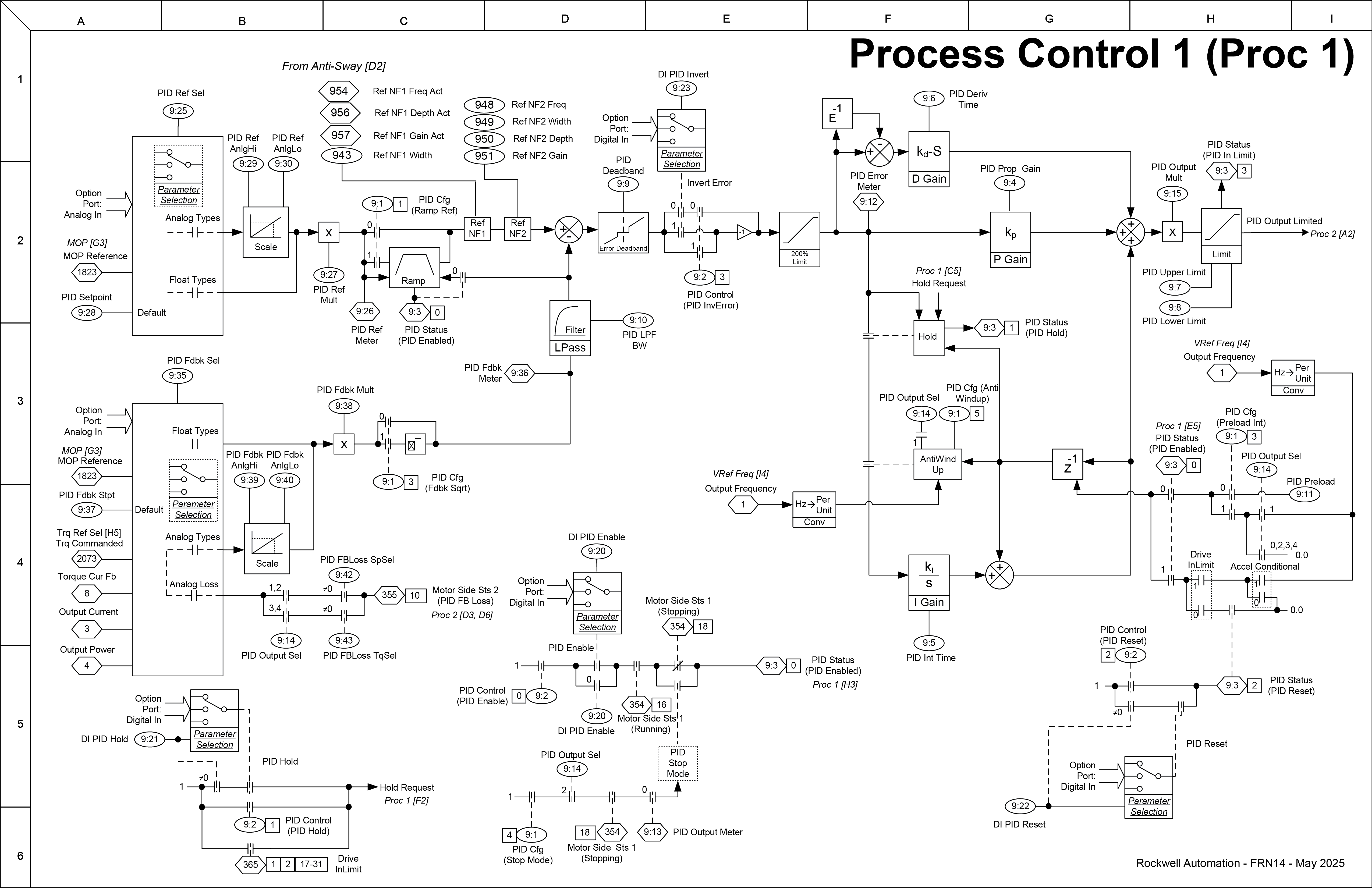

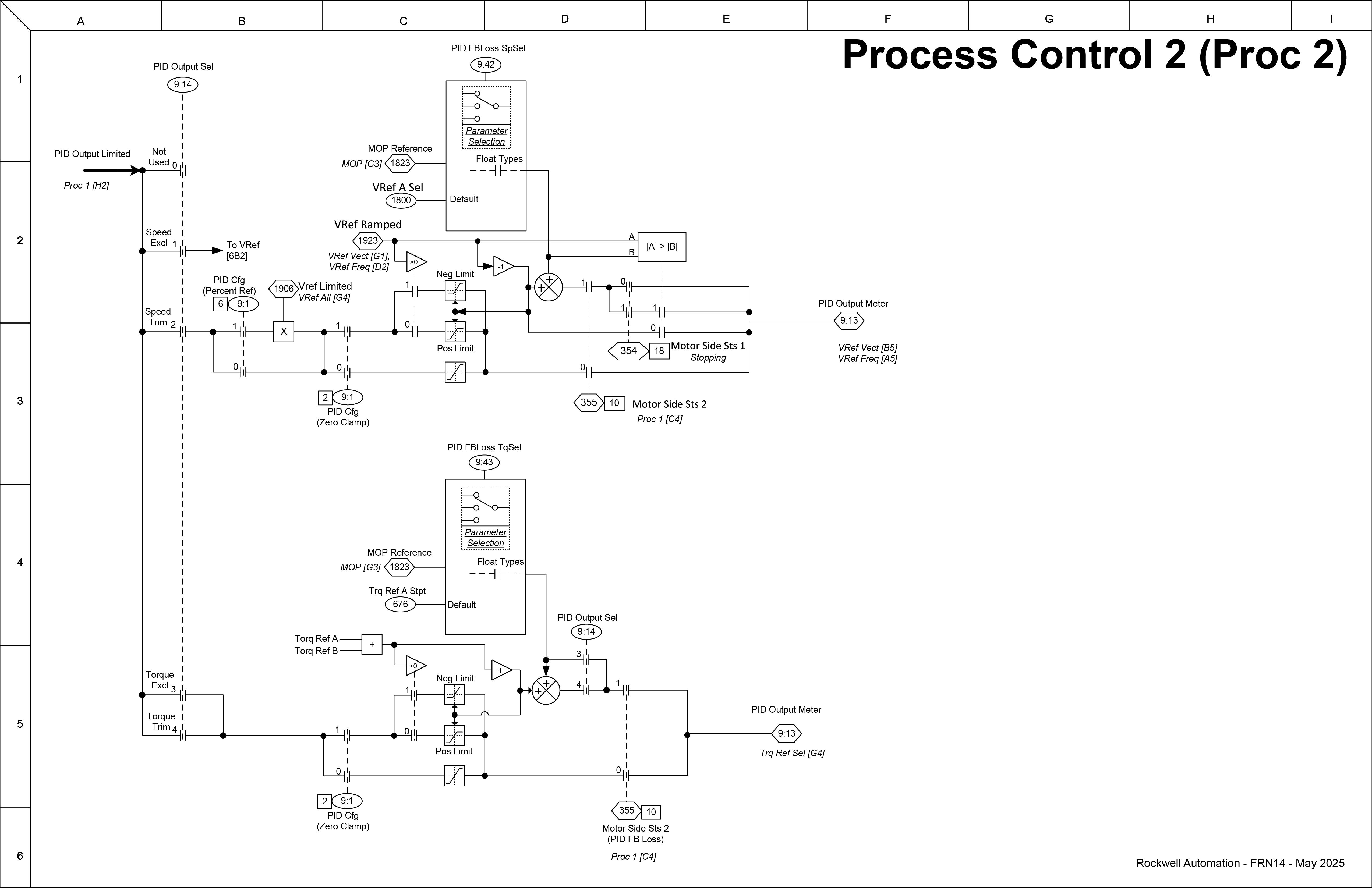

Process Control Diagrams

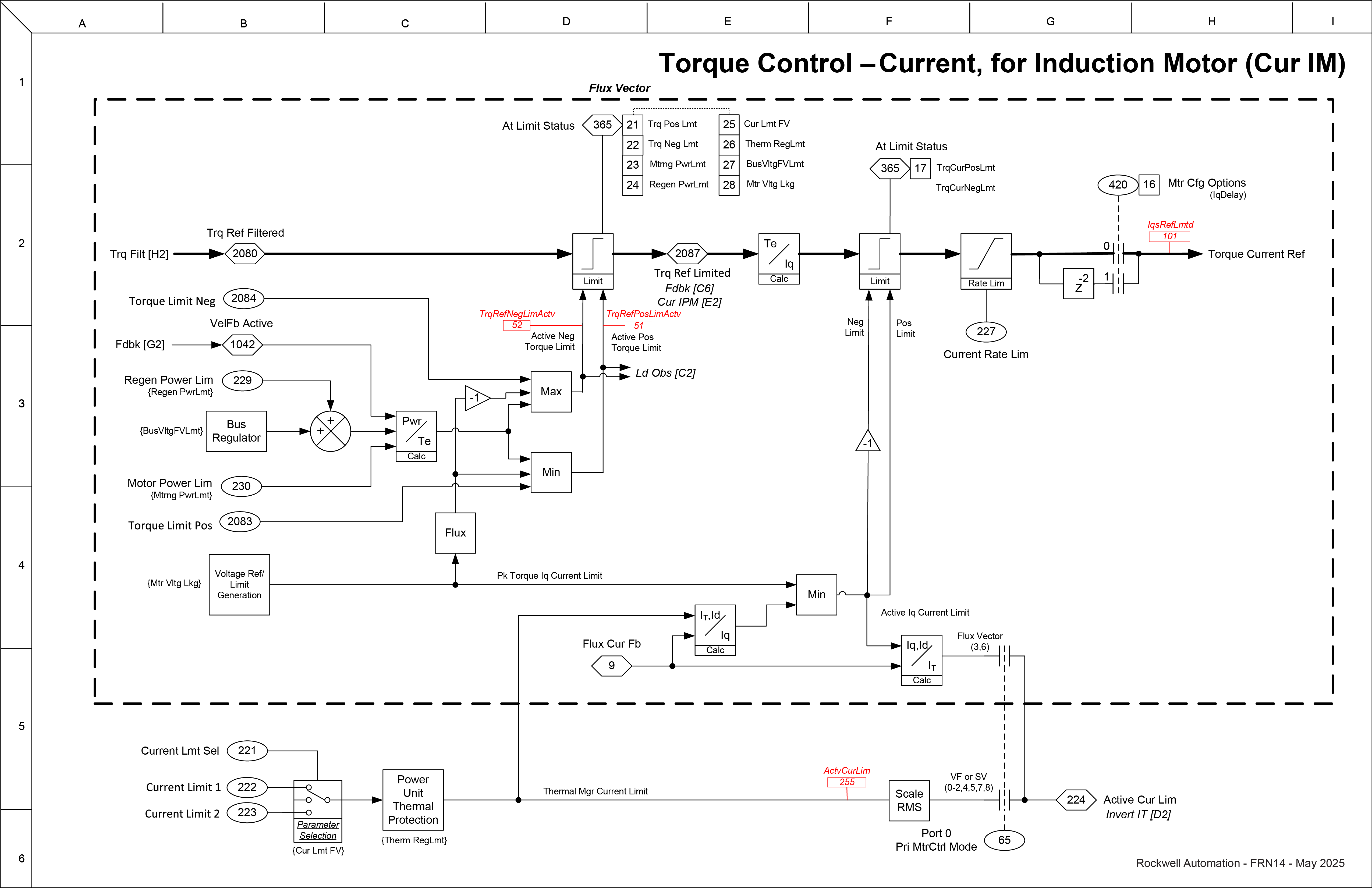

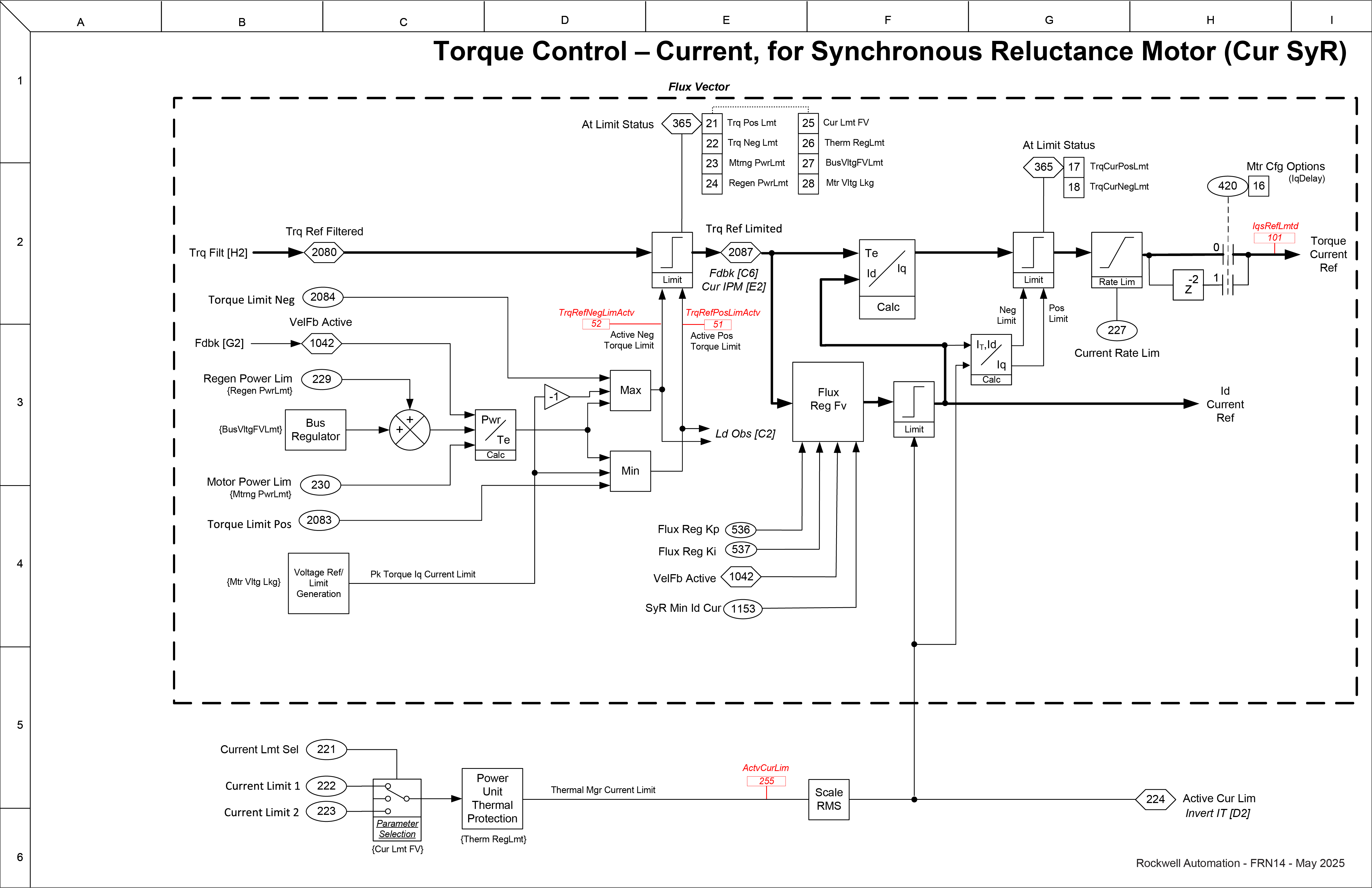

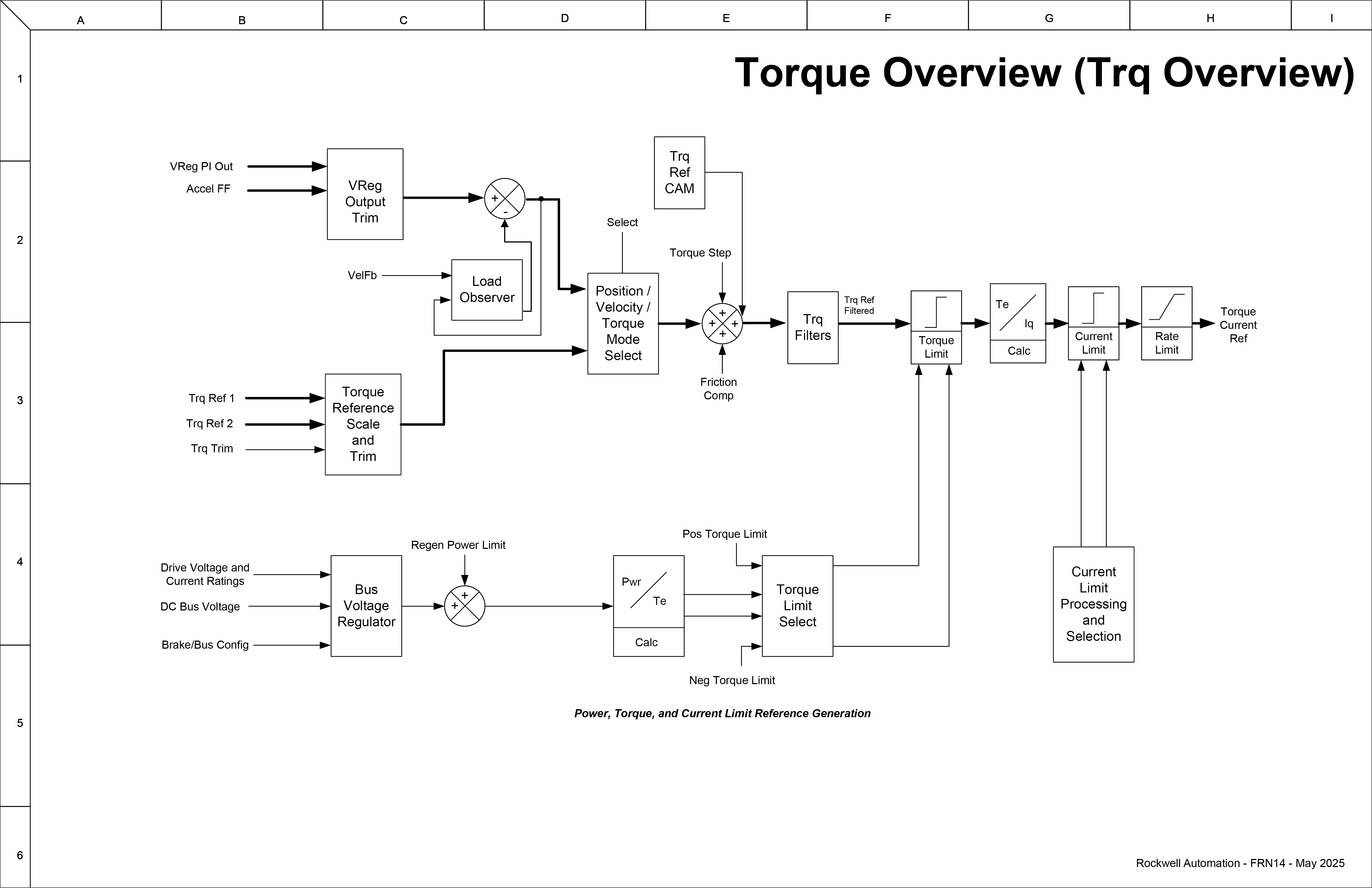

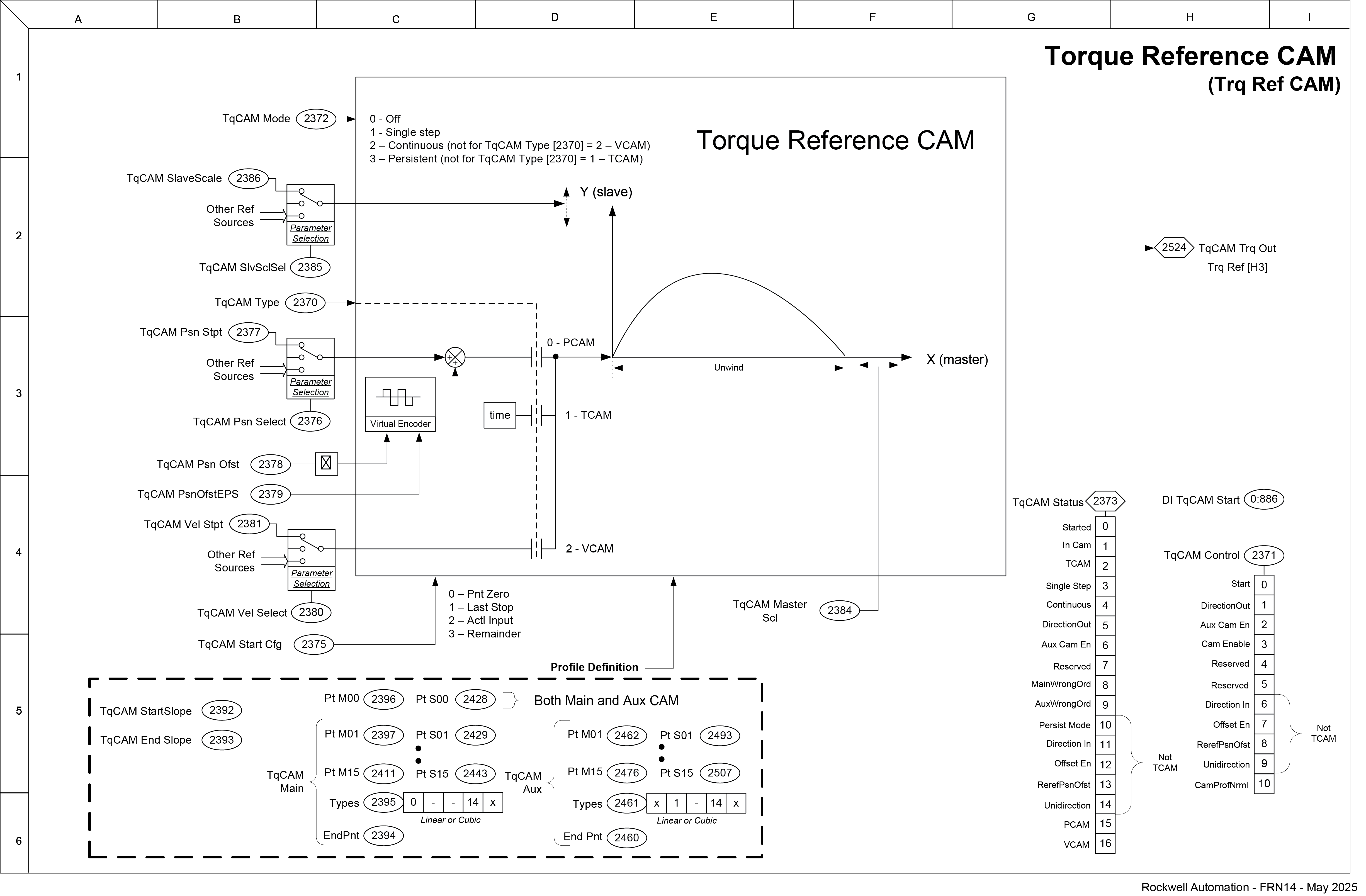

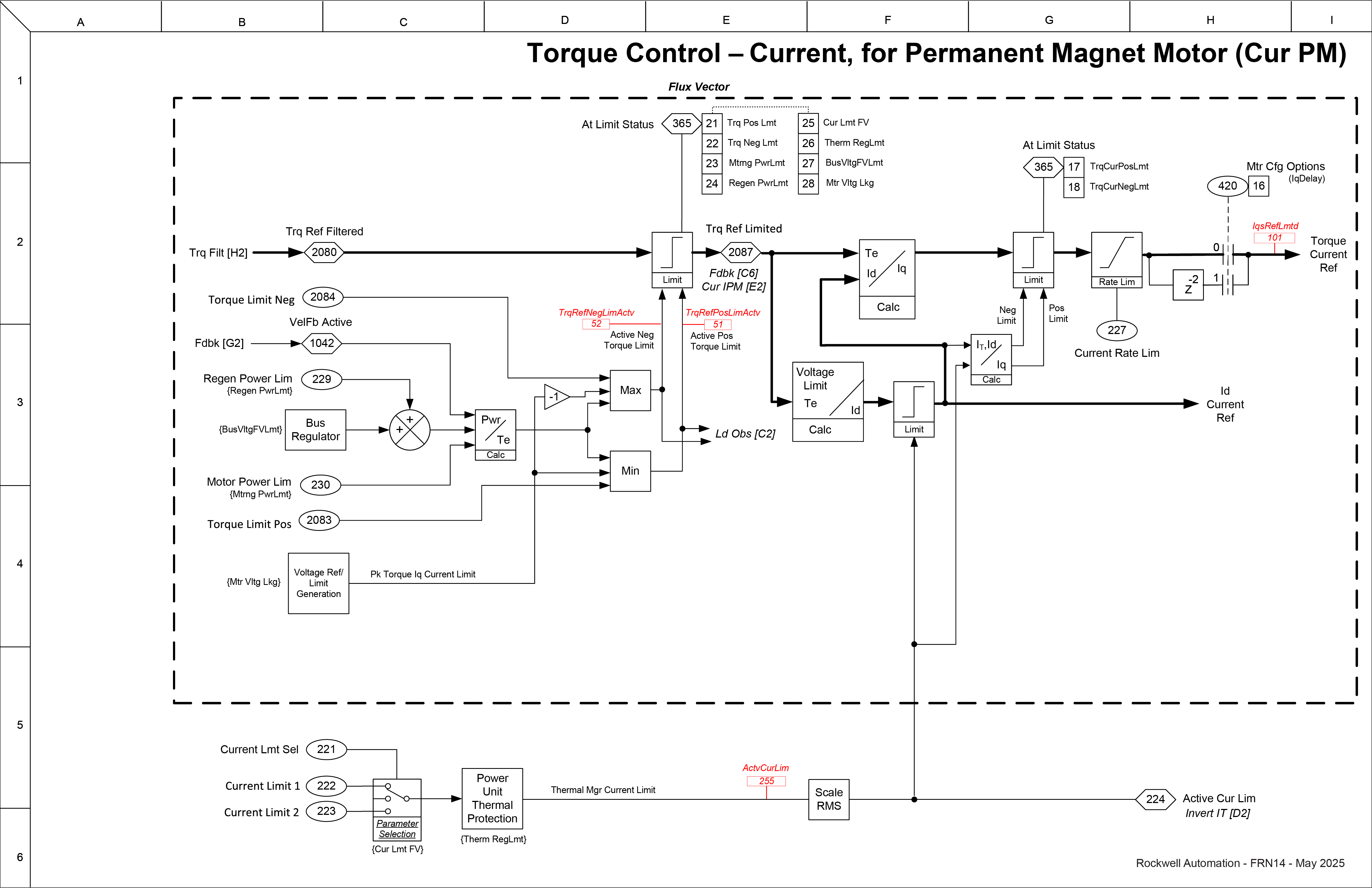

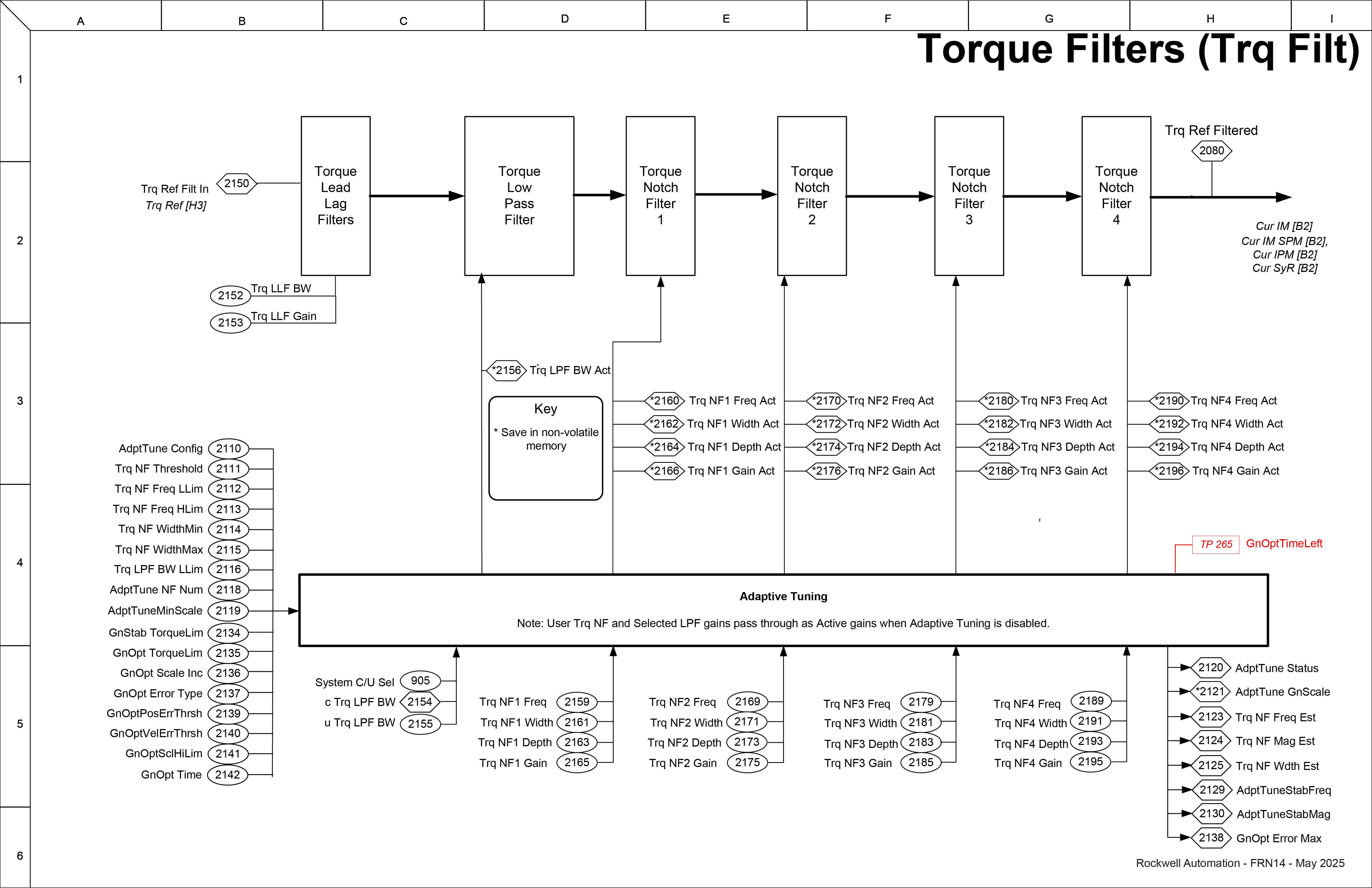

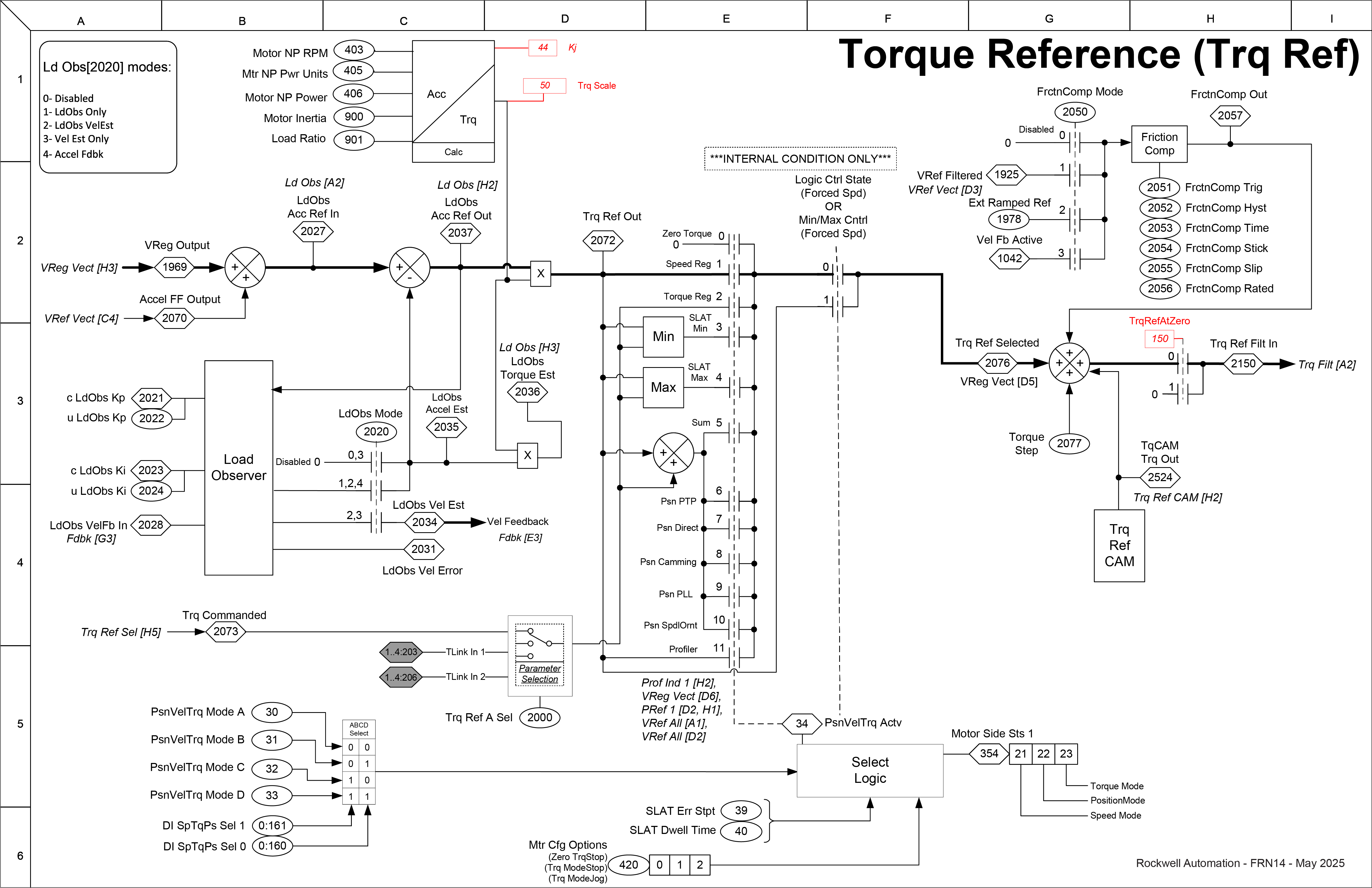

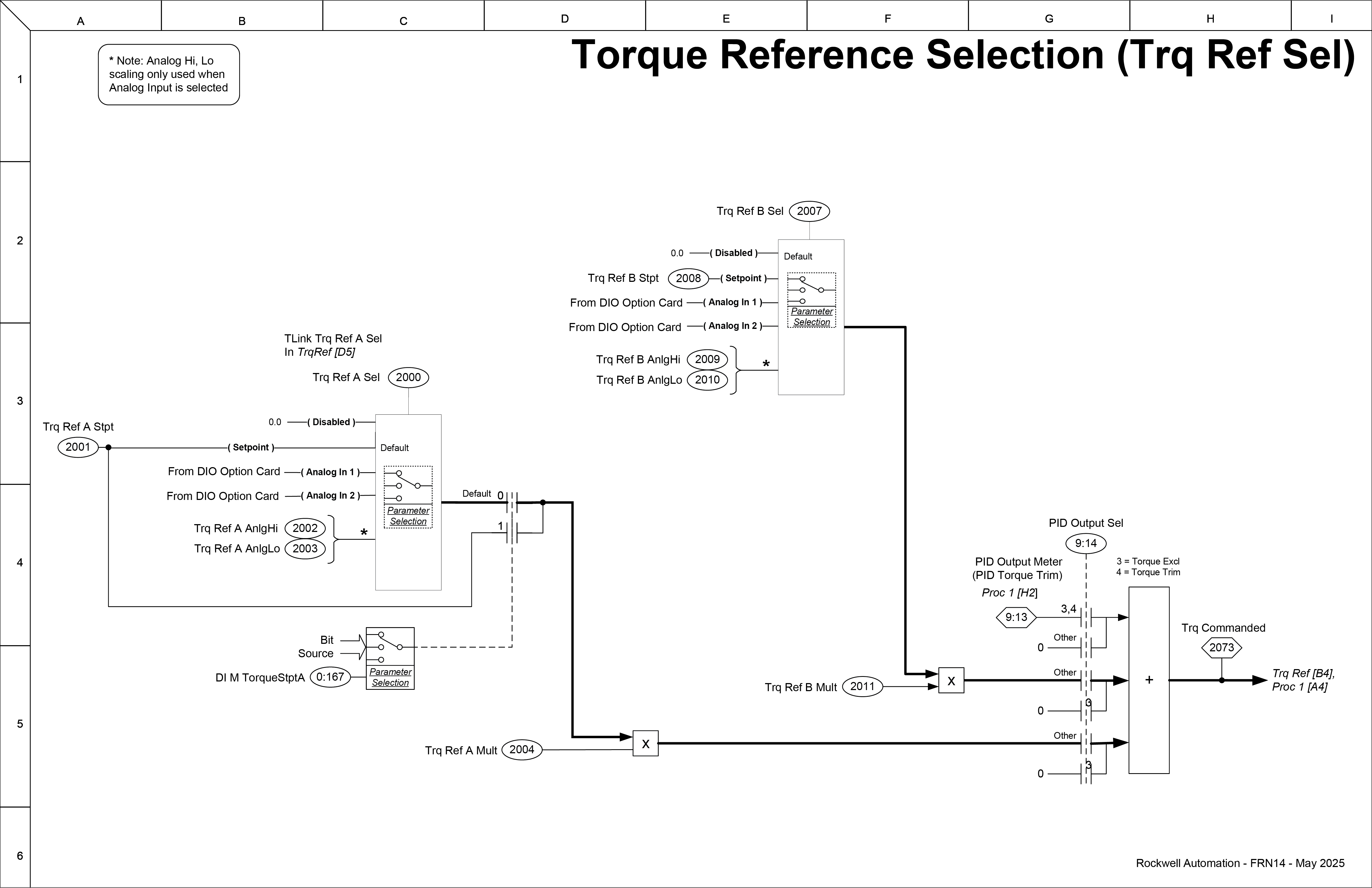

Torque Control, Filters, Overview, and Reference Diagrams

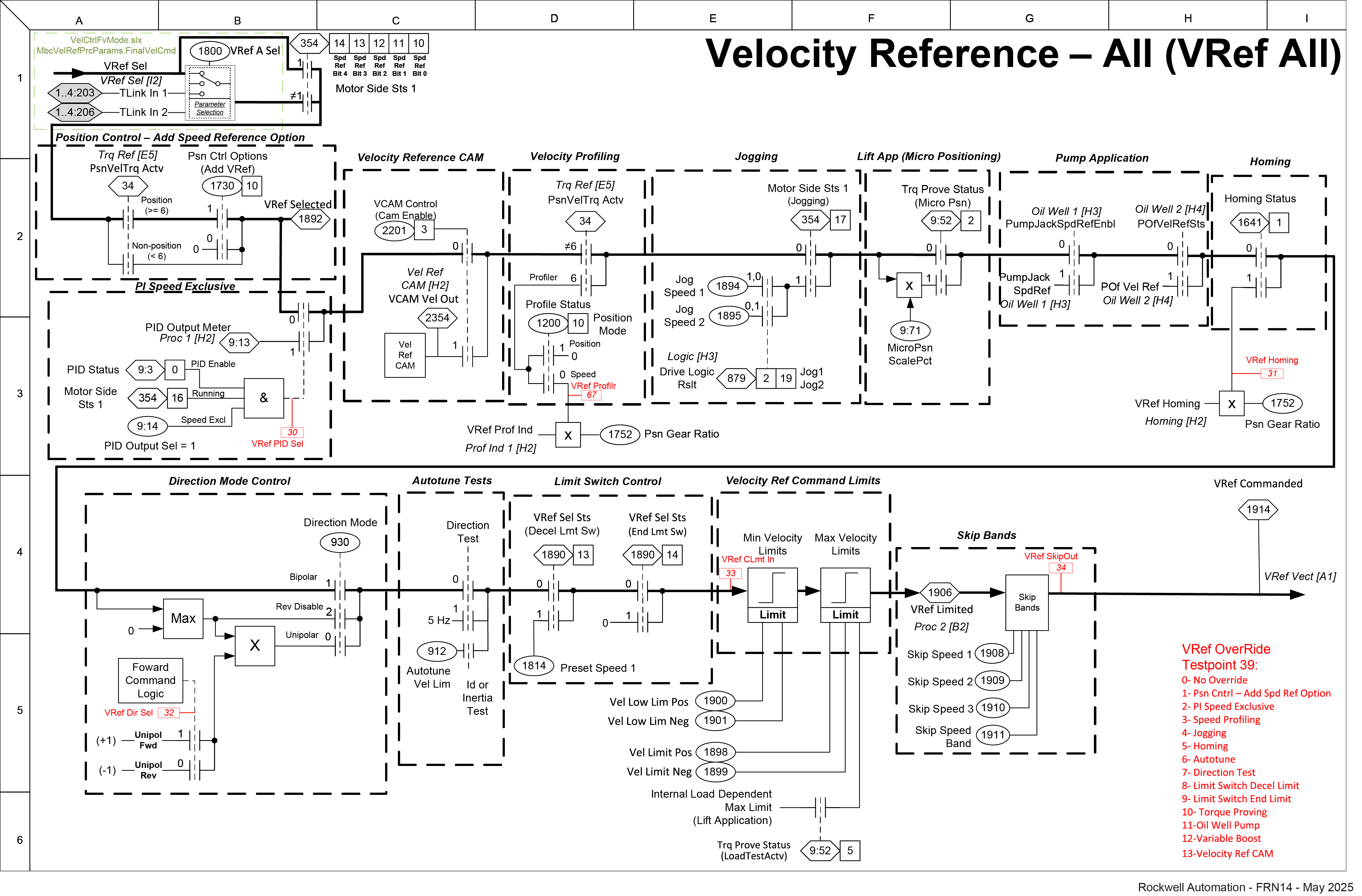

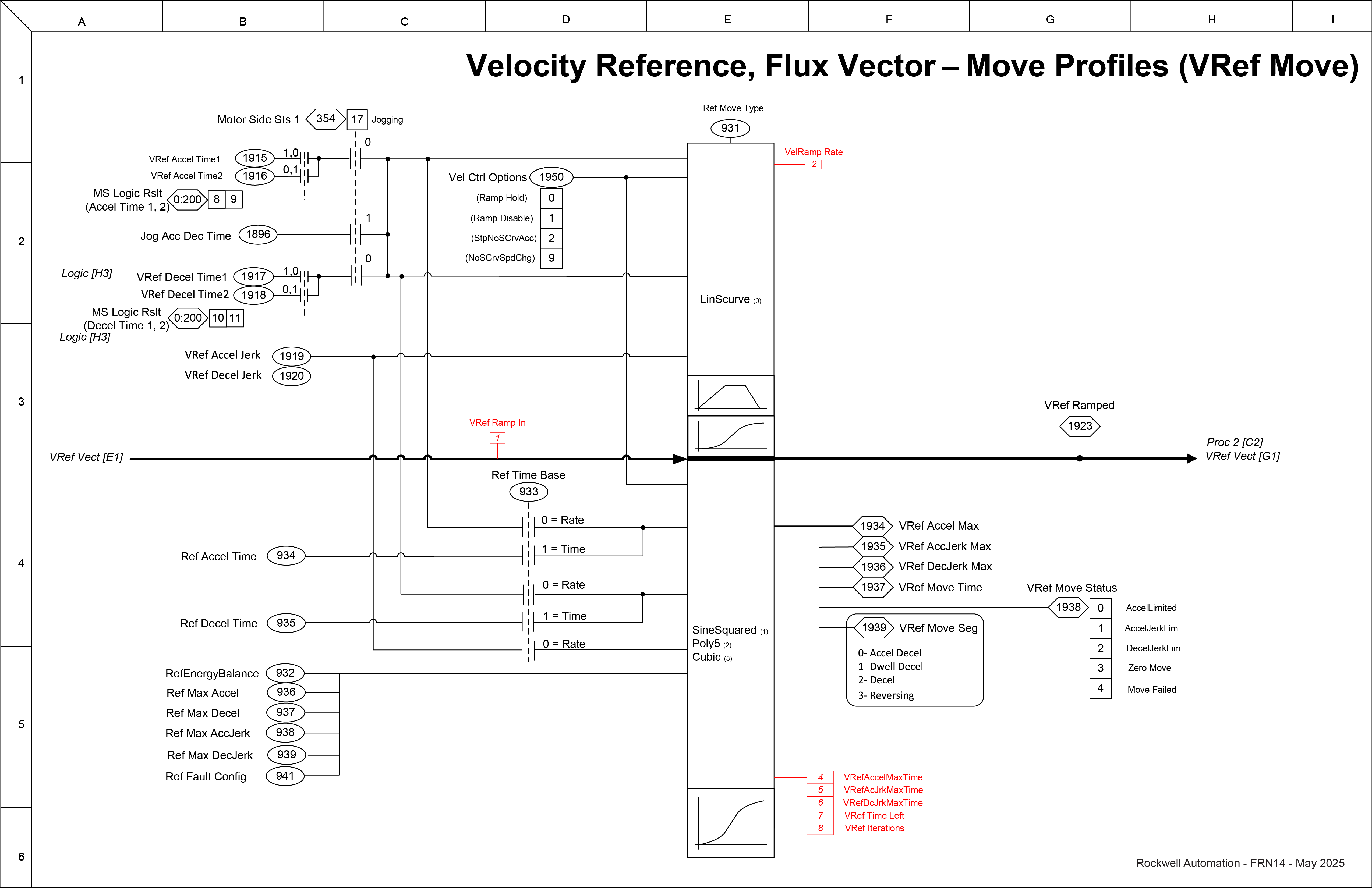

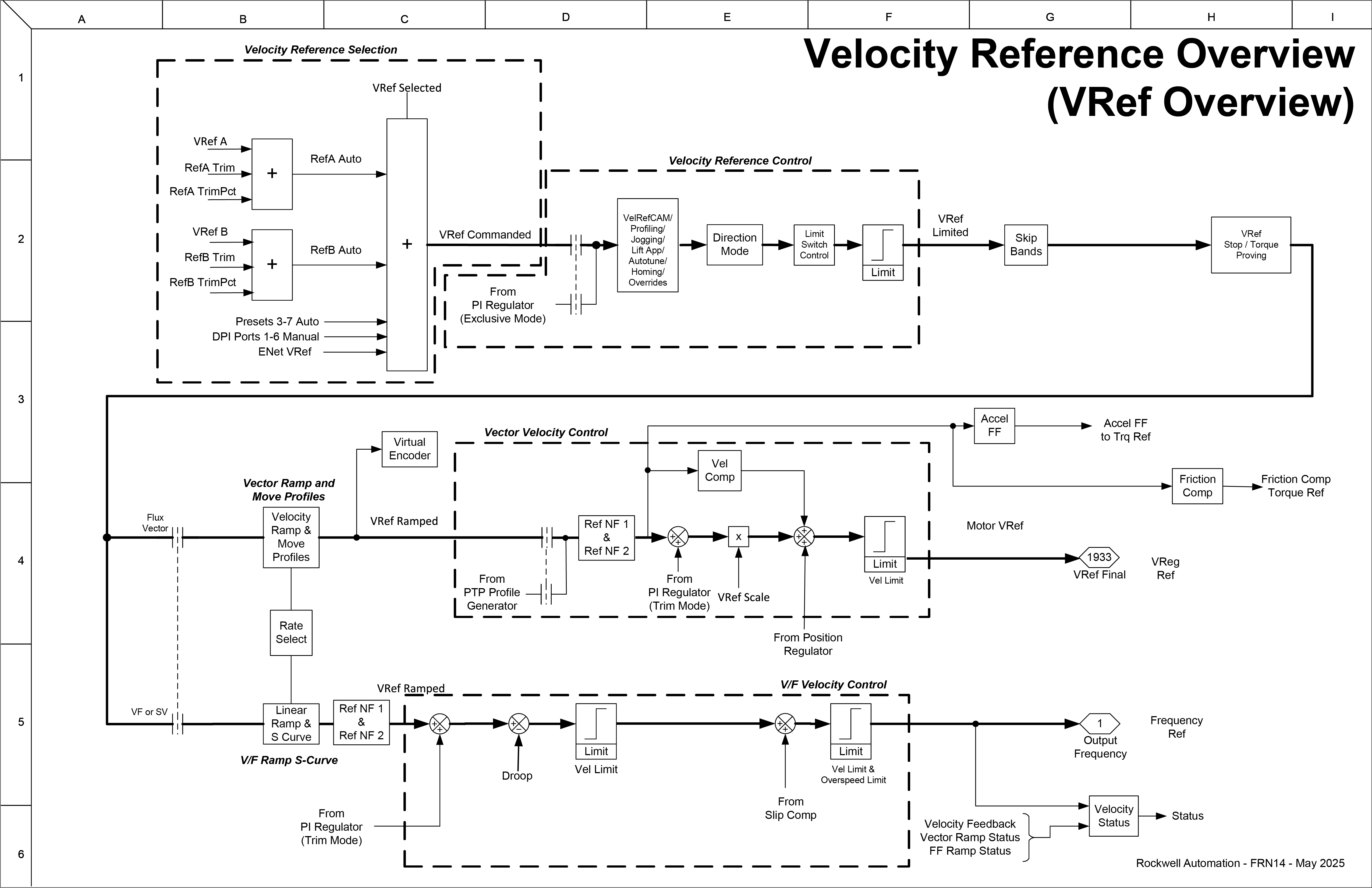

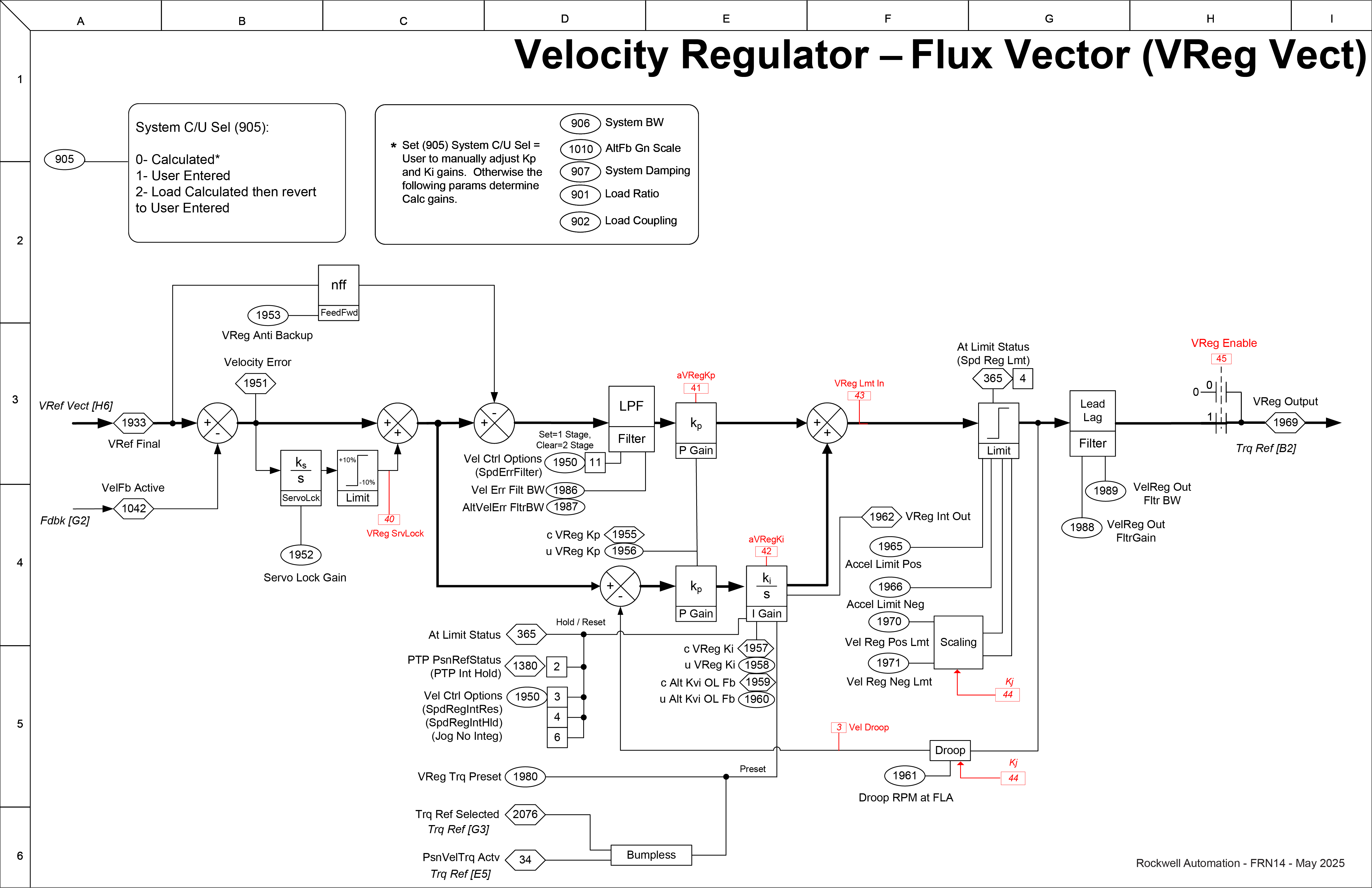

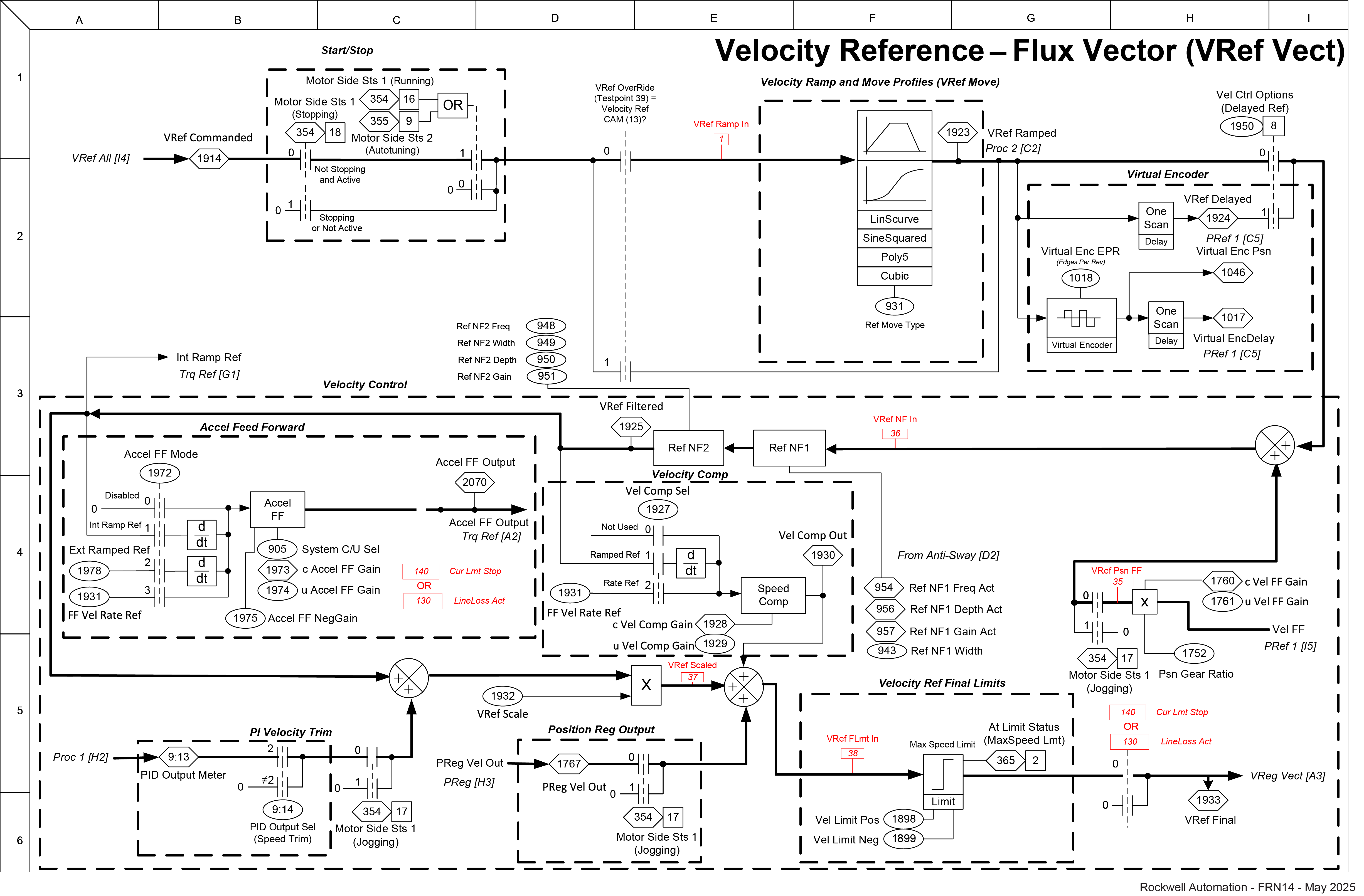

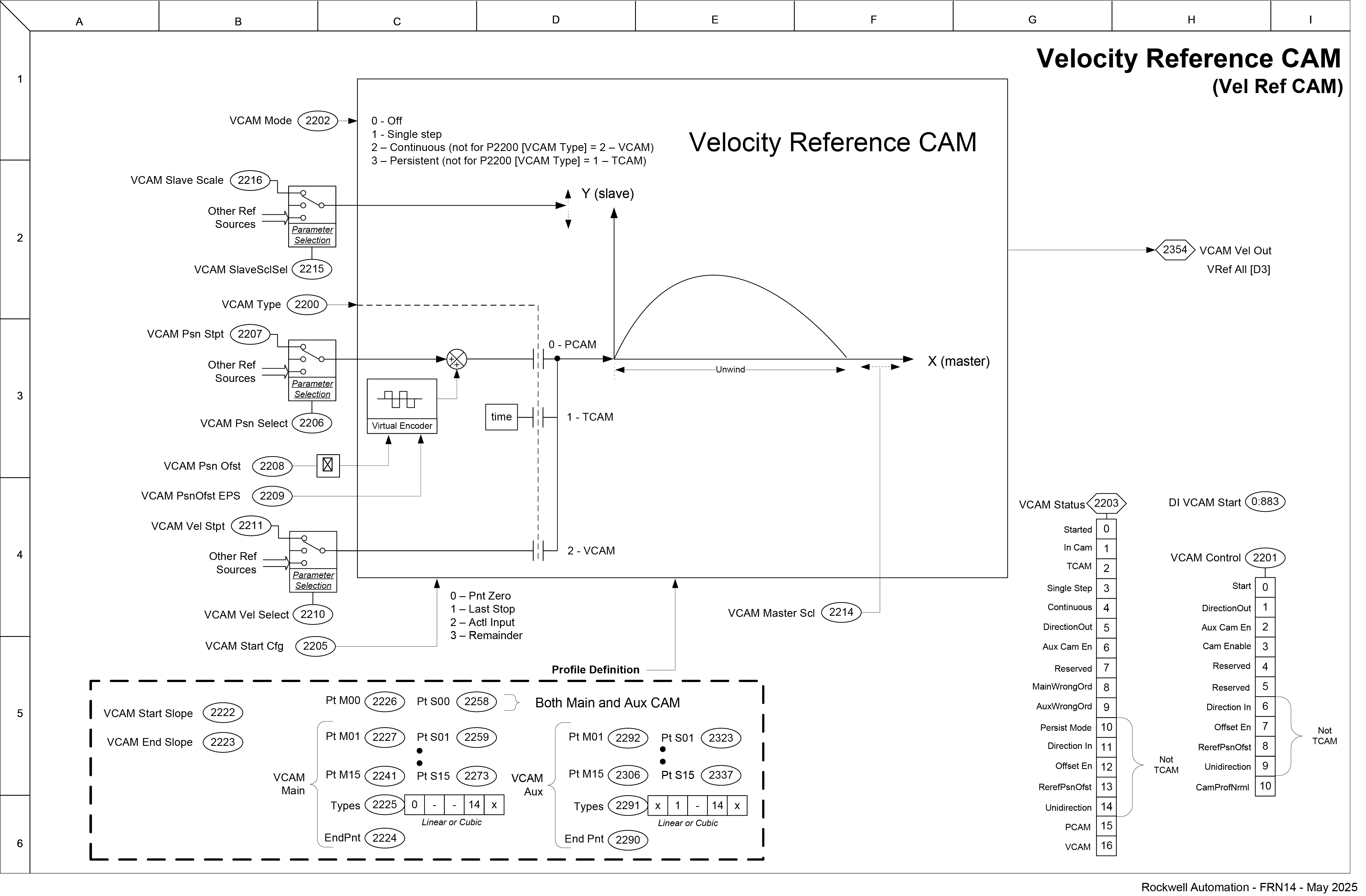

Velocity Reference and Regulator Diagrams